U.S. EPA’s Semi-Annual Regulatory Agenda – PFAS Update

Twice per year, the U.S. Environmental Protection Agency (U.S. EPA) publishes The Semiannual Regulatory Agenda. The Spring 2023 agenda was recently published and includes regulations that are expected to be proposed or finalized during the upcoming term. As per- and poly-fluoroalkyl substances (PFAS) regulatory actions keep progressing at all levels, it’s no surprise that the Spring 2023 agenda includes several PFAS-related actions expected by U.S. EPA. A summary is provided below.

PFAS National Primary Drinking Water Regulation Rulemaking:

U.S. EPA is in the process of finalizing a new National Primary Drinking Water Regulation (NPDWR), inclusive of maximum contaminant levels (MCLs), and maximum contaminant level goals (MCLGs) for six PFAS. This regulatory action is in response to the Fourth Regulatory Determinations published by U.S. EPA on March 3, 2021, which included a drinking water regulatory determination for perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS). Under the Safe Drinking Water Act (SDWA), U.S. EPA must propose an NPDWR and an MCLG within 24 months after a regulatory determination is made and must promulgate an NPDWR within 18 months after the proposal is made. On March 14, 2023, U.S. EPA proposed an NPDWR and MCLGs for PFOA, PFOS, perfluorononanoic acid (PFNA), hexafluoropropylene oxide dimer acid (HFPO-DA), commonly known as “GenX”), perfluorohexane sulfonic acid (PFHxS), and perfluorobutane sulfonic acid (PFBS). The rule is expected to be finalized by January 2024. You can read more information on the proposed rule at “New PFAS National Primary Drinking Water Regulation.”

Changes to Certain PFAS under the Toxics Release Inventory (TRI):

On December 20, 2019, the National Defense Authorization Act for Fiscal Year 2020 (NDAA) was promulgated. Per Section 7321 of the NDAA, U.S. EPA was directed to evaluate whether certain PFAS meet the TRI listing criteria by December 2021, and to continue to add any other PFAS by December 2023. Section 7321(c) of the NDAA provides a framework for PFAS to be automatically added to the TRI list on January 1 of the year following certain U.S. EPA actions. Specifically:

- Final Toxicity Value: The Administrator finalizes a toxicity value for the PFAS or class of PFAS.

- Significant New Use Rule: The Administrator makes a covered determination for the PFAS or class of PFAS.

- Addition to Existing Significant New Use Rule: The PFAS or class of PFAS is added to a list of substances covered by a covered determination.

- Addition as an Active Chemical Substance: The PFAS or class of PFAS to which a covered determination applies is:

- Added to the list published under Section 8(b)(1) of the Toxic Substances Control Act (TSCA) and designated as an active chemical substance under TSCA Section 8(b)(5)(A); or

- Designated as an active chemical substance under TSCA Section 8(b)(5)(B) on the list published under TSCA Section 8(b)(1).

As such, U.S. EPA is developing rulemaking to add certain PFAS to the list of reportable chemicals under TRI. The list of reportable PFAS under TRI has continued to grow since the publication of the NDAA. The original list included 172 PFAS chemicals for TRI reporting year (RY) 2020, increased to 176 for RY2021, and increased to 180 for RY2022. U.S. EPA issued a final rule on June 23, 2023, that will again increase the list of reportable PFAS under TRI to a total of 189 for RY2023.

Of note, U.S. EPA’s proposed rule that would eliminate the de minimis exemption for PFAS under TRI is not addressed in the Spring 2023 agenda.

PFAS Designated as Inactive on the TSCA Inventory; Significant New Use Rule (SNUR):

On January 26, 2023, U.S. EPA issued a proposed rulemaking for a SNUR under TSCA for those PFAS that are designated as “inactive” on the TSCA inventory. Persons subject to the SNUR would be required to notify U.S. EPA at least 90 days before commencing any manufacturing (including importing) or processing of the chemical substance for a significant new use. U.S. EPA must then review and issue a determination on the notification before the manufacturing or processing may commence. U.S. EPA is considering public comment on this proposed SNUR.

Addressing PFAS in the Environment:

On September 6, 2022, U.S. EPA published a proposed rule to designate PFOA and PFOS as “hazardous substances” under The Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA). The public comment period for this proposal closed on November 7, 2022, and U.S. EPA is in the process of reviewing public comments. However, in April 2023, U.S. EPA issued an Advanced Notice of Proposed Rulemaking (ANPR) in which U.S. EPA was seeking public input on additional PFAS-related designations under CERCLA. This public comment period closed on June 12, 2023, and comments are currently being evaluated by U.S. EPA. Examples of items that U.S. EPA was seeking input on are:

- The designation of seven PFAS, besides PFOA and PFOS, and their salts and structural isomers as “hazardous substances.” These seven PFAS are:

- PFBS

- PFHxS

- PFNA

- HFPO-DA (“GenX”)

- PFBA

- Perfluorohexanoic acid (PFHxA)

- Perfluorodecanoic acid (PFDA)

- The designation of precursors of the seven PFAS listed above, as well as PFOA and PFOS, as “hazardous substances.”

- The designation of certain categories of PFAS as “hazardous substances.” A category of PFAS refers to a set of PFAS that share one or more similar characteristics. Characteristics of interest could include, but are not limited to, chemical structure (e.g., carbon chain length, functional group), physical and chemical properties, mode of toxicological action, precursors or degradants, or co-occurrence. An example of a potential category provided was long-chain perfluoroalkyl carboxylate (LCPFAC), as defined in U.S. EPA’s 2020 SNUR for LCPFAC.

How to Prepare

In order to prepare for potential upcoming PFAS regulation, here are a few actions you may want to consider:

- Conduct an overall evaluation of your operations and any potential PFAS-related activities. Examples of activities to focus on during an evaluation are aqueous film forming foam (AFFF) usage or any PFAS-containing product formulas, or identifying risk for potential water, waste, or air releases.

- Develop site procedures for identification and quantification of PFAS materials and releases.

- Establish a routine frequency for supplier notification and safety data sheet (SDS) reviews in order to flag materials that may contain PFAS.

Stay informed on regulatory progress by subscribing to ALL4’s 4 the Record Articles. ALL4 can assist you with PFAS strategies as you are preparing for new regulations. If you have any comments or questions, please reach out via email (kturney@all4inc.com).

WOTUS: Why is the SCOTUS Decision on Sackett II Important?

On May 25, 2023, the Supreme Court of the United States (SCOTUS) handed down a landmark decision in the Sackett v. EPA case. The decision and opinion for this court case will change how the United States Environmental Protection Agency (U.S. EPA) and the Army Corps of Engineers regulate the Waters of the United States (WOTUS).

Background

In 2004, Idaho landowners, Michael and Chantell Sackett (Sacketts), purchased property near Priest Lake and began backfilling the property with dirt in preparation for building a new home. The property is approximately 300 feet from Priest Lake. The land was dry, but U.S EPA contended that vegetation present on the property may be indicative of wetlands and to cease “illegal dumping of dirt and rock” until such time as they made a final decision. The Sacketts were threatened with penalties of up to $40,000 per day.

The Sacketts sued under Chapter 7 of the Administrative Procedures Act (APA), which provides for judicial review of “final agency action for which there is no other adequate remedy in a court,” 5 U. S.C. §704. In 2012, SCOTUS decided the case. SCOTUS held the Sacketts may bring a civil action under the APA to challenge the issuance of U.S. EPA order. The court concluded that while the agency stated it did not provide a final action, there was an action that was de facto a final action with the threatened penalties.

The Sacketts then started the process again based on the SCOTUS decision. The case made it back through the courts to decide whether the Sacketts indeed filled in a WOTUS without obtaining a permit. On May 25, 2023, SCOTUS held that the land in question was outside the jurisdiction of U.S. EPA since it did not meet the definition of WOTUS under the Clean Water Act (CWA).

Court Opinions

SCOTUS has confirmed that a water body must be “relatively permanent,” which the U.S. EPA states must be “standing, or continuously flowing waters,” meaning that seasonal water bodies, flowing only during a rainy season, ice melts, or other non-continuous periods would not be covered under the CWA. The majority held that only wetlands that are “indistinguishable” from adjacent jurisdictional waterbodies based on a “relatively permanent” surface-water connection are subject to regulation as WOTUS, with allowances for “temporary interruptions” in that connection.

Legal Professionals reviewing the court decision point out that a new WOTUS rulemaking will have to “pinpoint the boundaries of CWA jurisdiction occupying the space between the Court’s phrases ‘continuous surface connection’ and ‘temporary interruptions in surface connection.’”

New Activities

Federal lawmakers, state agencies and industry are pushing for U.S. EPA to respond to the Sackett decision. Meanwhile, two of the three WOTUS cases being heard in federal court are paused pending a revised definition from U.S. EPA. U.S. EPA and the Corp of Engineers plan to “surgically” amend the WOTUS definition finalized early this year, with a final rule that incorporates the Sackett precedent, which is scheduled for September.

What does this mean for you?

This means additional litigation and new or revised rules at the federal level. Keep in mind, this decision affects federal jurisdiction over certain waters. It does not affect a state’s jurisdiction over those same waters. Several states have more stringent rules or additional rules around waters within their boundaries that will continue to apply. ALL4 recommends reviewing not only federal rule changes, but also state rules that will continue to be enforced. If you have questions pertaining to WOTUS or other water related projects, please reach out to one of our Project Managers or Karen Thompson at kthompson@all4inc.com.

South Coast Air Quality Management District (SCAQMD) Amended Rule 1147 and Rule 1147.2

The South Coast Air Quality Management District (SCAQMD) amended Rule 1147 on May 6, 2022 and adopted Rule 1147.2 on April 1, 2022 to further reduce nitrogen oxides (NOX) and carbon monoxide (CO) emissions from gaseous fuel-fired combustion equipment, and specifically in the case of Rule 1147.2, from metal melting furnaces, heat treating furnaces, heating furnaces, and forging furnaces. For gaseous fuel-fired combustion equipment applicable to Amended Rule 1147, July 1, 2023 began the compliance countdown to achieve the applicable Rule 1147 NOX and CO emissions limits. The specific compliance date for each applicable unit is dependent on the unit burner age; however, for units with burners older than 12 years of age, compliance was required as of July 1, 2023.

Background

Rule 1147 is a source specific rule that applies to miscellaneous gaseous fuel-fired combustion equipment (i.e., ovens, afterburners, calciners, furnaces) with a rated heat input of greater than or equal to 325,000 British thermal units (BTU)/hour at non-Regional Clean Air Incentives Market (RECLAIM), RECLAIM, and former RECLAIM facilities. Upon adoption, Rule 1147 established NOX emissions limits of 20 to 60 ppmv depending on application, process, temperature, and implementation timeframes, and a CO emission limit of 1,000 ppmv for all applicable equipment categories. Units that did not meet these original Rule 1147 limits (prior to the May 6, 2022 amendments) are required to meet the applicable limits in Amended Rule 1147 when the burner reaches 12 years of age, or July 1, 2023, whichever is later. Units that do meet the existing Rule 1147 limits are required to meet the applicable limits in Amended Rule 1147 when the burner reaches 32 years of age or July 1, 2023, whichever is later.

Rule 1147.2 is a command-and-control rule that requires facilities that operate furnaces used for metal melting, metal heat treating, metal heating, and metal forging to comply with lower concentration limits (relative to Rule 1147). Rule 1147.2 transitions facilities out of RECLAIM – non-RECLAIM facilities with affected units are subject to the requirements of Rule 1147.2 and are no longer subject to Rule 1147.

Provisions to Rule 1147.2

Applicability:

Furnaces used for metal melting, metal heat treating, and metal heating and forging that are required to obtain a South Coast AQMD permit.

Emissions Limits:

Rule 1147 (non-RECLAIM) units have a transition NOX concentration limit of 60 ppmv @ 3% O2, dry, and former RECLAIM units have a transition NOX concentration limit of 102 ppmv @ 3% O2, dry or are subject to their existing NOX emission limit, whichever is lower. Both of these limits apply until a unit becomes subject to the concentration limits in Table 1 of Rule 1147.2 or the alternative concentration limits in Table 2 of Rule 1147.2. All units will eventually be subject to the concentration limits in Table 1, except units that can demonstrate NOX emissions of less than one pound per day qualify for an exemption from the concentration limits of this rule. Refer to Tables 1 through 3 of Rule 1147.2 for a breakdown of the source-specific limits.

Compliance Demonstration and Source Testing:

- Initial:

- Units located at a former RECLAIM facility are required to source test within 24 months of April 1, 2022. Units may use a previous SCQAMD-approved source test conducted before the date of the rule adoption as the basis for subsequent testing provided the source test and protocol are representative of the operation and equipment.

- New units are required to source test no later than 18 months after issuance of the Permit to Construct.

- Ongoing:

- Units with a rated heat input capacity ≥10 MMBtu/hr are required to test every three years. If annual heat input is less than 23 billion Btu per year, testing is required every five years.

- Units with rated heat input capacity < 10 MMBtu/hr are required to test every five years.

Monitoring:

- Units with a rated heat input capacity ≥40 MMBtu/hr must utilize a NOX continuous emissions monitoring system (CEMS) certified pursuant to Rule 218.2 and Rule 218.3 for non-RECLAIM or former RECLAIM facilities, or Rule 2012 at a RECLAIM facility. For more on Rules 218.2 and 218.3 and the significant changes in CEMS requirements related to them, our previous blog provides an overview of the major changes.

- Units utilizing a NOX CEMS to comply with the applicable NOX emissions limit must average data over an 8-hour rolling interval.

- Units that use ammonia as part of their emissions control system are required to either source test for ammonia quarterly or install and maintain a certified CEMS to measure ammonia. If the unit has demonstrated compliance with the quarterly source test requirements for four consecutive quarterly source tests, compliance can be demonstrated annually.

What should you do?

- Evaluate whether your combustion equipment is subject to the new emissions limits of Rule 1147 and Rule 1147.2 as of July 1, 2023, or when the burner reaches the age thresholds detailed above, whichever is later.

- Develop a plan to comply with Rule 1147 and 1147.2 – the rules require facilities to conduct initial and periodic testing and monitoring of emissions, and to report their emissions data to the SCAQMD. Facilities should develop monitoring plans and procedures for demonstrating compliance with testing, monitoring, and recordkeeping requirements pursuant to the applicable requirements.

ALL4 has a dedicated team of professionals specializing in emissions source testing, continuous monitoring systems (CMS), and reporting source testing and CMS data. Reach out to Aditya Shivkumar or Matt Carideo for more information on recent SCAQMD rule updates.

California Air Resources Board Proposes Rules to Phase out Hexavalent Chromium Use at Chrome Plating and Chromic Anodizing Facilities

In late May, California Air Resources Board (CARB) proposed updated airborne toxics rules for chromium electroplating and chromic acid anodizing operations to phase out hexavalent chromium use by chrome plating and chromic acid anodizing facilities, citing both the potent toxicity of hexavalent chromium and a disproportionate effect of hexavalent chromium emissions on disadvantaged communities.

What does this mean for decorative chrome plating facilities?

Decorative chrome plating facilities will have the option to meet either a 2027 or 2030 deadline to phase out hexavalent chromium. Facilities that choose to meet the 2027 deadline will have more access to incentives that will help financially with the transition to less toxic alternatives. Facilities that choose to meet the 2030 deadline must implement building enclosure requirements by 2026 and may have less grant funding available for their transition.

What does this mean for functional chrome plating facilities?

Functional chrome plating facilities, such as hard chrome plating and chromic acid anodizing for aircraft parts, will also be required to phase our use of hexavalent chromium by January 1, 2039. CARB has stated that starting in 2032, an assessment of alternative technology for replacement of hexavalent chromium in functional chrome plating will begin.

Additionally, although functional chrome plating facilities will not be required to phase out hexavalent chromium until 2039, the facilities will be required to comply with housekeeping, best management practices, and building enclosure requirements identified by the key compliance dates discussed below.

What are the key compliance dates?

Although the earliest date facilities in California must cease using hexavalent chromium in plating operations is January 1, 2027, there are some important earlier dates in the Proposed Amendments to the Airborne Toxic Control Measure for Chromium Electroplating and Chromic Acid Anodizing Operations (Chrome Plating ATCM) published in May 2023 that must be considered for both decorative and functional chrome plating.

- January 1, 2024 – Updated housekeeping measures must be instituted. Additionally, chrome plating operations must be completed under the direction of an individual who has completed the California Air Resources Board Compliance Assistance Training Course on Chrome Plating (required every two years).

- July 1, 2024 – Best Management Practices such as minimizing dragout, spray rinsing requirements, limitation of air sparging, and barrier requirements for buffing, grinding and polishing must be implemented.

- January 1, 2025 – Facilities that will continue using hexavalent chromium in decorative chrome operations must inform the local air pollution control or air quality management district of the choice to continue using hexavalent chromium.

- January 1, 2026 – Chrome plating tanks must meet emission limits in the Proposed Amendments to the Chrome Plating ATCM published in May 2023.

- January 1, 2026 – Facilities that have not ceased using hexavalent chromium must comply with building enclosure requirements for plating and buffing, grinding, and polishing operations.

- January 1, 2032 – CARB completes first technology review of functional chrome plating alternatives.

- January 1, 2036 – CARB completes second technology review of functional chrome plating alternatives.

- January 1, 2039 – Functional chrome plating using hexavalent chromium can no longer be conducted in California.

How can we help?

ALL4 has extensive experience helping facilities comply with California regulations. If you have any questions or want to discuss strategies for compliance please contact our team at info@all4inc.com.

Unlocking a Sustainable Future: How ISSB’s Game-Changing Standards Revolutionize ESG Reporting

In today’s rapidly changing and interconnected world, reliable and transparent data is crucial for informed business and investment decisions. To address this need, the International Financial Reporting Standards (IFRS) Foundation has made a significant effort to establish global standards that enhance environmental, social, and governance (ESG) and sustainability-related disclosures. The recent launch of the International Sustainability Standards Board (ISSB) and its inaugural sustainability disclosure standards, IFRS S1 and IFRS S2, marks a major milestone in achieving this objective.

Analysis of ESG and sustainability risk has gained prominence in business and investment decision-making, with consumers and investors recognizing their impact on a company’s short-term and long-term viability. However, the multitude of disparate ESG initiatives and disclosures, along with their lack of comparability, create significant challenges in assessing and comparing companies’ sustainability performance and erode trust in reporting. The ISSB addresses these challenges by striving to establish a common language and universal standards for ESG and sustainability reporting, enabling consistent enforcement and verification. The IFRS ISSB’s initiative aims to enhance trust and confidence in corporate sustainability disclosures, providing investors with reliable information for their investment decisions.

The inaugural sustainability disclosure standards, IFRS S1 and IFRS S2, offer companies a comprehensive framework to effectively communicate sustainability-related risks, opportunities, and climate-related information to investors and stakeholders. IFRS S1 covers general sustainability disclosures, allowing companies to convey both short-term and long-term risks and opportunities. Complementing IFRS S1, IFRS S2 focuses specifically on climate-related disclosures, integrating recommendations from the Task Force on Climate-related Financial Disclosures (TCFD). This emphasis underscores the critical role climate-related information plays in effective decision-making. The development of these global standards is a response to extensive market feedback and calls for standardization from influential global bodies such as the G20, the Financial Stability Board (FSB), and the International Organization of Securities Commissions (IOSCO). As the financial risks associated with sustainability impacts become more evident, the demand for consistent and comparable information on the impact of sustainability factors on a company’s prospects continues to grow. These standards empower investors and stakeholders by integrating sustainability-related information with financial statements, providing a comprehensive view of a company’s exposures.

In recognition of the ISSB Standards’ alignment with the recommendations of the TCFD, the FSB has requested that the IFRS Foundation assume responsibility for monitoring companies’ progress on climate-related disclosures. This transfer of monitoring responsibilities consolidates the progress made in climate-related disclosures and ensures continued enhancement of sustainability-related reporting. “The TCFD has been a trailblazer in raising the practice and quality of climate-related disclosures, providing much-needed information to investors about climate-related risks and opportunities…The ISSB has built upon and consolidated the market-leading investor-focused sustainability-reporting initiatives to deliver the ISSB Standards, with the TCFD recommendations at the heart of this. As such, the ISSB welcomes the FSB’s request to transfer the TCFD’s monitoring responsibilities to the ISSB from 2024 and the opportunity to build on TCFD’s legacy. This announcement provides yet further clarification of the so-called ‘alphabet soup’ of ESG initiatives for companies and investors.”1

The ISSB is committed to supporting the effective implementation of IFRS S1 and IFRS S2, which provide a global baseline for sustainability-related disclosures worldwide. The IFRS S1 and IFRS S2 will both become effective starting on January 1, 2024, with earlier applications of the IFRS S2 permitted if IFRS S1 General Requirements for Disclosure of Sustainability-related Financial Information is also applied. While IFRS S1 and IFRS S2 establish a solid foundation for sustainability reporting, the ISSB remains forward-thinking. The board is currently engaging in a consultation process to identify and prioritize future standard-setting areas beyond the inaugural standards. This consultation aims to ensure the standards remain relevant and responsive to evolving market needs.

The establishment of the ISSB by the IFRS Foundation and the issuance of the inaugural sustainability disclosure standards represent a significant milestone in ESG and sustainability reporting. These standards provide a solid foundation for the ESG movement, enabling companies to disclose their sustainability-related information in a consistent and comparable manner. By reinforcing trust, comparability, and accountability within the corporate reporting landscape, the ISSB’s standards empower investors and stakeholders to make informed decisions aligned with their sustainability objectives. As the ISSB continues to foster global adoption and implementation, the transformative impact of these standards will be realized, paving the way for a more sustainable and resilient future.

If you are interested in learning more about how ALL4 can assist your company with its IFRS disclosure strategy and development, emissions reduction strategies, net-zero goals, or adaptation, please reach out to ALL4’s James Giannantonio, Managing Consultant of ESG & Sustainability, at jgiannantonio@all4inc.com.

U.S. EPA Releases the ECHO Clean Air Tracking Tool (ECATT) and EJScreen 2.2

In the last few weeks, the United States Environmental Protection Agency (U.S. EPA) has released one new tool, the Enforcement and Compliance History Online (ECHO) Clean Air Tracking Tool (ECATT), and updated another, releasing EJScreen version 2.2. These new tools combine numerous data sources and appear to be the next step in facilitating cumulative impact analyses (CIA) related to projects near environmental justice (EJ) communities.

Enforcement and Compliance History Online Clean Air Tracking Tool

ECATT was released to the public on May 31, 2023. It is not an EJ tool specifically but is another means of making facilities’ environmental data available to the public. ECATT “provides an integrated view of Clean Air Act Data and is the only U.S. EPA interface to combine emissions, enforcement and compliance, environmental justice, air monitoring station, and modeled toxic risk data,” according to U.S. EPA.

The powerful tool combines several sources of data:

- Emissions data by facility (from the National Emissions Inventory (NEI) and Toxics Release Inventory (TRI)),

- Enforcement and compliance history (from the ECHO database),

- Environmental Justice Indicators (from EJScreen),

- Air monitoring data (from U.S. EPA’s Air Quality System (AQS) database and other sources), and

- Modeled air toxics risk data (from AirToxScreen).

ECATT offers two main searches:

- The Air Monitoring Stations (AMS) search provides data about air monitoring stations that measure ambient or outdoor concentrations of Hazardous Air Pollutants (HAPs) and Criteria Air Pollutants (CAPs). The search can be used to identify areas with high pollutant concentrations and higher potential for health impacts and identify the facilities emitting in those areas. Specifically, the AMS search:

- Provides searchable data on criteria pollutants (CAPs) and

hazardous air pollutants (HAPs) across the U.S. EPA monitoring network. - Allows searching on individual or user-defined groups of pollutants in any combination desired.

- Allows display of trending data for individual monitors and pollutants.

- Allows mapping of pollutant data vs. EJ data with thresholds (i.e., “all monitors with cancer risk > 10 in a million where 3+ EJ indices are over the 80th percentile”).

- Provides searchable data on criteria pollutants (CAPs) and

- The Emissions Screener search provides data on stationary sources regulated under the Clean Air Act (CAA). Users can analyze the data reported to EPA to identify top emitters and answer questions such as: who is emitting, where are they emitting, which pollutants are they emitting, and how much are they emitting? The search organizes emissions data by facility, industry, or pollutant. Through the facility report, users can access each facility’s Air Pollutant Report to view detailed emissions data. Specifically, the Emissions Screener search:

- Allows search by individual facilities, industry sector(s) or pollutants.

- Allows search on who is emitting? Where? Which pollutants? And how much?

- Allows drill down on specific facility emissions and enforcement data.

The Emissions Screener has powerful search capabilities, such that you could select an entire industrial sector, search for any facility in that sector that meets certain criteria (level of cancer risk, in an EJ area, etc.), and get a list of facilities that can then be sorted by risk, emission levels, etc. The user can then click on individual facilities to get detailed emissions data, enforcement history, and other environmental information.

There are two video tutorials that show how to use the tool, and U.S EPA has been holding office hours to demonstrate the tool as well.

EJScreen 2.2

On June 26th, U.S. EPA released EJScreen version 2.2 which includes new data sets designed to help agencies and users evaluate multiple factors that may impact communities. The new version of the tool includes:

- All demographic indicators are updated to use data from the Census Bureau’s American Community Survey (ACS) 2017-2021 5-year summary. The data sources for most of the EJ indexes were also updated to more recent data.

- A new EJ and supplemental index, “Toxic Releases to Air,” which incorporated data from the TRI and is based on the Risk Screening Environmental Indicators (RSEI) toxicity-weighted results for the air pathway, based on 2021 TRI data.

- A redesigned and modular reporting system that allows for more customization of the report to meet a specific user’s needs. The past “Printable Standard Report” is still there but redesigned as the “EJScreen Community Report.” This new report also includes health, climate, and critical service gap data.

- Additional demographics, breaking down Census data by race, languages spoken, and gender.

- New map layers with health disparities including cancer, people with disabilities, critical service gaps on housing, health, insurance, and transportation accessibility.

- A new map layer that includes U.S. EPA regulated facilities that are subject to enforcement actions for being out of compliance drawn from the Enforcement and Compliance History Online (ECHO)

These tools are part of a continuing set of steps that U.S. EPA and other agencies have been making towards facilitating the inclusion of CIA and cumulative risk analyses (CRA) into the evaluation of impacts on overburdened communities as described in the recent draft Guidelines for Cumulative Risk Assessment Planning and Problem Formulation released for public comment by U.S. EPA on June 16th.

What Does it Mean to You?

ECATT and EJScreen 2.2 are part of an expanding line of tools and other information sources making facilities’ environmental data more easily accessible. ECATT may be the most comprehensive tool combining air pollutant information and EJ information to date, and EJScreen continues to offer more and more layers and the ability to drill down to increasing levels of granularity on social and health demographics. It is important to review these tools to make sure that there are no surprises when you want to do a project or renew your permits and that the data in the tools is accurate. Care needs to be taken when developing emissions reports for submittal to state and federal agencies so that the data is complete and accurate, as this data is used to populate the NEI and TRI and ultimately incorporated into ECATT and EJScreen.

If you have concerns about the potential implications of ECATT or EJScreen or need help parsing through these tools, feel free to contact your ALL4 Project Manager or Rich Hamel. We’ll continue to monitor EJ guidance from the administration and states and the tools available to evaluate EJ concerns as they develop. We can also help you evaluate permitting risks, from EJ concerns to regulatory issues, and assist in developing a strategy to make the permitting of your project as efficient as possible.

Setting Water Reduction Targets: Reducing water consumption reduces wastewater generation while also reducing risk

A careful assessment of water use can reveal consumption risks and resource use inefficiencies. Setting water reduction goals creates a quantitative way to validate the efficacy of efficiency improvements, expose potential failures and malfunctions and drive inefficiency and risk from the system. Customers, investors and other stakeholders are interested in knowing their exposure to water-related organizational risks and societal impacts as a result of investing in or partnering with a company. Especially when processes or products are highly water dependent, located in water stressed areas, or subject to existing or pending water access restrictions or cost increases. Below are a few ways water use can be mitigated.

In the United States Environmental Protection Agency (U.S. EPA) Guide for Industrial Waste Management and the National Pollutant Discharge Elimination System (NPDES) Compliance Inspection Manual, the U.S. EPA discusses several options that can help reduce wastewater amounts through source reduction.

- Reformulation/redesign of products, such as substituting raw materials that might require less water usage.

- Technological modifications such as modifying the equipment and process used during production. Modifications can help reduce the amount of raw material that is needed during production along with the amount of time needed in between maintenance of the equipment through the use of mechanical cleaning devices. Replacing components of the equipment with high-pressure, low volume hoses and nozzles can help reduce water usage during the cleaning process.

- In process recycling/reuse of water can help cut down on the overall amount of wastewater produced during the process, from the cleaning of equipment and general facility use.

- Good housekeeping/operating procedures, such as regularly scheduled maintenance of equipment and routine plant inspections can help avoid spills and identify where materials can be used more effectively, resulting in reduced material usage.

U.S. EPA also provides a list of water management techniques that can be implemented to help track water usage and minimize the amount of wastewater produced at a facility.

Water Management Techniques

- Meter/Measure/Manage

- Using a meter to measure the water usage can help save on water usage amounts, and also give an idea of how much water the facility is using in each step of the process. Once a management practice is put into place the data can be used to track usage over time and show where improvements to the process have been made.

- Optimize cooling tower blowdown water and other sources of water such as boilers.

- Applicable to laboratories and large consumers of water.

- Condensate from air conditioners can also be used as part of the cooling tower process.

- Condensate from boilers can be recirculated back to the boiler through the installation of pipes and pumps.

- Replace restroom fixtures, such as new toilets and faucet aerators.

- Eliminate single-pass cooling and instead opt for recirculating water systems.

- Use water-smart landscaping and irrigation, such as planting native vegetation and using soil moisture sensors to dictate when water irrigation is needed. Recovered rainwater can also be used to reduce the amount of water used in irrigation through the use of a storage tank that accumulates the rainwater.

- Control steam sterilizer tempering water to not discharge at a continuous flow by replacing older models with updated versions to only have tempering water when necessary, helping to save on costs and water consumption.

Where to Start?

Consider setting a goal that is specific, relevant, measurable, attainable, and time based to your operations. Setting a specific goal that is relevant to your operations can give a clear direction on where improvements can be made and the motivation behind the goal, such as wastewater treatment system upgrades, societal influences, or upgrades needed to meet future demands. When goals are measurable and attainable, evaluating progress and working towards a goal is achievable and sets a clear timeline of when the goal is met by setting a deadline.

For example, setting a goal to reduce water consumption does not set a clear goal of what is expected or when it will be achieved. However, specifying a goal of reducing water usage and discharge by 20% in 12 months gives a clearer objective that has a set timeline. Data collection of water usage and water discharged are two areas where water consumption trends can be used to measure progress in improvements and identify trends over time for when water usage is greater during a certain time of year. Identifying major points of usage and discharge along with analytical sampling of wastewater discharge can also help pinpoint areas that can be improved upon to see how increased or decreased usage affects water quality which is necessary to meet current and future permit regulations.

ALL4 can assist you with tracking water usage/consumption trends, along with assisting clients to meet permit regulations and stay up to date on upcoming regulations. ALL4 can develop and execute a net zero or net positive water strategy; and disclose that strategy through platforms such as CDP or bespoke communications. Please contact Colleen Nagel at cnagel@all4inc.com or Connie Prostko-Bell at cprostko-bell@all4inc.com for more information or support with your project.

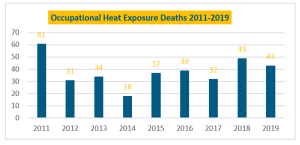

Occupational Injuries and Fatalities Rising with the Summer Heat

With the summer heat quickly rising, what are you doing to do to avoid occupational heat exposure for your employees? Occupational heat exposure can lead to heat related injuries, illnesses, and in some cases, become fatal. Under the General Duty Clause, Section 5(a)(1) of the Occupational Safety and Health Act of 1970, employers are required to provide their employees with a place of employment that “is free from recognized hazards that are causing or likely to cause death or serious harm to employees.” The Bureau of Labor Statistics reports an average of 38.22 worker-related deaths per year in U.S. due to environmental heat exposure. The Bureau of Labor Statistics Experts believe the actual number of heat-related fatalities may be underreported or misreported as another cause, such as heart attacks. Along with the average of 38.22 worker-related deaths, exposure to environmental heat leads to an average of 2,830 recordable occupational injuries and illnesses per year involving days away from work. June through September creates the highest risk and Texas, California, Kanas, and South Carolina tend to have the highest number of nonfatal injuries and illnesses due to heat exposure according to the Bureau of Labor Statistics. OSHA has published many heat exposure case studies as a result of enforcement investigations. These studies may help employers better understand the risks of occupational heat exposure and lessons learned.

Who is most at risk?

Occupational heat exposure can occur both indoors and outdoors and does not always occur during a heat wave. The following is a list of industries where workers are more likely to suffer heat-related illnesses.

| Outdoors | Indoors |

| Agriculture | Bakeries, kitchens, laundries (any sources with indoor heat-generating appliances) |

| Construction | Electrical Utilities (boiler rooms) |

| Landscaping | Iron and steel Mills |

| Package Delivery | Manufacturing with local heat sources like furnaces (paper products) |

| Oil and gas well operations | Warehousing |

What is your responsibility as an employer?

OSHA suggests that all employers, especially those who’s employees work outdoor in warm weather, are around heat sources such as ovens, fires, or hot tar, perform strenuous physical activities, or work in heavy or non-breathable work clothes create a Heat Illness Prevention Plan. Many U.S. states have their own OSHA approved state plans, so it is important to know those guidelines to stay in compliance. For example, California’s Heat Illness Prevention Standard requires employers to provide training, water, shade, and planning. A temperature of 80°F triggers the requirements. NIOSH also has a recommended heat standard. The graphic below shows some of the many elements to take into consideration when creating a plan and training for your employees who are exposed to hazardous heat.

Important components to consider when creating a Heat Illness Prevention Plan include:

- Who will provide daily oversight of working conditions?

- How will you help new workers or workers returning from any type of leave acclimatize to the environment?

- How will you ensure that first aid is available and that a protocol is in place to handle situations where care beyond first aid is needed?

- What engineering controls will be used to mitigate heat stress?

- How will heat stress be measured and how will you determine if heat stress is hazardous?

- How to respond when the National Weather Service issues a heat advisory or heat warning?

- What training will be provided to workers and supervisors to recognize early symptoms of heat stress?

What happens now?

OSHA is continuing to push forward with their Heat Illness Prevention Campaign to protect employees, enforce the General Duty Clause, and educate employers. ALL4 has immense experience in helping employers create policies meeting regulatory requirements and we will continue watching the developing rules and regulations around Occupational Heat Exposure.

If you have concerns about the potential implications of occupation heat exposure, other job hazards, policies, regulations, or EHS digital solutions for your company and you’d like to discuss them, feel free to contact your ALL4 Project Manager or Cindy Castillo at ccastillo@all4inc.com. We’d be happy to assist you in any way we can!

What you Need to Know About Recently Finalized Updates to Philadelphia’s Air Toxics Regulations Effective January 1, 2024

Philadelphia’s Air Management Services (AMS) recently posted edits to its May 2022 proposed revisions to Air Management Regulation (AMR) VI concerning the control of emissions of toxic air contaminants (TACs), sometimes referred to as air toxics. At a public meeting on April 27, 2023, the Air Pollution Control Board approved the proposed amendments to AMR VI as final and designated the effective date of the updated regulation as January 1, 2024. This will be the first major update to AMR VI since its original promulgation in 1981. The full report of this public meeting can be found on the Philadelphia AMS Notice Board.

As noted previously, the revised AMR VI largely resembles the New Jersey Department of Environmental Protection’s (NJDEP’s) air toxics program that includes toxic substances regulations and a risk assessment process, with some notable additions. The revised AMR VI regulation includes some additional air toxics not listed in the NJDEP requirements, such as diesel particulate matter, and will require inclusion of existing background levels of air toxics in the risk assessment. The process for determining the existing background air toxics concentration levels is presently not well defined.

The list of TACs in AMR VI has been expanded from the existing 99 to 217 pollutants, including nearly all 187 pollutants currently classified as hazardous air pollutants (HAPs) by the U.S. Environmental Protection Agency (U.S. EPA) pursuant to Section 112 of the Clean Air Act (CAA). The reporting threshold is the annual emissions rate level in pounds per year from a source that, when exceeded, would trigger the requirement to conduct a health risk analysis. A source with potential air toxics or HAP emissions below this reporting threshold would not require an air toxics risk assessment and would be considered an insignificant source (i.e., would not require a permit or certificate) assuming all other air permit exemption criteria were met.

This regulation has the potential to affect the regulated community broadly because all Title V facilities applying for any installation permit or plan approval for new or modified equipment that emit a TAC that exceeds its risk screening threshold (found in Table 1 of the Technical Guidelines for AMR VI) will now be required to conduct an initial health risk assessment using: AMS’s Risk Screening Workbook; U.S. EPA’s air quality screening model, AERSCREEN; or an alternative air screening model approved by AMS on a case-by-case basis. TACs that do not pass this initial health risk assessment (i.e., the TAC has a cancer risk > 1 in a million and/or has a non-cancer hazard quotient > 1) will need to go through a refined risk screening assessment using modeling software such as U.S. EPA’s AERMOD, which utilizes stack- and source-specific data and representative meteorological data. Risk at a level greater than or equal to 50 in a million constitutes an unacceptable risk, and AMS will not approve a permit application at this risk level.

Additionally, and likely the most significant change in AMR VI, is that Title V facilities will be required to conduct a facility-wide health risk assessment if the permittee is seeking an initial Title V permit or seeks to renew an existing Title V permit for a facility where air toxics will be emitted in excess of the reporting thresholds.

With an effective date of January 1, 2024, AMR VI will need to be addressed by facilities regulated by AMS that submit permit applications on or after that date. Air permit applications will invariably become significantly more complex for facilities to prepare and for AMS to approve.

ALL4 has been tracking the development and approval of this regulation closely. We have experts fluent in navigating New Jersey’s stringent air toxics requirements and will likewise be able to help your facility prepare for Philadelphia’s impending regulatory update. If you have questions about how these updates affect your Philadelphia facility, don’t hesitate to reach out to me at lzhu@all4inc.com or your regular ALL4 contact.

Wastewater Pretreatment Standards: How Do I Avoid $100,000 Fines?

This past May, the United States Environmental Protection Agency (U.S. EPA) levied a fine of $100,000 against Newburg Egg Processing Corp. for an alleged violation of the Clean Water Act. The company, an egg processor based in Woodridge, New York, allegedly violated their pretreatment standards by allowing excessive levels of nitrogen and ammonia to be discharged to the publicly owned treatment works (POTW), the local entity responsible for receiving and treating the company’s wastewater before being discharged into a local creek. The company’s failure to adequately pretreat their effluent caused these pollutants to overwhelm the POTW’s capacity to treat the wastewater, which then caused multiple exceedances of the POTW’s National Pollutant Discharge Elimination System (NPDES) permit limits.

U.S. EPA Regional Administrator Lisa Garcia expressed the agency’s interest in maintaining a keen eye on any such violations, stating that “Newburg Egg and other companies must comply with all aspects of the Clean Water Act including properly treating their industrial wastewater.”

Which Pretreatment Standards apply to me?

While a POTW is subject to NPDES permitting at a federal level, dischargers to the POTW are subject to regulation by the POTW, which usually takes the form of an industrial user permit. These industrial users are subject to pretreatment standards, as defined in 40 CFR Part 403.3 as “the reduction of the amount of pollutants, the elimination of pollutants, or the alteration of the nature of pollutant properties in wastewater prior to or in lieu of discharging or otherwise introducing such pollutants into a POTW.” These standards are categorized into three groups:

- General and specific prohibitions;

- Categorical pretreatment standards; and,

- Local limits.

The first group of prohibitions are established in 40 CFR §403.5 and are largely intuitive, applying to all users. General standards prohibit the introduction of any pollutant(s) which would cause pass through to or interference with a POTW, while specific prohibitions specify characteristics of wastewater that are not allowed to be discharged to the POTW.

General and specific prohibitions and categorical pretreatment standards are established in 40 CFR Part 403 and the applicable Part of 40 CFR, Subchapter N, respectively. Subchapter N defines 59 different categories of industrial users, based on industrial classification code(s), and promulgates standards for each, while local limits in addition to, but not less stringent than, these standards may be established by the POTW.

U.S. EPA approves State agencies to administer their own NPDES programs under which the State agencies approve municipal NPDES permits for local POTWs. Because the POTW is responsible for developing and administering a pretreatment program that operates in compliance with its own NPDES permit, you may encounter situations where the local limits being implemented are more stringent than those established at the Federal level. Industrial users are strongly encouraged to develop and maintain a good working relationship with their local regulators, as users can experience variability in their regulation based on the size of the municipality, regulator turnover, and many other factors. Ultimately, however, permittees are responsible for their own compliance with pretreatment standards to avoid escalating enforcement action from State and Federal agencies.

Staying in Compliance

Understanding which standards your facility is subject to and how to meet them are crucial first steps in maintaining compliance with your wastewater pretreatment standards. The alternative is potential violations of permit limits and pretreatment standards, which can be costly with U.S. EPA fines reaching from $25,000-$50,000 per day for initial violations up to $50,000-$100,000 per day for subsequent violations.

ALL4 is here to answer your questions, help you evaluate how regulatory changes impact your operations, and assist your facility with all aspects of environmental compliance. If you have questions about the pretreatment standards at your facility, navigating the industrial user permitting process, or other wastewater-related issues please reach out to Mitchell Blair at mblair@all4inc.com or Cody Fridley at cfridley@all4inc.com.