What You Need to Know About the Proposed Updates to the e-Manifest Rule

The e-Manifest system was created to allow for tracking of electronic submittals for manifests from generator to disposal facility with the final information already reported to the United States Environmental Protection Agency (U.S. EPA). It was designed to eliminate possible errors and speed up the tracking process. However, the database has not been fully implemented and hard copies of manifests are still being uploaded to the system. In 2018, U.S. EPA launched the e-Manifest system. Since then, the agency has been working to deploy and implement the system, moving from paper submissions to electronic tracking and reporting of hazardous waste.

U.S. EPA is now proposing changes to the e-Manifest rules. Specifically:

- to incorporate shipments of hazardous waste that are exported for treatment, storage, and disposal,

- the international movement document-related requirements of the export and import of shipments, and

- to three manifest related reports (discrepancy, exception, and unmanifested waste reports).

In addition, U.S. EPA is also proposing changes to the Toxic Substances Control Act (TSCA) manifest regulations for polychlorinated biphenyls (PCB) wastes to allow for e-Manifest use. These changes will affect generators and transporters, storage and disposal facilities (TSDF).

While the proposal is primarily designed to integrate imports and exports of hazardous waste, the proposed changes to the discrepancy, exception, and unmanifested waste reports will have a larger impact on the regulated community. Changes to submissions and timeframes are highlighted below.

- Allow generators using electronic or hybrid manifests to use the e-Manifest system to satisfy exception reporting requirements. U.S. EPA is proposing to restrict electronic exception reporting to manifested shipments using electronic manifests (hybrid or fully electronic) pursuant to § 262.24(c).

- Revise the current 35/45-day Large Quantity Generator (LQG) exception reporting timeframes in § 262.42(a) and (c)(2), and § 761.217(a) and (b) to better conform to timeframes for submittal and processing of paper manifests in the e-Manifest system, thus adjusting it to a 40/50-day timeframe. The agency is not proposing additional time for Small Quantity Generators (SQG) to verify receipt of their shipments by the destination facility. The current SQG timeframe for verification of shipment delivery is 60 days (§ 262.42(b)).

- Integrate Discrepancy Reports into the e-Manifest system. A discrepancy report includes four elements: (1) a copy of the manifest at issue; (2) the significant discrepancy type (i.e., significant difference in quantity or type); (3) date of signature of the receiving facility; and (4) a description explaining the discrepancy and attempts to reconcile it.

- Allow receiving facilities to use the e-Manifest system to satisfy discrepancy reporting requirements and the proposal to adjust the discrepancy reporting timeframe to allow receiving facilities up to 20 days to reconcile a shipment. Unlike the proposed restriction to limit electronic submission of Exception Reports to electronic manifests, U.S. EPA is proposing to extend electronic reporting of Discrepancy Reports to all manifest submission types, including paper.

- Accept only electronic submissions of Unmanifested Waste Reports to the system by the receiving facility, with the goal of integrating Unmanifested Waste Reports into the e-Manifest system. The agency would not accept Unmanifested Waste Reports through a written, hard copy report. U.S. EPA would revise the reporting content specified in §§ 264.76 and 265.76 for hazardous waste and § 761.216 for PCB wastes. Unlike electronic discrepancy and exception reporting, U.S. EPA proposes to impose a user fee, equivalent to the user fees for electronic manifests, on receiving facilities for each submission of an Unmanifested Waste Report.

- Add an email address field to Item 5 of the generator block of the paper manifest so that the e-Manifest system can email copies of completed paper manifests to the generator’s email address in lieu of the receiving facility having to mail copies to the generator’s postal mail address. Under the proposal, the e-Manifest system would also send notifications to unregistered generators via their email address requesting that they register and obtain an account in e-Manifest for their site.

In addition to these proposed changes, U.S. EPA is requesting comments on modifications to the manifest to collect information required during biennial reporting. The agency is looking to integrate the e-Manifest system with the RCRA Info system and allow direct transfer of data from the manifest to the report.

As the technology has developed, the use of electronically created, stored, and transmitted data has become more available to the environmental industry. To that end, U.S. EPA is working to integrate databases, providing less manual input of data and hopefully less discrepancies from typographical errors. However, this also means that information appearing on the manifest must be reviewed for accuracy as the initial documents are created, putting more emphasis on consistent and complete reporting.

ALL4 will continue to monitor this proposal and others as we update you on changing regulations. If you have questions regarding hazardous waste compliance or permitting, reach out to one of our team members – Heather Brinkerhoff at hbrinkerhoff@all4inc.com or Karen Thompson at kthompson@all4inc.com.

The Pennsylvania RACT III Rule Is Almost Here

Pennsylvania’s draft rule known as “RACT III” [25 Pa. Code §§ 129.111-129.115, Additional RACT Requirements for Major Sources of NOX and VOCs for the 2015 Ozone NAAQS] has been slowly making its way towards finalization but it’s not there quite yet. Pennsylvania Department of Environmental Protection (PADEP) recently released the “Draft Final” version of the rule, which they hope to move through the various levels of approval and finalize the rule some time in 2Q2022.

We previewed the proposed RACT III provisions in a previous article. Based on the “Draft Final” version of the rule, it has not been completely overhauled but changes have been made based on the public comments on the August 2021 version of the draft rule. Outlined below are some of the changes made since the previous draft version:

- All submittals will be due December 31, 2022, and submittals may be made electronically.

- Submissions must include notification of being an affected facility and the facility’s RACT Plan including which sources are exempt, those that will meet presumptive requirements, and any case-by-case sources along with proposed compliance plans where controls are needed. Facilities that will comply with presumptive RACT limits must still provide notification to PADEP.

- Several clerical/administrative corrections were made.

- PADEP added a definition for “combustion source,” but have verbally noted that they need to make a distinction as yet for combustion turbines for applicability purposes.

- New or updated presumptive limits/requirements for the following sources:

- Flares used for air pollution control

- Process heaters between 20-50 MMBtu/hr

- Municipal solid waste landfills

- Municipal solid waste combustors

- Combustion turbines < 4,100 BHP

- Rich burn internal combustion engines > 100 BHP

- “Other combustion sources” > 20 MMBtu/hr

- Case-by-case RACT determinations made for RACT II may be used for RACT III. However, facilities need to submit an analysis, certified by the responsible official, that the previous case-by-case determination still stands. The analysis must include:

- A determination that no new control technologies have become available since RACT II

- A determination that the technical and economic feasibility analyses still stand, which shows that the control cost is equal or greater than $7,500/ton of NOX controlled and/or $12,000/ton of VOCs controlled. PADEP has verbally stated that these cost effectiveness values do not define a control cost threshold for new case-by-case submittals.

Unfortunately, PADEP did not provide any relief to the daily average continuous emissions monitoring system (CEMS) requirements that were in the draft rule for certain sources (e.g., boilers). In addition, there was no language added to clarify how the daily average should be calculated, although verbally they have indicated it will be based on the total pounds emitted and total BTUs burned in a day. PADEP has also verbally indicated at this month’s AQTAC meeting that they will not provide an exclusion for startup, shutdown, and malfunction (SSM) events. We have not yet seen a response document to the public comments on the draft rule, but PADEP is expected to provide further clarifications on how to comply with the daily average requirement.

The January 1, 2023 compliance deadline cannot change since it is driven by U.S. EPA. Therefore, the submittal and implementation deadlines will be a tight turnaround similar to RACT II implementation (i.e., given an estimated end of 2Q2022 finalization, facilities will only have approximately 6 months to get everything in). We are strongly recommending that affected facilities start looking at rule applicability now, which will put you in a better position to respond to the rule within the short turnaround expected later this year. Give us a call or drop me an email to discuss the specifics on how this rule will impact your facility.

Vapor Intrusion Mitigation Barriers – Bigger Might be Better, But Is It Necessary?

Vapor intrusion (VI) occurs when vapor-forming chemicals migrate from a subsurface source (e.g., contaminated soil or groundwater) into an overlying building, causing a potential human health exposure risk. When VI is suspected or confirmed, the primary method of mitigating the risk is to install a vapor mitigation system. In an existing building, a vapor mitigation system typically consists of a sub-slab depressurization system similar to a radon removal system. However, in new construction, a VI mitigation system typically consists of a sub-slab vapor barrier underlain by gravel and a piping network to passively direct subsurface vapors away from the building and to the atmosphere.

One of the main goals of VI mitigation system design is to select the most appropriate sub-slab vapor barrier, based on chemical compatibility, thickness, regulatory acceptance, durability, diffusion properties, ease of construction, and costs. There has been significant advancement in the VI practice over the past two decades, but mostly in assessing and quantifying the indoor air quality and hypothetical risk. When it comes to selecting and designing the appropriate VI mitigation barrier for a specific project, there is a general absence of science-based regulatory guidance, resulting in the designer simply asking vendors for their recommendation of the most appropriate product. This doesn’t sound like good engineering practice. As such, ALL4 conducted an independent evaluation of several VI mitigation barriers and developed a proprietary modeling tool to select the most appropriate VI mitigation barrier for a given project.

ALL4 first evaluated the Johnson and Ettinger (J&E) VI model and attempted to modify the model to accommodate and accurately predict indoor air concentrations and subsequent human health risk reductions because of installation of a vapor barrier. Although this was achievable, the model becomes unstable with such a thin barrier layer (10s of mils) and this instability must be countered by “tricking” the model (e.g., adjusting other input variables beyond their normal ranges). The result of this exercise was that most VI mitigation membranes result in hypothetical indoor air concentrations and subsequent human health risks that are several orders of magnitude below typical risk levels (e.g., 1 x 10-6). But given the model instability, ALL4 pressed on…Fick’s first law of diffusion.

Fick’s first law of diffusion can be used to model a VI barrier, but this method is an overly conservative approach. Specifically, this method assumes all volatile organic compounds (VOC) are present immediately below the barrier and no attenuation or degradation factors are considered that may otherwise reduce the predicted indoor air concentration (e.g., no attenuation due to concrete slab, no biotic or abiotic degradation, no mixing, no air exchanges, etc.). Regardless, this method was applied and essentially verified the J&E model findings above. Based on this confirmation, ALL4 developed a proprietary vapor barrier design model, based on Fick’s Law, and taking into account site-specific conditions, VOC-specific factors, membrane properties (e.g., thickness, diffusion factors) and a factor of safety developed from the landfill liner installation industry (defect factors). For most projects, even with moderate to high subsurface contamination, the design model supports the following conclusions:

- Essentially any commercially available VI mitigation barrier with even a marginal diffusivity coefficient will more than adequately reduce the predicted indoor air VOC concentrations to orders of magnitude lower than acceptable risk levels.

- Membrane thickness is primarily a durability, constructability, regulatory, factor of safety and cost consideration since even the thinnest of barriers, in theory, will result in acceptable risk reductions. As a benchmark, 30 mil appears to be the current federal design minimum (that’s 30 mils of low diffusion membrane, not the entire composite (not the whole sandwich…just the meat)).

- Pre-manufactured sheet/roll products versus spray-applied composite products perform similarly in the theoretical modeling exercise, and as such, the decision for one or the other should be based on site-specific factors such as density of penetrations, installation convenience and relative costs.

- Don’t be tempted by the “Cadillac” product, even if the site has relatively high subsurface concentrations, as most basic barriers have more than adequate diffusion protection. Any departure from the basic barrier membrane should be in consultation with the client, since more robust products are presumed to come with a higher price tag. And this begs the following question: Why are vapor mitigation barrier manufacturers continuing to develop more robust and less diffusive vapor barriers? That’s for the manufacturers to answer.

ALL4 has remediation practitioners available to discuss your specific needs. Feel free to contact Paul Hagerty (phagerty@all4inc.com) or Nick Konefal (nkonefal@all4inc.com) with any questions or to discuss your next vapor intrusion mitigation design project.

CARB Zero-Emission Forklift Implementation

Background

The California Air Resources Board (CARB) is developing a measure that will require the use of zero-emission forklifts within fleets throughout California. The Zero-Emission Forklift Measure was supported in Governor Newsom’s Executive Order N-79-20 signed on September 2020. The purpose is to accelerate deployment of zero-emission technology in forklifts throughout the state to reduce emissions of oxides of nitrogen (NOx), fine particulate matter (PM), other criteria pollutants, toxic air contaminants, and greenhouse gases (GHG). Mobile sources, including off-road equipment, are the largest contributors to the formation of ozone, PM, diesel particulate matter, and GHG emissions in California. The Zero-Emission Forklift Measure is intended to reduce emissions from off-road vehicles as part of CARB’s State Implementation Plan, Mobile Source Strategy, and Sustainable Freight Action Plan.

Proposed Applicability

The proposed measure will apply to any person, business, public utility, special district, or government agency that operates, allows the operation of, owns, leases, rents, offers for sale, offers for lease, or offers for rent an Affected Forklift in California.

An Affected Forklift means an internal-combustion forklift with a lift capacity of 12,000 pounds or less that is not a: rough terrain forklift; military tactical vehicle; pallet jack; forklift with a permanently integrated telescoping boom as its primary work implement; forklift with a diesel-fueled or alternative-diesel-fueled off-road compression-ignition engine subject to the In-Use Off-Road Diesel Fueled Fleets Regulation; or forklift owned or operated by a facility subject to the Mobile Cargo Handling Equipment at Ports and Intermodal Rail Yards Regulation.

Proposed Fleet Operator Requirements

Starting January 1, 2026, a fleet operator may not acquire, possess, operate, or allow the operation of an Affected Forklift in California unless:

- The forklift is a 2025 or previous model-year forklift with a 2025 or previous model year engine that has been reported by the fleet operator in accordance with the Reported Fleet Phase-Out Provisions of the proposed measure;

- The forklift is a 2025 or previous model-year forklift with a 2025 or previous model year engine that qualifies for the low-use exemption of the proposed measure; or

- The forklift is a 2025 or previous model-year forklift with a 2025 or previous model year engine that is a rental forklift rented by the fleet operator in accordance with the Limited Rental Allowance provisions of the proposed measure.

The proposed measure would amend section 2433, title 13, of the California Code of Regulations to state that off-road large spark-ignition engines manufactured for sale, sold, or offered for sale in California in 2026 and thereafter must not exceed emissions of 0.0 grams per break horsepower-hour or 0.0 grams per kilowatt hour of NOx, hydrocarbons, and carbon monoxide.

Next Steps

CARB is currently requesting feedback on the proposed measure through email and individual meetings. Contact David Eiges (Air Resources Engineer Staff Lead, david.eiges@arb.ca.gov) and David Chen (Advanced Emission Control Strategies Section Manager, david.chen@arb.ca.gov) if you would like to provide input.

The next CARB workshop on the proposed measure will be scheduled for the summer of 2022. The Zero-Emission Forklift Implementation is scheduled for Board consideration in 2023.

ALL4 is available to guide your facility through the development and implementation of the Zero-Emission Forklift Measure. ALL4 is offering a guidance package for the measure that includes: an evaluation of your existing fleet, a preliminary phase-out plan for affected forklifts, a Low-Use Exemption evaluation, a Limited Rental Provision Evaluation, coordination of individual meetings with CARB, and representation during upcoming workshops and group meetings. For information on a compliance plan tailored to your facility please contact our team at info@all4inc.com.

Additional Information

For additional information on the status of implementation and review schedule please visit the California Air Resources Board Zero-Emission Forklift website at:

https://ww2.arb.ca.gov/our-work/programs/zero-emission-forklifts

Industrial Stormwater Updates in the Southeast

2022 is an active year for industrial stormwater general permits in the Southeast United States. Current general permits in Alabama, Georgia, South Carolina, and Tennessee all expire within the next few months. Here is the ‘big picture’ overview of activity surrounding each of these permit renewals.

Alabama

Alabama Department of Environmental Management (ADEM) has several active general National Pollutant Discharge Elimination System (NPDES) permits for different industrial sectors. Permits for multiple sectors are set to expire in 2022, the majority in September. Facilities with current permit coverage should receive an email from the Alabama Environmental Permitting and Compliance System (AEPACS) notifying your facility of the permit expiration date and the requirement to submit a new Notice of Intent (NOI) to retain coverage under the new permit. NOIs and application fees must be submitted 90 days prior to the current permit expiration date. The 90-day deadline has already passed for both the Food and Lumber and Wood sectors. A list of all general NPDES permits and their expiration dates can be found on ADEM NPDES Permits website.

Georgia

Georgia Environmental Protection Division (GEPD) has issued a draft version of their NPDES Industrial Stormwater General Permit (IGP). There are significant proposed updates from the 2017 IGP. ALL4 has thoroughly reviewed the draft permit and provided a summary of the most impactful changes in our article Georgia Industrial Stormwater – Change is Coming! The new IGP is scheduled to go into effect on June 1, 2022. Facilities wishing to retain current coverage will have 30 days from the effective date to submit a new NOI and 90 days to make necessary changes to their Stormwater Pollution Prevention Plan (SWPPP). The draft permit and other pertinent information can be found on GEPD website.

South Carolina

The Industrial Stormwater General Permit (SCR000000) is currently on public notice and has already undergone both South Carolina Department of Health and Environmental Control (SCDHEC) and U.S. EPA approval. The current SCR000000 permit expired on September 30, 2021. However, language within the permit allows for the permit to remain in effect until such time that a new one is issued. Facilities with current coverage will need to submit an NOI within 90 days of the new permit’s effective date. A copy of the draft permit can be found on the SCDHEC stormwater website. The draft permit should become effective sometime within the third quarter of 2022. The most noticeable change in the draft permit from the current permit is that quarterly benchmark and impaired stream monitoring will also be required in the fourth year of permit coverage, not only in the first year. The draft permit also makes allowances for composite sampling, instead of grab sampling only, for benchmark monitoring.

Tennessee

On March 10, 2022 Tennessee Department of Environment & Conservation (TDEC) issued an update on their website regarding their NPDES Industrial Stormwater General Permit – Tennessee Multi Sector Permit (TMSP). Previously, TDEC reissued the 2015 TMSP for another two years. That reissuance became effective on July 20, 2020 and was set to expire on June 30, 2022. Due to the timing of the release of the new federal Multi Sector General Permit and ongoing challenges of the COVID-19 pandemic, TDEC has decided to reissue the current TSMP for a three-year period. Once reissued, this extension is expected to expire on June 30, 2025. Facilities with a current NOI on file with TDEC do not need to take any additional action to retain coverage throughout this three-year period.

ALL4 is continually tracking updates to stormwater permits across the Southeast and is available to assist facilities with the following:

- Site assessment to determine stormwater permit coverage requirements

- NOI submittal

- Individual NPDES stormwater permit application if a general permit is not available

- SWPPP preparation and updates

- Discharge Monitoring Report (DMR) and annual reporting submissions

- Training

Please contact Anna Richardson at arichardson@all4inc.com with any questions you may have on how these changes could affect your facility.

Five Key Takeaways from ALL4’s Environmental, Social, and Governance Panel Discussion

ALL4 held its first Environmental, Social, and Governance (ESG) Webinar on Wednesday, March 16th, 2022. The first of a multi-part series, the webinar, Environmental, Social, Governance (ESG) Panel Discussion: What You Need to Know & Why Is It Suddenly Business Critical, featured a panel discussion from industry practitioners at the corporate and facility level, a private equity investor, and ALL4 ESG consultants. These are the five key takeaways:

1) Learn this phrase: people, profit, planet.

In 1994, John Elkington coined the concept of triple bottom line, an economic approach where social, economic, and environmental (people, profit, planet) factors all express the health and wellbeing of an organization. Sustainability uses the triple bottom line approach to evaluate the success of, and outlook for, an organization. Sustainability then contributes to ESG. ESG is an integrated business model to identify, measure, and manage the risks and opportunities that determine the forward viability of an organization. All three concepts, triple bottom line economic approach, sustainability, and ESG, are formed around three basic elements: people, profit, planet.

The end goal of both sustainability and ESG is resilience – the capacity to thrive in the face of change – and change is something organizations have been challenged to manage in the past, are experiencing now, and will continue to be challenged with in the future.

2) The only path is forward.

ESG as a concept was coined back in 2005 but has recently gained more momentum due to public awareness of climate change and social justice. ESG has become business critical and impacts all facets of a business, from communication to customers and everything between. There is no indication that the ESG momentum will slow any time soon. Organizations need to begin their ESG journey to maintain and gain customers, investors, and employees.

3) There are multiple market pressures: odds are your organization is feeling at least one of them.

During the webinar, we surveyed our global attendees to find out what pressure(s) they have felt to start their ESG journeys. The results were:

- Customer Requirements: 57%

- Investors/Financers/Insurers: 50%

- Employees/Community: 41%

- Regulatory: 43%

- None: 5%

Customers want to buy from organizations that are integrating ESG into their business models so they can in turn show investors that they are purchasing with ESG in mind. Investors look for organizations practicing ESG so they can lower the level of risk to their portfolios. It’s almost full circle: an organization needs to operate with ESG in mind so that they can attract investors, and investors need to invest in ESG proactive companies to keep investing.

Depending on where an organization is located, it may be experiencing pressures from government to help meet climate and sustainability goals. Several political entities, including the European Union and Unites States, have committed to climate and sustainability goals they can only meet with the help of industry.

Equally present to those external pressures are the internal pressures from employees. The next generation of workforce has shown that ESG friendly companies rank high in their career search. Additionally, current employees care that their employers practice ESG because their organization often affects the community they are living in.

4) ESG is and will be a journey for everyone.

ALL4 believes that profound changes are happening in our shared ecosystem, in societies and in the global economy. These changes present both risk and opportunity for people, natural systems, governments and businesses. Companies who adapt their operating plans to include the various aspects of ESG will have a greater chance to succeed in this rapidly changing landscape.

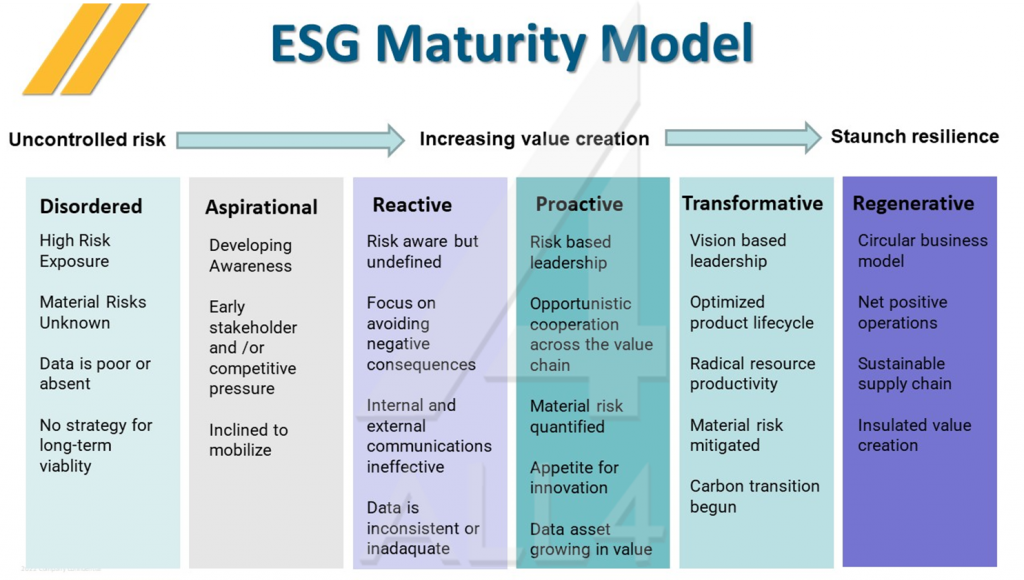

To help shape the ESG journey, ALL4 has created an ESG Maturity Model. There are six stages of the ESG journey, ranging from disorganized to regenerative. The model compares the ESG stages to the level of an organization’s risk. Each stage an organization advances in the ESG Maturity Model decreases that risk, until the organization arrives at the regenerative stage and achieves staunch resilience.

5) If you are just now starting your ESG journey…

We also surveyed the webinar attendees to see where they landed on the ESG Maturity Model: 9% said they were in the disordered stage; 89% said that they were in the aspirational, reactive, or proactive stages; and 3% said they were in the regenerative stage. There is still time for organizations to start their ESG journey and work towards that staunch resilience.

ALL4 assists companies in understanding their ESG risks and opportunities and helps them move along the ESG Maturity Model at a pace that aligns with their business objectives, one step at a time. From identification of stakeholders and performing materiality assessments, to lifecycle analyses and Scope 1, 2 and 3 emissions support, to framework guidance and reporting, and to goal setting, ESG strategy and communication, ALL4 supports our clients with a wide variety of ESG services.

ALL4’s ESG Panel Discussion was the first of ALL4’s planned ESG series. Join us in May for “A Practical Guide to Getting Started on your ESG Journey.” Stay tuned to ALL4’s Webinar schedule for updates and registration details.

Until then, here are a few ESG resources available to you:

- Recording of ALL4’s Environmental, Social, Governance (ESG) Panel Discussion: What You Need to Know & Why Is It Suddenly Business Critical?

- ALL4’s 4 the Record Articles:

- ESG Evolves and Escalates as Climate and Other Pressures Mount – by Connie Prostko-Bell, ALL4 Practice Director of ESG and Sustainability

- Climate Impacts and Expanding CDP Reporting for 2022 – by Daryl Whitt, ALL4 Technical Director for Climate Change and Sustainability

- ESG and What it Means to Business – by Rich Hamel, ALL4 Technical Director

If you have any questions about ESG and how ALL4 can assist you, please contact ALL4’s Practice Director for ESG and Sustainability, Connie Prostko-Bell at cprostko-bell@all4inc.com or 970.397.0264.

Internal Revenue Code Section 45Q – Carbon Oxide Sequestration Tax Credit

Congress first introduced section 45Q of the tax code in 2008 as part of the Energy Improvement and Extension Act. The credit is meant to incentivize investment in carbon capture and sequestration (CCS) technologies. The credit also supports beneficial use of carbon oxides instead of sequestration though at a lower credit amount per ton. Generally speaking the credit is intended for power plants and other stationary industrial facilities emitting carbon oxides, direct air capture (DAC) projects and beneficial use projects. The owner of the capture equipment is eligible to claim the credit or may transfer the credit to the market actor storing or using the carbon oxides.

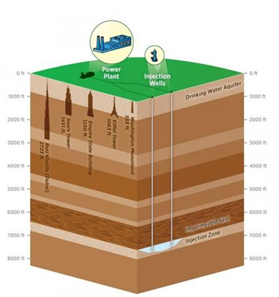

What is Carbon Capture and Sequestration (CCS)?

Carbon capture refers to extraction of carbon oxides from active anthropogenic sources such as power plants or large industrial processes. It can also refer to capture of carbon oxides from the atmosphere, called Direct Air Capture (DAC). Sequestration is the process of ‘permanently’ securing carbon oxides or otherwise altering them to eliminate them from contributing to the atmospheric burden and driving global warming.

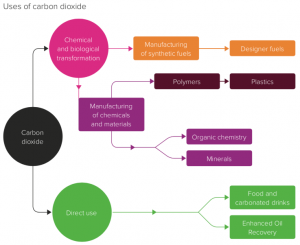

What is Carbon Capture and Utilization (CCU)?

The CC part of CCU is the same as the CC part of CCS. The difference is in what becomes of the carbon once it is captured. The U in CCU refers to the application of the captured carbon to so-called ‘beneficial uses’. Not all beneficial uses are equally beneficial. This variation is somewhat reflected in the value of the tax credits in 45Q where the credit is less for CO2 used for Enhanced Oil Recovery (EOR). Technologies are not mature enough yet but incentives such as 45Q can help drive innovation reveal opportunities for new revenue streams.

Figure 2 Ways to Use CO2 Royal Society

What is Being Proposed?

45Q was reformed and expanded in 2018 and is again up for amending in the 117th Congress under S.986 The Carbon Capture, Utilization, and Storage Tax Credit Amendments Act. The 2018 enhancements included extending the credit to eligible carbon monoxide in addition to carbon dioxide making the credit more widely accessible. While carbon monoxide has only weak radiative properties it contributes more significantly to global warming indirectly primarily by reacting with hydroxyl (OH) radicals rendering them unavailable to react with more potent greenhouse gases such as methane. When OH reacts with methane it reduces the lifetime of the molecule in the atmosphere thus reducing the global warming potential of the molecule. In addition 2018 reforms included broader eligibility for beneficial use projects and increased credit values.

Key changes proposed in the current legislation involve:

- Direct Pay provides a mechanism for market actors who earn tax credits under 45Q to instead realize equivalent cash payments. The credits would be treated as taxes paid and if the results in the taxpayer exceeding their tax liability, they could receive a cash refund from the IRS.

- Extending the window to start construction five years to 2030.

- Raising the credit per ton amounts – Currently credit values are set to ramp to $35 ton for carbon oxides stored geologically as a result of being used for enhanced oil recovery (EOR), $35 / ton for beneficial uses and $50 / ton for geologic storage not as a result of EOR by 2026. The proposed amendments: ‘Increase the 45Q credit value for direct air capture projects from $50 to $120 per metric ton for CO2 captured and securely stored in saline geologic formations and from $35 to $75 per ton for CO2 securely stored in oil and gas fields, or for beneficial utilization as fuels, chemicals, and useful products’ according to the Carbon Capture Coalition.

- Reduced thresholds – currently power plants must capture at least 500,000 tons annually and other types of facilities or projects must capture 100,000 or 25,0000 tons to quality for the credit. The current proposal would remove those requirements making the credit available to a much larger number of market actors.

According to Madelyn Morrison, External Affairs Manager of the Carbon Capture Coalition, “Congress now must deliver the broad portfolio of federal policy support for carbon management in pending budget reconciliation legislation, including direct pay and multi-year extension of the 45Q tax credit, increased credit values for industry, power and direct air capture, and dramatically reduced annual capture thresholds. Combined with the commercialization funding contained in the infrastructure law, these enhancements to the 45Q tax credit would result in an estimated 13-fold increase in carbon management capacity and annual CO2 emissions reductions of 210-250 million metric tons by 2035.”

It’s been a year since S986 was introduced in the Senate and referred to the Finance Committee. No action has been taken since then. The landscape of carbon taxes and credits, incentives and deterrents, risks and opportunities will grow increasingly complex as governments and market actors urgently seek to address climate change. It can be bewildering. A great place to get started is to understand the carbon footprint of your processes and products against the regulatory and competitive markets in which you operate. ALL4’s ESG and Sustainability, Air Quality, Carbon and Climate experts stand ready to help you navigate and innovate. You can contact Connie Prostko-Bell at cprostko-bell@all4inc.com or 610-422-1110.

Sources: USEPA, Carbon Capture Coalition, Great Plains Institute, Congress.gov, Hepburn, C., Adlen, E., Beddington, J. et al. The technological and economic prospects for CO2 utilization and removal. Nature 575, 87–97 (2019).

Ethylene Oxide Update

UPDATE May 31, 2022: Following U.S. EPA’s nationwide 2021 and 2022 Information Collection Requests (ICR) sent to facilities that use or process ethylene oxide, U.S. EPA is looking to take action on emissions, emissions sources, processes, and control technologies. Based on responses to the ICRs, U.S. EPA is planning to release information ahead of the expected chemical sector rulemakings in 40 CFR Parts 60 and 63. U.S. EPA’s focus is fugitive emissions and risk thresholds. Information is expected to be released in the coming weeks. Give us a call to how you can get ahead of the next steps!

Ethylene oxide emissions and their impacts continue to be a major focus for the U.S. Environmental Protection Agency (U. S. EPA), state and local agencies, non-governmental organizations, and communities across the country. Regulations, measurement technology, and community awareness are evolving at a rapid pace. The following is a brief update on ethylene oxide happenings at both the federal, state, and community levels.

On January 19, 2022, U.S. EPA sent out an information collection request (ICR) to eight different companies to collect information in support of the Agency’s required review of several chemical sector rules in 40 CFR Parts 60 and 63. This followed publication of a proposed consent decree in December of 2021 that requires U.S. EPA to publish several proposed chemical sector rules by December 16, 2022, and publish finalized rules by March 29, 2024. The January 2022 ICR requires companies to provide a broad array of information on their processes and emissions, including information related to ethylene oxide emissions. Furthermore, the request requires companies to conduct stack testing and fenceline monitoring for ethylene oxide emissions. Survey responses were due to the Agency in late March, and stack testing and fenceline monitoring results are due by July 19, 2022.

Shortly after issuing the ICR, U.S. EPA published a proposed reconsideration of the final 2020 National Emission Standards for Hazardous Air Pollutants: Miscellaneous Organic Chemical Manufacturing Residual Risk and Technology Review (or MON RTR). As part of this action, the Agency proposed to maintain the 2016 integrated risk information system (IRIS) ethylene oxide risk value and reject the petitioner’s request to use the Texas Commission on Environmental Quality effects screening level (ESL) risk value. U.S. EPA based their decision on the Agency’s assertion that petitioners did not present any new justification as to why U.S. EPA should reject the IRIS value, and that the arguments raised by petitioners were addressed in either the MON RTR 2020 final rulemaking or in previous actions by U.S. EPA. Comments on U.S. EPA’s proposed reconsideration were due on March 24, 2022.

U.S. EPA’s action in the proposed reconsideration indicates that the Agency will more than likely maintain their use of the 2016 IRIS value when assessing risk from ethylene oxide in the upcoming revisions to the chemical sector rules and the National Emission Standards for Hazardous Air Pollutants: Ethylene Oxide Commercial Sterilization and Fumigation Operations rule.

In additional to rulemakings, U.S. EPA has been measuring background levels of EtO in communities. According to U.S. EPA’s “Ethylene Oxide – Updates” website, measurements taken from approximately 18 monitors in the National Air Toxics Trends Stations (NATTS) network and the Urban Air Toxics Monitoring Program (UATMP) indicate an annual average concentrations ranging from 0.2 to 0.4 micrograms per cubic meter. However; in a white paper linked from the same website, “EPA’s Work to Understand Background Levels of Ethylene Oxide,” the Agency puts a disclaimer on the accuracy of the presented findings, citing limitations stemming from method detection limits and possible bias resulting from the canisters used in the ambient sampling method. Ethylene oxide measurement techniques were discussed at the Air & Waste Management Association’s Air Quality Measurement Methods and Technology Conference that was held on March 8 and 9 in San Diego, which included presentations on current measurement technologies and method detection limit advancements.

U.S. EPA also recently released a new tool call “AirToxScreen,” (Air Toxics Screening Assessment) as the successor to the National Air Toxics Assessment (NATA). The Agency states AirToxScreen is a screening tool that can be used by state and local air agencies to study risks from air toxics. The tool provides facility emissions information and calculates risk at the census-track level, although U.S. EPA says that results “are best applied to larger areas – counties, states and the nation.” Ethylene oxide is included in the list of pollutants incorporated into the tool. Users can either use the interactive AirToxScreen mapping tool to view risk information for selected areas or download data and results directly from the U.S. EPA website.

Community involvement continues to be a big focus in the ethylene oxide arena as well. The West Virginia Department of Environmental Protection (WVDEP) hosted an open house on March 26 along with U.S. EPA to provide public updates on ethylene oxide emissions in Kanawha County following fenceline and background monitoring for ethylene oxide in the area in late January 2022. Monitoring occurred near the Union Carbide Corporation and Covestro LLC facilities in South Charleston, and near the Union Carbide Corporation and Specialty Products US, LLC facilities in Institute WV. Monitoring was prompted by the results of the NATA released in August of 2018 which showed potential for elevated cancer risks in the area. Prior to the monitoring, U.S. EPA and the WVDEP conducted a community meeting on September 23, 2021. Additional details are available on WVDEP’s website.

Additionally, the U.S. EPA, the Delaware Department of Natural Resources and Environmental Control, and the Delaware Division of Public Health plan to hold a community meeting on April 13 to address health data, facility updates, and other activities at a local ethylene oxide production facility. These local updates follow several community meetings conducted by U.S. EPA and state agencies in 2021 aimed at providing community members with information about ethylene oxide, facility emissions, and health risks. Community meetings similar to those in West Virginia and Delaware have occurred in Texas, Louisiana, Georgia, Missouri, Illinois, and South Carolina. South Carolina continues to partner with U.S. EPA to monitor and understand ambient ethylene oxide concentrations in various communities.

Ethylene oxide regulation continues to evolve, with both new and updated regulations, measurement technologies, and community awareness. U.S. EPA continues to publish more and more data on facilities’ emissions, projected impacts, and compliance history in easily accessible online tools. Emissions and impacts are often screening type assessments – ALL4 can help you evaluate your emissions estimates and assess risk from your facility’s emissions of air toxics like ethylene oxide using a more refined analysis. If you’re interested in learning more about the information available to the public in your community and how upcoming regulations may impact your facility or community, please contact Philip Crawford or your ALL4 project manager for additional information.