Environmental Permitting and Compliance for New Bourbon Distillers

In the last decade, we’ve seen many new distilleries and the expansion of existing distilleries in Kentucky and other states ─ the Bourbon Boom. Before bottling your new bourbon product, there are many planning steps that have to occur. Environmental permits are required before starting operations and other permits may be required before breaking ground. For development of new distilleries or new bourbon storage warehouses, be aware of the following permitting concerns:

- Air quality permits for volatile emissions from fermentation and stillage processing and particulate emissions from grain handling;

- stormwater discharges during construction and for operations post-construction; raw water usage permits; wastewater permits for stillage discharges to local sewers; and

- waste permits depending on characterization of generated byproduct wastes from the distillation process.

Air Quality Permitting and Planning

Many states, including Kentucky, require an air quality permit before beginning site construction. Distillers should work closely with their design team to understand process controls, especially those related to management of ethanol, which is a volatile organic compound (VOC). Sources of fugitive VOC emissions include fermentation, distilled products storage and transfer, barrel aging in bourbon storage warehouses, and distillation byproducts processing (e.g., drying of stillage). Combustion of fuels for process heat is also a sources of VOC emissions. Additional sources of emissions from combustion could include engines for fire pumps or emergency power generators. Grain handling and conveying is typically the primary source of particulate emissions. Particulate emissions from silo storage or milling can be controlled using dust collectors. Fugitive particulate emissions from truck traffic on facility roads should be considered as part of the effort to quantify potential emissions from site operations.

Water Permits and Planning

One of the key characteristics for site development is the source of available raw water, such as limestone water, which adds minerals and is helpful as a pH buffer to keep pH consistent; this promotes yeast growth during fermentation. Distillers may apply additional treatment to improve the quality of source water if necessary. For raw water usage, the distiller should review state regulations if pumping water from lakes, rivers, or groundwater. Kentucky state regulation requires a permit for withdrawals of 10,000 gallons per day or more.

Permitting through the U.S. Army Corps of Engineers (USACE) CWA Section 404 Program is required if planned development on greenfield sites includes stream crossings or disturbance of ponds, streams, or wetlands. The 404 permit requires the developer to pay an in-lieu mitigation credit fee to offset disturbance. The purpose of the Kentucky Wetland and Stream Mitigation Fund is to restore, create, enhance, or preserve the Commonwealth’s wetlands or streams that may be damaged or destroyed. Distillers should work with contractors or consultants to determine the extent of stream disturbance and whether general nationwide USACE permitting or individual USACE permitting is necessary. Approval of the state’s CWA Section 401 water quality certification is required for any disturbance of the waters of the commonwealth to ensure consistency with Kentucky’s water quality standards.

Management and control of discharges from stormwater runoff is required once site disturbance begins. Permitting for construction activities which disturb greater than one acre is usually the responsibility of the construction contractor as part of the construction bid. Contractors should be aware of which states have primacy to permit discharges to receiving waters; otherwise, federal standards apply. Many states require submission of a Notice-of-Intent to construct which includes detailed site plans with proposed stormwater controls (e.g., silt fencing and rock check dams) and a site-specific management plan. If a construction contractor prepares the Stormwater Pollution Prevention Plan (SWPPP), historically known as a Best Management Plan (BMP), any templates based on the U.S. EPA Construction General Permit (CGP) should be tailored to the site-specific controls proposed and address local and state requirements. Stormwater construction activities could include multiple permits if distilleries construct barrel storage warehouses over a phased schedule. Once construction is complete and operations begin, coverage under either the U.S. EPA Multi-Sector Permit for Industrial Activities or under a state general stormwater permit is required for stormwater runoff from activities exposed to precipitation such as fuel handling and/or transfer, any uncovered grain handling, unloading or conveying, and uncovered transfer and handling of dried distiller’s grain solubles (DDGS). Similar to construction, BMP or SWPPP implementation is required to document operating procedures and management practices to prevent or reduce pollution.

An understanding of local (city or county) ordinances is beneficial for planning purposes, especially with regards to wastewater discharges. Primary wastewater streams come from stillage processes to separate water from the spent grains. Wastewater streams will likely include condensate from evaporation and reject from the centrifuge, which may require pretreatment prior to final discharge to lower the biochemical oxygen demand (BOD). If sewers are not available for discharge of process wastewaters, individual National Pollutant Discharge Elimination System (NPDES) permits are needed for direct discharges of wastewater to rivers or streams. Additional wastewater sources that require permitting in Kentucky may include domestic sanitary flow, boiler water blowdown, air compressor condensate, cooling water, raw water source treatment, and equipment wash down water. Typically, each discharger will maintain one discharge permit for each facility. Therefore, stormwater discharges that could be permitted under a general discharge permit would be rolled into the individual NPDES permit.

Smaller distilleries located near urban areas may choose to discharge wastewaters to the local municipal wastewater treatment plant via available sewers. Although these discharges may or may not require pretreatment based on the strength of the wastewater, a local discharge user permit is required to regulate the discharge to sewer to prevent the discharge from adversely affecting the municipality’s wastewater treatment plant operations.

Waste Considerations

Management of stillage is a concern for distilleries in Kentucky, whether the stillage is managed as a solid waste requiring disposal offsite or as a byproduct for reuse. Historically, farmers have hauled dried distiller grains with solubles (DDGS) from distilleries for use as a supplement for livestock feed. As the ratio of stillage quantity to available farms has increased, there is more consideration for onsite pretreatment and/or alternative offsite transfer options. Not relying on a single solution for stillage treatment or transfer of stillage offsite may be a wise long-term decision regardless of location. Agreements with farmers may change over time and there is potential for additional regulation of stillage from the Kentucky Department of Environmental Protection as distilleries increase production statewide.

Chemical Storage Considerations

Distilleries should be aware of other regulatory compliance plans or permitting beyond air quality and discharges required prior to start up. If total storage of petroleum products (e.g., diesel fuel) is above 1,320 gallons counting only containers greater than 55 gallons, the facility is subject to 40 CFR Part 112 which requires development of a Spill Prevention, Control and Countermeasure (SPCC) Plan to protect surface waters and groundwater. Distilleries may also need to prepare a spill prevention and control plan for their hazardous chemicals inventory to prevent releases and comply with local sewer ordinances. Additionally, many states require permits for installation of storage tanks planned for storage of hazardous chemicals or fuels.

Hazardous chemicals stored on site may be subject to the Emergency Planning and Community Right-to-Know Act (EPCRA) if quantities meet certain thresholds. Under Occupational Safety and Health Administration (OSHA) Hazard Communications (HAZCOM), a hazardous chemical is any chemical requiring hazard communication; essentially any chemical with a safety data sheet for the chemical would meet the definition of hazardous chemical unless specifically exempted in regulation. Distilled spirits are the most common bulk material that distilleries store in tanks on site that would meet the EPCRA definition for hazardous chemicals because of flammability. The trigger for bulk hazardous chemicals is 10,000 pounds. For distilled spirits, this amount is approximately 1,300 gallons. Additional chemicals that surpass threshold triggers could include corrosives (industrial batteries), fuels, or cleaning chemicals. Chemicals categorized as extremely hazardous substances (EHS) have lower thresholds; 500 pounds is a common threshold for most of these chemicals (e.g., sulfuric acid). Once operations begin, distilleries should further review and confirm applicability with Sections 312 and 313 of EPCRA which require annual reporting of chemical inventory and releases of toxic chemicals, as listed by U.S. EPA, to the environment.

Site Development Considerations

Plans for construction of barrel storage warehouses for expansion of larger distillery operations on undeveloped land may trigger additional environmental siting requirements beyond air, water, and waste compliance. If tree removal is necessary, distillers should be aware of regulations for protection of endangered species. Site developers should coordinate with the U.S. Fish and Wildlife early in the site planning process to understand how restrictions may impact timing of construction. For habitat removal greater than 100 acres, the developer can pay a mitigation fee to a conservation trust fund that is used to help fund habitat conservation and restoration projects as an offset for the disturbed acreage. Additional requirements include the prohibition of tree cutting from April 1 through October 14.

ALL4 works with several distilleries and assists them with a broad range of environmental permitting and compliance needs. If you have questions about your requirements or are planning to expand distillery operations to a new location, please contact Dan Hardin at 502-254-0402 or dhardin@all4inc.com.

Section 401 of the Clean Water Act (CWA) – Proposed Improvement Rule

Regulatory Background

The State 401 Water Quality Certification Program reviews and authorizes selected federal licenses and permits. Any entity (including federal, state, and local government agencies) that plans to work, deposit, or place dredged or fill material in jurisdictional waters of the United States is required to obtain a permit and state certification. Examples of federal licenses and permits subject to the 401 Water Quality Certification include those issued by the United States Army Corp of Engineers (USACE) for discharge of dredged or fill material under Clean Water Act §404, and for activities that may potentially discharge into navigable waters, and hydropower licenses issued by the Federal Energy Regulatory Commission (FERC).

Effective April 6, 2022, the Supreme Court reinstated the United States Environmental Protection Agency’s (U.S. EPA) vacatur of the 2020 Clean Water Act 401 Certification Rule. On June 9, 2022, U.S. EPA published the proposed Clean Water Act Section 401 Water Quality Certification Improvement Rule in the Federal Register. This proposed rule would update the existing regulations to be more consistent with the statutory text of the 1972 CWA. The public comment period ends August 8, 2022.

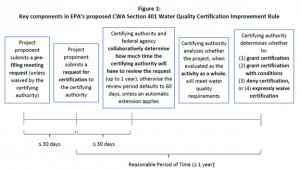

Key components of the proposed rule include:

- A pre-filing meeting with the state at least 30 days before requesting certification.

- Submissions would include a copy of the draft federal permit and any existing and readily available data or information related to potential water quality impacts from the proposed project.

- S. EPA regulations would be updated to provide the states with a role in determining the “reasonable period of time” to review the request for certification. If the certifying authority and federal agency do not reach an agreement within 30 days on the length of time for review, it will default to 60 days from receipt of the request for certification. The default is automatically extended upon notice by the certifying authority (before the end of the period) that the certifying authority’s public notice requirements will take longer than 60 days or if there is a force majeure event.

- S. EPA proposes that when a certifying authority reviews a request for certification, it looks at whether the activity as a whole will comply with water quality requirements, which include water quality-related state or Tribal laws.

- A certifying authority may make one of four certification decisions on a request for certification: (1) grant certification; (2) grant certification with conditions; (3) deny certification; or (4) expressly waive certification.

What Do You Need to Know?

The process and information required may have changed after April 6, 2022. Environmental Managers should review their own State procedures during the planning stages of the project. State forms and procedures have reverted to the pre- 2020 Clean Water Act 401 Certification Rule requirements.

For those facilities that do not frequently require federal permitting, common activities that will trigger federal permitting and state certification can include, but are not limited to:

- Placement of dredged or fill materials into waters and/or wetlands

- Structural fill such as culverts and bridge support

- Road and utility crossings

- Gravel mining/removal

- In-stream basins

- Dredging, excavation, channel widening, or straightening

- Flooding, excavating, draining, and/or filling a wetland

- Bank sloping; stabilization

- Stream channel relocation

- Water diversions

- Diverting, obstructing, or changing the natural flow or bed of any surface waters and/or wetlands

- Constructing a barrier across a stream, channel, or watercourse that will create a reservoir; dams, weirs, dikes, levees, or other similar structures

If you have questions about 401 Certifications or have a project you need assistance with, please contact one of our team members: Karen Thompson at Kthompson@all4inc.com, Anna Richardson at ARichardson@all4inc.com, Paul Hagerty at PHagerty@all4.com, or Peter Stein at PStein@all4inc.com.

Why Environmental, Social, and Governance (ESG) matters when times get tough

It’s hard these days not to consider the possibility of near-term economic downturn. Yes or no? If and when? How long and how deep? There are no sure answers to those key questions at present. This level of uncertainty inevitably leads to conversations about how best to staunch an organization for changing conditions. Those discussions are happening in any institution that manages budgets, including households, businesses, and governments.

Concurrently we are experiencing an explosion of activity in the market related to management and disclosure of Environmental, Social, and Governance (ESG) risk. Much of the ESG momentum focuses on climate related risk and energy dependency, and for good reason. There is an increased sense of urgency driven by stakeholder awareness of the real consequences of climate change and the volatility of the energy economy. Investors are demanding data to understand how climate related risks, a company’s carbon intensity, and/or the transition to a low carbon economy could hinder returns or present opportunities.

Interest is intense enough that three major institutions are separately seeking to finalize updated standards for climate related disclosures, including the International Financial Reporting Standards (IFRS), the U.S. Securities and Exchange Commission (SEC), and the European Financial Reporting Advisory Group (EFRAG). The good news is that, while there are differences, all three efforts are influenced by the Task Force on Climate Related Disclosure (TFCD) and GHG Protocol approaches that provide important commonalities necessary for consensus, compatibility, and decision making.

Its not just Climate Risk

Stakeholders are also applying pressure to companies to disclose how the company’s business activities impact communities and ecosystems and how labor and safety practices impact the workforce in order to reveal risks to the company’s license to operate, access to natural resources, and threats to the stability of the labor force. Further, there is demand for transparency related to how a company is managed, how executives are incentivized, how a company confronts risk, and whether the organization operates legally and complies with regulations. All of these elements matter to investors and other stakeholders because any one of them could potentially impact an organization’s ability to create value and adapt to changing market conditions. The upside is that ESG metrics also represent opportunities for innovation, enhanced competitiveness, supply chain reliability, adaptation, operational efficiency, and cost controls.

Companies are responding, with varying levels of enthusiasm, by investing in identifying risks and exposures related to their environmental liabilities, social impacts, and governance practices. As with any investment, money, mindshare, and time are required inputs in order to benefit from the effort. The investment horizon for ESG projects can be short, medium, or long term. For example, a simple energy efficiency initiative may see return within 12-18 months, but it may take several years to bring an innovative new product to market. Typically, the more complex the risk the longer the investment horizon. Appetites for short term gains are much stronger, but the rewards of long-term investment in ESG performance are often what it takes to effectively transition to a more favorable economy.

ESG investments should always address carefully considered material issues in order to yield meaningful returns. Material issues are those issues reasonably likely to have a significant effect on the operating condition or market valuation of a company. Therefore, well-executed investments in ESG-related material issues should position an organization to better weather tough times. This is critically important to keep in mind in the face of economic uncertainty. Tim Cook, CEO of Apple, has famously said: “We believe in investing during downturns.” That strategy has certainly paid off for Apple investors. ESG is not simply window dressing, or even just the right thing to do. Sustained investment in and focus on ESG material issues could be the difference between thriving or failing in a time of recession.

The Upside

Even in downturns some companies thrive. There are endless examples of innovative companies pivoting to fill unmet market needs, or whose practices avoid supply chain disruption or who are able to reduce costs because their optimized operations minimize reliance on scarce natural resources or third-party energy, or because their investments in people and communities encourage loyalties that pay dividends even in the harshest economic conditions. All of these opportunities can be revealed using well managed ESG metrics.

- During the Great Depression Martin Guitars employed a number of strategies to stay afloat including investing in innovative designs that allowed them to drive demand with revolutionary guitar styles, such as the Dreadnought and the 14-fret neck.

- One of the very first products brought to market by Panasonic founder Konosuke Matsushita was an electric plug that was built using recovered screws from used lightbulbs. This circular approach helped Panasonic survive the devastated Post-WWII Japanese economy. At that time, it was extremely difficult to source raw materials due to scarcity, expense, and restrictions. Many companies failed. But Panasonic’s inherent approach to resource preservation during manufacture and collection of used material for incorporation in new products allowed Panasonic to thrive.

- Another ESG success story is Texas Roadhouse. The hospitality industry was hit hard by the Covid-19 pandemic. In 2020 the late Kent Taylor, CEO of the steakhouse chain, donated his salary and bonus, around $800,000, along with an additional $5 million to an emergency fund the company already had in place to help employees. Mr. Taylor was known to say, “we are a people company that just happens to serve steaks.” Not only did the company survive the downturn but they are thriving in a still difficult environment. First quarter 2022 revenues were about $13 million over analyst projections despite raising prices 3.2%. This success has been attributed to customer loyalty: a direct result of the emphasis on the customer experience delivered by motivated frontline staff. Kent Taylor demonstrated the truth of Larry Fink’s observation that: “Stakeholder capitalism is not about politics. It is not a social or ideological agenda. It is not ‘woke.’ It is capitalism, driven by mutually beneficial relationships between you and the employees, customers, suppliers, and communities your company relies on to prosper. This is the power of capitalism.”

A Business Model for Resilience

ESG seems to stir up controversy in some circles. It has been used lately as a headline grabber with dramatic claims that ESG is at best a distraction and at worst a threat to prosperity. Others may feel that investment in ESG performance is a ‘nice to have.’ But the truth of the matter is that the businesses that are best positioned to weather downturn and build long-term enterprise value have ESG performance woven tightly into their business model. Those organizations have data-driven governance structures that consistently confront risk, reward innovation, ensure compliance, demonstrate accountability, and value transparency. They effectively identify and manage environmental and social risks and capitalize on opportunities. They create metrics to track performance, quantify exposures and measure returns. Companies who meaningfully invest in addressing ESG material issues are simply well-run businesses with vision-based leadership and an appetite for innovation, and they are positioned to thrive in dynamic and challenging conditions.

If you are interested in exploring the opportunities a robust ESG program offers your organization please reach out to Connie Prostko-Bell Director, ESG & Sustainability Practice at Cprostko-bell@all4inc.com 610-422-1110.

Installing a New Continuous Monitoring System? Here Are Some Things You May Want to Consider.

The day has come – a driver such as a new regulation or a sustainability initiative has resulted in your facility needing to install a Continuous Monitoring System (CMS). We get it – that task can be very daunting. To help, we’ve put together a list of the top things to consider as you embark on this journey.

- Who is on your team?

The installation of a CMS requires a team of resources. Your stakeholders could include folks from internal facility resources such as Environmental, Instrumentation, Operations, and even Information Technology. The external resources could include consultants, integrators, and vendors. Don’t forget the internal or external resources explicitly assigned to manage this project. Without effective project management, a successful and timely CMS installation will not be achievable. - What is the regulatory or company driver for the CMS?

The first step in installing a CMS is understanding the why behind the monitoring. Understanding why you are required to implement continuous monitoring will dictate the type of monitoring system, the resources you engage in the process, and how you will demonstrate compliance or quantify processes against key metrics moving forward. Do you need a CMS to comply with a regulation or are you installing it so you have better information? The why will define the how for monitoring including the type of CMS, the data collected by the CMS (i.e., calculation, averaging, validation, etc.), and the quality assurance of the CMS.

- How do you want to integrate and implement the CMS into your facility?

The end-goal of a CMS installation program must be considered at the beginning of the program. Be a dreamer, imagine what the ultimate success of the CMS program looks like. Who will be the accountable parties? Will the Instrumentation personnel be responsible for the recordkeeping associated with CMS downtime and Operations personnel be responsible for the recordkeeping associated with deviations or excess emissions? What other goals may the CMS or Data Acquisition and Handling System (DAHS) be able to help achieve? Use a whiteboard to outline the ultimate workflow considering notification, response, and recordkeeping responsibility. You will have to know the end result to ensure that the design of the CMS can get you there.

- What type of monitoring system do you need?

CMS is a broad term – it encompasses a variety of systems. To determine which system your facility needs, you will need to consider what type of data is going to be collected? Monitoring opacity? You will need a Continuous Opacity Monitoring System (COMS). Monitoring NOX, SO2, CO, etc? Time to start looking at a Continuous Emissions Monitoring System (CEMS). Will you need to quantify mass emissions (i.e., lb/hr)? You may need a stack flow monitor. Collecting process data (think temperature, pressure, etc.)? A Continuous Parameter Monitoring System (CPMS) will be the way to go. - Do you know all of the different equipment needed?

Once you have made the decision on the type of monitoring system that you need, it’s time to consider what that system actually entails. What type of sampling system will you need and how will you store the data? What type of DAHS will be used? To quality assure your data, what reference gases or other calibration standards will you need? Even more importantly, what pieces of equipment will you want to keep onsite in your spare parts department in the event of required maintenance? - Where will all of the equipment be stored?

Ok, we’ve decided on what equipment we need, but where the heck are you going to actually put all of this onsite? Some facilities opt to erect a specific CMS shelter. When doing this, it’s important to consider the footprint of the shelter and whether you have enough room in the field for it. Will this shelter need to have its own HVAC system to ensure the sampling system lines don’t freeze or the equipment doesn’t overheat? And finally, is there an easily accessible power source to run all of this equipment? - What type of connection will the data be shared over?

This is often a question that isn’t considered until later in the installation process but can have a significant impact on the overall budget and timing. How will all of the CMS information get around your facility? What infrastructure (i.e., fiber or hardwire) is available to move the data around? Can the CMS data be collected over Modbus or will data be collected via 4-20 millamp signals? - What is your deadline for installing the CMS?

So, we’ve determined the monitoring system we want, outlined all of the equipment that’s actually needed to run that system and decided where we’re going to store it. How long is it going to take to get this thing up and running? Right now, more than ever, it’s very important to consider supply chain issues (see Katie’s article ). What used to take about 6 weeks, could now take 6 months. - Do you know what your quality assurance requirements will be?

Phew – we’ve planned it all out, right? Before we let you off the hook that easily, we would be remiss if we didn’t talk about a system’s certification requirements. If the CMS is being installed for a regulatory reason, there will be specific initial and ongoing certification requirements that must be followed. As part of this, you will need to consider the type of reference gases or other calibration standards that you will need to have onsite to complete the quality assurance activities. For ongoing, more intensive quality assurance activities, you will want to consider what external vendors you will need (i.e., a testing company) and how often you will need the vendor to come onsite (once a year? once a quarter?).

When you are tasked with the installation of a CMS (and maybe even after reading this), your head may be swimming. We’ve been there. However, after being involved in numerous CMS installations, these are the right questions to ask in order to bring some certainty to your CMS installation. Need help getting out of the gate? Please do not hesitate to reach out to me at mbarber@all4inc.com.

Texas Releases New Readily Available Permit (RAP) for Power Generation Engines

The Air Permits Division (APD) at the Texas Commission on Environmental Quality (TCEQ) has released a new Readily Available Permit (RAP) for power generation engines. The RAP can be used to authorize up to 10 diesel-fired engines used for the purpose of generating power and 10 associated diesel fuel storage tanks. It cannot be used to amend an existing New Source Review (NSR) preconstruction permit and is only allowed for the issuance of an initial permit.

What is a RAP?

A RAP is a case-by-case minor NSR preconstruction permit that APD has developed to streamline the process for reviewing and issuing the final permit. RAPs exist for certain types of facilities where the character of emissions and associated emissions calculations are consistent, and a standard set of special conditions can be defined by the TCEQ. When a proposed project meets the specific criteria defined by a RAP, it qualifies for the more efficient review process associated with these types of permits. The applicant fills out the RAP workbook for the relevant facility type and submits the required application documents through the State of Texas Environmental Electronic Reporting System (STEERS). Note that RAPs do not require modeling as part of this streamlined permitting process. In most cases, RAPs will qualify for a consolidated public notice where the requirements for both 1st and 2nd public notice are met with a single action. The expected result is that the final permit is obtained in less time than if a traditional minor NSR permit application had been submitted.

What types of projects qualify for the power generation engine RAP?

The power generation engine RAP can be used to authorize projects involving the installation of up to 10 diesel-fired engines and 10 associated diesel storage tanks that meet the following criteria:

- The engines are used to generate power.

- The RAP is for an initial permit issuance only and not proposing to amend an existing NSR permit.

- Project emissions increases, without considering any decreases, do not exceed the Prevention of Significant Deterioration (PSD) or Nonattainment New Source Review (NNSR) major source thresholds at existing minor sites or the significant emissions rates at existing major sites.

- The project does not result in any upstream or downstream production increases.

- The customer has a compliance history classification of Satisfactory or High.

- The emissions do not exceed the limits prescribed by the RAP.

- The engine and tanks can comply with all representations and special conditions specified by the RAP.

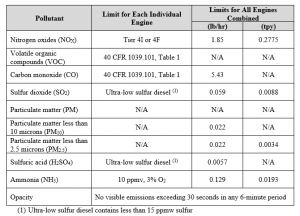

What are the maximum emissions allowed for engines to qualify for the RAP?

The engines authorized by the RAP must comply with the following emissions limits:

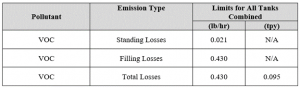

What are the maximum emissions allowed for diesel tanks to qualify for the RAP?

The tanks authorized by the RAP must comply with the following emissions limits:

With what special conditions and RAP representations do my engine(s) and storage tank(s) need to comply?

The engines and tanks authorized by the RAP will be required to comply with the following conditions and permit representations:

- Engines authorized by the RAP are limited to a combined total of 300 hours of operation per rolling 12-month period.

- Engine stack parameters must meet the following minimum requirements: height ≥ 25 ft, diameter ≥ 0.66 ft, temperature ≥ 828 degree F, and velocity ≥ 168.7 ft/s.

- Selective Catalytic Reduction (SCR) must be in operation for any engine that is equipped.

- A non-resettable runtime meter must be installed on all engines.

- For engines in Houston-Galveston-Brazoria (HGB) or Dallas-Fort Worth (DFW) ozone nonattainment areas, the engine cannot operate for testing or maintenance between 6:00 AM and noon except if manufacturer’s testing requires a run of over 18 consecutive hours or if you are verifying the reliability of emergency equipment immediately after unforeseen repairs.

- All startups and shutdowns of an engine for which any control device is not in operation shall not exceed 30 minutes per event.

- No more than one diesel tank can be filled at one time.

- The total amount of time diesel tank filling operations occur in a year cannot exceed 24 hours per rolling 12-month period.

- Tanks must utilize submerged fill and all uninsulated exterior surfaces exposed to the sun must be white or aluminum.

- Records of the engine manufacturer’s design and operation specifications and all emissions-related maintenance requirements, hours of operation, fuel delivery date, quantities delivered, duration of tank filling, fuel sulfur content, engine maintenance, and visible emission observations must be maintained.

What’s the Bottom Line?

The power generation engine RAP is intended to provide a more efficient process for obtaining a minor NSR permit for power generating diesel-fired engines and their associated diesel storage tanks in the state of Texas. ALL4 is available to help you evaluate whether the RAP is the right choice for your project and can provide support preparing all application documents necessary to obtain a final permit. If you have questions, please reach out to Christopher Ward at cward@all4inc.com.

EPA Publishes 29th Annual U.S. Greenhouse Gas Inventory

In April 2022, the United States Environmental Protection Agency (U.S. EPA) released the 29th annual Inventory of U.S. Greenhouse Gas Emissions and Sinks (GHG Inventory).

Background

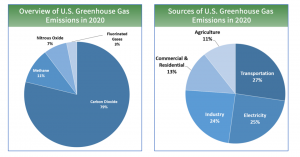

Since 1990, the U.S. EPA has developed a nationwide GHG inventory, engaging researchers, federal partners, stakeholders, consultants, industry, and environmental organizations. The GHG inventory includes carbon dioxide, methane, nitrous oxide, hydrofluorocarbons, perfluorocarbons, sulfur hexafluoride, and nitrogen trifluoride emissions. The final GHG emissions number is calculated using the total GHG production from man-made sources minus the total carbon dioxide stored in carbon sinks. Carbon sinks are sources that remove carbon dioxide from the atmosphere including, but not limited to, forests, vegetation, soils, and the ocean.

The Greenhouse Gas Reporting Program (GHGRP), promulgated at 40 CFR Part 98, established mandatory GHG reporting requirements for owners and operators of certain industrial facilities. The GHGRP is used by the GHG Inventory to quantify and better understand the sources and types of GHG emissions emitted from U.S. industry. The GHGRP does not cover all annual U.S. greenhouse emissions and sinks (e.g., the GHGRP does not include emissions from the agricultural, land use, and forestry sectors), but it is an important component in the calculation of national-level emissions in the Inventory. Between the GHGRP and the GHG Inventory, you can find the total U.S. GHG emissions, review trend data for the past 25 years, browse a map to find the largest emitters in your area, compare facility emissions across an industrial sector, and find reported GHG emissions by state.

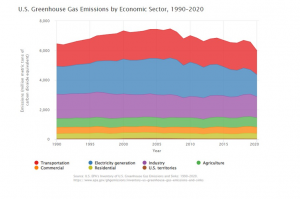

Key Takeaways from the 2020 U.S. GHG Emissions Inventory

U.S. GHG emissions decreased 9% from 2019 to 2020 mostly due to impacts of the COVID-19 pandemic on travel and economic activity. The decrease is also said to have resulted from energy market trends, technological changes, and carbon intensity of energy fuel choices.

The largest source of U.S. GHG emissions in 2020 was the transportation sector (27%), closely followed by the electricity sector (25%) and industry sector (25%). The commercial and residential sectors accounted for 13% of U.S. GHG emissions, and the agriculture sector accounted for 11% of the U.S. GHG emissions.

Note: All emissions estimates from the Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2020.

Exploring the U.S. GHG Inventory

The U.S. EPA GHG Inventory website (https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks) provides several resources from the GHG Inventory, including a full 1990-2020 inventory report, an annual fast fact sheet, data highlights, an interactive inventory data explorer, and other specific information. The inventory data explorer allows you to filter information based on sector, category, GHG, year, and geography; this can be a useful tool to compare a facility’s emissions with other similar facilities.

What is the GHG Inventory used for?

The GHG Inventory is used for several purposes:

- Educating citizens on U.S. GHG emissions

- Informing the U. S. EPA, researchers, federal partners, policymakers, and stakeholders

- Submitting GHG emissions to the United Nations Framework Convention on Climate Change (UNFCC)

- Comparing GHG emissions between sectors and emitters

- Tracking year to year changes

If you have any questions about GHG inventories and how ALL4 can assist you, please contact ALL4’s Technical Director for Climate Change and Sustainability, Daryl Whitt at dwhitt@all4inc.com or 987.777.3076.

South Coast Air Quality Management District’s Warehouse Indirect Source Rule

South Coast Air Quality Management District (SCAQMD) adopted Rule 2305, Warehouse Indirect Source Rule – Warehouse Actions and Investments to Reduce Emissions (WAIRE) Program in May of 2021. SCAQMD Rule 2305 applies to warehouses larger than 100,000 square feet and requires a reduction in nitrogen oxide (NOX) and diesel particulate matter (PM) emissions from mobile sources associated with the operation of subject warehouses.

The first step towards compliance is to determine the WAIRE Points Compliance Obligation (WPCO) for the warehouse. The WPCO is calculated based on the number and type of truck trips to and from the warehouse annually and subject facilities must maintain records of daily truck trips to and from the warehouse with truck class information. Once the WPCO is determined, warehouse operators can choose between three options or use a combination of the three options to meet their compliance obligation.

- The first option is the payment of an annual mitigation fee of $1,000 per WAIRE Point.

- The second option is to participate in the menu-based points system of the warehouse rule to reduce NOX and PM emissions. The number of WAIRE Points earned from the menu depends on the action or investment. WAIRE Menu actions include:

- Acquisition and use of zero emission and near-zero emission trucks.

- The installation and use of electric vehicle supply equipment or electrical charging stations.

- The installation and use of solar panels.

- The installation and use of a hydrogen station.

- The final option is to follow an approved Custom WAIRE Plan. A Custom WAIRE Plan must:

- Demonstrate how the proposed action will earn WAIRE Points and how the emissions reductions are quantified and verified.

- Describe NOX and/or diesel particulate matter emissions reductions from the proposed action.

- Achieve emissions reductions no later than three years after plan approval.

- Reduce emissions within three miles of the warehouse.

- Include a schedule of key milestones and a description of the location where the proposed actions will occur.

Custom WAIRE Plans must be submitted for approval prior to implementation and may be rescinded if there is inadequate progress towards completion of the plan.

SCAQMD’s Warehouse Indirect Source Rule has a three-year phase-in period based on warehouse size. The initial compliance period for each phase consists of January 1 through December 31 of the compliance year.

- Phase 1 consists of the largest warehouses, greater than or equal to 250,000 square feet. Phase 1 warehouses have an initial compliance period during 2022 and must submit their Initial Annual WAIRE Report (AWR) by January 31, 2023.

- Phase 2 includes warehouses greater than or equal to 150,000 square feet to less than 250,000 square feet. The initial compliance period for Phase 2 warehouse is 2023, with initial AWR due by January 31, 2024.

- Phase 3 consists of warehouses between 100,000 and 150,000 square feet. The initial compliance period for Phase 3 warehouses is 2024 and these warehouses must submit their initial AWR no later than January 31, 2025.

An Initial Site Information Report (ISIR) must be submitted by July 1 of the initial compliance period. The ISIR must contain warehouse information, truck trip information, and anticipated methods to meet the WAIRE Points Compliance Obligation. The Annual WAIRE Report must include warehouse operator information, truck trip data, how WAIRE points were earned, and information about the WAIRE points.

ALL4 has generated strategies to ensure compliance with SCAQMD Rule 2305 including development of a WAIRE Program Recordkeeping Tool and conducting a WAIRE Points Initiative evaluation to help clients identify options to reduce their WPCO. If you have questions about SCAQMD’s Warehouse Indirect Source Rule, please contact Emily Dykeman at edykeman@all4inc.com or 909.477.7129.

Universal Waste Series – Common Mistakes Managing Used Lamps

Universal waste regulations allow the company to not count the designated waste as hazardous as long as the company complies with Chapter 40 of the Code of Federal Regulations (CFR) §273. “Used Lamps” is the first of a series of 4 The Record articles providing common mistakes and best practices to avoid having to count universal waste as hazardous waste.

The universal waste standards streamline the hazardous waste management standards for wastes that are commonly generated in relatively small quantities. There are three intended outcomes from the streamlined regulations according to the United States Environmental Protection Agency (U.S. EPA) website:

- Promote the collection and recycling of universal waste

- Ease the regulatory burden on retail stores and other generators that wish to collect these wastes and transporters of these wastes

- Encourage the development of municipal and commercial programs to reduce the quantity of these wastes going to municipal solid waste landfills or combustors

General universal waste management requirements

- One-year storage limit for universal waste accumulation

- Universal waste must be stored in structurally sound containers that are compatible with the waste and prevent breakage, spillage, or damage

- Universal waste containers must contain a label containing the phrases “Universal Waste” and the specific universal waste type. The start date of universal waste accumulation also needs to be included on the label

- Employees must be trained on applicable waste handling and emergency procedures

- Universal waste releases must be immediately contained

- Universal waste that meets the definition of hazardous materials per the U.S. Department of Transportation (U.S DOT) must contain the proper hazardous materials label and proper shipping paperwork per 49 CFR 172. U.S DOT hazardous material training must also be completed by any employee involved in the transportation of hazardous materials

- Track and maintain records of all universal waste shipments

- Universal waste must be sent to a universal waste destination facility

Handlers of universal waste can be classified as a small quantity handler (accumulates < 5,000 kg of universal waste at any one time) or a large quantity handler (accumulates > 5,000 kg of universal waste at any one time). A large quantity handler of universal waste must notify the Regional Administrator (or State Agency where the state has primacy) and have received a U.S. EPA identification number before exceeding the 5,000 kg accumulation storage limit.

Used Lamp management

In 40 CFR §273.9, lamps are defined as “the bulb or tube portion of an electric lighting device”. Common types of lamps include fluorescent, high intensity discharge, neon, mercury vapor, high pressure sodium, and metal halide lamps. A used lamp becomes a waste when it is discarded, and an unused lamp becomes a waste once it is determined to be discarded.

What are common used lamp management mistakes?

- Not having a dedicated and commonly known storage area for universal waste

- Exceeding the one-year storage limit for used lamp accumulation

- Maintenance practices such as taping used lamps together or storing used lamps in the same container with new lamps

- Storing used lamps in the same area as new lamps without clear storage delineation

- Storing used lamps outside of a storage container

- Failing to label or appropriately label storage containers (using improper labels or not including the accumulation start date) for used lamps

- Failing to keep containers storing used lamps completely sealed unless used lamps are being added to the container (this includes even small openings in containers such as bankers boxes)

- Assuming LED lamps are exempt from universal waste regulations

- Cleaning up broken used lamps without proper PPE, or in a manner that increases the likelihood that hazardous constituents are released to the environment

- Using a lamp crusher

- Not completing the DOT hazardous material training if shipping universal waste that meets the definition of hazardous materials

How can I avoid common used lamp management mistakes?

- Pick a dedicated and commonly known universal waste storage area that allows for proper storage and is reasonably close to the source of universal waste generation

- Include detailed instructions for proper used lamp management in an annual universal waste training program. Also include the location of the universal waste storage area and which personnel are responsible for managing the universal waste program

- Develop a Standard Operating Procedure for used lamp management and distribute to applicable personnel. Review and update the SOP routinely

- Have a consistent inspection program that provides detailed corrective actions to employees responsible for used lamp management

- Keep track of supplies such as boxes, tape, and labels

- Schedule pick-ups at intervals that avoid exceeding the one-year storage limit

- Stay up to date on newer lamp technologies such as LED lamps

- Complete the U.S. DOT hazardous material training and complete the refresher training within the three-year requirement

If you have any questions about universal waste or specifically “Used Lamps”, please reach out to me at agolding@all4inc.com or Karen Thompson at kthompson@all4inc.com. ALL4 is here to answer your questions and assist your facility with all aspects of hazardous and universal waste management.

U.S. EPA to Ban Chrysotile Asbestos

The United States Environmental Protection Agency (U.S. EPA) issued a proposed rule under the Toxic Substances Control Act (TSCA) to ban chrysotile asbestos. The rule was published in the Federal Register (FR) on April 5, 2022 and is currently in a public comment period that will end on June 13, 2022. Once finalized, the rule will be codified in Title 40 Code of Federal Regulations (CFR) 751. The proposed rule is a result of the TSCA risk evaluation for asbestos, part 1: chrysotile asbestos, completed in December 2020. This evaluation determined that the risk to human health caused by chrysotile asbestos is unreasonable.

Asbestos is known to be a carcinogen and causes multiple adverse health issues, particularly when inhaled. The Occupational Safety and Health Administration (OSHA) Permissible Exposure Limit (PEL) for asbestos is 0.1 fibers per cubic centimeter of air as an eight-hour time-weighted average (TWA), with an excursion limit (EL) of 1.0 asbestos fibers per cubic centimeter of air over a 30-minute period. To protect human health, U.S. EPA considered implementing an existing chemical exposure limit (ECEL) of 0.005 fibers per cubic centimeter as an 8-hour TWA but opted to ban chrysotile asbestos altogether instead. Asbestos is no longer mined in the United States, and chrysotile asbestos is the only type still imported to the United States. Chrysotile (serpentine) asbestos is less harmful than the other five types: crocidolite (riebeckite), amosite (cummingtonite-grunerite), anthophyllite, tremolite, and actinolite.

The proposed rule has the potential to affect users, manufacturers, importers, processors, distributors, and disposers of chrysotile asbestos, including the following industries:

- Oil and Gas Extraction (NAICS code 211)

- Chemical Manufacturing (NAICS code 325)

- Fabricated Metal Product Manufacturing (NAICS code 332)

- Transportation Equipment Manufacturing (NAICS code 336)

- Gasket, Packing, and Sealing Device Manufacturing (NAICS code 339991)

- Motor Vehicle and Motor Vehicle Parts and Supplies Merchant Wholesalers (NAICS code 4231)

- Motor Vehicle and Parts Dealers (NAICS code 441)

- Automotive Repair and Maintenance (NAICS code 8111)

As currently written, the proposed rule will prohibit the import and use of chrysotile asbestos in diaphragms and chemical production sheet gaskets two years after its effective date. Brakes, other friction products, and other gaskets that contain chrysotile asbestos will be banned 180 days after the effective date of the final rule. These products are the only types still known to contain chrysotile asbestos.

One significant use of chrysotile asbestos is in the chlor-alkali industry, which uses chrysotile asbestos diaphragms in the production of chlorine. The diaphragms are used to separate anodes and cathodes during the electrolysis of brine, where chloride ions are converted to chlorine. Asbestos is used due to its durability and resistance to the caustic soda co-product.

The diaphragms contain per- and polyfluoroalkyl substances (PFAS), but prohibiting them might increase the use of PFAS because they could be replaced by membranes that contain even higher concentrations of PFAS. Such membranes are an alternative to the asbestos diaphragms, and their use could cause more PFAS to be released into the environment. Like asbestos, PFAS are linked to harmful health effects and are becoming more widely regulated, especially in water. U.S. EPA evaluated this and determined that the benefits of banning chrysotile asbestos outweighed the risks.

Companies in the chlor-alkyl industry should watch for potential changes in the regulations pertaining to PFAS. The Safe Drinking Water Act (SDWA) and Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) could have updates regarding PFAS. ALL4 will continue to monitor the regulatory climate concerning PFAS and alert any clients that might be affected. ALL4 is also here to assist with any related environmental issues. If you have questions about how the proposed rule could affect your facility’s compliance, or would like to discuss strategies for product substitution, please contact us.