The Fifth Revision of the TCEQ’s Penalty Policy Finalized

Policy Finalized

The Texas Commission on Environmental Quality (TCEQ) recently finalized their Penalty Policy which will result in higher fees and more violation events for industry. These changes were motivated by recent incidents that have caused significant public and environmental impact in Texas. The Penalty Policy is intended to cover statutorily authorized penalties under a variety of programs, including but not limited to, air quality, dam safety, water quality and use, and waste.

The effective date for the Fifth Revision of the Penalty Policy is January 28, 2021. Violations documented in investigations commencing on or after January 28, 2021 are subject to the new policy.

Background

For investigations conducted prior to January 28, 2021:

- The Fourth Revision of the Penalty Policy (effective April 1, 2014) applies to violations that occurred on or after September 1, 2011, and that are included in Enforcement Action Referrals (EARs) assigned on or after April 1, 2014.

- The Third Revision of the Penalty Policy (effective September 1, 2011) applies to violations that occurred on or after September 1, 2011, and that are included in EARs assigned before April 1, 2014.

- The Second Revision of the Penalty Policy (effective September 1, 2002) applies to violations that occurred before September 1, 2011.

Penalties are evaluated by the TCEQ using percentages of a maximum penalty. The determined percentage is multiplied by the highest penalty amount for the statute and this becomes the base penalty amount. Changes to these percentages can have a significant impact on the total base penalty for enforcement. The following sections outline the final updates and impacts of the revision to the TCEQ Penalty Policy.

UPDATES

TCEQ’s revised Penalty Policy includes increased penalties for actual releases and potential releases for major and minor sources (as defined in the Penalty Policy), increased penalties for programmatic violations, increased frequency of imposed penalties for continuous violations events, and inclusion of a penalty enhancement for emissions events that can be enforced in counties with a population of 75,000 people or more.

- For major sources experiencing actual release events, the statutory maximum penalty recommended for moderate and minor harm will increase from 30 to 50% and 15 to 30% respectively. The base penalty amount will increase due to this change.

- For minor sources experiencing actual release events, the statutory maximum penalty recommended for major, moderate, and minor harm increase from 30 to 50%, 15 to 25%, and 5 to 15%, respectively. The base penalty amount will increase due to this change.

- For programmatic major violations, the recommended statutory maximum penalty will increase from 15 to 20% for major sources and 5 to 10% for minor sources. The base penalty amount will increase due to this change.

- For continuous events that do not have a daily frequency period, frequency periods will increase by one step (i.e., single events will be tracked quarterly, quarterly events will be tracked monthly, and monthly events will be tracked weekly). The smaller evaluation time period will likely result in a higher total penalty for continuous events.

- For sites which have violation events in counties with a population of 75,000 or more, a penalty enhancement of up to 20% can be enforced.

In addition to the updates listed above, the revised Penalty Policy affects dry cleaners, aggregate production operations, and underground petroleum storage tanks.

- For dry cleaners that are not registered, a penalty up to $50 per day will be issued for every day after the 30thday registration fees are due. The same penalty applies to late dry cleaner registration applications for every day after the 30th day the application must be submitted.

- For aggregate production operations that operate without registration, the yearly penalty will increase from $10,000 per year to $20,000 per year. The maximum total penalty will increase from $25,000 to $40,000.

- For facilities that have underground petroleum storage tanks on site, major source designation will increase from 50,000 gallons per month to 100,000 gallons per month.

Contact information, a link to the final TCEQ Penalty Policy document, and more information can be found on the TCEQ’s website here. If you have any questions about the revised TCEQ Penalty Policy, reach out to Houston Project Manager, Meghan Skemp at mskemp@all4inc.com or 281.937.7553 x307.

Are You in Compliance? Top 5 Overlooked Environmental Requirements for Data Centers

Your company spent millions building the next generation data center. Money was spent to acquire land, establish infrastructure, construct the building, and purchase and install high-tech cloud, cooling, and critical back-up power supply equipment. On the environmental side, stormwater permits/plans were obtained, your air permit is in hand and you’re logging generator run times, and you know about the annual hazardous materials reporting due March 1. The site is now operating but are there gaps in your environmental compliance program? Do you know what you may not know?

- Refrigerants and the Clean Air Act. Thousands of server racks and large uninterruptible power supplies (UPS) operating 24/7 need to be kept cool or they run the risk of overheating and your reliability takes a nosedive. Chillers and air handlers with evaporator coils are often found in data centers to cool such equipment. These closed-loop systems contain and cycle a refrigerant that is likely regulated under the Clean Air Act and may have a high global warming potential. Inspections, maintenance, leak tracking, and use of certified technicians and equipment are some of the requirements for facilities using cooling units, particularly those with greater than 50 pounds of refrigerant.

What to do: If your cooling system maintenance is not done in-house, ensure your contractor is well versed in 40 CFR 82 Subpart F, performs leak tests and verifications, tracks leak rate calculations, maintains excellent maintenance and equipment inventory records for your sites, and can show proof of technician and equipment certifications. If your team handles refrigerant internally, all of this applies and more. Note the recent revisions to the rule and further, more stringent revisions under the new administration. Developing a Refrigerant Management Plan is a great solution and should be a best management practice, otherwise you may be dealing with a violation of the Clean Air Act.

- Wastewater, FIFRA Approved Chemicals, and Pretreatment Standards. Water-cooling systems are often injected with chemicals (e.g., Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) approved biocides/fungicides to prevent growth of bacteria, and/or other chemicals for corrosion control) that may adversely impact the municipal treatment plant or publicly owned treatment works (POTW) to which the water-cooling system blowdown is discharged. Under the National Pollution Discharge Elimination System (NPDES), POTW’s must remain in compliance with their water discharge limits. If water received from industrial users, such as data centers, contains chemicals that will compromise the POTW process or water quality, the industrial user can be held accountable. Depending on your jurisdiction, there may be notification requirements prior to discharging chemically-treated water to the POTW. There may also be a requirement to ensure your water treatment chemicals are pre-approved prior to use.

What to do: Contact your local water authority to learn the specifics of your jurisdiction and what chemicals you can and cannot use in your system before they contact your facility to ask questions.

Bonus tip: If your water-cooling system discharges to stormwater drains instead of sanitary drains, ensure you have the proper NPDES permits (or your state’s equivalent) if applicable. Notifications, sampling, reporting, and more may be required depending upon your location, discharge flow rate and contents, and chemical use.

- Spill Prevention, Control, and Countermeasure (SPCC). If your data center stores at least 1,320 gallons of oil products aboveground, is your SPCC plan in place prior to starting operations? Are spill response materials in place? Are monthly inspections occurring, documented, and signed? Have you increased oil storage capacity by more than 55 gallons since the original SPCC plan was developed? (Think data center expansions, oil drum storage, or transformer replacements.) If so, you have 180 days from the time the additional material arrived to revise your plan and each time thereafter. Tick Tock…

What to do: Keep abreast of equipment and product deliveries which could trigger the SPCC revision timeline, particularly in the data center environment where processes can change very rapidly. And don’t forget that annual training requirement and associated records!

- Speaking of petroleum products and hazardous materials… Aside from the required Emergency Planning and Community Right-to-know Act (EPCRA) notifications to the various agencies and the annual reporting mentioned earlier, do your local jurisdictions have additional hazardous material storage requirements? These can include above ground tank registrations, initial or annual regulatory inspections, and/or permit requirements.

What to do: Localities differ in what they require, so check with the local fire marshal’s office or other emergency planning entity to ensure you have not missed these important requirements.

- Lithium Ion (Li-ion) Batteries storage and disposal considerations. Battery storage has both safety and environmental considerations. As Li-ion batteries begin overtaking their competitor, lead acid batteries (LABs), in data center UPS systems, data centers need to be ready when the batteries’ lifespans cease. Fortunately, these batteries can be recycled, but not without risk. There are a number of inherent issues with Li-ion batteries that must be understood when considering their end-of-life journey. While their lifespan is longer than LABs, the chemistry of Li-ion batteries varies and plays an important role in how they should be handled.

Lithium is highly reactive and difficult to control. Influences such as high temperatures, using a higher than recommended charging voltage, a short circuit, or even excess strain on the battery can cause an exothermic reaction. If a Li-ion battery is crushed or punctured, a thermal event can result. The larger the battery, the stronger the thermal reaction and the higher the likelihood of igniting adjacent flammable materials, creating a safety and environmental nightmare.

What to do: From a safety perspective, ensure Li-ion batteries are not exposed to high temperature or prolonged sunlight. Only allow trained personnel to remove them from hardware, ensuring they are not damaged in the process. Handle and package them carefully so casings are not damaged, cores do not come into direct contact with each other, and make sure batteries are professionally discharged before sending out for recycling. Never mix damaged and undamaged batteries. Do not store discarded Li-ion batteries inside of a building since there is a high risk of short-circuiting and catching fire. When sending batteries off-site, always use permitted treatment facilities, which have specialized tools, processes, and controls for dismantling the batteries. To comply with environment requirements, ensure Li-ion batteries are included in the EPCRA hazardous materials planning and reporting and do not discard them in an unauthorized manner.

Was there something on this list new to you? Do you need a gap analysis performed on your compliance program and associated permits and plans? Are you expanding soon and need support? Do you want to hear more on environmental, health, and safety considerations for data centers? Please contact us if you have questions, feedback, or need help with a project.

Status of the National Ambient Air Quality Standards (NAAQS)

The U.S. Environmental Protection Agency (EPA) was hard at work at the end of 2020, finalizing several regulatory actions related to the NAAQS. The Clean Air Act (CAA) requires U.S. EPA to review, and revise if necessary, the NAAQS on a five-year schedule. There are many steps in the review process and it rarely takes just five years (although former U.S. EPA Administrator Scott Pruitt issued a memo in 2018 in an attempt to streamline the process and keep on schedule). Recent NAAQS activity and what actions might be coming next are summarized below.

Sulfur Dioxide (SO2)

U.S. EPA set a 1-hour SO2 standard in 2010. Although NAAQS designations typically occur in two to three years, the fourth and final round of designations for the 1-hour SO2 standard was just completed on December 21, 2020. These most recent designations were based primarily on three years (2017-2019) of ambient monitoring data from new monitors that were sited next to large SO2-emitting sources that were covered by the SO2 Data Requirements Rule (DRR) and chose to monitor instead of submit an air dispersion modeling demonstration. However, in the case of Beaverdam Township in western North Carolina, the attainment designation was a result of recent significant SO2 emissions reductions by the local pulp and paper mill and their work with the NC Division of Air Quality and U. S. EPA to establish a source-specific State Implementation Plan (SIP) that memorialized those emissions reductions and established federally enforceable emissions limits. Air dispersion modeling of the mill’s emissions limits and the most recent monitoring data combined to demonstrate that Beaverdam Township is in attainment with the 1-hour SO2 NAAQS. Additionally, with the long delay in the designation process, some areas that were designated nonattainment in the initial rounds based on monitoring are up for reclassification to maintenance as the ambient SO2 concentrations in those areas fell due to emissions reductions or site closures. In other nonattainment areas, SIPs are in place to bring those areas into compliance.

With the December action, all areas in the U.S. have been designated either nonattainment or attainment/unclassifiable with respect to the 1-hour SO2 standard. We note, however, that this final action has not yet been published in the Federal Register, as the new administration is reviewing the actions taken by the outgoing administration that have not yet been published. As of January 31st, 2021, there are 26 areas designated nonattainment for the 1-hour SO2 NAAQS, with a further 15 areas in maintenance having come out of nonattainment. U.S. EPA published a decision to retain the 2010 standard in March 2019, so we shouldn’t see much action related to whether they are retaining or revising the 1-hour SO2 NAAQS for a couple of years.

Ozone

U.S. EPA last revised the ozone standard in October 2015, lowering the 8-hour standard previously finalized in 2008 from 75 to 70 parts per billion (ppb). At present, there are 50 areas designated nonattainment for the 2015 ozone NAAQS, many of which are large and cover multiple counties. The most recent review of the ozone NAAQS was completed in late 2020, and U.S. EPA published its decision to retain the current standards without revision on December 31, 2020, with an effective date of the same day. The decision not to lower the ozone standard has already resulted in petitions for review from public health and environmental groups, who believe that the current standards are not low enough. We should see some activity soon that will signal whether the current administration will review the December rule.

Fine Particulate Matter

U.S. EPA recently concluded its review of the NAAQS for particulate matter less than 2.5 microns in diameter (PM2.5). This review included a call for information, a 2016 integrated review plan, a 2018 integrated science assessment, and a 2019 policy assessment. The draft policy assessment stated that depending on the weight put on various studies, a lower PM2.5 standard could be supported. However, the current CAA Scientific Advisory Committee (CASAC) members recommended retaining the current PM2.5 standards after reviewing the information prepared during the review. U.S. EPA determined that the current PM2.5 (and PM10) NAAQS were adequate and finalized a rulemaking in December 2020 to retain the current standards without revision.

The decision was viewed as fairly controversial and U.S. EPA has been petitioned to review this rulemaking. The current administration could either grant the petition, review the last administration’s work, and determine if a different outcome is warranted, or they could deny the petition and instead perform a new review, develop their own record, and come to their own conclusions based on a fresh analysis during the next 5-year period. Measurement of PM2.5 emissions can be challenging for certain sources, but if the PM2.5 NAAQS is lowered, facilities will likely need to gather better data to refine emissions estimates and air quality modeling approaches. Additional ambient monitoring could also be required. A lower standard could reduce the “headroom” between background and the annual PM2.5 NAAQS by half or more and leave very little margin for new emissions as many parts of the country are already very close to the annual PM2.5 standard.

What’s Next for NAAQS?

As the Biden administration begins to pursue its environmental agenda, the most likely activity around the NAAQS is the potential reconsideration of the decisions to keep the ozone and PM2.5 standards at their current levels. The SO2 NAAQS is no longer as hot a topic as it was with the completion of the SO2 DRR designations and because many of the sources targeted by the rule have shut down or repowered from coal to natural gas or other fuels with much lower sulfur content. The PM10 NAAQS was last reviewed in 2012, when the annual standard was vacated, and while it is technically due to be reviewed again, the more stringent PM2.5 NAAQS now seems to be the focus. The nitrogen dioxide (NO2) NAAQS were reviewed and kept at their current levels in 2018, so the next review should be completed in this administration. For a time, there was talk that the carbon monoxide (CO) NAAQS might be eliminated entirely. But for now, the current CO NAAQS remain intact, though they are well overdue for another review, having last been formally reviewed in 2011 and eventually upheld in lawsuits in 2014. It remains to be seen whether greenhouse gas regulatory efforts could result in a carbon dioxide (CO2) NAAQS.

While other pollutants have occasionally been discussed for potential elevation to criteria pollutants to be covered by a NAAQS, no additions seem to be on the immediate horizon. For now, we’ll have to keep an eye on developments with the ozone and PM2.5 NAAQS, and the growing attention being paid to non-criteria pollutants at the state and federal levels. Please contact Amy Marshall or Rich Hamel for more information.

State-Specific Considerations for SPCC Plans

Series Introduction

This blog series will address frequently missed or misunderstood state-specific requirements for petroleum containing aboveground storage tanks (AST) with respect to Spill Prevention, Control, and Countermeasure (SPCC) compliance under 40 CFR Part 112.7(j). 40 CFR Part 112.7(j) requires facilities “…include in your [SPCC] Plan a complete discussion of conformance with the applicable requirements and other effective discharge prevention and containment procedures listed in this part or any applicable more stringent State rules, regulations, and guidelines.” in addition to the requirements found at 40 CFR Part 112.

Although the U.S. Environmental Protection Agency (U.S. EPA) regulates discharges of oil from containers under the SPCC regulations found at 40 CFR Part 112, the actual AST requirements are often implemented at the state level, as a result of state environmental and fire code regulations. State-based requirements can vary from simply needing to install an additional form of overfill prevention on a tank all the way to submitting a comprehensive application with a state agency or developing a separate contingency plan that must be maintained in conjunction with an SPCC plan. These are the kinds of state-specific requirements that must be addressed in your SPCC plan as the requirements pertain to SPCC regulated containers and equipment and will be discussed in this blog series.

States that have already been identified for inclusion in this blog series based on state-specific regulations are presented in the table below. This table will continue to be updated with additional states and blog links, so continue to check back periodically as states continue to be added.

| State | Regulation | Related Blog |

| DE | Aboveground Storage Tanks (Title 7 Del.C. §1352) | State-specific Considerations for SPCC Plans in Delaware |

| FL | Aboveground Storage Tank Systems (Chapter 62-762, F.A.C.) | State-specific Considerations for SPCC Plans in Florida |

| MD | Oil Pollution and Tank Management (COMAR 26.10) | State-specific Considerations for SPCC Plans in Maryland |

| NJ | Discharges of Petroleum and Other Hazardous Substances Rules (N.J.A.C. 7:1E) | State-specific Considerations for SPCC Plans – NY and NJ |

| NY | Petroleum Bulk Storage and Major Oil Storage Facilities (6 NYCRR Parts 610, 611, and 613) | State-specific Considerations for SPCC Plans – NY and NJ |

| NC | Aboveground Storage Tanks | State-Specific Considerations for SPCC Plans in North Carolina and South Carolina |

| PA | Administration of the Storage Tank and Spill Prevention Program (25 Pa. Code Chapter 245) | State-specific Considerations for SPCC Plans in Pennsylvania |

| SC | Aboveground Storage Tanks | State-Specific Considerations for SPCC Plans in North Carolina and South Carolina |

| VA | Facility and Aboveground Storage Tank Regulation (9 VAC 25-91) | State-specific Considerations for SPCC Plans in Virginia |

If you have any questions on the impacts of state-specific AST regulations on your facility’s spill planning efforts, please feel free to reach out to Sahil Bharucha at sbharucha@all4inc.com or 571-392-2592 x505.

U.S. EPA’s Interim Guidance on the Destruction and Disposal of PFAS

On December 18, 2020, U.S. Environmental Protection Agency (U.S. EPA) issued interim guidance for public comment on the destruction and disposal of per and polyfluoroalkyl substances (PFAS) and PFAS-containing materials. This guidance document is in response to the National Defense Authorization Act (NDAA) for Fiscal Year (FY) 2020, which directed U.S. EPA to publish interim guidance no later than one year from the date of enactment of the FY2020 NDAA (i.e., no later than December 19, 2020). The guidance includes destruction and disposal technologies from both existing, publicly available information as well as research and development that is currently in progress. You can read the full interim guidance document here, but an overview is below.

Chemicals/Materials Covered:

The guidance specifically addresses six PFAS-containing materials as specified in the FY2020 NDAA. However, U.S. EPA notes that “…the information included in this guidance would probably be suitable for other types of PFAS and PFAS-containing materials…” The six materials are:

- Aqueous film-forming foam (AFFF)

- Soil and biosolids

- Textiles, other than consumer goods, treated with PFAS

- Spent filters, membranes, resins, granular activated carbon (GAC), and other waste from water treatment

- Landfill leachate containing PFAS

- Soil, liquid, or gas waste streams containing PFAS from facilities manufacturing or using PFAS

Technologies Covered:

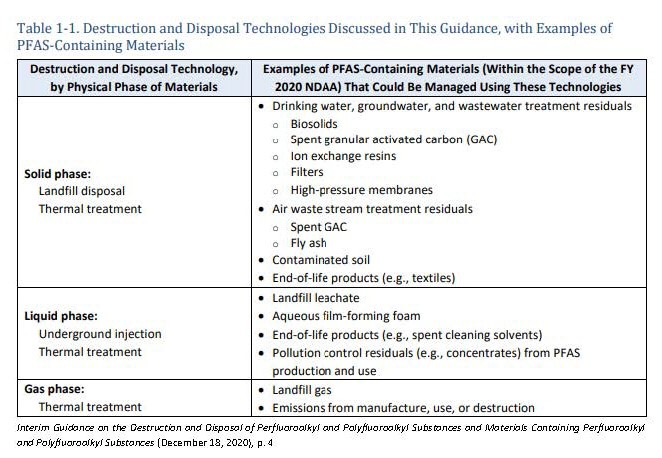

Disposal and destruction technologies are summarized in the guidance document according to the physical state of the PFAS-containing material. As expected, the only currently viable destruction method that is discussed is thermal treatment (i.e., hazardous waste combustors, carbon reactivation units, sewage sludge incinerators, municipal waste combustors, and thermal oxidizers). However, landfilling and underground injection are both listed as viable disposal methods. In addition, note that thermal treatment is stated to have “higher levels of uncertainties regarding their capacity to manage the migration of PFAS into the environment” compared to landfilling and underground injections. This, in part, is due to the potential formation and spread of new PFAS during thermal treatment as a result of incomplete destruction or recombination of reactive intermediates. Table 1-1 from the interim guidance document (below) provides a summary of the identified available technologies.

In order for a disposal or destruction technology to be included in this list, it had to meet U.S. EPA’s intended scope. This means the technology either has the potential to destroy PFAS (i.e., break the carbon–fluorine bonds) or is capable of controlling migration of PFAS in the environment. For this reason, other potential options, such as the land application of biosolids, were not included.

Additional Notes:

There is a lot of very informative, highly-technical information in the guidance document. However, below are a few key items of clarification I believe are worth noting.

- Data is very limited and there is much more we need to learn. As mentioned above, this guidance document was released due to the FY2020 NDAA deadline. In fact, the Federal Register publication notice states “The guidance provides information on technologies that may be feasible and appropriate for the destruction or disposal of PFAS and PFAS-containing materials. It also identifies needed and ongoing research and development activities related to destruction and disposal technologies, which may inform future guidance.” Emphasis added in bold text.

- This guidance does not represent an enforceable rule or policy.

- The guidance does not establish a PFAS concentration threshold that would trigger the need for “destruction” or “disposal”.

- Interim storage (approximately two to five years) is noted as a potential option while research continues on some of the more “uncertain” technologies. This is an option if immediate destruction or disposal is not critical.

- The guidance document also addresses the concept of Environmental Justice and the need to evaluate potentially vulnerable populations living near PFAS destruction or disposal sites.

U.S. EPA is accepting public comment on this guidance until February 22, 2021 and we are expecting U.S. EPA to receive many comments on this controversial topic. Please contact me with any comments or questions at kturney@all4inc.com or (610) 422-1143.

Texas: Suspension of Certain 30 TAC Provisions and Power Emergency Procedure

With the severe winter weather in Texas coupled with the power emergency the state is facing, the Texas Commission on Environmental Quality (TCEQ) has taken action to suspend certain provisions of 30 Texas Administrative Code (TAC). On February 13, 2021, TCEQ made the request and received governor approval. A second request was made on February 15, 2021.

Essentially, TCEQ requested written approval for the suspension of certain 30 TAC rules because they may prevent, hinder, or delay necessary actions needed to respond to the severe winter weather event. TCEQ states that such suspension is requested only to the extent the rules actually do prevent, hinder, or delay necessary action in coping with this disaster. Any suspension is limited to the duration of the disaster and is restricted to the applicable counties. TCEQ cautions that all regulated entities should take all available actions necessary to ensure compliance with environmental regulations and permit requirements and they must prepare and maintain records related to the actions and suspended rules, as they have the burden of demonstrating that noncompliance was necessary. The delay of report submittals is to be minimized and resume as soon as feasible. TCEQ notes that some of these rules may have federal counterparts in statute or regulation and this suspension would not apply to such federal counterparts.

Various subparts of the following 30 TAC Chapters are covered by the suspension:

- 101 – General Air Quality Rules

- 106 – Permits by Rule

- 111 – Control of Air Pollution from Visible Emissions and Particulate Matter (PM)

- 114 – Control of Air Pollution from Motor Vehicles

- 115 – Control of Air Pollution from Volatile Organic Compounds (VOC)

- 117 – Control of Air Pollution from Nitrogen Compounds

- 285 – On-Site Sewage Facilities

- 305 – Consolidated Permits

- 309 – Domestic Wastewater Effluent Limitation and Plant Siting

- 312 – Sludge Use, Disposal, and Transportation

- 319 – General Regulations Incorporated into Permits

- 321 – Control of Certain Activities by Rule

- 327 – Spill Prevention and Control

- 330 – Municipal Solid Waste

- 334 – Underground and Aboveground Storage Tanks (and Tex. Water Code § 26.351(b))

- 335 – Industrial Solid Waste and Municipal Hazardous Waste

The TCEQ Second Suspension Request specifies the applicable subchapters as well as the Impediment to Disaster Response. Specifics of the initial request, approvals and governor’s disaster proclamation can be found at the links below, and we suggest you check TCEQ’s website for any additional updates after publication:

- TCEQ Suspension Request (02-13-2021)

- Approval of the Second Request by the Governor’s Office

- Approval of the Request by the Governor’s Office

- Governor Abbott’s Severe Winter Weather Disaster Proclamation

So how might these temporary suspensions benefit a facility? For a facility subject to 30 TAC 117, Subchapter B, Combustion Control at Major Industrial, Commercial, and Institutional Sources in Ozone Nonattainment Areas, there may be challenges with the various control, monitoring, and testing requirements. Facility personnel may not be able to get to the site to be able to perform the monitoring or testing for example. TCEQ recognizes that the control, monitoring, testing, and other requirements at major sources of nitrogen oxides in the Beaumont Port Arthur (BPA), Houston Galveston Brazoria (HGB), and Dallas Fort Worth (DFW) ozone nonattainment areas may not be possible during a disaster. This is just one of many potential situations that could occur.

Additionally, on February 10, 2021, the Procedure for Requesting TCEQ Enforcement Discretion Relating to a Power Emergency in Texas for Electric Reliability Council of Texas, Inc. (ERCOT), Midcontinent Independent System Operator, Inc. (MISO), or Southwest Power Pool, Inc. (SPP) (aka Entity) was updated. When one of these Entities determines that it is, or likely will be, unable to reliably meet its system electric demand and reserve requirements or that a local reliability issue exists with the generation facilities that are expected to be available to serve that demand, the Entity may notify TCEQ of the Power Emergency to request that TCEQ consider exercising its enforcement discretion with respect to a potential violation under TCEQ jurisdiction.

Once TCEQ receives notification and request for enforcement discretion, they will consult with the Office of Compliance and Enforcement (OCE) to consider the request and approve if appropriate. TCEQ will communicate their response directly with the Entity and then confirm by written communication the TCEQ’s decision.

If granted, the Entity will promptly provide a written communication to its market participants notifying them of TCEQ’s determination. At the conclusion of the Power Emergency, the Entity will notify its market participants that the Entity has ended its request for TCEQ enforcement discretion. The regulated community must maintain records of operation that occurred during the Power Emergency including records required under TCEQ authorizations and rules. The regulated community must send a list of all violations for which they will seek enforcement discretion to TCEQ. TCEQ will provide this list to the appropriate TCEQ Regional Office. Refer to the procedure for more specifics and to required communications from your Entity in certain power emergency situations, as applicable.

For questions about the suspended subchapters of 30 TAC and/or the Power Emergency Procedure, please reach out to ALL4’s Houston Office Director, Kristin Gordon, kgordon@all4inc.com or 281.937.7553 x301.

New Jersey Environmental Justice and Air Quality Permitting

New Jersey’s new Environmental Justice Law (effective September 18, 2020), N.J.S.A. 13:1D-157 requires the New Jersey Department of Environmental Protection (NJDEP) to evaluate the potential impacts of certain facilities on environmental and public health stressors in overburdened communities (OBC) when reviewing permit applications.

How Are Overburdened communities Identified?

To be classified as an OBC, a community must meet one of the following criteria:

- >35% of the households qualify as low-income households (at or below twice the poverty threshold as determined by the United States Census Bureau);

- >40% of the residents identify as minority or as members of a State recognized tribal community; or

- >40% of the households have limited English proficiency (without an adult that speaks English “very well” according to the United States Census Bureau).

NJDEP published a list of the 331 municipalities in the state in which OBCs are located. If you’re not sure if your facility is located in an OBC, check out NJDEP’s interactive mapping tool.

Is My Facility Affected?

Facilities that are affected by this law include:

- major sources of air pollution (i.e., facilities with Title V permits);

- resource recovery facilities or incinerators;

- sludge processing facilities, combustors, or incinerators;

- sewage treatment plants with a capacity of >50 million gallons per day;

- transfer stations or solid waste facilities;

- recycling facilities that receive >100 tons of recyclable material per day;

- scrap metal facilities;

- landfills; or

- medical waste incinerators.

What Are The Permitting Requirements For My Facility?

If your facility falls under one of the categories listed above, there are additional requirements that must be met when preparing a permit application for a new facility, an expansion of an existing facility, or a renewal of a major source permit:

- Environmental Justice Impact Statement –

The facility is required to assess any existing environmental or public health stressors affecting the OBC along with new ones that cannot be avoided by the proposed permitting activity. The environmental justice impact statement must be provided to NJDEP as well as the governing body and the clerk of the municipality of the OBC at least 60 days before the public hearing. It will also be published on NJDEP’s website.

- Public Hearing –

A public hearing must be conducted in the OBC. NJDEP will use the testimony and written comments to evaluate potential permit conditions to avoid or reduce environmental or public health impacts to the OBC. Note: NJDEP may already provide enhanced public notification processes for some communities.

- Additional Permit Application Fee –

NJDEP plans to assess an additional Environmental Justice fee for affected permitting activities.

We anticipate Environmental Justice to continue to be a hot-button topic in New Jersey and the federal level, so expect to see more news come out during 2021.

Feel free to share and comment, or if you have any questions on how Environmental Justice could impact your projects, please contact us.

Introducing ALL4 ASSERT | Digitally Transforming Annual Emissions Reporting

What are your most valued time saving tools? I love grocery pick-up and delivery. My involvement consists of 10 minutes ordering in the mobile app. If I use the pick-up option, I drive to the store and pop my trunk. It is more than a timesaver because I avoid the impulse buys and purchase exactly what I need.

With convenience everywhere, many of us still manually enter annual emissions data into various state emissions inventory reporting systems. This data entry occurs during peak environmental reporting season when we are spending half a month, in some cases more, documenting our environmental compliance and submitting reports. Many state and local regulatory agencies offer an import option as an alternative to manual data entry and a robust IT department is not necessary to capitalize on the benefits. ALL4 ASSERT (Automated State-Specific Emissions Reporting Tool) will allow your facility to take advantage of this option without significant changes to your current annual reporting workflow. Select your state, and with one click, ALL4 ASSERT extracts data from your spreadsheet and produces files (e.g. CSV, XML, JSON) containing your emissions data that are compatible with your state’s emissions inventory reporting system. The produced files may then be imported into your state’s system, such as the State and Local Emissions Inventory System (SLEIS), supported by numerous states across the country. The import populates process and emissions data fields rendering tedious manual data entry and quality assurance a forgettable pastime.

As with grocery pick-up, ALL4 ASSERT is more than a timesaver and accomplishes the following:

- Improvement of data integrity by promoting consistency and automating numerous state-specific data checks (validations) to find errors before the data are uploaded to the state’s system.

- Promoting timely reporting and avoidance of penalties associated with late or erroneous data.

- Inherent streamlined change management because the logic is in one location. The application is modularized and state-specific allowing for quick updates on a state-by-state basis.

- Peace of mind with ALL4 maintaining the tool and providing training eliminating the security concerns that can come with a macro imbedded in a workbook and more commonly loss of institutional knowledge of imbedded macros with staff turnover.

There are two options available to take advantage of ALL4 ASSERT.

- Full-Service Emissions Inventory Preparation, Import File Generation, and Upload for Certification

- Subscription Service for Import File Generation and Upload for Certification

ALL4 will provide training with both options. ALL4 ASSERT is currently serving facilities in Arkansas and South Carolina which utilize SLEIS for annual emissions reporting. In addition to the many states which utilize SLEIS, states including but not limited to Alabama, Georgia, Pennsylvania, and Texas also offer bulk emissions upload options. ALL4 is currently adding state compatibility to ALL4 ASSERT. If you would like a demonstration or more information about our subscription service, please contact Jenny Brown at 678-293-9432 or jbrown@all4inc.com.

What’s new in CAERS?

This week is an important week for Georgia facilities as they start the registration process for annual and triennial reporting in the Combined Air Emissions Reporting System (CAERS). For more information on what important steps you need to take for your facility to be ready for reporting within CAERS, be sure to check out our first article – Getting Ready for CAERS 2.0. Facilities that were included in the CAERS 2020 pilot reporting year will notice some upgrades and new features as they begin reporting for 2021. Continue reading to learn more about the latest upgrades to CAERS!

TRI-MEweb Data Sharing

While this may not be a new feature, CAERS will include a more robust hazardous air pollutants (HAP) data sharing program from your facility’s annual emissions inventory (EI) with TRI-MEweb. While this is optional, Georgia Environmental Protection Division (GEPD) is highly recommending all facilities include HAP emissions data with their annual emissions report. Otherwise, GEPD will use HAP augmentation to estimate HAP emissions from your facility, which may not be accurate for your facility’s operations. This can be beneficial to your facility for several reasons:

- Less manual data entry across reports for faster reporting;

- Increased reporting accuracy be removing additional data entry; and

- Emissions data will receive State, Local, and Tribal (SLT) review and facilities will be allowed to correct any errors before the data is copied to your Toxic Release Inventory (TRI) report.

It is important to be aware that data will not be available to transfer to TRI-MEweb until the EI has been certified. However, certifying the EI does not also certify the TRI report and does not mean you are required to use the reported EI data in your TRI report. The TRI report will still be available for editing and will have to be reviewed and certified in TRI-MEweb. Remember, EI reports are due June 30th and TRI reports are due on July 1st, so if you would like to take advantage of the TRI data transfer feature, you will need to submit your EI early to leave plenty of time for TRI reporting!

Bulk Upload

CAERS has expanded options available for entering emissions data into the system. Facilities will be able to submit their EI in one of three ways: manual data entry into the CAERS webform, bulk data entry in the user interface (useful if your facility has submitted in CAERS before and/or if your facility has no control devices), or by using the bulk upload spreadsheet. All facilities will have access to a bulk upload template to download from their CAERS facility homepage. This template will be pre-populated with facility and emissions source information from their most recent EI submittal.

A new required feature of EI reporting will include the mapping of emissions through any control devices before exiting through the release point. For facilities reporting in CAERS for the first time, the control paths will not be pre-populated and will need to be developed in either the webform or the bulk upload spreadsheet. For returning facilities who reported as part of the pilot program and developed control paths last year, control paths will only need to be reviewed and updated as necessary.

Multiple Throughput Measurements

Alternative throughput measurements have been added to allow calculation of different pollutant emissions using emissions factors with different base units of measure for the same process. For example, this is useful for boilers that use two sets of emissions factors, one on a heat input (MMBtu) basis and another on a natural gas throughput (MMscf) basis, to calculate total emissions. Under the pilot program, only emissions factors for one of these throughput measurements could be applied and emissions under the alternate throughput measurement had to be manually entered. Under the new build of CAERS, a duplicate process can be made under that unit using the same source code with the alternate throughput measurement.

Communication

In order to streamline communication, GEPD has set up email addresses for specific questions and inquiries concerning CAERS reporting:

- For all questions concerning the EI within Georgia Environmental Connections Online (GECO) or within CAERS, please send them to Inventory@dnr.ga.gov

- For questions about the CAERS application, please send them to helpdesk@epacdx.net

- If you want to use the JSON bulk upload feature or have suggestions on how to make CAERS better, please send them to caer@epa.gov

If you have any questions concerning CAERS or would like assistance reporting in CAERS, please reach out to Stacy Arner at 678.460.0324 x213 or sarner@all4inc.com. Thanks for reading!