Why are Safety Data Sheets Important in the Workplace?

What are Safety Data Sheets? The health and safety of all employees is essential to providing the best services to clients. Reduction in chemical source illness and injuries in the workplace allow employers and employees to work safely with chemical materials. In order to maintain this standard, the Occupational Safety and Health Administration (OSHA) constructed the Hazard Communication Standard, which ensures that all employees keep their staff safe through communicating chemical information with Safety Data Sheets (SDS). In 2012, OSHA made major changes to the Hazard Communication Standard to standardize the criteria for classification of hazards and provide labels for the chemicals to be consistent and easier to understand. These changes align with the GHS (Globally Harmonized System of Classification and Labeling of Chemicals). The GHS is a living document that provides an internationally negotiated approach to labelling and formatting hazardous chemicals. The change also involved revising the name from Material Safety Data Sheet (MSDS) to SDS.

This is the first in a series of 4 The Record (4TR) articles that will provide you with how and when to use your SDS in other regulatory programs such as TRI reporting, Air Emissions Calculations, release reporting, and waste determinations to name a few.

SDS include information on the properties of chemicals and their safety measures that should be followed by the chemical manufacturer, distributor, or importer and to the consequent user. SDS are created by the manufacturer or distributor of hazardous chemicals. They include 16 sections which include listing properties, hazards, safety precautions for storing and protective measures for handling the chemical. The standardized information contained in SDSs makes it easy and effective for providing information on chemicals.

- How can I find information in the Safety Data Sheet? SDSs have 16 sections that contain information such as:

- The properties of each chemical

- The physical, health, and environmental health hazards associated with the chemical

- Protective measures

- Safety precautions for handling, storing, and transporting the chemical

Sections 1 through 8 contain general information about the chemical, identification, hazards, composition, safe handling practices, and emergency control measures (e.g., firefighting). The first aid and accidental release measures described in these sections are helpful in case of exposure to chemicals. This information should be helpful to those that need to get the information quickly. Sections 9 through 11 and 16 contain other technical and scientific information, such as physical and chemical properties, stability and reactivity information, disposal practices, toxicological information, exposure control information, and other information including the date of preparation or last revision. It should be noted that SDSs are only required for hazardous chemicals, but many customers require SDSs on all products, whether they are hazardous or not. OSHA does not require or encourage this practice; they can’t prohibit producers from distributing nonhazardous SDSs. Items that are not hazardous or are exempted are listed in the OSHA HazCom Standard 29 CFR 1910.1200.

- How does this apply to employers and their employees? The HCS requires employers to keep an updated Safety Data Sheet for every hazardous chemical used or stored in the facility, regardless of the frequency or amount of chemical used. Facilities where hazardous chemicals are handled are required by law to either retain hard copies of SDS or teach all employees how to obtain SDS electronically. Administrators can request additional copies of SDSs from chemical manufacturers at any time. Employers must ensure that the SDSs are readily accessible to employees for all hazardous chemicals in their workplace. Employees must be trained in the physical and health hazards of the chemicals in the workplace, the recommended measures to use products safely, and recommended emergency procedures for cleaning up a spill or release of chemicals.

- How do I keep up with revisions being made to SDS? The GHS is updated every biennium to improve alignment and effectiveness of SDSs. Referring to revision 7, OSHA is proposing changes to the HCS to improve the comprehensibility and utility of the standard and allow the HCS to keep up with new technologies to better protect workers’ health and safety. It is unknown when the proposed rulemaking will be voted on by Congress, but the Final Rule was originally supposed to be issued in June of 2023.

ALL4 is here to answer your questions and assist your facility with keeping up with regulatory changes. All4 offers numerous OSHA Compliance services within the environmental, health and safety consultation field. Identifying and reducing hazards in the workplace for your facility can be challenging, and All4 is able to interpret and evaluate the correct strategy to achieve regulatory compliance, reduce risk and provide a safe and healthy workplace. If you have any questions or would like to speak to one of our Health and Safety Practitioners, please contact Noel Attwood at nattwood@all4inc.com or Kevin Chaplin at kchaplin@all4inc.com.

Data Quality Part 5: An Additional Component ─ Sensitivity

We started this journey with the following thought: Defining data quality and implementing a data quality program furthers the goal that the data collected serve the intended purpose, i.e., informed decision making. In this article, we’ll explore “sensitivity.” This one seems obvious; we want a measurement that can provide meaningful data at the point in the measurement that is meaningful to us. Ok, Gene, help me out again – what? Let’s do another anecdote and an analogy.

I have a friend who, in a previous life, was a plant manager at a methamphetamine manufacturing facility. Obviously, it is very important, and of great interest to lots of folks beyond the manufacturers, that they account for all the methamphetamine, all the time. They produce their product into 20‑kilogram batches, and periodically remove a small sample (1-5 grams) to do analysis. There was some regulatory audit, and the auditors wanted to know where the small sample came from. You can see where this is going: we took 1 gram out of the 20-kilogram barrel, the barrel still weighs 20 kilograms, why doesn’t this add up. We know that this is all about measurement error; that 1 gram is undetectable with the tools that were used to measure the 20-kilogram drum. There’s kind of two ways to look at this: 1) the 1-gram sample is negligible (within the measurement error) of the 20-kilogram batch, or 2) the method used to measure 20 kilograms is not sensitive enough to answer the question (which is inventory control to the nearest gram). This story highlights sensitivity of measurement, and the question of what a number means, in terms of range, or imprecision, or whatever. We use a shortcut called “significant figures” to try to convey that information. This is a bit of a rabbit hole, and I’m not going there in detail, but let’s think about what “20 kilograms” means: Is it 20 but not 21? Is it 20.00, but not 20.01? And, as a shortcut to understanding and defining the statistical values, we use significant figures. Within the convention of “significant figures,” “20” is different from “20.00.”

Another analogy: I buy a new power tool, which requires assembly, and I drop (and lose) one of the screws required to assemble it. Hi-ho, hi-ho, I’m off to Home Depot 🎵. But let’s look at this question in a little more detail:

- Where is my replacement screw: Home Depot

- Where is Home Depot: In the shopping center at the Braker exit from MoPac

- Where is Home Depot: At the north end of the shopping center

- Where is the door to Home Depot: South facing side of the building

- Where are the screws: Aisle 17

- Where are the specialty screws: In the specialty screw drawers in Bays 8 and 10

- Where is my replacement screw: Second column from the right, third drawer down

- Where is my replacement screw: Far right side of the drawer, halfway back.

It’s kind of a silly analogy, but it demonstrates the point of having a sensitive enough measurement. And of asking the questions within the correct range (doesn’t do me any good to look for a specialty screw in the plumbing aisle).

And if you’ve made it this far, here’s are a couple cool links showing relative scales:

Let’s unpack that screw analogy a little bit. As we can see, the question: “where is the screw?” has lots of correct answers. And each of them is useful at some point (other than maybe “lost under my workbench”). Let’s see if we can relate this to an environmental measurement question: “how much chromium is in the groundwater?” This question can likewise have lots of answers. If the true value is 21.4 ppm, then the following are all true as well: <100, 20±10, 21±1, >1. If they’re all correct, how do we choose? And remember, we’re not choosing from these answers, we’re choosing a set of measurement tools and data quality objectives. So we go back to the beginning: what’s the underlying question? We need to know the intended data use and need to define the measurement approach. And then to define the quality activities overlaid on the measurements. If the question is: “Is chromium below 150 ppm?” then three of those results support the conclusion of “yes” and one doesn’t answer the question. If the question is “Is chromium below 150 ppb?”, three of those results support the conclusion of “no” and one doesn’t answer the question.

The end game for this quality component, and actually for the whole measurement system, is that the measurement needs to be sensitive enough to tell a “pass” from a “fail.” It follows that the measurement system needs to be most robust at the point of “pass/fail.” Notably, if the measurement is most robust at the point of “pass/fail” then the measurement must be less robust at values that are of no interest to “pass/fail” and the data generated away from the robust point of “pass/fail” are less certain. Said another way, properly executed measurements are valid and usable for their intended purpose and may not be usable and valid for other purposes.

Let’s talk about “data mining”. Data mining is the idea of digging through previous measurements for a new purpose. And this gets real thick, real quick. So, one last analogy. Let’s think about my lost screw. Before I go to Home Depot, I’m going to go check my handy-dandy collection of leftover screws. Maybe I find the exact thing I’m looking for (same thread, same head, same color). Maybe I find one that will work but isn’t quite right (longer, wrong color). And maybe I find one that’s actually a little bit poor (shorter, wrong head shape). And maybe I don’t find anything that works at all. When I “mined” for a screw, I didn’t have any control over what I might find; the only control I have is to understand the limitations relative to my final need.

Switching back to a measurement, presumably, any measurement in an existing data set is robust at the pass/fail point of the original investigation, and of course, less robust at any other point. If our new purpose is interested in a different level (either a different absolute value, or a different level of data quality), then the existing (mined) data is less robust (and less useful) at this new level. The uncertainty in this mined data set is necessarily greater than it would be if we had defined a measurement program (as opposed to a mining program). And it might be unacceptable (screw too short) and inappropriate (screw with wrong head or wrong color) for the purpose, the intended use, the informed decision-making that triggered the data mining exercise in the first place. Bottom line, data mining has to be done carefully, with an eye toward the original intended use, and the new data use.

Next Time: Wrapping a big bow around data quality

Until then, feel free to contact either of us:

- Gene Youngerman, gyoungerman@all4inc.com, 512.649.2571

- Aditya Shivkumar, ashivkumar@all4inc.com, 281‑201-1239

Links to other blogs from our Data Quality Series:

Operate a Commercial Sterilization Facility? 40 CFR Part 63, Subpart O Amendments Are Coming in 2024 with More Stringent Emission Limits & Advanced Continuous Monitoring Requirements

The U.S. Environmental Protection Agency (EPA) has proposed amendments to the National Emission Standards for Hazardous Air Pollutants (NESHAP) for Ethylene Oxide (EtO) Commercial Sterilization and Fumigation Operations (40 CFR Part 63, Subpart O) that if finalized, will require the 86 commercial sterilizers in the US to use more stringent pollution controls and advanced continuous source monitoring methods to confirm the effectiveness of the controls on regulated sources of EtO. The proposed NESHAP amendments are based on the US EPA’s recent risk and technology review (RTR) of this source category and aim to reduce EtO emissions from commercial sterilization facilities by up to 80% per year, thereby decreasing EtO exposure in nearby communities. U.S. EPA proposed to require all commercial sterilizers to comply within 18 months of promulgation and to demonstrate continuous compliance via annual performance tests and operating limits, or by using an EtO continuous emissions monitoring systems (CEMS).

You may be thinking, “Ok…we already demonstrate compliance with Subpart O through an initial performance test and continuous parametric monitoring anyway, what’s really going to change for us?”

Simply, a lot. With these amendments, U.S. EPA is telling the regulated community that they do not believe the current monitoring approach is sufficient to ensure continuous compliance with the new emissions limits. The major changes were summarized in this ALL4 article.

To meet the proposed new and revised emissions limits, facilities will need to install new or add-on controls to several types of air emission sources. To demonstrate compliance, EPA is proposing that facilities either use an EtO CEMS, or conduct initial and annual performance tests in conjunction with continuous parameter monitoring. The performance testing methods and procedures, as well as the CEMS performance specifications and procedures for ongoing quality assurance/quality control (QA/QC) are proposed to be significantly revised.

Revisions to the EtO CEMS performance specifications and QA/QC procedures include:

- Removal of 40 CFR Part 60, Appendix B, Performance Specification (PS) 8 as an option for continuous monitoring on the basis being that it is not selective for EtO.

- Proposed PS-19 in 40 CFR Part 60, Appendix B for EtO CEMS installation and initial certification requirements that addresses sampling and analytical technologies for more recent EtO measurement technologies, i.e. or specifically FTIR and Cavity Ringdown Spectroscopy.

- Removal of 40 CFR Part 60, Appendix B, PS-9 on the basis that the underlying technology (i.e., gas chromatograph) fits within the proposed structure of PS-19.

- Proposed QA Procedure 7 in 40 CFR Part 60, Appendix F that establishes procedures for assessing EtO CEMS data quality on an ongoing basis. Updates include the requirement to develop a written QA/QC plan that details step-by-step procedures and operations for each of the following activities:

- Daily calibration drift (CD) checks

- Quarterly cylinder gas audit (CGA) or Dynamic Spiking Audit (DSA)

- Annual relative accuracy test audit (RATA)

- Systems must achieve a minimum sampling frequency of once every 15 minutes for consistency with the General Provisions of 40 CFR Part 63, Subpart A, as opposed to once per hour as currently specified in 63.364(e) of Subpart O. Note that time shared monitoring across different measurement points is acceptable provided the time-sharing criteria for EtO CEMS in amended Subpart O are met.

- Compliance based on a 30-day rolling average determined from the sum of that day’s average and the previous 29 daily averages, divided by 30.

Revisions to the performance testing methods and procedures include:

- Removal of EPA Test Methods 2D, 18, 25A and California EPA Air Resources Board (CARB) Method 431, as more robust measurement technology will be needed to measure much lower EtO concentration levels required by the amendments.

- Addition of EPA Test Methods 1 and 320 for determining the location of sample ports and for Fourier Transform Infrared Spectroscopy (FTIR), respectively.

- Update performance test requirements to determine control efficiency for sterilization chamber vents (SCV) to complete the test under normal, representative conditions that align with Clean Air Act (CAA) National Stack Testing Guidance issued in 2009. Rather than completing the test on a chamber with no product, the testing will need to be conducted during normal sterilizer chamber conditions.

- For all emission source types, SCV, chamber exhaust vents (CEV), aeration room vents (ARV) and room air for facilities where EtO use is at least 10 tpy, 24-hour test runs are required. For facilities where EtO use is less than 10 tpy, 1-hour test runs are required.

- Updates to how the operating limits are established and minimum requirements for the instrumentation used for monitoring.

When we say a lot is changing for those of you applicable to the commercial sterilization NESHAP, we really do mean it. The proposed amendments to Subpart O could cause your facility to purchase new controls to achieve the proposed emissions limits, update your ongoing compliance demonstration procedures (i.e., performance testing or CEMS program), or just cause you to get familiar with CEDRI for periodic reporting purposes. By this point, you’re probably wondering when this is going to happen. The comment period on the proposed rule ended on June 27, 2023 and EPA has a consent decree deadline to issue a final rule by March 29, 2024. If the proposed timeline is finalized, facilities will be required to comply with these new requirements within 18 months of promulgation. ALL4 is tracking regulatory developments related to EtO and will summarize the requirements of the final rule when it is promulgated.

For any questions on the proposed amendments or how they will affect your facility, or for assistance updating your testing and monitoring programs, do not hesitate to reach out to Matt Carideo at mcarideo@all4inc.com or 610-422-1139.

Life Cycle Assessment

Life Cycle Assessment (LCA) is a powerful tool used to assess the environmental impact of a product, process, or service throughout its entire life cycle. It considers the environmental impact of various stages of the product’s life, including raw material extraction, production, use, and end of life. LCA is not just limited to carbon emissions; it includes environmental impacts in eutrophication, land use, resource depletion, human toxicity, ozone depletion, and more.

What is a Life Cycle Assessment?

LCA is a systematic evaluation of the environmental impacts associated with a product or activity throughout its life cycle. It considers the entire value chain, from the extraction of raw materials, through production, distribution, use, and disposal or recycling. Performing an LCA allows a company to quantify the environmental impacts of a product or process which can help companies improve their environmental footprint.

What are the main goals of conducting a Life Cycle Assessment?

The primary goals of conducting an LCA are to quantify and understand the environmental impacts of a product or a process, identify potential areas of improvement in the life cycle stages where environmental risks, impacts, externalities, and resource dependencies are significant, and guide customer and company decision-making related to selection of more sustainable alternatives.

What are the benefits of conducting a Life Cycle Assessment?

An LCA exercise can reveal insights into the viability, risk, and/or impacts of your products or processes. LCAs can help companies identify points of large environmental impact, enabling the development of more sustainable products and processes. Understanding the life cycle impacts of a product can help companies differentiate themselves in the marketplace and respond to growing consumer demand for sustainable products, giving them a competitive edge. More and more companies are holding themselves to sustainable procurement standards (e.g., Walmart), and in turn require their suppliers to have certain sustainability metrics. LCA creates transparency and enables engagement with stakeholders, fostering dialogue on environmental impacts and sustainability. Finally, LCA can help inform policy and decision making as it provides objective data that can guide decision-makers in choosing more environmentally friendly options and implementing more environmentally friendly regulations. LCA can also identify dependencies on limited or unreliable resources or point out inefficiencies and productivity opportunities.

How can Life Cycle Assessment add value to a business?

LCA is a decision-making tool, and an LCA exercise elucidates quantifiable benefits and actionable information along a product’s life cycle. Stakeholders can utilize comparative LCA to compare the footprints of different products and/or systems. Reducing a product’s environmental impact can increase process efficiencies and in turn decrease financial costs. These comparisons can help identify not only the more environmentally sustainable product life cycle, but also optimize financial outcomes and increase sales and brand loyalty. For example, Unilever found in a case study that a third of consumers are opting to buy from brands that they believe are doing environmental good. The same study uncovered that approximately one in five people would actively choose brands that make their sustainability credentials clearer on their packaging and in their marketing.

What are the limitations or challenges associated with Life Cycle Assessment?

There are limitations to LCA that can make it challenging to qualify and validate results. There is inherent uncertainty associated with LCA which stems from data availability and quality. Gathering accurate and comprehensive data on all environmental impacts for all life cycle stages can be challenging, particularly when considering complex global supply chains. There are many LCA databases from third parties available from different industries and areas around the world. The most detailed LCA databases are based on European supply chains which do not provide precise results for supply chains for products or processes based in the United States. Another source of variation in results comes from system boundaries. Defining the boundaries of the LCA can be subjective and may lead to different interpretations and results. It is important to assess the system boundaries when comparing different LCAs. Another source of uncertainty is associated with the impact assessment methods used to calculate the values. There is an associated uncertainty with all impact assessment methods, and it is important to pick the correct impact assessment method for the type of LCA being conducted. LCAs are very dynamic in nature and are influenced by shifting markets conditions, technological advancements, and changes in energy sources, so it is important to update LCAs over time.

Conclusions

Life Cycle Assessment is a valuable tool for assessing and improving the environmental performance of products and activities. By considering the entire life cycle, LCA enables a comprehensive understanding of environmental impacts and provides insights for sustainable decision-making. LCA continues to play a vital role in guiding businesses, policymakers, and consumers towards a product with minimal impacts and an environmentally friendly brand image. If you want to find out more about conducting an LCA, contact Louise at lshaffer@all4inc.com or your ALL4 PM.

U.S. EPA Proposes Benzene Fenceline Monitoring for Coke Oven Facilities

The U.S. Environmental Protection Agency (EPA) has proposed amendments to the National Emissions Standards for Hazardous Air Pollutants (NESHAP) for Coke Ovens: Pushing, Quenching, and Battery Stacks (PQBS) and Coke Oven Batteries (COB) at 40 CFR Part 63, Subparts CCCCC and L. These proposed revisions are a result of their Clean Air Act (CAA) mandated risk and technology review (RTR) for PQBS and their technology review for COB and address previously unregulated hazardous air pollutants (HAPs) and HAP emissions sources. As part of the proposed amendments, the U.S. EPA will require all Coke Oven Facilities to measure fugitive benzene emissions at the fenceline (where fenceline is equivalent to the perimeter) of their facility using passive samplers.

According to U.S. EPA, benzene is ever-present at coke oven facilities, accounts for about 70 percent of emissions of all volatile compounds and is a surrogate for organic HAPs from fugitive sources at these facilities. U.S. EPA proposes to require a minimum number of passive samplers collecting two-week time-integrated samples continuously, following EPA Method 325. These samples would be analyzed for benzene, background corrected for each sampling event, assessed against an annual action level, with results reported to U.S. EPA on a quarterly basis and made available to the public.

Passive Sampling

Passive sampling involves using small inert-coated metal tubes filled with an adsorbent and special cap that allows ambient air to diffuse onto the sorbent at a fixed rate, thereby retaining the compound of interest. Following a two-week sampling period, the tubes are collected and sent to a laboratory for analysis, with new tubes installed to maintain continuous sampling.

A minimum of 12 samplers are proposed, with deployment no later than one year after the effective date of the final rule for existing facilities, or by the effective date of the final rule or start up (whichever is later) for new facilities.

U.S. EPA estimates costs for fenceline monitoring to be $116,000 per year; however, these costs do not include effort associated with development of a monitoring plan, data assessment, quarterly reporting, or other quality assurance activities.

Benzene Concentration Action Level

U.S. EPA is proposing an action level of 3 micrograms per cubic meter (µg/m3) benzene based on modeled fenceline concentrations from emissions inventories associated with data for 2016 and 2022 facility-wide risk assessments. This proposed action level is intended to reflect fugitive emissions sources only and exclude background concentrations. A facility would exceed this action level when the highest of the rolling annual average fenceline concentrations (corrected for background) is greater than 3 µg/m3.

To account for background, U.S. EPA proposes that each facility would determine a delta concentration (Δc), calculated as the lowest benzene sample value subtracted from the highest benzene sample value for each two-week period. This approach is intended to subtract out any estimated contribution from background emissions that do not originate from the facility.

If the rolling annual average exceeds the concentration action level, within five days of calculating the rolling annual average, the coke oven facility must initiate a root cause analysis to determine the primary and contributing causes of the exceedance. This root cause analysis must be completed within 45 days of initiation, followed by the corrective action plan to reduce emissions. The coke oven facility would not be deemed out of compliance with the proposed concentration action level if appropriate corrective action measures are taken.

Data Reporting

To report and submit results, coke oven facilities will be required to calculate a rolling annual average within 30 days of completion of each sampling episode and report the data for each sampler within 45 days of the end of each quarterly period through U.S. EPA’s public electronic reporting and data retrieval portal. This submittal will include the individual sample results from each sampler, coordinates of all sampler locations, biweekly 12-month rolling average concentration values, and notes for each value (e.g., background corrections used, if the value was under detection, or an outlier that was removed from the data set).

What Does This Mean for my Facility?

Following collection of a year’s worth of data to generate the rolling annual average, facilities would need to demonstrate compliance with the action level within three years of the effective date of the final revised NESHAP. (We note that U.S. EPA is also proposing new standards for several unregulated HAPs and sources of HAPs at coke oven facilities that will require additional monitoring, testing, recordkeeping, and reporting.)

How can ALL4 help?

As your facility begins to plan for implementation of benzene fenceline monitoring, don’t hesitate to ask for assistance. ALL4 would be glad to discuss any of the following:

- Developing an air monitoring plan.

- Installation and placement of passive samplers to meet the proposed rule.

- Collecting, processing, and submitting samples.

- Training for facility personnel.

- Creation of spreadsheet-like tools to record bi-weekly data and calculate annual rolling averages.

- Analyzing raw data to subtract out background concentrations as appropriate.

- Installation and maintaining meteorological equipment for on-site ambient meteorological data (not currently part of the rule but will help with background concentration calculations).

- Conducting quality assurance audits to verify the collection of representative samples.

- Preparing electronic reports for U.S. EPA.

- Preparing root-cause analysis and corrective action plans to submit to U.S. EPA if the facility exceeds concentration action level.

We can also help with strategy around implementation of the other requirements U.S. EPA is proposing to add to the NESHAP. For more information on Benzene Fenceline Monitoring please contact Kyle Hunt at khunt@all4inc.com or 512.705.0123.

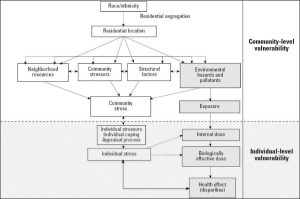

U.S. EPA releases Draft Cumulative Risk Assessment Guidelines for Planning and Problem Formulation

On June 16, 2023, the United States Environmental Protection Agency (U.S. EPA) released a draft document “Cumulative Risk Assessment (CRA) Guidelines for Planning and Problem Formation” that describes the steps for the planning of CRAs and offers guidance for when cumulative risk assessments could be useful. The CRA guidance is responsive to the charge given by Executive Order 13985 on Advancing Racial Equity and Support of Underserved Communities Through the Federal Government, which directed all agencies of the federal government to “pursue a comprehensive approach to advancing equity for all, including people of color and others who have been historically underserved, marginalized and adversely affected by persistent poverty and inequality.”

How Does a Cumulative Risk Assessment Differ from a Traditional Risk Assessment?

A traditional risk assessment has five steps:

- Planning

- Hazard Identification

- Dose-Response Analysis

- Exposure Assessment

- Risk Characterization

A traditional risk assessment usually focuses on the cleanup of a single contaminated site, or the evaluation of the impact of an individual chemical. For many years traditional risk assessment has been criticized because its narrow focus does not allow it to accurately capture the risks associated with exposure in situations where there may be simultaneous exposure to multiple stressors1 that could influence vulnerability.

The new draft CRA guidelines are focused on the “Planning” and “Hazard Identification” steps of a traditional risk assessment and describe how these stages of a traditional risk assessment change when conducting a CRA. The new guidance outlines eight milestones in the CRA planning process. These include:

| Cumulative Risk Assessment Planning Milestones

1. Initiating factors 2. Identification of stakeholders 3. Statement of purpose 4. Evaluation of the fit for purpose 5. Scoping summary statement 6. Conceptual Model 7. Weight of evidence evaluation 8. Analysis plan |

The first milestone, initiating factors, is aimed at identifying the environmental issue that the CRA is intended to address. For example, this could include informing a regulatory action, addressing a community health concern, or to comply with broader U.S. EPA priorities such as children’s health, environmental justice, or sustainability. The initiating factors are used to help focus the CRA in terms of the geographic area, population, stressors, health effects and the time frame in which the CRA is to be completed.

The second milestone focuses on how to involve stakeholders (i.e., interested members of the public, affected industries, public health or environmental organizations or other government agencies) early and often in the decision-making process. The timing, frequency, and level of community involvement will depend on several factors including regulatory requirements, what environmental issue is being studied, and community interest. Common questions asked during this milestone include:

- What are the opportunities for stakeholder involvement?

- Who are the stakeholders?

- What communication materials are needed to effectively engage stakeholders?

- What mechanisms will be most effective for engaging different stakeholders?

A statement of purpose (Milestone 3) is used to clearly identify what the CRA is intended to accomplish or produce. At a minimum, the CRA needs to state the initiating factors and the risk management decision the CRA is intended to inform.

The fit for purpose (Milestone 4) stage of a CRA lays out the scope. It identifies the key aspects of the CRA and includes information around the environmental issue being studied such as the stressors being evaluated, dose response factors, demographics, genetic variability, age of the population being evaluated, the health status, health behaviors (e.g., smoking, diet), social determinants (e.g., socioeconomic status, environmental justice factors), other analyses (uncertainty and variability, economic, etc.…), and lastly identifies limitations (e.g., funding, schedule, legal, availability). The fit for purpose milestone generates a scoping summary statement (Milestone 5) which lays out the general objectives, constraints, and boundaries of the CRA.

At this stage of a CRA, the analysis may be broken into “Tiers” where initial conservative estimates of exposure and health effects are made to provide a crude estimate of risk. If the initial tier results in no or low risk, it may inform as to whether more detailed assessment of risk is necessary.

Milestone 6 focuses on developing a conceptual site model (CSM), which is a written or pictorial depiction of the pathways connecting hazards to health outcomes in a population of interest. CSMs are used to inform the work product, and usually incorporate the following considerations:

- The rationale for the stressors, exposure pathways, exposed population, health endpoints and risk metrics being considered.

- The basis for the model.

- The data sources available and resource implications of collecting additional data.

A CSM is intended to be developed iteratively and include input from other stakeholders and experts. CSMs should be updated when new data is available that may alter the original model. An example CSM from the U.S. EPA draft guidance document is provided below.

The weight of evidence (WoE), Milestone 7, is the process used by the CRA Team to identify possible exposure-health response relationships and exposure-response modifiers to be considered in the CSM. The results can be expressed qualitatively or quantitatively, depending on the information available and the needs of the CRA. The WoE will support or be used to provide the evidence base necessary to develop plans for the analysis phase. Evidence evaluation and data quality assessment requirements should be considered throughout the CRA to ensure the final assessment meets the general objectives of the CRA.

The final milestone, Milestone 8, lays out the analysis plan. The analysis plan clearly identifies what analyses will be done and what methods and inputs will be used. The analysis plan should describe any data collection needs, as well as any preliminary risk estimates. The analysis plan should also describe what exposure data is needed and the metrics that will be used to assess health outcomes. The analysis plan should determine what techniques are available to assess cumulative exposure and how it will assess baseline conditions. Lastly, the analysis plan should discuss how it will evaluate the quality of the data obtained as well as outline the cost and schedule for the CRA.

What Does it Mean to You?

The draft CRA guidelines lay the foundation for considering current and anticipated cumulative risk analytical methods. Notably the CRA guidelines do not provide guidance on what health endpoints should be evaluated or which analytical methods to use when conducting a CRA. The draft CRA guidelines do not discuss what is considered a “safe” level of exposure to multiple stressors. U.S. EPA is developing separately a framework for cumulative impact assessment which it identifies as a complementary assessment strategy to CRA that may address these issues. U.S. EPA is accepting comments on the draft CRA guidance until August 30, 2023.

If you have concerns about the potential implications of the draft CRA guidelines or need help parsing through it, feel free to contact your ALL4 Project Manager or Joe Sabato. We’ll continue to monitor cumulative risk and cumulative impact assessment guidance from the U.S. EPA and states as additional tools and guidance documents become available. We can also help you evaluate permitting risks, from EJ concerns to regulatory issues, and assist in developing a strategy to make the permitting of your project as efficient as possible.

1 Stressor is used by U.S. EPA to describe any physical, chemical, biological, or psychosocial agent that could induce an adverse response. In other words, it’s what someone is exposed to that elicits an adverse health effect.

U.S. EPA Issues New Emissions Standards for Greenhouse Gas Emissions From Both New and Existing Fossil Fuel-Fired Electric Generating Units

On May 11, 2023, the U.S. Environmental Protection Agency (U.S. EPA) proposed regulations addressing greenhouse gas (GHG) emissions from fossil fuel-fired electric generating units (EGUs). The rulemaking includes changes to the current New Source Performance Standards (NSPS) for Greenhouse Gas Emissions for Electric Generating Units (40 CFR Part 60, Subpart TTTT), a newly proposed subpart for GHG emissions from Modified Coal-fired Steam EGUs and New and Reconstructed Stationary Combustion Turbine EGUs (40 CFR Part 60, Subpart TTTTa), and Emissions Guidelines (EG) for GHG from existing EGUs (40 CFR Part 60, Subpart UUUUb). Additionally, the proposal includes repealing the Affordable Clean Energy (ACE) rule, or Subpart UUUUa. The following includes a brief overview of the changes that U.S. EPA is proposing.

Revised NSPS TTTT

Subpart TTTT regulates GHG emissions from fossil fuel-fired EGUs and was initially promulgated in October 2015. U.S. EPA is proposing several editorial amendments and changes that are intended to update incorrect or outdated information and add compliance flexibility. Specifically, they would like to add compliance options for EGUs either serving a common electric generator or using a common stack and are soliciting comments for possibilities on how to achieve this. The preamble indicates that the final version of the rule may include language that allows the approval of alternative procedures. Finally, U.S. EPA added language stating that maintaining records of electric sales to demonstrate that a stationary combustion turbine meets the conditions for the heat input-based standard is required. Amendments to Subpart TTTT were proposed in 2018 that would have revised standards for new coal-fired steam generating units, but those amendments are not being finalized or addressed at this time.

New NSPS TTTTa

The required 8-year review of Subpart TTTT was completed, and it was determined there have been developments in available control measures for stationary combustion turbines. As a result, the creation of a new subpart, Subpart TTTTa, has been proposed. The subpart will regulate emissions from new and reconstructed stationary combustion turbines and “large” modifications to fossil fuel-fired steam generating units. Modifications to stationary combustion turbines and new or reconstructed fossil fuel-fired steam generating units are not addressed as there are not any changes qualifying as NSPS modifications to existing turbines or newly planned coal-fired steam generating units that were identified. Therefore, it was concluded that there was no need to propose standards for these situations.

New and reconstructed stationary combustion turbines (defined as constructed or reconstructed after May 23, 2023) have been subcategorized based on the “load” of the turbine and a best system of emissions reduction (BSER) determined for each. There are three subcategories that have been identified: (1) low load; (2) intermediate load; and (3) base load. The BSER identified for the ‘low load’ subcategory has a single phase, while the BSERs identified for the ‘intermediate’ and ‘base load’ subcategories have multiple phases with an extended timeline proposed for demonstrating compliance. The standards are included in the following table.

| Turbine Load Category | Potential of Electric Sales Threshold | 1st Phase | 2nd Phase | ||

| Description | Compliance Timeline | Description | Compliance Timeline | ||

| Low | < 20% | Lower emitting fuels,

160 lb. carbon dioxide per million British thermal units (CO2/MMBtu), heat-input based standard |

Final rule publication date | N/A | N/A |

| Intermediate | 20% – X [1] | High-efficiency simple cycle turbine with best operating and maintenance practices | Final rule publication date | Low-GHG hydrogen (H2) | Co-firing 30% – 2032 |

| Base | >X [2] | High-efficiency combined cycle turbine with best operating and maintenance practices | Final rule publication date | Carbon capture and storage (CCS); or | 90% CCS – 2035 |

| Low-GHG hydrogen | Co-firing 30% – 2032 | ||||

| Co-firing 96% – 2038 | |||||

[1] Intermediate load turbines are those with net electric sales that exceed 20% and are less than a value that is calculated with the design efficiency and potential electric output of the turbine. U.S. EPA estimates that this upper limit will be between 33 – 40% for simple cycle combustion turbines and 45-55% for combined cycle combustion turbines.

[2] Base load turbines are those with net electric sales that exceed a value that is calculated with the design efficiency and potential electric output of the turbine. U.S. EPA estimates that this threshold will be between 33-40% for simple cycle combustion turbines and 45-55% for combined cycle combustion turbines.

The ‘intermediate’ and ‘base load’ phase one requirements to be a high-efficiency simple cycle or combined cycle turbine, and definitions for “best operating and maintenance practices” have not been included in the draft proposed rule language. However, U.S. EPA has provided context in the rule preamble and is soliciting comment on what aspects of these requirements to include. Additionally, they are proposing to define low-GHG hydrogen as hydrogen produced through a process that results in a GHG emissions rate of less than 0.45 kilograms (kg) of carbon dioxide equivalent per kg of H2 [kg CO2-e/kg H2 (1 lb CO2-e/2.2 lb H2)] on a well-to-gate basis. This definition is consistent with the Inflation Reduction Act (IRA).

In addition to regulating new and reconstructed stationary combustion turbines, Subpart TTTTa specifies a standard for fossil fuel-fired steam generating units that undergo a “large” modification. This approach is like the existing Subpart TTTT, which defines a “large” modification as a modification that results in greater than a 10% increase in hourly emissions of CO2. For these modified sources, U.S. EPA has proposed CCS with a 90% capture efficiency.

Repeal of UUUUa (ACE) and New UUUUb

When U.S. EPA establishes an NSPS for new sources within a specific category, it must also specify EG for existing sources, unless the pollutant is regulated under the National Ambient Air Quality Standards (NAAQS) program, Clean Air Act (CAA) section 108-110, or the National Emission Standards for Hazardous Air Pollutants (NESHAP) program. Individual state and tribal authorities then utilize the EGs to develop a state plan that must be reviewed and approved by U.S. EPA. When the original NSPS for GHG from EGUs was promulgated, the EGs for existing sources was proposed as Subpart UUUU. This subpart is also referred to as the Clean Power Plan (CPP). Subsequently, the U.S. EPA repealed the CPP and replaced it with the ACE rule (Subpart UUUUa). Although a series of District of Columbia (D.C.) Circuit Court and U.S. Supreme Court decisions impacted both the CPP and ACE rules and their embedded provisions, the result of the litigation was that the CPP remained repealed with the ACE rule in effect. U.S. EPA has since determined that the heat rate improvements required by ACE on their own do not qualify as BSER for existing sources, and additional standards are required. Therefore, with this action, they are proposing to repeal the ACE rule and create a new subpart, Subpart UUUUb.

The standards in Subpart UUUUb are split between existing fossil fuel-fired steam generating units and stationary combustion turbines. For existing fossil fuel-fired steam generating units (those constructed prior to January 8, 2014) that meet the general applicability criteria, U.S. EPA has proposed standards for subcategories of these units based on the fuel type and operating time horizon for coal-fired units and load level for oil and natural gas-fired units. These affected steam generating units must comply with the applicable standard by January 1, 2030. A summary of the proposed standards is included below.

| Affected EGUs | Subcategory Definition | Standard | Degree of Emission Limitation |

| Long-term existing coal-fired steam generating units | Coal-fired steam generating units that have not elected to commit to permanently cease operations by January 1, 2040 | CCS with 90 percent capture of CO2 | 88.4 percent reduction in emission rate |

| Medium-term existing coal-fired steam generating units | Coal-fired steam generating units that have elected to commit to permanently cease operations after December 31, 2031, and before January 1, 2040, and that are not near-term units | Natural gas co-firing at 40 percent of the heat input to the unit | A 16 percent reduction in emission rate |

| Near-term existing coal-fired steam generating units | Coal-fired steam generating units that have elected to commit to permanently cease operations after December 31, 2031, and before January 1, 2035, and commit to adopt an annual capacity factor limit of 20 percent | Routine methods of operation | No increase in emission rate |

| Imminent-term existing coal-fired steam generating units | Coal-fired steam generating units that have elected to commit to permanently cease operations before January 1, 2032 | Routine methods of operation | No increase in emission rate |

| Base load continental existing oil-fired steam generating units | Oil-fired steam generating units with an annual capacity factor greater than or equal to 45 percent | Routine methods of operation and maintenance | No increase in emission rate |

| Intermediate load continental existing oil-fired steam generating units | Oil-fired steam generating units with an annual capacity factor greater than or equal to 8 percent and less than 45 percent | Routine methods of operation and maintenance | No increase in emission rate |

| Low load (continental and non-continental) existing oil-fired steam generating units | Oil-fired steam generating units with an annual capacity factor less than 8 percent | None proposed | None proposed |

| Intermediate and base load non-continental existing oil-fired steam generating units | Non-continental oil-fired steam generating units with an annual capacity factor greater than or equal to 8 percent | Routine methods of operation and maintenance | No increase in emission rate (lb CO2 /MWh-gross) |

| Base load existing natural gas-fired steam generating units | Natural gas-fired steam generating units with an annual capacity factor greater than or equal to 45 percent | Routine methods of operation and maintenance | No increase in emission rate (lb CO2 /MWh-gross) |

| Intermediate load existing natural gas-fired steam generating units | Natural gas-fired steam generating units with an annual capacity factor greater than or equal to 8 percent and less than 45 percent | Routine methods of operation and maintenance | No increase in emission rate (lb CO2 /MWh-gross) |

| Low load existing natural gas-fired steam generating units | Natural gas-fired steam generating units with an annual capacity factor less than 8 percent | None proposed | None proposed |

For existing fossil fuel-fired stationary combustion turbines, U.S. EPA has limited its proposal to the largest and most frequently operated base load turbines. These are units greater than 300 megawatts (MW) with an annual capacity factor greater than 50%. The standards proposed for these types of turbines are identical to the second component of the standards proposed for new and reconstructed base load turbines. (90% CCS by 2035; or low GHG co-firing, achieving 30% co-firing by January 1, 2032 and 96% co-firing by January 1, 2038). Reference to a second, follow-up rulemaking was included in the preamble. This indicates that they may try to regulate the remaining smaller units, including both those that are frequently and less frequently used. However, with the proposed rule, there are no requirements that would be applicable to these types of turbines.

With the proposed compliance deadline longer than 16 months following the state plan submittal deadline, the U.S. EPA is also requiring that the plans include increments of progress deadlines for long-term and medium-term steam generating units as well as stationary combustion turbines. These include:

- Submittal of a final control plan;

- Completion of awarding contracts;

- Initiation of on-site construction or installation of emission control equipment;

- Completion of construction and/or installation;

- Commencement of permitting programs for pipeline construction;

- A report describing where CO2 will be injected underground for sources that are applying CCS;

- A demonstration of available low-GHG hydrogen supply for sources that are implementing co-firing of low-GHG hydrogen; and

- Deadlines for final compliance

Further, for sources that are imminent-term, near-term, and medium-term steam generating units that will be shutting down, the EGs require establishment of milestones to hold owners and operators accountable to their shutdown plans. These include:

- Preparation and submittal of an initial milestone report;

- Annual milestone status reports;

- Final milestone report following closure; and

- Posting of milestone reports on publicly available Carbon Pollution Standards for EGUs website, established by owners and operations of affected EGUs.

Resources for Development of Plans for Existing Sources

State, tribal, and federal authorities are responsible for creating and submitting plans to establish emissions standards that align with the EGs for existing sources in the newly created Subpart UUUUb. The EGs include information that must be included in a plan submission. U.S. EPA has established criteria (presumptive standards) to determine whether plan requirements are equivalent to the proposed standards in the EGs. There are also guidelines for the types of information and evidence states must provide if they would like to apply a less stringent standard to a particular facility or type of facility, based on the remaining useful life and other factors (RULOF). These include the source’s age or physical limitations of installing emissions control equipment. Additionally, other options for state plans, including emissions averaging and trading, are allowed. Meaningful engagement with relevant stakeholders is required for plan development, including consideration of potential impacts and benefits to communities most affected by emissions from affected EGUs. The final plans are required within 24 months after the final EGs are published in the Federal Register, with a mandated compliance deadline of January 1, 2030. The compliance deadline is based on consideration of how long U.S. EPA anticipates it would take for operators to assess their affected EGUs and bring them into compliance.

What do I need to do?

The current unified agenda indicates a target date for a final rule of spring 2024 and in the preamble, U.S. EPA hinted at a June 2024 target for final promulgation of the EGs. State plans would be required within 24 months of this date, with an approximate deadline for those plans of June 2026. The comment period for the proposed changes ended on August 8, 2023. Therefore, as of publication of this article, the comment period will have recently closed. The U.S. EPA solicited comments on multiple aspects of the proposal. Considering this, and that over 1,000,000 comments were received, it is likely that the final rules will contain several changes from the draft texts included in the proposal.

There are various applicable compliance deadlines associated with the proposed rules, depending on whether the affected EGUs are new or existing, and whether they are steam generating units or combustion turbines. For stationary combustion turbines, the compliance deadline will also depend on whether the CCS or low-GHG hydrogen compliance options are selected. Additionally, compliance deadlines are among the many aspects of the proposal that the U.S. EPA has solicited comments on.. Therefore, the details are subject to change while they review and develop the final rules. However, affected entities should begin reviewing their fleet inventories and considering how promulgation of the proposed standards and compliance timelines will impact their long-term operational plans.

This article only provides an overview of some of the key changes associated with the proposed rules and is not a complete inventory of all of the requirements or revisions. If you have additional questions or would like to gain an understanding of how the new rules could affect your facility’s compliance program, please reach out to me at cward@all4inc.com. ALL4 is monitoring all updates published by the U.S. EPA on this topic, and we are here to answer your questions and assist your facility with any aspects of regulatory compliance.

EPA Proposes Changes to Air Emissions Reporting Requirements

The U.S. Environmental Protection Agency (EPA) has proposed changes to its Air Emissions Reporting Requirements (AERR) rule. Under the current AERR rule, state, local, and some tribal agencies are required to report criteria air pollutant (CAP) emissions across various sectors and source types to U.S. EPA. Broadly speaking, these proposed changes would require thousands of facilities to report detailed information on their hazardous air pollutant (HAP) emissions to either their local agency or directly to the U.S. EPA on an annual basis. If finalized, these changes will increase the frequency of emissions reporting for many facilities (either to the state or directly to U.S. EPA), will increase the type and amount of information reported annually for all covered facilities, and will expand the HAP and “incidental CAP” emissions reporting obligation to many small facilities that are not currently required to report emissions. U.S. EPA’s justification for the proposed rule is gathering “sufficient information to identify and solve air quality and exposure problems.” Information collected under the AERR forms the basis for several U.S. EPA programs, including the National Emissions Inventory (NEI) and the National Air Toxics Assessment (NATA).

The elements U.S. EPA is proposing to add to the AERR rule at 40 CFR Part 51, Subpart A that affect facilities with HAP emissions generally include the following:

- If HAP emissions are above the thresholds in Table 1B to Appendix A of 40 CFR Part 51, Subpart A, either states or facilities would electronically report annual HAP emissions for each release point at the facility to U.S. EPA on an annual basis. Whether the state or the facility reports will depend on whether U.S. EPA approves the state’s reporting program. Note that some of the thresholds for individual HAP emissions are so low that many area sources of HAP emissions would be required to report.

- Minor CAP sources that qualify for HAP reporting will also be required to report “incidental CAPs,” meaning that if the facility’s emissions are over the HAP reporting threshold but not the CAP reporting threshold, they will report the CAP that is associated with the HAP (e.g., a HAP metal and PM5).

- Emissions data for small electric generating units (e.g., peak shavers and small units that do not report into the Clean Air Markets program) would be required to be reported.

- Emissions from offshore and portable facilities would be required to be reported.

- Emissions from mobile sources at facilities would be required to be reported.

- Facilities would enter all source test and performance evaluation data electronically into the Emissions Reporting Tool (ERT).

- Although the proposed rule does not explicitly require additional HAP emissions testing, facilities will be required to use the “best available emissions estimation method” when reporting HAP emissions. U.S. EPA expects that facilities will base reported emissions on recent source data and would need to justify use of alternative emissions information.

Other miscellaneous requirements, definitions, and clarifications are also included in the proposal. These additional requirements would start with the 2026 inventory year; reporting of emissions would be required by May 31, 2027 and annually thereafter, with the deadline moving to March 31 in 2031. U.S. EPA is also considering whether to require reporting of per- and polyfluoroalkyl substances (PFAS) and other non-HAP compounds that are reported in the Toxics Release Inventory (TRI). U.S. EPA also requests comment on a separate malfunction reporting option, where facilities would report their malfunction emissions as a separate value from their other emissions. Note that U.S. EPA is considering all required data to be emissions data and therefore non-confidential.

A public hearing will be held on August 30, 2023 and comments on the proposed rule are due October 18, 2023. If finalized, the proposed changes will increase the reporting burden on thousands of facilities and further increase scrutiny of your environmental data. The likely outcome of this increased data collection will involve cumulative risk analyses and emissions benchmarking across similar types of facilities. If you would like assistance commenting on the proposal, evaluating what this rule could mean for your facility or company, or evaluating whether it’s time to implement a digital solution to make compliance with the upcoming changes easier, please contact your ALL4 project manager.

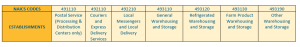

OSHA Brings Comprehensive Safety Inspections to Warehouses Nationwide

The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) launched a Nationwide Emphasis Program (NEP) bringing comprehensive safety inspections to warehouses and distribution centers nationwide to identify violations related to specific targeted hazards. This is a three-year emphasis program that went into effect on July 13, 2023. OSHA area offices will be given master lists of all facilities in their geographical area with a North American Industry Classification System (NAICS) code for Warehousing and Distribution Center Operations, Mail/Postal Processing and Distribution Centers, and Parcel Delivery/Courier Services. OSHA area offices will work their way through the lists conducting comprehensive safety inspections focused on hazards related to powered industrial trucks, material handling and storage, walking and working surfaces, means of egress, and fire protection. Heat and ergonomic hazards will be noted during all inspections and an additional health inspection will be performed if those hazards are present. The following table shows NAICS codes that will be covered under this NEP.

Why warehouses, why now?

The warehousing and distribution center workforce is experiencing tremendous growth, with close to 2 million people employed in the industry nationwide. The Bureau of Labor Statistics data shows injury and illness rates for these establishments to be well above the rate of private industry. OSHA stated that warehousing and distribution center operations pose a variety of serious safety and health hazards including, but are not limited to:

- Struck-by.

- Elevated work.

- Caught-in-between.

- Confined Spaces.

- Lockout/Tag out.

- Blocked aisles.

- Heat Illness.

- Electrical hazards.

- Slips, trips, and fall hazards.

- Powered Industrial Truck operations.

Incidents resulting from the above-mentioned hazards have resulted in death or serious physical harm in growing rates over the last decade. The need for this NEP is displayed in a recent warehouse fatality investigation done by OSHA involving a preventive powered industrial truck accident taking the life of warehouse laborer with more than four years on the job.

What is the Scope?

This NEP covers both programmed and unprogrammed safety inspections, emphasizing that it is a matter of when, not if, OSHA will inspect a facility. Unprogrammed Inspections are based upon fatalities, complaints, or referrals related to establishments in the specified NAICS codes. Along with those NAICS code, high injury rate Retail Establishments will also be covered under this NEP. Programmed safety inspections will come from the master list given to each OSHA area office, individual area offices can choose to randomize the list or work their way down in order. Per “National Emphasis Program on Amputations in Manufacturing Industries” workplace hazards targeted by this NEP will be:

- Powered Industrial Truck operations.

- Material handling/storage.

- Walking-working surfaces.

- Means of egress.

- Fire protection.

- Heat and ergonomic hazards must be considered and documented during each inspection under this NEP.

If your facility currently follows your State Plan for any of the above hazards, it is important to note that due to the seriousness and prevalence of these hazards nationwide, State Plans are required to participate in this new NEP. State Plans have the option of adopting an identical or different emphasis program, but the program must be at least as effective as this directive.

Next Steps

Facilities with any of these potential hazards need to be able to fully understand the depth of their responsibilities according to OSHA. This includes, but is not limited to, the trainings and refreshers they are providing employees, having up to date policies and plans, proper designations on powered industrial trucks and battery maintenance/storage, thorough audit documentation, complete OSHA injury and illness logs, and up to code facilities- free from hazardous conditions. This NEP was created to identify and reduce or eliminate hazards during warehousing and distribution center operations and OSHA will be conducting comprehensive inspections which they define as “a substantially complete and thorough inspection of all potentially hazardous areas of the establishment.”

If you have questions regarding compliance with OSHA regulations or would like to discuss gap assessments and compliance strategies before your inspection, please contact your ALL4 Project Manager or Cindy Castillo at ccastillo@all4inc.com. We would be happy to assist you in preparing for these inspections in any way we can.

California Hazardous Waste Generators: Complete Your Source Reduction Documents by September 1st, 2023

Did your facility generate more than 12,000 kilograms (kg) of hazardous waste or more than 12 kg of extremely hazardous waste in California during 2022? If so, then you might be required to prepare Hazardous Waste Source Reduction and Management Review Act of 1989 (SB 14) documents by September 1, 2023. A generator of hazardous or extremely hazardous waste is subject to a fine of $1,000 per day for failure to provide the required source reduction documents upon request.

WHAT IS SB 14?

SB 14 was passed to reduce the generation of hazardous waste at its source, reduce the release to the environment of chemicals that have adverse and serious health or environmental effects and document hazardous waste management information. SB 14 applies to a generator that routinely generates:

- More than 12,000 kg of hazardous waste in a reporting year

- More than 12 kg of extremely hazardous waste in a reporting year.

REQUIRED SB 14 DOCUMENTS

Since September 1, 1991, SB 14 has required generators to prepare documents every four years when the generation of hazardous waste exceeds the threshold during a reporting year. SB 14 requires the following:

- Preparation of three Hazardous Waste Source Reduction documents,

- Report Federal RCRA hazardous waste totals generated in the current reporting year, and

- Report non-RCRA California-only hazardous generated in current reporting year.

For generators subject to SB 14 the following documents must be prepared by September 1, 2023:

- A source reduction evaluation review and plan (“Plan”),

- A hazardous waste management performance report (“Performance Report”), and

- A summary progress report (”Progress Report”).

The Plan is a forward-looking document. The Plan must include an estimate of the quantity of hazardous wastes generated, an evaluation of potential source reduction approaches, a timetable for implementing selected source reduction measures and a four-year numerical goal.

The Performance Report must include an assessment of the effect on waste generation of each waste management approach implemented since the base-line year. Base-line year is the prior reporting year and is the year which the generator compares the current Reporting Year’s hazardous waste generation to. This year, generators will compare the current Reporting Year’s hazardous waste generation to 2018 reporting year.

The Summary Progress Report summarizes the result of implementing the source reduction measures identified in the generator’s previous Plan and the amount of reduction that the generator anticipated will be achieved by the implementation of source reduction selected in the current Plan.

While qualifying generators must complete all three SB 14 documents, the law no longer requires generators to submit these documents to the Department of Toxic Substance Control (DTSC). The generator must retain copies of the Plan, Performance Report, and SPR on-site and have the documents readily available for on-site review by DTSC or the Certified Unified Program Agency (CUPA) during inspection.

For any questions regarding this information, please contact Peyton Rodgers at prodgers@all4inc.com. Additionally, contact Meredith Garrett at mgarrett@all4inc.com to find out how ALL4 can help you.