U.S. EPA’s Draft PAL Guidance

This article is part of ALL4’s 4 The Record: Quarantine Series.

In mid-February 2020, the U.S. Environmental Protection Agency (U.S. EPA) released draft guidance for public review and comment on the Plantwide Applicability Limitation (PAL) provisions of the federal major new source review (NSR) air permitting rules. The PAL regulations are codified in the NSR Prevention of Significant Deterioration (PSD) rules at 40 CFR §52.21 and other NSR regulations including 40 CFR Part 51, §§165, 166, and Appendix S for non-attainment areas. The PAL regulations were established as part of the 2002 NSR Reform rules and allow facilities that are major stationary sources of air emissions to establish plantwide limits for regulated NSR pollutants. As long as the facility-wide emissions of the limited pollutant remain below the PAL level, the major NSR rules including PSD and/or non-attainment NSR do not apply when facility changes occur (see guidance document).

The draft guidance stems from U.S. EPA’s review of stakeholder input following 2017 Presidential outreach efforts on regulatory burden and reform. While a number of facilities have realized the advantages of PAL permits (U.S. EPA Indicates that approximately 70 PAL permits have been issued), others have been reluctant to pursue this permitting alternative primarily due to the lack of specificity in the rule and concern over future unforeseen implications. The guidance addresses the major concerns raised by the stakeholders regarding how the rules are implemented but, does not change the regulations. The intent appears to be directed at encouraging more widespread implementation of this permitting alternative. Some highlights of U.S. EPA’s guidance regarding the issues raised by the stakeholders include the following:

- Concern over the PAL permit reopening provision that gives the reviewing authority discretion to reopen and reduce a PAL to address NAAQS violations or Class I area impacts. Here, U.S. EPA points out that most NAAQS have short-term averaging periods while PALs are ton per year limits. Therefore, reopening a PAL would not likely be the mechanism to address such issues. Even if this approach was taken, the process must be open and transparent allowing for both the source and public participation.

- If a PAL permit expires without renewal, the rule includes provisions for distributing the PAL by establishing individual or grouped emissions unit limits for the entire facility. The rule provides no specificity on how the distribution will actually occur, which concerned stakeholders. S. EPA points out that while not specifying how the PAL will be distributed, the rule does provide a straightforward and flexible approach that begins with the permittee’s application and proposal for distributing the emissions. U.S. EPA also adds an important point on the PAL expiration issue. They state that when a PAL expires, none of the limits on capacity to emit covered by §52.21(r)(4) that were eliminated when the PAL was issued are required to be reestablished.

- The permit renewal provisions were another concern raised by stakeholders, specifically a concern that the PAL level would automatically be ratcheted down at the end of the 10-year PAL term. S. EPA reiterates the rule language that specifies that if a source’s baseline emissions (during the 10-year permit term) plus the applicable PSD significant emissions increase level (e.g., 40 ton per year for NOX) are equal to or greater than 80% of the PAL, the existing limit can be maintained with no change. U.S. EPA then goes on to point out that the rule does not mandate resetting the PAL to a lower level if the baseline plus significance level are lower than 80% of the PAL, leaving it to the discretion of the reviewing authority on a case-by-case basis. U.S. EPA provides several examples and concludes by noting that the limit can be reset at levels up to the current PAL if the applicant can provide supporting justification.

- The regulations have no provisions for terminating a PAL. S. EPA indicates that it does not expect requests for PAL termination to be common and maintains its earlier position that handling such requests will be addressed by the source and the reviewing authority on a case-by-case basis.

- The PAL regulations specify that the permits contain enforceable requirements for monitoring systems to accurately determine plantwide emissions for demonstrating compliance. S. EPA notes that while they believe continuous emission monitoring systems (CEMS) and predictive emission monitoring systems (PEMS) may provide the most reliable approach for quantifying emissions, the regulation specifically provides that three other alternatives can also be used including mass balance, continuous parameter monitoring systems (CPMS), and emission factors. Stakeholders raised concerns that complex and costly continuous monitoring systems would be required. They also expressed concerns regarding the lack of rule specifics regarding emission factor adjustment, validation testing, and data availability for monitoring systems. U.S. EPA addressed the concerns with each of these issues. With regards to emission factor adjustment U.S. EPA notes that baseline factors must also be considered when adjusting a factor for PAL monitoring purposes. With respect to validation testing U.S. EPA notes that testing for other CAA purposes and testing of similar units could support a reviewing authority’s decision to not require additional validation testing. U.S. EPA goes on to point out that the regulations do not require a PAL permit to contain alternative procedures to address monitoring data unavailability and that circumstances should be considered when determining the value for establishing such procedures in a permit. U.S. EPA also includes examples for data substitution from a current PAL permit.

- S. EPA acknowledged that there is confusion regarding how to handle replacement units (as defined in the PSD rules) when determining baseline emission rates and for setting PALs. In this guidance U.S. EPA clarifies that the baseline emissions for the replacement unit are the baseline emissions for the unit it replaced.

U.S. EPA closes out the guidance by highlighting general advantages of PAL permits. Any major stationary source that regularly struggles with evaluating PSD applicability for facility changes should still consider the possible upside of operating under a PAL. ALL4 has helped a number of facilities obtain PAL permits and we’re always happy to discuss this alternative compliance approach that we believe, can actually give your facility a competitive advantage. Please reach out to John Egan at jegan@all4inc.com with any questions about the draft guidance or PALS in general.

Pennsylvania RACT III Update – Three Strikes and You’re Out!

This article is part of ALL4’s 4 The Record: Quarantine Series.

There is a fundamental phrase in baseball, three strikes and you are out. The regulated community is wondering how much change will come with Pennsylvania’s Reasonably Available Control Technology (RACT) rules because RACT III is coming on the heels of RACT II. Will RACT III be the last of Pennsylvania’s RACT rules? This probably will not be the case if the ozone national ambient air quality standard is lowered as Pennsylvania is located within the ozone transport region (OTR).

Contact Us

RACT II vs. RACT III

On the heels of RACT II rule being incorporated into the Pennsylvania State Implementation Plan (SIP), a draft of this newest rule was discussed at the April 2020 air quality technical advisory committee (AQTAC) meeting. The sentiment that was conveyed is that RACT III will include updates (relative to RACT II) to meet regulatory and technical requirements and will also address concerns that were expressed and lessons that were learned during RACT II implementation. This most recent rule is at the preliminary stages of development and an official rule has not yet been proposed. Several important highlights of what you can expect in the RACT III rule (based on what we know at this stage of the process) are provided below.

- Affected facilities will be required to make a detailed notification. The notification requirement will apply to facilities, regardless of whether the facility is subject to presumptive requirements or will propose a case-by-case analysis. It is unclear if notification will extend to non-major NOX or VOC emitting facilities in the state, but it is a possibility.

- Emissions units in existence before August 3, 2018, will be subject to the RACT III requirements.

- The presumptive RACT limit for electric arc furnaces is not expected to include a numerical emissions limitation. However, there will be a work practice standard to operate the source in accordance with the manufacturer’s specifications and with good operating practices.

- Combustion units (i.e., boilers) rated between 20 and 50 MMBtu/hr heat input will have tune-up requirements consistent with the Maximum Achievable Control Technology (MACT) rule for boilers.

- Compliance with this latest RACT update’s emissions limits for combustion units with continuous emissions monitoring systems (CEMS) will be on a 30-operating day basis. However, the averaging period will be daily during the ozone season (i.e., May 1 through September 30).

- The presumptive NOx emissions limit for simple cycle combustion turbines will be ratcheted down for many units (depending on size rating).

- A presumptive NOX limit for combustion sources (e.g., direct-fired furnaces, ovens) of greater than 20 MMBtu/hr will be added.

- The NOx emissions limit for cement kilns will be lowered (e.g., reduced from 3.44 lb/ton of clinker to 3.0 lb/ton clinker for long dry kilns).

- Several source-specific RACT limits will be specified in the rule.

Watch Our Presentation on RACT 3

The draft RACT III rule regulatory development schedule is for PADEP to complete the technical development of the rule with submittal of a nearly complete draft to the environmental quality board (EQB) during the third quarter of 2020. A proposed rule is expected in the fourth quarter of 2020. Once a final rule is published in the Pennsylvania bulletin, facilities will have 6 months from the compliance date to complete notifications and submit case-by-case analyses.

While it’s unclear if Pennsylvania will fully achieve its air quality goals with RACT III as the last strike, it is more likely that we are only at the seventh inning stretch and RACT rules will continue to follow future changes in the ozone NAAQS. If you have questions about how the Pennsylvania RACT rules or other air quality regulations may apply to your facility, please reach out to me at nleone@all4inc.com or 610-933-5246 x121.

Refrigerant Rules: Update to the Update

This article is part of ALL4’s 4 The Record: Quarantine Series.

In October 2019, we posted a rundown of highlights of the refrigerant rule updates that became effective in 2018 based on the three-year compliance phase-in for the final rule that was published in November 2016. The key items from 40 CFR Part 82 (Protection of Stratospheric Ozone), Subpart F (Recycling and Emissions Reduction) that became effective in 2018 for regulated refrigerants and equipment include:

- New requirements for equipment that contain any amount of refrigerant. The rule previously only required recordkeeping for units that contained 50 or more pounds of refrigerant.

- The rule had expanded the definition of “refrigerant” in 2017 to include substitute substances [e.g., hydrofluorocarbons (HFCs) and hydrofluoroolefins (HFOs)], as previously it only included Class I and Class II ozone depleting substances (ODS) or blends containing such [generally, chlorofluorocarbons (CFC) and hydrochlorofluorocarbons (HCFC)], but the rule as updated in 2016 included requirements for substitute substances (i.e., non-exempt substitutes).

Contact Us

The U. S. Environmental Protection Agency (U.S. EPA) received significant pushback on the proposed December 2010 Leak Repair Rule, which was not finalized and in fact, was withdrawn with the November 2016 rulemaking. Some of the 2010 provisions were removed, others broadened or re-proposed, and the rule was published six years later. Many concerns with the 2016 final rule still existed after issuance, but specifically around the expansion of the maintenance and leak repair provisions to appliances that contain 50 or more pounds of non-exempt substitutes, which became effective January 1, 2019. Those opposing the provision argued that U.S EPA’s inclusion of non-exempt substitutes was unlawfully restrictive and an overextension of U.S. EPA’s authority. As a result of statutory re-interpretation, U.S. EPA published a final rule in the Federal Register on March 11, 2020, which became effective April 10, 2020. The final rule removes briefly applicable (effective January 1, 2019 and reversed effective April 10, 2020) maintenance and leak repair provisions for appliances with more than 50 pounds of non-exempt substitutes. The rule effective April 10, 2020 will again narrowly apply the maintenance and leak repair provisions to appliances with a full charge of 50 pounds or more of Class I and Class II refrigerants or blends containing a Class I or Class II refrigerant. However, the final rule effective April 10, 2020 does retain the previously expanded requirements for the use of non-exempt substitutes including:

- Disposal of old appliances,

- Certification of technicians to ensure leaks are minimized when appliances are serviced, and

- Venting prohibition during maintenance, servicing, repair, or disposal of appliances.

Be aware that state-level regulation may be more stringent than the recently issued final U.S. EPA rule regulating refrigerants. California, Connecticut, Delaware, Maine, Massachusetts, New York, Rhode Island, Vermont, and Washington either have more stringent phase-out restrictions of certain HFCs or have announced their intent to phase out HFCs prior to potential rule amendments by the Federal government. The intent by the states to mitigate HFC release may include potential state rule amendments for enhanced operator and maintenance training for equipment containing HFCs (i.e., substitute substances).

And, regardless of whether refrigerant conditions are included in your air permit (or even if you don’t have an air permit), it does not negate the requirement to comply with this Federal refrigerant regulation if your facility has refrigerant-containing equipment.

Stayin’ Chill and Current on Refrigerant Regulatory Changes (30 min recording)

As always, ALL4 is available to answer any questions you may have. If you’re interested in having ALL4 conduct a virtual refrigeration training for your personnel, contact Sally Atkins at satkins@all4inc.com.

What You Should Know About Air Permitting in South Carolina

This article is part of ALL4’s 4 The Record: Quarantine Series.

As many of us are working from home right now, we are staying connected with the state environmental agencies to understand how we can work through the challenges that arise during our temporary normal. I’ve summarized what I’ve learned from conversations with South Carolina Department of Health and Environmental Control (DHEC) staff and provided links to electronic resources that are regularly kept up to date.

DHEC is currently accepting air permit applications via email in place of hard copy submittals. Key DHEC staff are still in the office to accept hard copy submittals that are sent via mail or that are hand delivered. Additional safety measures are in place for those who are hand delivering and receiving applications. Permittees that use the electronic submittal process will be asked to mail a hard copy of the application at a later date. The responsible official’s signature must be included with the electronic or hard copy submittal but for professional engineers (PE) who left their seals in the office, DHEC will work with you for submittals with this requirement. Signed air permit applications may be emailed to airpermitting@dhec.sc.gov.

Expedited air permit applications are now being accepted again after a temporary suspension. Prevention of Significant Deterioration (PSD) construction permit applications require a preapplication meeting 90 days prior to application submittal. Synthetic minor and minor permit types are encouraged to schedule a preapplication meeting, but it is not required. Preapplication meetings between the Permittee and DHEC are being held virtually via phone or through programs that support screensharing.

Review and processing of air construction permit applications has not visibly slowed but part of this is due to a noted reduction in the number of these types of applications being submitted. Permits are still being put out for public notice using DHEC’s Environmental Public Notice webpage. If requested, DHEC plans to hold public meetings virtually to fulfill their obligations to provide for public participation, consistent with the U.S. Environmental Protection Agency’s (EPA) Virtual Public Hearings and Meetings Memo.

DHEC maintains guidance on Environmental Regulatory Assistance during this time to offer case-by-case regulatory relief where the regulated community is impacted by COVID-19 and non-compliance is unavoidable. Guidance and deadline extensions are broken down by program. Recent programmatic air quality regulatory relief includes an extension to the emissions inventory due date from March 31, 2020 to April 30, 2020 and a 30-day extension to submit On-Site Implementation Logs (OSIL) that are due on or before April 29, 2020.

Permitting resources are made available online with a few of my most frequently referenced as summarized below.

- Issued air permits are located on DHEC’s website.

- DHEC provides forms and instructions for applications, reporting, and notifications for multiple programs in one location, including guidance on the expedited construction permitting process. Expedited permit applications are expected to be of the highest quality and are reviewed before being accepted into the program. Only expedited air permit applications require an application fee and the fee should be paid upon acceptance into the program, not prior. The applicant will have the opportunity to reapply for the program if the original application is not accepted.

- DHEC maintains a list of sources/activities that are exempt from construction permitting. Documentation must be maintained onsite for activities that fall into Section B of the list. To assist with compiling this documentation, DHEC offers the exempt source log (Form D-0721) and the Title V insignificant activity form (Form D-2944). A booklet is available to provide guidance and examples on making exempt source determinations and completing documentation requirements.

- Permittees are required to demonstrate that emissions from the facility will not interfere with the attainment or maintenance of any ambient air quality standard under SC Regulation 61-62.5, Standards No. 2, 3.1, 7, and 8, as applicable. This is completed through air dispersion modeling, exemption/deferral, or analysis based on other information. Air dispersion modeling guidance and exemptions are included in DHEC’s “Modeling Guidelines for Air Quality Permits” and analysis based on other information is provided in a separate document. Depending on the standard, site specific ambient monitoring may be used as the compliance demonstration on a case-by-case basis in place of air dispersion modeling.

If you need assistance with an air permitting project in SC, please contact Claire Corta, Steve Moore, or Amy Marshall.

Compliance Considerations for Chemical Recovery Combustion Sources at Pulp & Paper Mills

This article is part of ALL4’s 4 The Record: Quarantine Series.

The compliance date for amendments to 40 CFR Part 63, Subpart MM (National Emission Standards for Hazardous Air Pollutants for Chemical Recovery Combustion Sources at Kraft, Soda, Sulfite, and Stand-Alone Semichemical Pulp Mills) was on October 11, 2019, but that was not the end of compliance-related activities. The first periodic performance test is due by October 13, 2020, and while that may seem straightforward, there are several considerations around both testing and other parts of the rule, and the current COVID-19 National Emergency adds another layer of complexity.

40 CFR Part 63, Subpart MM regulates recovery furnaces, smelt dissolving tanks, and lime kilns at most pulp and paper mills, and establishes emissions limits for particulate matter (PM) and, for some sources, methanol or total hydrocarbons (THC). This article presents some routine considerations for testing, rule-related considerations, and COVID-19 considerations.

TESTING CONSIDERATIONS

As with any performance test, primary deliverables include notifications, as well as a test protocol, test plan, and test report. Each item is discussed further below.

Notifications

Notification requirements for the performance test and performance evaluation(s) are specified in the General Provisions under 40 CFR §§63.7 and 63.8, respectively. Notification of the performance test is required at least 60 days in advance of the scheduled test date, and notification of the performance evaluation should be submitted simultaneously. The notifications should typically be sent to the appropriate U.S. EPA Regional Office and your local air quality regulatory agency (referred to going forward as “state agency”). Your state agency may have additional notification requirements, so be sure to check your permit and any applicable regulations.

Test Protocol

The test protocol is typically developed by your stack testing firm, and many state agencies require it to be submitted with the notification. The test protocol contains a description of the procedures, test methods, analytical methods, calculations, quality assurance procedures, etc. that the stack testing firm will use to conduct the test and to analyze the results.

Test Plan

The test plan for the performance test and performance evaluation is typically developed by the mill and sometimes in conjunction with the stack testing firm. The test plan contains a description of the sources being tested, how the mill will operate, how data will be recorded, designated personnel, etc. While the test plan is not required to be submitted, it may be requested, so it’s recommended to have it developed at the time of the 60-day notification.

The performance evaluation(s) of continuous monitoring systems (CMS) should be conducted prior to the performance test (e.g., scrubber flow rates, pressure drop, fan amperage). Neither the rule nor the General Provisions define how far in advance of the performance test the performance evaluations must be conducted, but for CMS that can be evaluated without a process shutdown, within 30 days is reasonable. The purpose of CMS performance evaluations is to ensure the validity of the parametric data collected during the performance test, because that data is used to establish operating limits. A CMS performance evaluation typically involves a calibration or other independent verification of the CMS output.

40 CFR Part 63, Subpart MM states that operating limits must be “confirmed or reestablished” during performance tests, and goes on to include terms such as “new,” “expanded,” or “replacement” operating limits. None of these terms are defined in the rule, so we recommend establishing a mill-specific procedure for confirming or reestablishing operating limits in advance, but it’s possible that your state agency will require an update of the operating limits based on the most recent performance test, regardless of whether you intended to simply confirm them.

Test Report

Within 60 days following the performance test, the test report must be submitted via U.S. EPA’s Compliance and Emissions Data Reporting Interface (CEDRI) using the Electronic Reporting Tool (ERT). Your state agency may also still require submittal of a hard copy test report. Be sure to understand whether submittal of the test report will be completed by the mill or the stack testing firm, and to receive a draft of the test report with enough time to adequately review the results prior to the 60-day submittal deadline.

More information about performance testing can be found here.

RULE-RELATED CONSIDERATIONS

Additional amendments to 40 CFR Part 63, Subpart MM were proposed on October 31, 2019, that primarily pertained to corrections and clarifications, but the most significant proposed amendment pertained to the method for establishing the smelt dissolving tank scrubber fan amperage minimum operating limit (where fan amperage is monitored instead of pressure drop). Mills expressed concern with the promulgated method of using the lowest hourly average fan amperage during the performance test. The proposed amendments updated the rule to provide three alternatives, but all options included new, additional provisions to operate the scrubber fan within 5% of the design revolutions per minute (RPM). Due to the age of these scrubbers, many mills may not know the design RPM of the fan or have the capability to measure RPMs during the performance test. Objections to this new requirement have been submitted with comments on the proposed rule, but until the rule is finalized, mills that intend to establish an operating limit for fan amperage during the performance test face uncertainty about how to set it. More information on the proposed amendments can be found here.

On April 21, 2020, the U.S. Court of Appeals for the District of Columbia Circuit (D.C. Circuit Court) remanded 40 CFR Part 63, Subpart MM back to U.S. EPA (without vacatur) in order to establish emissions limits for previously unregulated hazardous air pollutants (HAPs) that are known to be emitted from the pulp and paper mill chemical recovery combustion source category. 40 CFR Part 63, Subpart MM currently regulates PM as a surrogate for HAP metals, and methanol (for new kraft and soda recovery furnaces) or THC (for semichemical combustion units) as a surrogate for gaseous organic HAPs. However, Subpart MM does not contain standards for all existing chemical recovery combustion source HAP emissions, which can include mercury (Hg), dioxins and furans (D/F), non-dioxin organic HAP, hydrogen chloride (HCl), and hydrogen fluoride (HF). Stay tuned for more on this topic, as it also has far-reaching implications for other rules that do not have emissions limits for all HAPs emitted from a particular source category.

COVID-19 CONSIDERATIONS

Even before the COVID-19 National Emergency, mills expressed concern over the availability of stack testing firms due to all mills across the country subject to 40 CFR Part 63, Subpart MM needing to test their chemical recovery combustion sources by October 2020. This concern was further elevated due to the uncertainty around whether the updated procedures for setting the smelt dissolving tank scrubber fan amperage operating limit would be finalized for mills using fan amperage instead of pressure drop. With travel and onsite personnel restrictions now in place due to COVID-19, more mills will likely be testing even later in the year than originally planned. This, along with other non-pulp and paper facilities also delaying testing due to COVID-19, is expected to further limit the availability of stack testing firms.

As with all COVID-19-related guidance, we suggest doing as much as possible to maintain compliance and meet notification and testing deadlines. Should you find that COVID-19 directly impacts your ability to comply with the October 2020 testing deadline due to the limitations described above, document everything you can, and contact your state agency about the possibility of a compliance extension due to force majeure, a test waiver, or enforcement discretion in accordance with U.S. EPA’s published policy and your particular state agency’s position. More information about U.S. EPA’s enforcement discretion policy can be found here.

CFATS: Personnel Surety Program

This article is part of ALL4’s 4 The Record: Quarantine Series.

The U.S. Department of Homeland Security (DHS) administers the Chemical Facility Anti-Terrorism Standards (CFATS) program, intended to set standards and monitor the security of listed hazardous chemicals stored at certain locations. Each “high risk” facility covered by the CFATS program is required to submit and maintain an Alternative Security Program (ASP) or Site Security Program (SSP), which contains security measures that sufficiently meet all Risk-Based Performance Standards (RBPS). The vetting of facility personnel and unescorted visitors who have access to critical assets is one such standard. RBPS 12 – Personnel Surety requires facilities to account for four types of background checks on facility personnel and unescorted visitors who have or seek access to restricted areas and critical assets at high-risk facilities. These checks include measures designed to:

- Verify and validate identity

- Check criminal history

- Verify and validate legal authorization to work

- Identify people with terrorist ties

CFATS Personnel Surety Program (PSP) Process

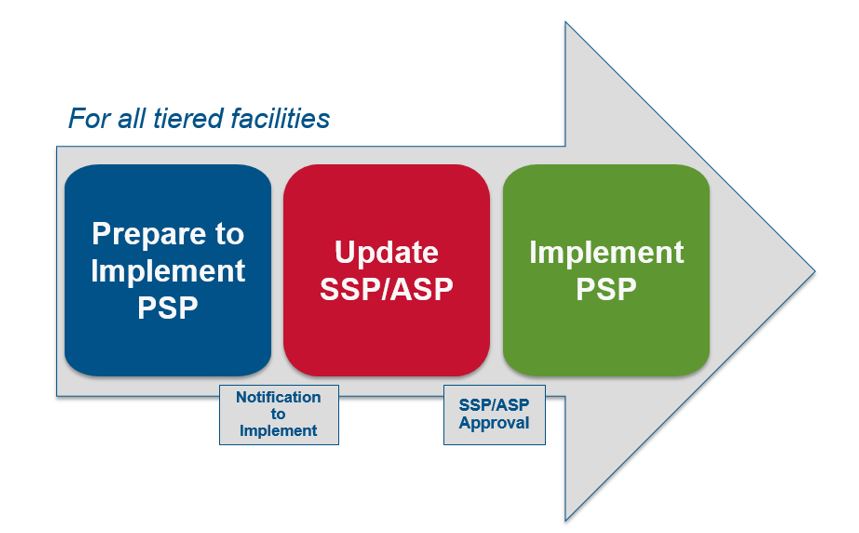

Part iv., screening people for terrorist ties, is implemented through the Personnel Surety Program (PSP). The Cybersecurity and Infrastructure Security Agency (CISA) has previously implemented the PSP at Tier 1 and 2 facilities; however, the Agency published a notice in the Federal Register (84 FR 32768) on July 9, 2019, that announced the full implementation of the PSP at all covered chemical facilities—including Tier 3 and Tier 4 facilities. Therefore, all facilities subject to CFATS that have not yet been required to implement RBPS 12(iv) will be required to do so in the near future. These high-risk chemical facilities will be individually notified by DHS in a phased manner when to begin implementing RBPS 12(iv). Each Tier 3 or 4 facility, when notified by DHS, will have 60 days to incorporate RBPS 12(iv) into their ASP or SSP by adopting measures to identify individuals with terrorist ties. Once the updated ASP or SSP is approved, facilities will have 60 days to implement RBPS 12(iv) and be actively identifying individuals. Figure 1 provides a visual representation of the PSP process.

Implementing PSP

There are two options for implementing RBPS 12(iv); both involve submitting certain information about affected individuals through a PSP Application located in the Chemical Security Assessment Tool (CSAT):

- Option 1 – allows impacted chemical facilities to submit certain information about affected individuals, and the Department will use that information to vet the individuals for terrorist ties, or

- Option 2 – allows DHS to verify affected individuals’ enrollments in other programs, including the Transportation Worker Identification Credential (TWIC) program, Hazardous Materials Endorsement (HME) program, and the Trusted Traveler Program. If Option 2 is selected, the facility can opt for DHS to automatically revert to Option 1 when DHS is unable to verify an affected individual.

An Authorizer, Administrator, or PSP Submitter can access the CSAT PSP Application through the PSP tab in the CSAT Portal after their facility has been approved to implement RBPS 12(iv). Facilities will have 60 days from approval of their updated ASP or SSP to submit all affected personnel with access to the Chemical of Interest (COI) area, including:

- Facility personnel

- Unescorted visitors

- Unescorted contractors

Note that any facility personnel who accesses the critical asset, regardless of whether he or she is accompanied by a screened employee, must also be screened for terrorist ties. All individuals should be notified prior to screening.

Ask How ALL4 Can Help You With the PSP Process

PSP Submission

An Authorizer or an Administrator can assign facility employees or third-party contractors to a PSP Submitter role. Facilities can have multiple PSP Submitters to share responsibilities for different personnel. Multiple groups can be created for different sections of affected individuals, and a PSP Submitter can be assigned for each group. Facilities may wish to assign an HR official as a PSP Submitter in order to incorporate the CSAT submission for an affected employee into the normal hiring process. They may also wish to designate an employee of a contracted company to handle the PSP Submissions of their contractors. Regardless of how the responsibility is shared, the Authorizer is encouraged to establish user roles and groups in CSAT to implement reasonable privacy limitations. The information submitted to DHS through the PSP process is considered Personally Identifiable Information (PII) and must be safeguarded. More information about user and group management can be found in their manual.

Submission of affected personnel information into CSAT can be done individually; however, those with a large number of affected personnel should take advantage of the bulk upload feature, which can process up to 10,000 individuals at a time. The Sample Bulk Upload template is an XLS file that can be accessed through the PSP tab in the CSAT Portal. The PII required for PSP screening varies between Options 1 and 2, but the minimum information required includes the affected individual’s full name, date of birth, and gender OR country of citizenship. Option 2 requires specific information pertaining to the program the individual is enrolled in. Additional information such as alias name, passport number, redress number and location of birth is optional.

Once the PSP Submission is uploaded through CSAT, the status of submittals will be “Submitted”. There is no more immediate action required by the facility or employee, and the Submission should be considered complete.

Ongoing PSP Requirements

Once the facility has completed the initial implementation of PSP, any new personnel or contracted employees must be submitted to DHS prior to being granted access to CFATS-restricted areas. Likewise, if an individual’s access to the CFATS-restricted area is removed (i.e. in the event of an employee leaving the facility or moving to a different area of the facility), DHS must be notified by removing the individual in the PSP tab of the CSAT portal. If an individual has temporary access to the CFATS-restricted area, you can enter the date that the individual’s access will expire in the optional field dated “Date Affected Individual Will No Longer Have Access.”

DHS encourages high-risk chemical facilities to submit updates and corrections to PSP data as needed in order to ensure that DHS’s checks for terrorist ties, which are done on a recurrent basis, are accurate.

Facilities should complete an annual review of the PSP database to ensure the list of individuals is accurate. More information can be found in the CSAT PSP Instructions.

If you have questions regarding CFATS or the PSP process, please contact me at lsmith@all4inc.com or at (770) 999-0269. ALL4 has assisted clients with completing top-screens, ASP/SSP development, implementation of planned measures, compliance documentation, and compliance inspections. Look for more CFATS content from ALL4!

Strategic Planning for COVID-19-Driven Production Projects

This article is part of ALL4’s 4 The Record: Quarantine Series.

DISCLAIMER: This article discusses general considerations around needing to respond to an acute COVID-19 situation that could result in a permit limit exceedance. It does not recommend that any permit limit be exceeded nor does it replace guidance from legal counsel that addresses your specific situation.

Much has been made of the ability of facilities to comply with environmental obligations during the COVID-19 pandemic. How will we comply with stack testing obligations if we are not able to have stack testing contractors on site? How will conduct routine monitoring if environmental staff members are sick and unable to work? These are just a couple of the questions that come up as we evaluate the hundreds of provisions that are contained in operating permits. In response to these concerns, U.S. EPA issued a COVID-19 compliance enforcement guidance memorandum and a number of state agencies have followed suit. Read my colleague Roy’s article to learn more about the U.S. EPA enforcement guidance.

Beyond making certain environmental obligations more difficult to address, COVID-19 has also changed the market dynamics and production demands for a lot of facilities. In certain instances, facilities that produce products in the pulp and paper industry or that contribute to critically needed equipment (e.g., medical equipment) have seen their production demands increase. This means that facilities are exploring projects required to increase production or are considering postponing previously scheduled downtime to keep operations running. In some cases this could also mean evaluating the need to exceed established permit production or emissions limits.

Does U.S. EPA’s enforcement memo allow for exceeding a production or emissions limit if the exceedance is being prompted by COVID-19-related production demands? The short answer is no. Some facilities are being directed by President Trump to produce new products (e.g., ventilators) using his powers under the Defense Production Act, which does not appear to provide exemptions from environmental obligations (not surprising since the Defense Production Act was introduced in 1950). Similarly, a state regulatory agency does not have the ability to provide a blanket compliance exemption from production or emissions limits. Given that, here are suggestions for steps to take when evaluating production or emissions limits in an acute COVID-19-provoked situation:

- Discuss the situation with internal or external legal counsel so that they can assess the ramifications.

- The immediate first step is to connect with your state regulator to explain the situation and the drivers behind it. They can provide you with an understanding of the discretion (or lack thereof) that will be used in enforcement down the road.

- Consider the true environmental implications of the potential permit limit exceedance. Will the exceedance of a production limit result in actual emissions increases versus current or baseline emissions rates? Will the exceedance be anticipated to create issues relative to ambient standards or state air toxics rules? Would an updated air dispersion modeling exercise produce a different permit limit? Can better data be obtained to refine an emissions estimate? Can changes be made at the facility to offset any emissions increases?

- Prepare documentation of any environmental impacts of exceeding the permit limit that can be submitted to the regulatory agency as soon as possible and follow up with the agency often as the situation progresses.

Feel free to contact me at cmccall@all4inc.com or (908) 328-9429 with questions or additional thoughts. We hope that all facilities that manufacture key products to help with the pandemic can make those products without limitation over the next several months.

Title V Renewal Best Practices: Burden or Opportunity?

This article is part of ALL4’s 4 The Record: Quarantine Series.

Do you have a Title V Operating Permit renewal coming up? If so, how do you hold the renewal process? Is it a strategic opportunity or an obligatory paperwork exercise? From our perspective, Title V renewals represent an opportunity rather than another box to check. In that spirit, here are some “best practices” that apply to your Title V renewal application process:

- View the Title V renewal process as an opportunity to clarify and improve your permit! Make unclear conditions clear. Make conditions that are difficult to certify compliance against easy to certify compliance against. Convert production limits into emissions limits to allow more operational flexibility. Examine opportunities to revise monitoring approaches, frequencies, or averaging periods to reduce burden and improve compliance. Make sure all the emissions units on the permit are still onsite and will be operational in the future. This seems obvious but is easy to lose sight of now that we are typically in the third, fourth, or even fifth renewal cycle for our operating permits. This once every five-year (or longer) event is also a good time to train new staff and to provide a better understanding of the “why” and “how” behind complying with each permit condition.

- Allow time (if you’re preparing internally) and/or budget (if you are seeking external help). Title V renewals have turned into check the box exercises rather than strategic opportunities in many cases – if they are treated as the latter they can create ongoing efficiency if conditions are streamlined and can minimize possible compliance issues if they are used to get environmental staff more familiar with the permit. As with any good thing – accomplishing those objectives takes time.

- Know the stakeholders. Consider your internal review process in terms of who from a facility management perspective needs to be involved and how information should be communicated to them. If you have new regulatory agency permit writers plan for more time to educate them on your permit. Understand if there could be any public comment on your renewal application (environmental groups are increasingly using Title V renewals as a venue to comment on permit conditions).

- Include proposed permit condition language for all of the proposed changes! This gets the facility closer to a permit that is clearer internally and typically allows the state agency to be more efficient in their review.

- Closely review the regulatory agency statement of basis (or equivalent for that agency) and draft permit conditions, especially if new requirements are being incorporated into the permit due to rule changes. Many agencies will share draft permit conditions and a statement of basis prior to issuing the final permit. Make time to closely review those conditions (and don’t forget to review the general conditions)! It is the last easy opportunity to make the permit as clear and efficient as possible, but often times comes up suddenly and while there are other seemingly more pressing things going on. Move this task alongside the other high priority items on your list.

- Submit the renewal application as far in advance of the due date as possible. Title V renewal applications are typically due 180 days in advance of the expiration of the existing operating permit. Having a determination of administrative application completeness in hand from the agency prior to the submittal deadline is ideal.

If you have any questions about these best practices feel free to contact me at cmccall@all4inc.com or at (908) 328-9429. Happy permitting!

Amendments to Paper and Other Web Coatings NESHAP

On March 11, 2020, U.S. EPA finalized minor amendments to the 2002 Paper and Other Web Coating (POWC) National Emission Standards for Hazardous Air Pollutants (NESHAP). The POWC NESHAP is codified at 40 CFR Part 63 Subpart JJJJ and applies to new and existing major stationary sources of hazardous air pollutants (HAP) at which web coating lines are operated. This includes pressure-sensitive tapes and labels, flexible packaging, photographic film, coated vinyl, wall coverings, sandpaper and other abrasives, paperboard boxes, vinyl flooring, industrial and decorative laminates, carbon paper and carbonless paper, and circuit boards and business forms. This action finalizes the residual risk and technology review (RTR) conducted for POWC. U.S EPA identified no new cost-effective controls under the technology review that would achieve significant further emissions reductions. Therefore, U.S. EPA proposes no revisions to the standards based on developments in practices, processes, or control technologies.

The amendments will become effective once published in the Federal Register and the compliance date for existing sources will be 365 days from the date of publication. Modified and reconstructed sources must comply upon startup.

The amendments include:

- The elimination of the startup, shutdown and malfunction (SSM) exemption. For existing sources, compliance with this provision will be required beginning 365 days from the date of publication in in the Federal Register.

- The addition of periodic air emissions performance testing. This will be required once every five years for facilities using thermal oxidizers and annually for facilities using catalytic oxidizers to demonstrate compliance with the standards.

- A new requirement for facilities to submit electronic copies of compliance reports and performance tests through U.S. EPA’s Central Data Exchange (CDX) using the Compliance and Emissions Data reporting Interface (CEDRI).

- The addition of provisions for more flexible monitoring requirements. For example, the amendments allow the use of several consensus standards as an alternative to U.S. EPA Method 24 for determining the volatile organic compound (VOC) content for coatings.

- Amendments to provide regulatory clarity.

If you have any questions about the changes to the POWC NESHAP, or questions about any of the other myriad of printing and coating rules, reach out to Bob Kuklentz at rkuklentz@all4inc.com or at (610) 933-5246 x124.

What Do You Need to Know About Air Permitting in Pennsylvania?

This article is part of ALL4’s 4 The Record: Quarantine Series.

As the teleworking environment continues for the foreseeable future, we’re sharing what we know about how the Pennsylvania Department of Environmental Protection (PADEP) is operating based on first-hand experience and conversations with PADEP personnel.

Like many agencies, all offices are closed, and staff are teleworking as able. Their websites states “staff that are able are teleworking, and still fulfilling the mission of the department. This includes reviewing permits, responding to complaints and environmental emergencies, and other work.” Let’s dig in to what that means.

Much of PADEP’s work depends on the mail, whether that be permit applications or compliance-related submittals. Mail is still being delivered, but only via the United States Postal Service (USPS) until arrangements with private carriers can be established. PADEP representatives (typically the regional Air Program Manager) are monitoring mail that is delivered to each regional office and scanning the information to the appropriate personnel. PADEP typically requires three (preferably unbound) hard copies of permit applications, but it was not uncommon for them to request an electronic copy anyway. Staff continue to be appreciative of receiving electronic copies of hard copy submittals, so we recommend submitting in both formats to expedite review. That’s one less document that someone needs to scan and send electronically (be sure to copy the Air Program Manager on the electronic copy so they know it doesn’t need to be scanned).

The exception to this approach is confidential business information. PADEP has strict procedures in place for accepting and maintaining hard copy confidential business information. If you need to submit confidential business information to support a permit application, we recommend sending that via hard copy only so that it can be properly managed, and sending as much non-confidential information as possible electronically. For example, consider sending confidential data via hard copy, but sending a version of that data on a percentage basis electronically so that the actual units of measure are not present.

PADEP is similarly initiating more electronic communications with regulated entities. While PADEP has provided electronic copies of permits before, the official copy has always been a hard copy. PADEP is now contacting facilities about consenting to accept electronic copies of formal communications and documents like permits in lieu of a hard copy. PADEP indicates they will revert back to hard copies for official documents when things return to normal.

PADEP also shared that they have a File Transfer Protocol (FTP) site available to share electronic files that may be too large for email. They note, however, that there is no mechanism for them to delete files from this site, and anything uploaded may remain indefinitely and will be visible to anyone accessing the site. To access the site, you will need to request a username and password from PADEP.

The Permit Decision Guarantee timeframes have been suspended. PADEP’s website states that “staff will continue to process received permit applications. However; due to operational conditions, applicants may experience delays receiving decisions.” The request for determination (RFD) process continues to be available online. The Continuous Emissions Monitoring Data Processing Service (CEMDPS) also continues to be available online, but PADEP staff in the CEMS Section may have limited access.

PADEP indicates that public hearings may continue virtually through video conferences, and is also limiting onsite inspections to those “that are critical to public health and safety.” If an inspection is required to issue a plan approval (construction permit), PADEP recommends requesting an extension. Similarly, due to essential business-related limitations on operations, travel restrictions, visitor restrictions, etc., PADEP recognizes that compliance with certain permit requirements may not be possible under these unique circumstances. While every effort should be made to meet compliance obligations, PADEP has established a form and email address for requesting a temporary suspension of regulatory requirements and/or permit conditions. As with any state, we recommend doing as much as possible to maintain compliance and addressing potential non-compliance scenarios in advance, such as requesting an extension for a requirement, rather than relying on enforcement discretion alone. And be sure to document all efforts.

More information on PADEP’s response to COVID-19 can be found on their website. Please reach out to me or any of your ALL4 contacts with questions.