Sticky Situation: What You Should Know About PFAS

Per- and polyfluoroalkyl substances (PFAS) are a group of more than 3,000 emerging contaminants that have been heavily utilized in a wide range of industries including military training, consumer product manufacturing, and emergency services. Although most of the releases have been caused through manufacturing and firefighting foams, many household items contain PFAS due to its non-stick nature. Rain coats, pots and pans, and many food packages contain small amounts of this contaminant. It is the non-stick quality of these chemicals that makes them so difficult to destroy. The carbon-fluoride bonds in PFAS make it extremely chemically and thermally stable, as well as hydro and lipophobic. The pathway of dispersion among these chemicals appear to be long-range in atmosphere and ocean transport. These compounds may pose a threat for adverse health effects given their suspected toxicity, mobility, and potential for bioaccumulation in proteins. However, scientists and engineers are still learning more about the toxicological information of PFAS.

Due to the emerging health concerns associated with PFAS, U.S. EPA has published a drinking water concentration guideline for PFAS of 70 parts per trillion (ppt). The drinking water guideline, which importantly is not a regulatory standard, has the possibility to decrease as newer research becomes available. There is a wide range of activity occurring at the state level addressing PFAS. Some state agencies have developed their own guidelines and mandated water monitoring programs, while other state agencies continue to assess and seek more information about PFAS before taking formal action. All of this state agency activity is occurring as class action lawsuits have been filed against specific manufacturing facilities for possible PFAS water contamination. As state agency and legal activity ramps up, companies are evaluating the possible future implications of PFAS regulation and in some instances evaluating options for controlling and removing PFAS concentrations from wastewater streams.

Contact us with your questions about PFAS

During my senior year of college at Villanova, I was able to participate in research surrounding PFAS in ground water. Two classmates and I spent half of the year reading research articles and creating a technology matrix of available remediation strategies, and the second half of the year we conducted a case study surrounding a naval base and PFAS discharge. Granulated activated carbon (GAC) is the current accepted remediation technology for PFAS contaminated water, but not without complications. GAC is a separation technology and not a destruction method. This means that the carbon can adsorb PFAS, but not destroy the toxin. Collection technologies like this tend to be more expensive than destruction remediation due to added transportation costs of collected materials for destruction via incineration. Another remediation hinderance stems from natural organic matter. Most of the current research efforts use a mixture of PFAS in pure water. Contaminated water, soil, and air will contain different compounds that naturally occur in the environment, leading to a decrease in collection efficiency. Research surrounding PFAS chemistry has a long way to go before finding the optimal combination of collection and destruction methods.

Most PFAS attention thus far has focused on drinking water as a source of concern. In my time so far at ALL4, it has been interesting to learn about the possible air quality contribution to PFAS in ground water. PFAS emissions generated by facilities will exit stacks and be deposited onto surrounding bodies of water. While little is known about the extent of this possible air quality contribution, state agencies are attempting to learn more about it and could take air quality-related action in the future. At ALL4 we are taking our knowledge from research like the study that I described and combining it with a tremendous level of sampling and air emissions testing knowledge from some of our partner companies, the purpose of which is to identify how facilities might consider preparing for air permitting and sampling implications of PFAS in the future. Stay tuned for additional updates, and if you have PFAS related questions feel free to contact me at 610.933.5246 x176 or at KAune@all4inc.com.

Cleaner Air Oregon Regulation: Call to Action and Lessons Learned So Far

By now I’m sure you’ve heard of or already been involved in some aspect of Oregon Department of Environmental Quality’s (DEQs) new Cleaner Air Oregon (CAO) risk-based toxic air contaminant permitting program. You may also be asking yourself, when am I going to get “called-in” and should I do anything before I get “called-in?” DEQ recently (March 2019) completed their call-in prioritization analysis utilizing 2016 air toxics emissions inventories, their Level 1 Risk Assessment Tool, demographic statistics, and “other” criteria for prioritization to place all facilities in Oregon into 4 Prioritization Groups. Group 1 sources should expect to be called-in this year and Group 2 sources should expect to be called in next year.

Once a facility is called-in, a regulatory clock starts ticking on a number of CAO requirements depending on the type of analysis (Level 1, 2, 3, or 4) that you opt to evaluate your facility under. The post call-in deadlines make it critical to get started on your CAO analysis before you’re called-in. Getting started before you’re called-in will allow time to determine what level of analysis to utilize, identify and prioritize refinements to your air toxics emissions estimates, identify if public participation is likely, identify if emissions controls or a toxic best available control technology (TBACT) analysis is necessary, or if ambient monitoring is necessary all before the clock starts ticking. Having time to make these decisions and evaluate the impacts will help to minimize impacts on operational flexibility and potential capital costs down the road.

ALL4 offers the following insights most likely to impact your evaluation based on our CAO experience so far:

- The Level 1 Risk Assessment Tool can be highly conservative especially for the following scenarios:

- Short distances (i.e., less than 100 meters) from emissions sources to residential receptors,

- Short stacks, and

- Fugitive emissions sources and especially large fugitive emissions sources (i.e., waste water treatment systems).

- A few uncontrolled emissions sources and/or emissions sources not subject to a National Emissions Standard for Hazardous Air Pollutants (NESHAP) Maximum Available Control Technology (MACT) standard can drive facility-wide risk levels.

- 24-Hour acute metal air toxic emissions can drive risk assessments for low emitters because of conservative Risk Based Concentration (RBC) thresholds.

- Risk Action Levels (RALs) are based on combining the impacts from all air toxics at each receptor and therefore are additive.

- The CAO permitting program includes requirements for community engagement with required public meetings if certain RAL are exceeded.

Based on experience to-date I’d expect most facilities in the Group 1 and Group 2 prioritization to need to conduct a Level 3 CAO analysis which involves the use of U.S. EPA’s recommended air dispersion model AERMOD. If you have never completed an AERMOD analysis for your facility this is another reason to get started ahead of your call-in to allow time to develop the modeling inputs necessary to run AERMOD. If you’re interested in getting started on a preliminary CAO analysis before you’re called-in or have any questions about the process please feel free to give me a call at 610.422.1118 or email me at ddix@all4inc.com. Don’t be surprised if you hear from us directly as we seek to communicate what we have learned so far, identify where facilities may need assistance, and to potentially “compare notes” with other facilities that have started the CAO process.

Contact Us

CMS Data Management: The Importance of Log Books and Reconciling Your Data

Does your facility operate a continuous monitoring system (CMS) to demonstrate compliance with Federal and/or state monitoring requirements? If so, we want to reiterate the importance of maintaining records/logbooks of events associated with your CMS. In addition to potentially being required to do so by your facility’s air permit, keeping up-to-date records/logbooks can help tremendously while reviewing and reporting CMS data. To demonstrate the importance of logbooks and the impact they can have on CMS data, we will recap a recent finding that our team encountered while completing CMS reports.

The facility operates a continuous opacity monitoring system (COMS). During the reporting period, the COMS measured numerous opacity values in excess of the of the facility’s opacity limits. The data acquisition and handling system (DAHS) used the measured values to calculate compliance averages in excess of the applicable limits, resulting in many reportable. The impact here was potentially significant – if the excess opacity values were valid and representative of the facility’s operations, the facility would have received monetary penalties for the excess emissions reported by the facility. We took a closer look at the raw or “as-recorded” COMS data during the relevant time period and the comments recorded in the facility’s CMS logbooks to ensure validity and accuracy of the data.

The COMS data recorded during this time immediately looked suspicious to us. The operating record reported “normal operation” (i.e., no start-up, shut-down, or malfunction); however, the one-hour average values were noted to be significantly higher than what is expected to be emitted by the source during normal operation. Additionally, a review of the logbook comments found records that the COMS monitor malfunctioned during this time period. The logbook also documented that corrective maintenance was performed on the COMS monitor, and the suspiciously high opacity readings ceased after the monitor maintenance was completed.

Upon review and confirmation of the findings with the facility, it was determined that the impacted COMS data within the DAHS was invalid and non-representative due to the COMS malfunction. As a result, the data that was originally recorded by the DAHS as excess opacity emissions, could be reconciled and instead was accurately reported as monitor downtime in the COMS performance summary for the reporting period.

If the original report was submitted without a detailed review or reconciliation, the facility would have incurred fines from the regulating agency for reporting erroneous excess opacity emissions. Documentation of events associated with your CMS can not only save you time when reviewing and reconciling CMS data, it can save you from unwarranted violations and penalties. If you have questions about how to log events, what events to log, or anything else regarding your CMS please reach out to Matt Carideo (610.933.5246 x139 or mcarideo@all4inc.com) or Dustin Snare (610.933.5246 x126 or dsnare@all4inc.com). Additionally, to ensure that you do not miss out on future articles, signup for our 4 The Record below for timely updates of current hot issues, plus an in-depth article each month that highlights a regulatory topic.

What Happened: Air Quality Bills to Watch in the 86th Texas Legislative Session

In April 2019, I shared two articles regarding the legislative process in Texas. The first was an overview of the legislative process related to air-quality related bills considered during the 86th Texas Legislative Session (January 8, 2019 to May 27, 2019) found here. The second was a more in-depth look at several bills with a distinct air-quality permitting timing implication relating to timing issues associated with air quality permitting found here. With the 86th Texas Legislative Session now in the rear-view mirror, let’s check-in and see what happened with these bills considering what are the effective dates and how they are being implemented.

Commencement of Construction

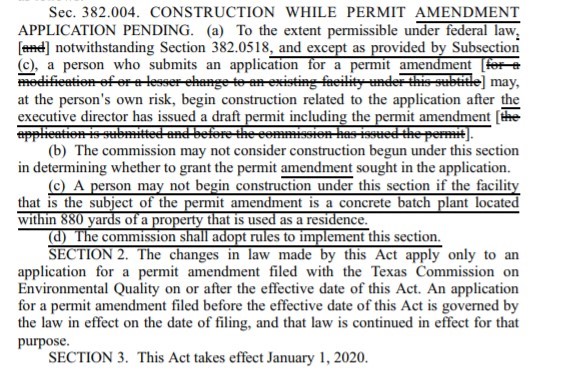

Commencement of Construction was addressed in Senate Bill 1501 (SB1501) and House Bill (HB2726). Specifically, commencement of construction of a project following the issuance of a draft permit for an amendment to an air quality permit. Section 382.004 of the Health and Safety Code would be amended to address “at risk” commencement of construction for permit amendment applications, where commencement of construction would be allowed for amendments upon issuance of a draft amended permit.

SB1501 was an identical bill to HB2726 and didn’t have any further relevant activity so we’ll focus on HB2726. HB2726 had good momentum in mid-April and it continued with the bill passing the House Committee, Senate Committee, and Senate, on May 7, 2019, May 16, 2019 and May 20, 2019, respectively. Several amendments were considered and implemented throughout the legislative process, one example is the exclusion of certain concrete batch plants. The Governor signed the bill on June 14, 2019. The bill becomes a law and is effective on January 1, 2020. ALL4 is tracking the development of the revisions and will provide updates as they become available.

The updates to Section 382.004 are illustrated in the figure below.

Expedited Permitting

The Texas Commission on Environmental Quality’s (TCEQ’s) expedited permitting program was represented in several bills and covered (1) the current fiscal biennium and (2) post September 1, 2019. In my April 19, 2019 article, it was noted that SB500 had passed the Senate and the House and was with the Governor. The bill was signed June 6, 2019 and the portion of SB500 relating to expedited permitting was effective immediately, providing needed funding for the expedited permitting program through August 2019.

Looking at the expedited permitting program post September 1, 2019, several different bills centered on expanding the program to include full time equivalent (FTE) TCEQ staff and allowing TCEQ to fund the program entirely via collected surcharges were moving forward. Specifically, S698 passed the House on May 16, 2019 and was signed by the Governor on June 2, 2019. The effective date is September 1, 2019.

Each of these bills when implemented will serve the regulated public well by potentially streamlining the permitting timeline as well as allowing at risk commence construction for prescribed scenarios. ALL4 understands that TCEQ is in the process of forming an expedited air quality permitting team, including staff from TCEQ. Stay tuned for updates on how these bills improve turnaround time for air quality permitting in Texas. Time will tell what the results will be. Interested in other key bills involving TCEQ? Check out their recent summary. (https://www.tceq.texas.gov/news/tceqnews/features/86th-texas-legislative-session-is-complete ) Have questions on these or other bills from the 86th Texas Legislative Session? Reach out to Houston Office Director, Kristin Gordon, at kgordon@all4inc.com or 281.937.7553 x301.

What’s Your Role in our Story?

Many stories begin with: “It was a dark and stormy night…,” “Once upon a time…,” “So I was drunk one night and…,” or “This one time, at band camp…” However, the story of the ALL4 Washington, D.C. (WDC) office begins with three people who met at work in Herndon, VA. Sally Atkins, Renee Cheng, and I found a comradery in our work ethics and positive attitudes while working together at a previous company, and it turned into friendship. When opportunity knocks for an entrepreneurial-esque venture with some of your favorite work people, how do you say no?! And thus, the WDC office was born, four years ago in May!

In our four years, we have continued long-standing relationships and enrolled new clients and contacts, enjoyed fun activities together, established a college recruiting program, said hello and fond farewells to members of our WDC team, provided coaching/mentorship/training to our personnel to foster growth, and made a name for ourselves in several industries outside of a “typical” ALL4 pursuit. Many in our client base are commercial or institutional sector facilities, such as data centers, healthcare, property management, and government, in addition to our industrial sector clients, such as automotive and cement manufacturers. We have an outstanding team here in Herndon, contributing internally and externally to ALL4’s impressive success! I write all of this today because a) I’ve not written a blog about the WDC office and it seemed high time I should as the Regional Office Director, and b) to ask if you know someone who might want to join our team.

The WDC office is looking to grow in 2019 by adding a project manager, a project engineer/project scientist, and a part-time administrative assistant to our staff. Click on the links to learn more! We are excited for the opportunities we can provide to new hires and how the WDC office can learn from our new team members. If you are interested, or know someone who may be, please reach out! You won’t find a “The End” here…our story is just beginning!

Proposed Rulemaking to Address Reclassification of Major Sources as Area Sources

The U.S. Environmental Protection Agency (U.S. EPA) proposed a rulemaking in the July 26, 2019 Federal Register to revise the 40 CFR Part 63, Subpart A General Provisions to include requirements for facilities that want to reclassify from a major source of hazardous air pollutants (HAP) to an area source. This rulemaking follows a January 25, 2018 U.S. EPA memorandum titled “Reclassification of Major Sources and Area Sources Under Section 112 of the Clean Air Act.” With the memo and rulemaking, U.S. EPA is reversing its longstanding “Once In, Always In” (OIAI) policy and has coined a new acronym: Major Maximum Achievable Control Technology (MACT) to Area (MM2A).

The U.S. EPA OIAI policy was set out in a 1995 John Seitz memo and stated that a major source of HAP had only until the first substantive compliance date of an applicable MACT standard to reclassify as an area source. After that time, once a MACT standard applied to a facility, it always applied. If a facility was subsequently determined to be an area source, it could only avoid MACT compliance obligations under future major source rules. U.S. EPA now believes that the OIAI policy is not consistent with a plain reading of the Clean Air Act. The January 2018 memo repealed the policy and U.S. EPA is now proposing to codify procedures for reclassifying from major source to area source (and vice versa). Note that this proposal supersedes and replaces the January 2007 proposed rule, which was a much simpler version of the current proposal (it essentially said that a source could reclassify at any time and would be subject to the new applicable requirements upon the effective date of the permit reclassifying the source).

U.S. EPA is proposing the following changes to the 40 CFR Part 63 General Provisions:

- Adding a new paragraph §63.1(c)(6) that states a major source can become an area source at any time by limiting its potential to emit (PTE) HAP. Until the PTE limitations become effective, the source remains subject to the major source requirements. After the PTE limitations become effective, the source is subject to any applicable 40 CFR Part 63 area source requirements.

- A major source that becomes an area source must meet applicable 40 CFR Part 63 area source requirements immediately (provided the first substantive compliance date for area sources has passed), except that the regulatory authority can grant up to 3 years additional time if the source must make physical changes or install additional controls.

- A major source that becomes an area source and then later becomes a major source again must comply with applicable major source MACT requirements immediately. If the standard has been revised since the source was last subject and the source must make physical changes or install additional controls to comply, the permitting authority can allow the same amount of time to comply as the amount of time allowed for existing sources subject to the revised standard.

- Reclassification does not absolve a source subject to enforcement action or investigation of any compliance obligations.

- Limitations on PTE must be legally and practicably enforceable. Definitions of those terms are being added at §63.2.

- Sources that reclassify must notify U.S EPA electronically via the Compliance and Emissions Data Reporting Interface (CEDRI). No sources will be exempted from electronic reporting.

U.S. EPA is also proposing to revise individual subparts under 40 CFR Part 63 that currently specify dates that would conflict with the MM2A revisions and to include new citations in each rule’s general provisions applicability table.

A public hearing will be held on August 15, 2019 in Washington, DC and comments on the proposed rule are due September 24, 2019. U.S. EPA has included 59 specific requests for comment on the proposed rule. They include, but are not limited to, the following:

- Whether this new interpretation is permissible.

- Examples of whether emissions will increase, or air pollution controls will be decommissioned if major sources reclassify to area sources.

- Whether U.S. EPA should prohibit emissions increases when major sources reclassify to area sources, and the legal basis for doing so.

- Whether the compliance timing provisions are appropriate.

- Whether the proposed criteria for HAP PTE limits are effective, whether they should include additional criteria, and whether state or local enforceability is sufficient.

- Whether they should codify minimum requirements for a reclassification request, including a hierarchy of acceptable data and methods.

- Whether public notice and comment should automatically be required when a source reclassifies.

- Whether additional changes are needed to individual subparts.

This regulatory proposal is part of the current administration’s regulatory streamlining efforts. It is meant to provide a mechanism for sources to reduce their regulatory burden and an incentive for facilities to implement pollution prevention measures or enhanced air pollution control technologies in order to reduce emissions to below major source levels. Although this is a proposed rule, some states have already allowed major sources to reclassify as area sources.

Although reclassification can potentially provide a significant reduction in regulatory burden, as you are considering the implications of reclassification, keep in mind that there could be other requirements that become applicable when a major source MACT standard no longer applies. These could include area source standards under 40 CFR Part 63 or state air toxics rules. You should also consider the potential for future expansion or contraction of the facility and the implications of a requirement to immediately comply with the relevant 40 CFR Part 63 standard upon the effective date of reclassification. Finally, you should consider whether accepting HAP PTE limits in your permit will result in requirements for additional monitoring, testing, and recordkeeping to demonstrate that emissions remain below the major source thresholds. Conducting a site-specific analysis, developing a compliance strategy, and obtaining the requisite air permit revision will take time. The pros and cons of major versus area source status should be carefully considered. Contact your ALL4 project manager or Amy Marshall with questions or for assistance with strategizing and permitting.