EPA Final Rule Addressing NSPS For EAF & AOD Vessels at Steel Plants

On August 25th, 2023, the United States Environmental Protection Agency (U.S. EPA) promulgated amendments to the Standards of Performance for New Stationary Sources (NSPS) for electric arc furnaces (EAF) and argon-oxygen decarburization (AOD) vessels. This action is in accordance with the Clean Air Act (CAA), which mandates that U.S. EPA review and possibly revise NSPS every eight years. Affected facilities that commence construction, reconstruction, or modification after May 16, 2022 must comply with newly promulgated requirements outlined in 40 CFR Part 60, Subpart AAb no later than August 25, 2023. Existing affected facilities that are subject to 40 CFR Part 60, Subparts AA and AAa must comply with promulgated revisions to those rules by February 21, 2024.

Background

The original NSPS, Standards of Performance for Steel Plants: Electric Arc Furnaces Constructed After October 21, 1974, and On or Before August 17, 1983 at 40 CFR Part 60, Subpart AA, was proposed in October 1974 and promulgated in September 1975. Subpart AA was reviewed by U.S. EPA in 1984, and a new Subpart AAa was established for affected EAF and AOD vessels that were constructed, reconstructed, or modified after August 17, 1983. Nearly 40 years later, it is no surprise that these standards have again been revised and updated.

What Revisions Were Made to the Standards for Particulate Matter?

During their review of Subparts AA and AAa, U.S. EPA ultimately identified several revisions related to definitions and monitoring procedures – most notably the opacity monitoring provisions related to shop opacity and the addition of an alternative opacity monitoring procedure in accordance with ASTM D752-16.

In addition to the changes promulgated under Subparts AA and AAa, U.S. EPA promulgated a new Subpart AAb that includes several substantial revisions as summarized below:

- 60.272b(a): The format for emissions limitations has been revised from a concentration basis [i.e., grains of particulate matter (PM) per dry standard cubic feet (dscf)] for each control device, to an “aggregate” basis (i.e., a total facility limit for PM from control devices in units of lb. PM/ton steel produced). The opacity limit for EAF melt shops during melting and refining activities has been reduced from 6% to 0%. However, the 6% opacity limit has been retained during charging and tapping activities. The control device opacity standard remains unchanged at 3%.

- 60.272b(b): The opacity limit for dust handling operations remains unchanged at 10%.

- 60.272b(c): Based on the decision from the 2008 United States D.C. Circuit Court of Appeals decision in the case of Sierra Club v. EPA, the exemption for limitations on opacity and other standards during startup, shutdown, and malfunction periods has been eliminated.

- 60.272b(d): Performance tests under Subpart AAb are required to be conducted every 5 years.

The new PM standard under Subpart AAb for PM reflects the best system of emissions reduction (BSER), which U.S. EPA determined is the use of a baghouse with a fabric filter for EAF and AOD vessels. Likewise, the new opacity standards under Subpart AAb also reflect BSER, which U.S. EPA determined is the use of a canopy hood and fabric filter to capture emissions during melt shop activities.

What Are the New Monitoring, Reporting and Testing Requirements?

U.S. EPA had originally proposed significant changes to the monitoring provisions under Subparts AA and AAa, and new monitoring provisions under Subpart AAb that included bag leak detection systems (BLDS), furnace static pressure monitoring, and volumetric flow and/or static pressure monitoring. Commenters suggested that such monitoring would require significant capital investment by facilities and U.S. EPA ultimately did not finalize those proposed revisions under 40 CFR Part 60, Subparts AA, AAa, and AAb. U.S. EPA has retained monitoring provisions under to Subparts AA, AAa, and AAb that allow for fan amperage monitoring to be used as a surrogate for monitoring volumetric flow or static pressure when it is recorded on a basis more frequent than once per shift. Fan amperage monitoring is also required to be performed as frequently as damper position measurements during the initial or most recent performance test used to demonstrate compliance with the PM standards.

What Does This Mean for My Facility?

Affected facilities that are constructed, reconstructed, or modified after May 16, 2022 must demonstrate compliance with the emissions standards and reporting provisions found in Subpart AAb upon startup. Facilities that remain subject to Subparts AA and AAa should review the proposed revisions carefully so that compliance with the revisions is achieved by February 21, 2024.

ALL4 has many experts in the organization that can assist with conducting a compliance test, implementing monitoring systems, and implementing proper performance standards at your facility. If you have questions or concerns about the standards and practices surrounding EAF and AOD vessels and you’d like to discuss them, feel free to contact your ALL4 project manager, or Daniel Hickey at Dhickey@all4inc.com. ALL4 monitors all updates published by U.S. EPA that have been published on this topic, and we are here to answer your questions and assist your facility with any aspect of regulatory compliance.

Recap of the CAPCA 2023 Fall Technical Workshop and Forum

This year’s fall Carolinas Air Pollution Control Association (CAPCA) technical workshop and forum included a football tailgate party exhibitor social, golf outing, and of course several technical topics of interest to those located in the Carolinas. In addition to the regulatory update from the United States Environmental Protection Agency (U.S. EPA) and the fireside chat with the air directors from South Carolina Department of Health and Environmental Control (SC DHEC) and the North Carolina Department of Environmental Quality (NC DEQ), conference topics focused on programs where compliance gaps often exist. Highlights from these program presentations are provided below.

Combustible Dust

The Occupational Health and Safety Administration (OSHA) has been focused on conducting combustible dust inspections through the Combustible Dust National Emphasis Program (NEP), which was most recently revised on January 30, 2023. Through this program, OSHA has cited multiple facilities for combustible dust hazards. Combustible dust can be a hazard at many industrial facilities including but not limited to those in the agriculture, food production, chemical manufacturing, fabric product manufacturing, woodworking, metal processing, and mining sectors. The National Fire Protection Agency (NFPA) requires dust producing facilities to conduct a combustible dust hazard analysis to prevent explosions before they occur. Facilities should review the NFPA standards and confirm whether a dust hazard analysis is needed, if not already implemented.

Note that the NFPA is in the process of clarifying and consolidating all combustible dust standards into one single standard, designated as NFPA 660: Standard for Combustible Dusts, with the first edition release expected in early 2025.

Ozone Depleting Substances (ODS)

The purpose of 40 CFR Part 82, Subpart F, is to reduce emissions of Class I and II refrigerants, or ODS, to the lowest achievable level by maximizing the recapture and recycling of such refrigerants during the maintenance, service, repair, and disposal of appliances, and to restrict the sale of these refrigerants. The general requirement to comply with this standard appears in many air permits; however, detailed requirements are not often listed. ALL4’s A.J. Golding presented on this topic and covered common findings, which included improper/incomplete records maintained by technicians, improper disposal of refrigerant containing equipment, missing inventory of regulated equipment (containing >50 lbs. Class I or II ODS), and more.

Additionally, A.J. has provided information on some of the questions posed during the conference below:

More information on refrigerants with higher flammability or higher toxicity: For refrigerants with higher flammability or higher toxicity, there are no new or specific requirements for EPA Section 608 technician training and certification, beyond what is already required and covered in the training, and the recommendation that technicians be trained to work safely with flammable refrigerants. It is recommended that you review any specific training, certification, and management questions about refrigerants with higher flammability or higher toxicity under your current or prospective EPA-approved technician certification program.

More information on calibration requirements for recycling and recovery equipment: There are no general calibration requirements for certified recovery and recycling equipment; however, there are calibration requirements for specific components of recycling and recovery equipment such as the balance, temperature, humidity, and pressure monitoring equipment. It is recommended that you consult the EPA-approved Air-Conditioning, Heating, and Refrigeration Institute (AHRI) and Underwriters Laboratories (UL) for specific recycling and recovery equipment calibration guidance.

Risk Management Program (RMP)

The Chemical Accident Prevention Provisions under 40 CFR Part 68 require development of Risk Management Plans for facilities that use extremely hazardous substances as defined in the rule. The Safer Communities by Chemical Accident Prevention (SCCAP) Rule proposes revisions to the RMP and is intended to strengthen the existing program. The final rule is still pending but includes enhanced process safety information, safer technologies and chemical alternatives, third party compliance audits, enhanced employee participation, enhanced community notification of chemical releases, and enhanced availability of information to the public.

Common issues found at facilities under the current rule included lack of comprehensive documentation of corrective action completion from compliance audits, the audits included Process Safety Management (PSM) elements but missed the RMP requirements, and RMP submittals did not include current data (e.g., population updates, contact information, environmental receptors).

Permitting Basics: Part 3 – After You Have Your Permit

The long awaited Part 3 of the Permitting Basics series was presented during the Thursday session. We learned about the permit appeals process from SC DHEC, as well as the split of SC DHEC into the Department of Public Health (DPH) and Department of Environmental Services (DES) that becomes effective July 1, 2024. The NC Department of Justice covered the stages of a contested case for challenging air permits and a representative from Dominion covered environmental justice policy and community outreach.

Finally, ALL4’s Steve Moore reviewed common permit compliance pitfalls, where key take aways included read your permit (and then reread your permit), understand definitions of time (e.g., does “annual” mean every calendar year or every 12 months?), and watch out for programs with common compliance misses (ODS, RMP, and Reciprocating Internal Combustion Engine rules).

ALL4 looks forward to seeing you in the spring at the CAPCA technical workshop and forum in Asheville, NC or maybe even sooner at a young professionals event! If you need support with one or more of these programs or need help with air permitting and compliance in North or South Carolina, please reach out to Claire Corta at ccorta@all4inc.com or 919-578-4195.

U.S. EPA Releases Several New Documents Related to Environmental Justice Policy

On November 9th, the White House Office of Management and Budget (OMB) finalized the first major change to the cost benefit guide for regulatory changes in 20 years, including changes that address the benefits of greenhouse gas rules, and putting an emphasis on the effects of regulations on disadvantaged communities. The revised “Circular A-4”, last updated in 2003, includes a lower initial discount rate used to reduce the estimate of the future health and economic benefits of rules (thus driving those values up), and directives for agencies to weigh the possible global as well as domestic benefits of regulations. The revisions would impact draft proposals submitted after February 29th, 2024, and draft final rules submitted after December 21st, 2024. Environmentalists and public health advocates are praising the revisions, largely because of the first ever emphasis of equity as a policy goal.

On November 15th, the United States Environmental Protection Agency (U.S. EPA) issued a 130-page draft document “Technical Guidance for Assessing Environmental Justice in Regulatory Analysis,” updating U.S. EPA’s first version of the document that was issued in 2016 during the Obama administration and attempting to cement the Biden administration’s goal of having EJ at the forefront of agency decision making. According to U.S. EPA, the guidance reflects “the state of the science; new peer-reviewed agency guidance; and new terminology, priorities and direction.” According to the Federal Register Notice, the guidance discusses “technical approaches and mandates that can be used to evaluate EJ concerns for regulatory actions.”

U.S. EPA adds that the guide builds on the experience the agency has in evaluating EJ “within the rulemaking analytic process and underscores the U.S. EPA’s ongoing commitment to ensuring the just treatment and meaningful involvement of all people with respect to the development, implementation and enforcement of environmental laws, regulations, and policies.” U.S. EPA will accept comments on the proposed guidance through January 15th, 2024. This is the latest in a series of documents we’ve seen since early 2023 that have outlined how EJ matters can be incorporated into existing regulatory and policy decisions. Some of these previous documents include:

- December 2022: memorandum on Environmental Justice in Air Permitting

- January 2023: Addendum to EPA Legal Tools to Advance Environmental Justice that integrates cumulative impact assessments.

- The November 9th cost-benefit guide described earlier in this update.

- The November 16th draft Achieving Health and Environmental Protection Through EPA’s Meaningful Involvement Policy. This document updates U.S. EPA’s 2003 Public Involvement Policy.

Finally, U.S. EPA updated its draft “Guidelines for Cumulative Risk Assessment Planning and Problem Formulation” on June 16th, 2023. While the revised guide attempts to expand the evaluation of EJ considerations, it also notes that gaps exist in the ability to link demographic characteristics to environmental stressors, a concern we’ve heard repeatedly in the context of how a cumulative impact assessment (CIA), that addresses both the environmental and social stressors in a quantitative manner and could be part of a larger cumulative risk assessment, would work. As an example of these complex challenges the draft notes “To better evaluate incremental changes associated with a regulatory action, U.S. EPA program offices expressed a need for dose-response curves that vary by demographic characteristics; information on how to consider exposures during critical life stages, such as childhood; and the link between genetic factors or behaviors that could give rise to greater susceptibility. Another frequently noted methodological gap was how to incorporate non-chemical stressors into the analysis and consideration of cumulative effects.” For a more detailed look at this document, see ALL4 Technical Director Joe Sabato’s blog on this topic.

What Do these Updates Mean to You?

These federal documents all serve the continuing integration of EJ concerns into all aspects of the Biden administration’s environmental agenda. While most of these don’t directly impact industry, there could be additional EJ related requirements that get integrated into new regulations that would trickle down to permitting activities in the future, and we continue to track whether formal cumulative impact assessments eventually become a requirement and how they might be implemented.

If you have concerns about the potential implications of these documents or need help parsing through them, feel free to contact your ALL4 Project Manager or Rich Hamel. We’ll continue to monitor EJ guidance from the administration and states and the tools available to evaluate EJ concerns as they develop. We can also help you evaluate permitting risks, from EJ concerns to regulatory issues, and assist in developing a strategy to make the permitting of your project as efficient as possible.

Michigan E. coli TMDL Expanding in 2024

Earlier this month, the Michigan Department of Environment, Great Lakes, and Energy (EGLE) issued a 2024 Draft Addendum to the Statewide Escherichia coli (E. coli) Total Maximum Daily Load (TMDL) for public notice and comment. In general, a TMDL is developed when a water body, or water bodies, is identified as not meeting state or federal water quality standards. The Statewide E. coli TMDL was originally approved by the U.S. Environmental Protection Agency (U.S. EPA) in 2019 and applies broadly to the state’s surface waters, which include the Great Lakes, inland lakes, streams, rivers, wetlands, and beaches; however, only those water bodies identified in Appendix 1 of the Statewide E. coli TMDL are impacted. EGLE has already updated the Statewide E. coli TMDL in 2020 and 2022, in each case adding additional impaired water bodies, and will continue to do so every two years based on future monitoring.

What impact does this have on my facility?

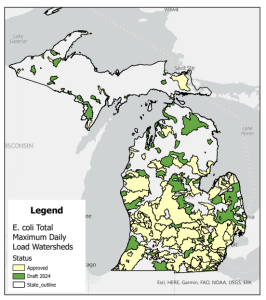

Depending on what type of permit coverage you have under the National Pollutant Discharge Elimination System (NPDES), there is likely already verbiage in your existing permit that identifies additional requirements around discharging to impaired waters, which are identified by the biennially updated Section 303(d)/305(b) list of impaired waterways. Individual and general permits for industrial, construction, and municipal stormwater and wastewater discharges have the potential to be impacted by this update. The areas identified by the 2024 Draft Addendum are identified in Figure 1 below:

Once the TMDL is approved by U.S. EPA, Michigan’s 303(d)/305(b) list will be updated to include the affected waterways. As a result, facilities with NPDES-covered discharges to those impaired waters will be required to consider E. coli in their stormwater pollutant source assessments, may have additional scrutiny of any E. coli permit limits for wastewater discharges, and in in all cases can expect to see additional language incorporated into permits around controlling discharges of E. coli.

When considering how this could impact your facility, keep in mind that NPDES permit requirements are evaluated during each permit renewal for consistency with approved TMDLs. It is also important to be aware of the additional conditions in most NPDES permits, which give EGLE the ability to require additional monitoring, request documentation above and beyond routine monitoring submittals, and even require the implementation of structural controls or treatment units.

How does my facility prepare?

Being proactive in identifying the implications of the 2024 Draft Addendum to your facility will save time, resources, and headache for you and your facility. Depending on the type of NPDES permit(s) at your facility, performing a review of your current permits, reviewing historical monitoring data, and surveying potential E. coli sources at your facility will help to assess how this change may impact your compliance status in the future.

EGLE is accepting comments on the 2024 Draft Addendum to the Statewide E. coli TMDL, which will be accepted via email to rippkem@michigan.gov until January 12, 2024. ALL4 has stormwater and wastewater experts available to assist your facility in preparing, reviewing, and submitting comments to EGLE. Our experts are also available to assist in identifying what risks are present at your facility and charting a path forward for eliminating sources of E. coli that could end up in a discharge. If you have any questions or would like to discuss how ALL4 can help you with these efforts, please reach out to Cody Fridley at 269.716.6537 or cfridley@all4inc.com.

EGLE TMDL Mapper: https://egle.maps.arcgis.com/apps/MapSeries/index.html?appid=2a060da30e25451292220861632b2c99

What Numbers Are; And What They’re Not. *Or* Why (When) Is 12 Times 12 Not 144

In 1963 and 1964, I was in 3rd Grade, and Mrs. Waugh taught me my 12-times tables. And I learned that 12 times 12 is 144. So, what am I going on about? Let me throw out three different questions:

How many is a dozen dozen eggs? (A gross)

If a single egg weighs 12 ounces, how much does a dozen eggs weigh?

And a more focused question for us, if the regulation says do not exceed 1.2, is a measurement result of 1.24 failing?

Well, Gene, you’re saying to yourself, 144 in the first two cases, and yes. Duh…

Not so fast.

Yep. A dozen dozen eggs is exactly 144 eggs. We have exactly 12 eggs in the dozen and exactly 12 dozen eggs.

Let’s look at the single egg. There’s two points to be made here: 1) We weighed this with a scale that measures to the nearest ounce and 2) we only weighed one egg. So, what we know, in a little more detail, is that our 12-ounce egg is somewhere between 11 and 13 ounces (big egg, right?). 12 eggs is somewhere between 132 and 156 ounces. Not 144 ounces.

Before we unpack the egg story, let’s explore an analogy. We all know how to tell time. And we all know that there are different meanings depending on how you say what time it is. Or what time you’ll do something:

- 10:15 is the same time as “quarter after ten”. But we don’t think about it in the same way. Is quarter after ten somewhere between 10:00 and 10:30, while 10:15 is between 10:10 and 10:20?

- “Come by the house at 10:15” feels different than “we’re serving brunch at 10:15”

- 10:15 sounds “sloppy” and 10:16 sounds “tight”. 10:15 has some slop with it (between 10:10 and 10:20) but 10:16 just sounds way tighter.

- Of course, if you’re cooking to a clock, and it’s supposed to be done in 7 minutes, and you look at your watch at 10:08, then 10:15 means 10:15, sharp.

Our point here is that what the number means (to you, to me) is somewhat contextual, based on the conversation, and based on the way the number is presented. Perhaps this provides a little background for a more detailed, more geeky conversation about measurements and calculations.

What happened with our eggs? We accounted for measurement uncertainty. That’s a big-word way of saying we understand the difference between “exactly 12” and a “fuzzy, measured 12”. I turned around the value we have (12), to assess what the value is not (11 or 13). When I think about it that way, I don’t want to claim that my dozen eggs weighs 144 ounces, and by implication, not 143 or 145 ounces.

Now, let’s think about what 140 means. In this context, it means “not 130” and “not 150”, while 144 implies “not 143 and “not 145”. If we look at my dozen eggs above, “not 130 or 150” seems like a lot better expression of the true value and possible range (132-156) than not “143 or 145”.

Okay Gene, I follow you this far, but how do I reflect this uncertainty in my calculations and expression of values? There is a formal statistical tool. We use words like “error”, “standard deviation”, and “confidence interval”. For every value you use in a calculation, you need to have (derive or assign or measure) an uncertainty, and then propagate that uncertainty across the calculation. Excel can do that for you (I think), but do you really want to do this? Hint: NO. There’s also a less formal, shortcut tool called “significant figures (sigfigs)”. Most of us learned this, and how to use it, but never really explored the reason why it works or how it reflects the idea of propagated uncertainty.

There are simple rules of sigfigs, different for multiplication and addition. For multiplication (or division), you simply count the number of sigfigs in your starting value(s) and use the smaller number in the result. 37/59 becomes 0.63; 37/59.04 is likewise 0.63.

37/59 = 0.63 ( between 36/60 = 0.600 and 38/58 = 0.655 )

Interestingly

37/59.04 = 0.63 ( between 36/59.05 = 0.610 and 38/59.03 = 0.644 )

Understanding why we use the lowest number of significant figures is left as an exercise for the reader.

For addition (or subtraction), it has to do with the relative magnitudes. Here’s an example: 0.34 + 0.0684 is 0.41.

0.34 + 0.0684 = 0.41 ( between 0.33 + 0.0683 = 0.3983 and 0.35 + 0.0685 = 0.4185

Even though one value had 2 significant figures, and the other 3, the assigned number of significant figures is associated with the “hundredths” value of 0.34. Said more formally, the final result is rounded to the same number of decimal places as the number with the least decimal places. In our case, 0.34 has the fewest decimal places and is used to define the significant figure in the final sum.

Is this a perfect solution? No. Sigfigs is a shortcut and an approximation. If you look a little closer, you note that the relative magnitude of the implied uncertainty changes with the size of the value; 84 (not 83 or 85) has a lot less uncertainty than 27 (not 26 or 28), despite having the same numbers of significant figures). And if you’re just looking at 470, do you know if it’s 460-480 or 469-471? And for that matter, the approach is a bit stilted. What if your reality is 465-475?

What’s the takeaway on this? Let’s try to be cognizant of the significance of the values used in a calculation. Don’t just put in 0.7024 because that’s what the calculator says. Think about what you’re implying with your number, and what your reader/user can infer from the number you present.

Does it matter? It matters to us. We want it to matter to you. When you see a permit or regulation that tells you that a limit is 30.47 pounds per hour, be cognizant that whoever wrote that likely didn’t understand what we just explained.

Hey Gene, you missed a question. That one above about 1.24 being passing if the limit is 1.2. There is a reference¹ that all EPA specifications are to be considered to be to (at least) two significant figures. That means that we round our result to the same two significant figures. If the limit is 1.2, that means 1.2, and not 1.20, and we are to round our result to the same level. 1.24 rounds to 1.2 and is passing. (However, if the limit in your permit is 1.20 and not 1.2, then 1.24 is not passing.)

A frequent question is “should we round and then calculate or calculate and then round?” Best Practice is to do all the calculations using unrounded values, and then round all values for presentation only at the final stage. An unavoidable consequence of this is that there may be rounding errors in the final presentation table. That is, it may not be possible to exactly reproduce the values in a table if all of them have been rounded for presentation. You might want to note that in a footnote.

In Summary…

Thanks for hanging with us all the way to the end. Talking about numbers/values – what they are, what they’re not – can get twisty and uncomfortable sometimes. We hope it’s a bit clearer, and that the concept of uncertainty, because that’s the heart of this, rings a bit truer. If you want to explore this, or any other data interpretation or use, feel free to contact either of us:

- Gene Youngerman, PhD Chemist and unrepentant science geek, 40 years experience doing stack testing and complex measurement programs. gyoungerman@all4inc.com, 512.649.2571

- Aditya Shivkumar, MS Environmental Engineer and data enthusiast, 9 years experience in data handling, statistical analysis, and environmental compliance. ashivkumar@all4inc.com, 281‑201-1239

¹https://www.epa.gov/sites/default/files/2020-08/documents/tid-024.pdf

2023 CA Recycling Exclusions Guide Part 1: Find the Right Hazardous Waste Exclusion for Your Site Today

Did you know that California has created exclusions from hazardous waste requirements in order to promote recycling at your business? If your business is generating hazardous waste that are able to be recycled on site or shipped off site for recycling, this waste stream may qualify for a recycling exclusion from hazardous waste regulations. Qualifying for a recycling exclusion can alleviate your business of training, inspection, and reporting requirements if certain criteria are met and the material is managed in accordance with the recycling exclusion requirements. In addition to the reduced regulatory burden, these exclusions can reduce the fees associated with generating hazardous wastes, like generator fees, environmental fees, manifest fees, tax fees, transportation fees and disposal fees. Plus, recycling your materials can boost your company’s Environmental, Social, and Governance program!

We have identified 19 categories of recycling exclusions and outlined the key qualifications for each category below. Skim through the categories to find out if any of your materials could qualify for a recycling exclusion and reach out to Meredith Garrett so that we can discuss this potential and strategize!

Note that this is not a comprehensive list of requirements for managing your recyclable materials, as additional conditions apply in order to comply with the exclusion requirements. Be on the lookout for more ALL4 articles discussing the dos and don’ts for managing your excluded recyclable materials.

Materials Recycled or Reused Onsite Only

-

- Materials recycled and used at the site where the material was generated1. Materials covered by this exclusion may be recycled or reused through a process called reclamation. Reclamation is when a material is treated to recover a usable product, or that it is regenerated. An example of reclamation is the regeneration of spent solvents through a purification process. This exclusion only applies to materials that may otherwise be categorized as non-RCRA hazardous wastes.

- Materials returned to the original process from which it was generated2. Materials that may qualify for this exclusion must be returned to the original process at the site where the material was generated. The material must substitute a principal raw material feedstock without first being reclaimed.

- Reclaimed secondary materials returned to the original process in a “closed loop”3. Materials in this category are returned to their original process from which they were generated in a closed loop system and are reclaimed. The entire process must be closed by entirely connected pipes, conveyances, and tanks. Reclamation of the material must not involve flame combustion such as in boilers, furnaces, or incinerators and the material must not be used to produce a fuel, or used to produce products that are used in a manner constituting disposal.

- Coolants, lubricants, and cutting fluids4. These materials may be excluded from hazardous waste regulations under certain scenarios when they are not considered a “discarded” material. The material must be necessary to the operation of the manufacturing equipment and be processed to extend the life of the material for continued use. It must be processed in the same manufacturing equipment in which the material is used or in connected equipment that returns the material to the originating manufacturing equipment for continued use.

- Intermediate manufacturing process streams4. Materials included in this category are produced as a part of a manufacturing process, reused in a manufacturing process that is designed for its use and is not accumulated in amounts greater than can be used in the manufacturing process. The material cannot be handled, stored, or processed in a manner that is inconsistent with its intended use or the operating requirements of the manufacturing process.

Materials Recycled or Reused Offsite or Onsite

-

- Materials used or reused as an ingredient to make a product2. This exclusion applies to ingredients used in an industrial process to produce a product. The material can either be recycled at the site where the waste is generated or at an offsite permitted recycling facility. This exclusion does not apply to reclaimed materials.

- Materials used as a safe and effective substitute for a commercial product2. The material can either be recycled at the site where the waste is generated or at an offsite permitted recycling facility. This exclusion applies to materials that would otherwise be categorized as either a RCRA or non-RCRA hazardous waste but does not apply to reclaimed materials.

- Material transported between two locations operated by the entity who generated it and recycled at the second site1. This exclusion applies to materials that would otherwise be categorized as non-RCRA waste, not RCRA waste, that is transported between two locations operated by the company who generated the material. The material is recycled at the site that it is transported to. Recordkeeping and transportation requirements apply.

- Material transported between two locations operated by the person who generated it and then shipped for offsite recycling1. This exclusion applies to materials that would otherwise be categorized as non-RCRA waste that is transported between two locations operated by the company who generated the material. The material is then shipped offsite for recycling to a permitted recycling facility. Recordkeeping and transportation requirements apply.

- Non-RCRA materials used or reused as an ingredient to make a product1. This exclusion applies to ingredients used in an industrial process to produce a product. The material can either be recycled at the site where the waste is generated or at an offsite permitted recycling facility. The material may be treated by one of the following methods: filtering, screening, sorting, sieving, grinding, physical or gravity separation without the addition of external heat or any chemicals, pH adjustment, or viscosity adjustment. This exclusion applies only to materials that would otherwise be categorized as non-RCRA hazardous waste.

- Non-RCRA materials used as a safe and effective substitute for a commercial product1. The material can either be recycled at the site where the waste is generated or at an offsite permitted recycling facility. The material may be treated by one of the following methods: filtering, screening, sorting, sieving, grinding, physical or gravity separation without the addition of external heat or any chemicals, pH adjustment, or viscosity adjustment. This exclusion applies only to materials that would otherwise be categorized as non-RCRA hazardous waste.

Other Specific Wastes

-

- Used oil 5. This used oil exclusion applies to oil that has been used and, as a result of use, extended storage or spillage, has been contaminated with physical or chemical impurities. The oil must not be mixed with any hazardous waste and must not contain any of the following: antifreeze, brake fluid, other automotive wastes, fuels, or solvents. The used oil must not be disposed of or used in a manner constituting disposal. A manner constituting disposal includes directly applying the material to the land or placing the material on the land (see 22 CCR 66261.2(d)(1)(A)). The used oil must have been refined from crude oil, or any synthetic oil, must not be treated by the generator, must meet purity standards, and must comply with certain notification, testing, and recordkeeping requirements.

- A product that has been processed from a hazardous waste at a permitted Treatment, Storage, Disposal Facility1. To qualify for this exclusion the material must be used as a product or distributed/sold for use in a manner for which the product is commonly used. Additionally, the product cannot contain constituents other than those for which the material is being recycled, that render the material hazardous. This exclusion does not apply to materials that would otherwise be categorized as RCRA waste

- Chlorofluorocarbon or hydrochlorofluorocarbon compound or a combination of chlorofluorocarbon or hydrochlorofluorocarbon compounds1. This exclusion applies when the material is being reused or recycled, and is used in heat transfer equipment, including, but not limited to, mobile air-conditioning systems, mobile refrigeration, and commercial and industrial air-conditioning and refrigeration systems, used in fire extinguishing products, or contained within foam products. This exclusion does not apply to materials otherwise characterized as RCRA hazardous wastes.

- Spent sulfuric acid used to produce virgin sulfuric acid3. This exclusion applies if the waste is not accumulated speculatively. Speculative accumulation is when a material is accumulated prior to being recycled and 75% of the material in inventory on January 1 has not been recycled at the end of the calendar year.

- Pulping liquors (e.g., black liquor)3. This exclusion applies to material that is reclaimed in a pulping liquor recovery furnace and then reused in the pulping process. This exclusion does not apply if the waste is accumulated speculatively.

Refinery wastes

-

- Petroleum refinery waste containing oil that is converted into petroleum coke at the same facility1. To qualify for this exclusion the material must be converted to petroleum coke at the same facility that the waste was generated at, and the resulting coke cannot be characterized as a hazardous waste. This exclusion applies to materials that would otherwise be categorized as non-RCRA wastes, not RCRA wastes.

- Oily waste, used oil, or spent nonhalogenated solvent that is managed by the owner or operator of a refinery1. The refinery generating the material must primarily process crude oil and the refinery must not be subject to permit requirements for the recycling of used oil, of a public utility, or of a corporate subsidiary, corporate parent, or subsidiary of the same corporate parent of the refinery or public utility. The exclusion only applies to material that is either burned in an industrial boiler, an industrial furnace, an incinerator, or a utility boiler that is in compliance with all applicable federal and state laws or is recombined with normal process streams to produce a fuel or other refined petroleum product. The material must be managed at the site where it was generated, or another site owned by the same entity. This exclusion applies to materials that would otherwise be categorized as non-RCRA wastes, not RCRA wastes.

- A fuel that is transferred to, and processed into, a fuel or other refined petroleum product at a petroleum refinery1. This exclusion applies to fuel that has been removed from a fuel tank and is contaminated with water or nonhazardous debris, of not more than 2 percent by weight, including, but not limited to, rust or sand. The exclusion also applies when the fuel has been unintentionally mixed with an unused petroleum product. This exclusion does not apply to materials that would otherwise be categorized as RCRA waste.

Did you find the exclusion right for you?

ALL4 can provide you with regulatory guidance, training, standard operating procedures, compliance evaluations and more to help your site qualify for the exclusions! Reach out to Meredith Garrett at mgarrett@all4inc.com or 909.477.7132 to get started today.

1HSC section 25143.2(d)

2HSC section 25143.2(b)

3CCR section 66261.4

4HSC section 25124(c)

5HSC section 25250.1

Proposed Amendments to National Emission Standards for Hazardous Air Pollutants: Rubber Tire Manufacturing

On November 16, 2023, the U.S. Environmental Protection Agency (U.S. EPA) published a proposed rule that would establish first time emissions standards for the rubber processing subcategory in the National Emission Standards for Hazardous Air Pollutants (NESHAP) for Rubber Tire Manufacturing (40 CFR Part 63, Subpart XXXX). This is the only subcategory in the Tire NESHAP that currently has no emissions standards. With the proposed rule, U.S. EPA is responding to the April 2020 decision by the U.S. Court of Appeals for the District of Columbia that obligates U.S. EPA to address unregulated HAP emissions from a source category when the Agency conducts the 8-year technology review required by the Clean Air Act (CAA) Section 112(d)(6).

Does this proposal apply to me?

If you are a HAP major source rubber tire manufacturing facility and you’re reading this article, then you probably already know that your facility is subject to this rule. So, the question then becomes, what part of my process will be subject to the proposed amendments? The subcategory in question here is the “rubber processing” subcategory, which includes rubber mixing. Any rubber mixer on site at your major source facility would be affected by the proposed amendments. Any existing source at the time of the proposed rule (i.e., sources that commenced construction or reconstruction on or before November 16, 2023) would be required to comply with the new standards within 3 years of publication of the final rule, while any source that commenced construction or reconstruction after the proposed rule would have to comply with the new standards upon startup.

What are the Proposed Amendments?

Emissions standards

To regulate the emissions of HAP from rubber mixing, U.S. EPA has proposed to set limits on total hydrocarbons (THC) and filterable particulate matter (fPM). U.S. EPA is proposing to use THC as a surrogate for organic HAP and fPM as a surrogate for metal HAP. U.S. EPA is proposing separate THC emissions limits for silica containing tire compounds and non-silica containing tire compounds based on the Agency’s assertion that there is a difference in emissions between the two. The limit proposed for existing sources is 9.4 grams of THC per megagram (g THC/Mg) rubber processed for silica-containing compounds and 45.4 g THC/Mg rubber processed for non-silica containing compounds, both on a 15-day rolling average. New sources have more stringent proposed limits based on the single best performing mixer from the dataset U.S. EPA reviewed. These limits are 2.1 g/Mg for silica-containing compounds and 17.2 g/Mg for non-silica containing compounds. U.S. EPA is proposing a fPM limit of 1.70 g fPM/Mg rubber processed or 0.37 g metal HAP/Mg rubber processed. These proposed limits would apply to both new and existing sources and the facility has the choice to decide which one to comply with.

Initial and Continuous Compliance Requirements

Initial compliance with the new emissions limits would be demonstrated via performance testing within 180 days of startup for new sources and within 3 years of the date of the final rule for existing sources. U.S. EPA is proposing that sources would conduct subsequent performance tests every five years. Additionally, U.S. EPA is proposing that a THC continuous emissions monitoring system (CEMS) must be installed at each mixer exit to continuously monitor THC emissions. U.S. EPA is also proposing that facilities would be required to monitor and record their production rate and type (e.g., lb/hr and silica or non-silica) in order to calculate production-based THC emissions on a 15-day rolling average. There are no emissions averaging provisions proposed, so compliance would be demonstrated for each individual mixer.

If facilities use a thermal oxidizer to control THC emissions, U.S. EPA is proposing that, in addition to a THC CEMS, sources will be required to continuously monitor the firebox temperature and maintain the temperature above the level established during the performance test on a daily average basis. U.S. EPA is also proposing that facilities install and operate a bag leak detection system (BLDS) on any fabric filters used to control fPM/metal HAP emissions. Compliance reports and notifications will be submitted electronically through U.S. EPA’s Compliance and Emissions Data Reporting Interface (CEDRI).

What’s next?

Comments are due to U.S. EPA on the proposed rule by January 2, 2024, although it is likely that commenters will request a comment period extension given the volume of data required to be reviewed and the impending holidays. U.S. EPA has not yet analyzed all emissions data received from their information collection request (ICR) and must do so (as well as analyze any data received during the comment period) before publishing a final rule; therefore, we expect the standards may change significantly in the final rule. Once the final rule is published, each major source facility with rubber mixers will need to determine what new standards and requirements apply and how to comply with them by the compliance date. ALL4 can assist facilities with understanding these new regulatory requirements, planning for compliance, reviewing emissions test data, obtaining vendor quotes for new emissions control systems, setting up new monitoring systems, establishing electronic compliance systems, and compliance reporting. If you have any questions, feel free to reach out to me at bjohnson@all4inc.com or (502) 874-4500 or to Philip Crawford at pcrawford@all4inc.com or (984) 777-3119.