Fuel Flow Monitoring Systems Part 1: Common Types and Uses

Fuel flow monitoring systems measure the amount of fuel consumed by a process and are typically used to measure gaseous or liquid fuels. There are many types of fuel monitors used in practice – differential pressure, coriolis, and ultrasonic are some of the most common measurement methods. The use of fuel flow monitors can go beyond just the obvious (i.e., measure flow). This article will cover some of the common types and uses for a fuel flow monitor. In Part 2 of this series, we will discuss common challenges and best practices to keep the monitoring system running smoothly.

Fuel Flow Monitor Types:

Let’s start first by discussing the most common types of fuel flow monitors and how they are typically used.

Differential pressure: The most common types of differential flow meters are orifice plate, venturi, and nozzle meters. Differential pressure monitors operate by measuring the difference in pressure between two points in the fuel system, usually before and after a restriction in the flow path. The pressure differential is proportional to the fuel flow rate and can be converted into a digital or analog output for display or further processing. Differential pressure meters have sensors that measure the pressure drop, temperature, and upstream pressure to calculate fuel flow rate. The sensors or the transmitters should be calibrated periodically to maintain their accuracy. Sensor or transmitter calibration can be completed while the meter is installed. In addition, the primary element i.e., equipment introducing flow restriction should be inspected for damage.

Coriolis: Coriolis monitors measure the mass flow rate of a fluid by utilizing the Coriolis effect. The Coriolis effect is a physical phenomenon that occurs when a mass is moving in a rotating reference frame. In the case of Coriolis monitors, the rotating reference frame is created by a vibrating tube through which the fluid flows. As the fluid passes through the vibrating tube, it causes the tube to twist, and the degree of twisting is proportional to the mass flow rate of the fluid. The monitor then measures this twist and calculates the mass flow rate of the fluid. Coriolis monitors are highly accurate. The installation and the orientation of the meters can vary depending on the type of fuel being measured. Typically, Coriolis monitors are removed from the flow path and sent to a laboratory for calibration.

Ultrasonic: Ultrasonic monitors measure fluid flow by utilizing the transit time or Doppler effect of ultrasonic waves. The monitors transmit ultrasonic waves through a fluid and measure the time it takes for the waves to travel a known distance. Ultrasonic monitors are non-invasive, meaning they do not require insertion into the pipe and do not affect the fluid flow. Ultrasonic meters are also used for stack flow measurements. Typically, ultrasonic meters are removed from the flow path and sent to a laboratory for calibration.

Common Uses:

Regulatory compliance: Data from fuel flow monitors may be used to demonstrate compliance with operating limits in a facility’s permit(s). For example, a common limit in air quality permits is maximum heat input to a process unit. Typically, heat input is calculated using a measured fuel consumption rate and an appropriate fuel heat content. Alternatively, the permit may limit the amount of a certain fuel that may be fired over a certain period of time. In addition, a fuel flow rate is often used to calculate emissions (either to demonstrate compliance with emissions limits or to meet other emissions reporting requirements), in combination with a monitored emissions concentration using an appropriate f-factor, or with a published emissions factor. The quality of the fuel flow data is important because the plant manager must certify compliance with applicable requirements in the permit.

Emissions budget programs: Fuel flow meters provide the necessary inputs to calculate the total mass emissions reported to federal or regional emissions budget programs such as the Acid Rain Program (ARP), Cross State Air Pollution Rule (CSAPR), or Regional Greenhouse Gas Initiative (RGGI). With the rising costs of emissions allowances, the quality of fuel flow data is even more important, as it has a significant impact on the number of allowances required to be purchased and ultimately, the operating cost of a plant.

Regulatory greenhouse gas (GHG) emissions reporting: The data collected by a fuel flow meter may be used to report GHG emissions under federal (40 CFR Part 98) and state specific GHG programs. GHG emissions calculated using calibrated fuel flow meters are more accurate and representative of actual emissions than default emissions factors.

ESG and sustainability performance indicators: Continuous monitoring systems are increasingly becoming a key source of data for ESG and sustainability initiatives. Data from fuel flow meters are directly used to measure carbon footprint, resource utilization, and process efficiency. As sustainability metrics become more relevant, the quality and accuracy of the data collected by the monitoring systems becomes more important. Stakeholders such as executive management, lenders, investors, and the public are increasingly interested in data sources feeding ESG metrics.

Facility Operations: Fuel flow rates are used for managing process operations. The flows also serve as an indicator of process efficiency and reliability. Typically, fuel flow rates represent the input to a process that can be compared with the output for understanding process efficiency. Sensitivity of process output to the input fuel flow can be used as an indicator of process reliability and functionality.

If you have any questions about fuel flow monitoring systems, please contact me at ashivkumar@all4inc.com. ALL4 has supported a variety of industries with implementing monitoring programs and developing data-driven solutions for maintaining compliance, optimizing operations, and meeting sustainability goals.

Top Takeaways from the IPCC’s AR6 Synthesis Report: Climate Change 2023

On March 20, 2023, the United Nations Intergovernmental Panel on Climate Change (IPCC), the world’s leading authoritative body on climate science, released its final installment of its Sixth Assessment Report (AR6) which is the AR6 Synthesis Report: Climate Change 2023. The IPCC started releasing their assessment reports on climate change beginning in 1990 and are the main resource for policymakers for understanding the current state of global climate change. The latest AR6 report has taken the IPCC eight years to complete and is the final report in its current reporting cycle with the next round of reporting expected in the 2030’s. The AR6 Synthesis Report was developed based on the content in the three Working Group Assessment Reports: Working Group I – The Physical Science Basis, Working Group II – Impacts, Adaptation and Vulnerability, Working Group III – Mitigation of Climate Change, and the three Special Reports: Global Warming of 1.5°C, Climate Change and Land, and The Ocean and Cryosphere in a Changing Climate. These reports were published by the IPCC between 2018 and 2022.

The changes we are experiencing on planet Earth due to global warming have been well documented by the IPCC in their assessment reports with the most recent AR6 reports painting a grim picture of the future if we continue on our current path. The AR6 Synthesis Report is being described as a final warning to society that the window to mitigate GHG emissions needed to advert catastrophic climate change is closing, and that efforts to adapt to climate change will only become more challenging in a warmer future. The AR6 Synthesis Report provides an overview of the status of global climate change with an outlook for the future with recommendations. Below is a summary of the top takeaways of the report broken down by each section.

Section A: Current Status and Trends

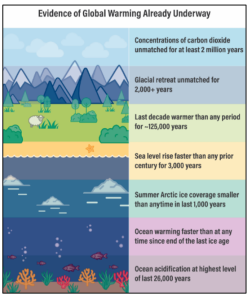

Human-induced global warming, which has already reached 1.1 degrees Celsius, has spurred changes to the Earth’s climate that are unprecedented in recent human history. Human activities, primarily through greenhouse gas (GHG) emissions, have unequivocally caused global warming, with global surface temperatures reaching 1.1 degrees Celsius above preindustrial (1850-1900) levels. GHG emissions have continued to rise due to the continued use of fossil fuels, unsustainable land use practices, and other unsustainable patterns of consumption and production. These disparities exist across all regions, between and within countries, and among individuals. The graphic below highlights the IPCC’s key findings of evidence that global warming is already underway.

https://www.wri.org/insights/ipcc-climate-report

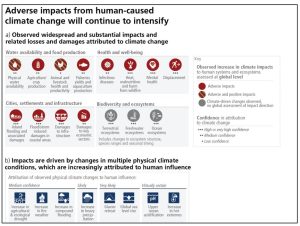

The widespread and rapid changes in our environment have led to a range of unfavorable impacts on the planet, with vulnerable communities disproportionately being affected. While adaptation planning and implementation have progressed, adaptation gaps persist and will grow if current human-induced GHG emissions rates continue without mitigation. Some ecosystems and regions have already reached their limits for adaptation, and maladaptation, the failure to adapt or adjust adequately or appropriately, occurs in specific sectors and regions. Furthermore, the financial support for adaptation remains insufficient, especially in developing countries.

The current Nationally Determined Contributions (NDCs) suggest that global warming will likely exceed 1.5 degrees Celsius during this century, making it more difficult to keep global warming below 2 degrees Celsius in the future. The projected GHG emissions from existing policies and financial institutions are currently not enough to meet the climate goals across all sectors and regions, highlighting the need for urgent accelerated action. The following graphic taken from the AR6 Synthesis Report describes how the adverse impacts from human-caused climate change will continue to intensify and evolve if no action is taken by society to curb GHG emissions.

https://report.ipcc.ch/ar6syr/pdf/IPCC_AR6_SYR_SPM.pdf

Section B: Future Climate Change, Risks, and Long-Term Responses

Climate-related risks are now higher than assessed in previous IPCC reports, with long-term impacts up to multiple times higher than currently observed. These risks escalate with each increment of global warming and will increasingly interact with non-climatic risks, creating compound and cascading effects that are more complex and more challenging to manage. Each additional increment of global warming that we experience will result in the intensification of multiple concurrent hazards. Avoiding these impacts will require deep, rapid, and sustained reductions in GHG emissions now. These reductions could begin to slow global warming within two decades and lead to noticeable changes in atmospheric composition within a few years. The United Nations Secretary-General Antonio Guterres remarked on the AR6 report findings stating that “the climate time bomb is ticking. But today’s IPCC report is a how-to guide to defuse the climate time bomb. It is a survival guide for humanity… as it shows, the 1.5°C limit is achievable. But it will take a quantum leap in climate action.”1

According to the Synthesis Report, some future changes in our climate are unavoidable or irreversible but can still be limited by significant GHG emissions reductions. With higher global warming levels, the likelihood of abrupt or irreversible changes increases, as does the probability of low-likelihood outcomes associated with potentially severe adverse impacts. The Synthesis report demonstrates that some climate impacts are already so severe they cannot be adapted to, leading to greater losses and damage. As global warming continues to increase, adaptation options will become constrained and less effective. Losses and damage will rise, and additional human and natural systems will reach adaptation limits. Maladaptation can still be avoided through the implementation of comprehensive adaptation actions. This will require multi-sectoral and inclusive, long-term planning and implementation. However, this will also bring co-benefits across various sectors and systems.

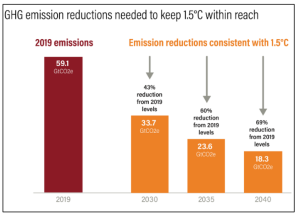

Limiting human-caused global warming will ultimately require net-zero carbon dioxide (CO2) emissions. Cumulative carbon emissions, and actions to start making significant carbon reductions, during this decade will largely determine whether warming can be limited to 1.5 degrees Celsius or even 2 degrees Celsius. “The IPCC finds that there is a more than 50% chance that global temperature rise will reach or surpass 1.5 degrees Celsius [before] 2040 across studied scenarios, and under a high-emissions pathway, specifically, the world may hit this threshold even sooner, [before] 2037. Global temperature rise in such a carbon-intensive scenario could also increase to 3.3 degrees Celsius to 5.7 degrees Celsius by 2100. To put this projected amount of warming into perspective, the last time global temperatures exceeded 2.5 degrees Celsius above pre-industrial levels was more than 3 million years ago.”2 The following graphic shows the GHG emissions reductions needed to keep the 1.5 degrees Celsius goal within reach.

https://www.wri.org/insights/2023-ipcc-ar6-synthesis-report-climate-change-findings

Without abatement, the existing fossil fuel infrastructure would result in projected CO2 emissions exceeding the remaining carbon budget for the 1.5 degrees Celsius pathway. Therefore, the world must rapidly shift away from burning fossil fuels which the IPCC considers the number one cause of the climate crisis. Modelled pathways to limit warming to 1.5 degrees Celsius or 2 degrees Celsius involve rapid, deep, and in most cases, immediate GHG emissions reductions in all sectors this decade. Global emissions are required to reach net-zero CO2 in the early 2050’s for 1.5 degrees Calcius pathways and the early 2070’s for 2 degrees Celsius pathways. If warming exceeds a specified level like 1.5 degrees Celsius, it could be gradually reduced by achieving and sustaining net-negative global CO2 emissions. This would require additional carbon dioxide removal, leading to greater feasibility and sustainability concerns. The AR6 Synthesis Report highlights that technology like carbon removal and the development of alternative low carbon fuels for transportation are now essential to limit the global temperature rise to 1.5 degrees Celsius.

The AR6 Synthesis Report now acknowledges the probability of a climate overshoot. Climate overshoot is the period in which warming increases past the 1.5 degrees Celsius threshold and then cools back down to a steady-state level below the 1.5 degrees Celsius threshold. “About 90 percent of climate models predict a period of climate overshoot, with years if not decades of higher global temperatures, before stabilizing at 1.5°C.”3 Climate overshoot would mean long periods of higher global temperatures that could result in catastrophic climate change. The additional climate-related risks for human and natural systems increase and are less predictable depending on the magnitude and duration of the overshoot.

Section C: Urgency of Near-Term Integrated Climate Action

The AR6 Synthesis Report states that climate change poses a dire threat to human well-being and planetary health, with a fast-shrinking window of opportunity to secure a livable and sustainable future for all. Swift and comprehensive climate action, this decade, could greatly reduce the projected losses and damages for humans and ecosystems in the future, while also providing numerous co-benefits such as improved air quality and health. However, delayed action could result in significant costs and irreversible consequences now, and for thousands of years into the future.

Achieving a sustainable future requires rapid, far-reaching transitions across all sectors, with the utilization of a diverse array of mitigation and adaptation strategies. Effective climate action is enabled through political commitment, well-aligned governance, institutional frameworks, and enhanced access to finance and technology. Clear goals, coordination, and inclusive governance processes facilitate impactful climate action, with regulatory and economic instruments playing a pivotal role. Equity, climate justice, and social inclusion are critical in driving ambitious climate actions and climate-resilient development, as support for the most vulnerable regions and populations is paramount. Climate change, as well as our collective efforts to adapt to and mitigate it, will exacerbate inequity should we fail to ensure a just transition.

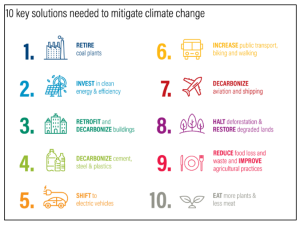

Climate resilient development benefits from incorporating diverse knowledge sources. Financing, technology, and international cooperation are essential for accelerated climate action. To achieve climate goals, both adaptation and mitigation financing must increase exponentially. While there is sufficient global capital to close investment gaps, barriers to redirecting capital to climate action must be addressed. Enhancing technology innovation systems and international cooperation through various channels will be key to driving global climate action forward. The graphic below from the World Resources Institute summarizes ten key solutions highlighted in the AR6 reports that will be needed to mitigate climate change and keep the planet on the 1.5 degrees Celsius pathway.

https://www.wri.org/insights/2023-ipcc-ar6-synthesis-report-climate-change-findings

If you are interested in learning more about how ALL4 can assist your company with emissions reduction strategies, net-zero goals, or adaptation, please reach out to ALL4’s James Giannantonio, Managing Consultant of ESG & Sustainability, at jgiannantonio@all4inc.com.

Sources:

- https://report.ipcc.ch/ar6syr/pdf/IPCC_AR6_SYR_SPM.pdf

- https://www.ipcc.ch/report/ar6/syr/

- https://www.wri.org/insights/ipcc-climate-report

- https://www.wri.org/insights/2023-ipcc-ar6-synthesis-report-climate-change-findings

- https://www.weforum.org/agenda/2023/03/climate-change-ipcc-emissions-risks-net-zero/

- https://www.ipcc.ch/about/history/#:~:text=In%201990%2C%20the%20First%20IPCC,consequences%20and%20requiring%20international%20cooperation

- https://www.edie.net/we-need-to-change-course-urgently-green-economy-responds-to-ipcc-report/

- https://www.worldwildlife.org/stories/what-is-climate-overshoot-and-why-does-it-matter#:~:text=What%20does%20a%20climate%20overshoot,is%20called%20a%20climate%20overshoot

- [1]‘We need to change course urgently’: Green economy responds to IPCC report

- [2]10 Big Findings from the 2023 IPCC Report on Climate Change

- [3]What is climate overshoot and why does it matter?

U.S. EPA Proposes SIP Calls for States with SSM Exemption Provisions

On February 24, 2023, the United States Environmental Protection Agency (U.S. EPA) proposed to reinstate State Implementation Plan (SIP) Calls for three states and issue new SIP Calls for eight states and local jurisdictions. All of the proposed SIP Calls pertain to provisions in the SIPs that allow for excess emissions during periods of startup, shutdown, and malfunction (SSM).

This action is one of several taken by U.S. EPA regarding SIP SSM provisions since 2015, and U.S. EPA provides a timeline of those actions in the Federal Register notice for context. To summarize, in 2015 U.S. EPA reestablished and updated its policy that SIP provisions allowing for excess emissions during periods of SSM were not permissible (2015 SSM Policy) and determined that the SIPs for 45 state and local jurisdictions conflicted with that policy and were therefore substantially inadequate. U.S. EPA issued SIP Calls to require those SIPs to be updated; however, the SIP Calls for Texas, North Carolina, and Iowa were rescinded in February 2020, April 2020, and November 2020, respectively, based on regional determinations that those SIPs were not, in fact, substantially inadequate. Of note, but without getting into the details, U.S. EPA weakened its 2015 SSM Policy via an October 2020 memo, which supported the Iowa SIP Call recission, but that memo was withdrawn in September 2021.

U.S. EPA has now proposed to reinstate the SIP Calls for those three states, and to issue new SIP Calls for eight states and local jurisdictions. The table below provides a brief summary of the state and local jurisdiction SIP provisions for which U.S. EPA has proposed to reinstate or issue SIP Calls, and U.S. EPA’s reasoning for those provisions being substantially inadequate.

State/Jurisdiction |

Provision |

Inadequacy |

Reinstated SIP Calls |

||

| Iowa | IAC 567-24.1(1) | Impermissible automatic exemption

Allows for excess emissions during periods of startup, shutdown, and cleaning of control equipment. |

| North Carolina | 15A NCAC 02D .0535(c) and (g) | Impermissible director’s discretion exemption

State agency has discretion to exempt excess emissions during SSM events. |

| Texas | 30 TAC 101.222(b)-(e) | Impermissible affirmative defense

Rule contains “affirmative defenses as to civil penalties for sources of excess emissions that occur during” upsets, unplanned events, and unplanned maintenance, startup, and shutdown (MSS) activities. |

New SIP Calls |

||

| Connecticut | CT Sec. 22a-174-38(c)(11) | Impermissible automatic exemption

CO and opacity limits for municipal waste combustors (MWC) allow for defined durations of SSM to be excluded). |

| Louisiana | LA. Admin Code Tit. 33 section 917 | Impermissible director’s discretion exemption

“Authorizes a state official to grant a ‘variance’ from any generally applicable SIP emission limitation if the state official ‘finds that by reason of exceptional circumstances strict conformity with any provisions of [Louisiana’s air quality] regulations would cause undue hardship, would be unreasonable, impractical or not feasible under the circumstances.’” |

| Maine | ME 06-096 Chapter 138-3-O | Impermissible automatic exemption

NOX Reasonably Available Control Technology (RACT) stationary sources using continuous emissions monitoring systems (CEMS) can exclude periods of startup, shutdown, equipment malfunction and fuel switching from 24-hour daily block arithmetic average emission rates. |

| ME 06-0096 Chapter 150-4-C | Impermissible automatic exemption

Visible emission standard for outdoor wood boilers and outdoor pellet boilers allows for defined durations to be excluded. |

|

| North Carolina | 15A NCAC 02D .1423(g) | Impermissible automatic exemption

Emission standards for large internal combustion engines allow for defined durations of SSM and maintenance to be excluded. |

| North Carolina (Buncombe County) | WNCRAQ Air Quality Code section 1-137(c) | Impermissible director’s discretion exemption

Excess emissions may be permissible if demonstrated to the Director that they are due to a malfunction. |

| North Carolina (Mecklenburg County) | MACAPCO Rule 2.0535(c) | Impermissible director’s discretion exemption

Excess emissions may be permissible if demonstrated to the Director that they are due to a malfunction. |

| Tennessee (Shelby County) | Shelby County Air Code 3-17 (City of Memphis Code 16-83). | Impermissible unbounded director’s discretion exemptions

“Allows a state official to excuse excess visible emissions after giving ‘due allowance’ to the fact that they were emitted during startup or shutdown events.” |

| Wisconsin | Wis. Admin. Code provisions NR 431.05(1) | Impermissible automatic exemption

Allows for opacity exceedances when combustion equipment is being cleaned or a new fire is being started. |

| Wis. Admin. Code provisions NR 431.05(2) | Impermissible unbounded director’s discretion exemptions

Allows for opacity exceedances from portable sources “for stated periods of time, as permitted by the department, for such purpose as an operating test, use of emergency equipment, or other good cause, provided no hazard or unsafe condition arises.” |

|

| Wis. Admin. Code provisions NR 436.03(2) | Impermissible director’s discretion exemption

Allows for emissions exceedances under defined circumstances, including when there is a correction plan; during scheduled maintenance, startup, or shutdown; or certain uses of emergency equipment. |

|

Comments on U.S. EPA’s proposed findings of substantial inadequacy and reinstatement/issuance of SIP Calls are due by April 25, 2023. In the final action, U.S. EPA will establish deadlines by which states and local jurisdictions must submit revisions to their SIPs. U.S. EPA is proposing to grant the maximum amount of time allowed by the Clean Air Act (CAA), 18 months, for states and local jurisdictions to submit SIP revisions. U.S. EPA states this timeline is appropriate “considering the affected air agencies’ need to develop appropriate regulatory provisions to address the SIP call and conduct any required processes for developing a SIP.” Indeed, in order to submit a SIP revision, states and local jurisdictions will need to propose amendments, receive and consider comments, and finalize the underlying regulations before submitting the SIP revisions to U.S. EPA for consideration.

States and local jurisdictions have discretion to decide how to address the provisions that U.S. EPA has proposed to find substantially inadequate. For example, in cases where a regulation contains an automatic exemption, they may elect to eliminate the exemption, or put an alternate standard in place. As a regulated entity, consider how the affected provisions are applicable to your operations, and how changes to those provisions may impact your operations. Stay engaged in the rulemaking process – review the proposed changes, attend public hearings, and consider submitting comments.

We will continue following this action and post an update when finalized. Please contact Lindsey Kroos or your Project Manager with questions or for support with the rulemaking process.

U.S. EPA has Finalized NOx Limits to Curb Ozone Transport from non-EGUs in 20 States

On March 15, 2023, the U.S. Environmental Protection Agency (EPA) signed a final rule titled Federal “Good Neighbor Plan” for the 2015 Ozone National Ambient Air Quality Standards” (NAAQS). This final rule contains first-time requirements to limit emissions of nitrogen oxides (NOX) during ozone season from nine types of non-electric generating units (non-EGUs) in the following 20 states: Arkansas, California, Illinois, Indiana, Kentucky, Louisiana, Maryland, Michigan, Mississippi, Missouri, Nevada, New Jersey, New York, Ohio, Oklahoma, Pennsylvania, Texas, Utah, Virginia, and West Virginia. The final rule does not include requirements for non-EGUs in Minnesota, Wisconsin, or Wyoming, differing from the 2022 proposal.

The rule establishes NOX emissions limitations and associated compliance requirements during the ozone season for the following emissions unit types for sources in non-EGU industries: reciprocating internal combustion engines (RICE) in Pipeline Transportation of Natural Gas sources; kilns in Cement and Cement Product Manufacturing sources; reheat furnaces in Iron and Steel Mills and Ferroalloy Manufacturing sources; furnaces in Glass and Glass Product Manufacturing sources; boilers in Iron and Steel Mills and Ferroalloy Manufacturing, Metal Ore Mining, Basic Chemical Manufacturing, Petroleum and Coal Products Manufacturing, and Pulp, Paper, and Paperboard Mills; and municipal solid waste combustors. The compliance date for non-EGU requirements is May 1, 2026, with an option to request an extension if it is not possible to install the required controls by then.

The rule will apply to all existing emissions units and to any future emissions units constructed in the covered states. The following table shows the final non-EGU emissions limits.

| Industry | Emissions Unit Type | Form of Final Emissions Limits | Final Ozone Season NOX Emissions Limits |

| Pipeline Transportation of Natural Gas | RICE > 1,000 brake horsepower (BHP) | Grams per horsepower hour (g/hp-hr) | Four Stroke Rich Burn: 1.0 g/hp-hr

Four Stroke Lean Burn: 1.5 g/hp-hr Two Stroke Lean Burn: 3.0 g/hp-hr |

| Cement and Concrete Product Manufacturing | Kilns with potential to emit (PTE) > 100 tpy NOX | Pounds per ton (lb/ton) of clinker | Long Wet: 4.0 lb/ton

Long Dry: 3.0 lb/ton Preheater: 3.8 lb/ton Precalciner: 2.3 lb/ton Preheater/precalciner: 2.8 lb/ton |

| Iron and Steel Mills and Ferroalloy Manufacturing | Reheat Furnaces with PTE > 100 tpy NOX | Pounds per million British Thermal Units (lb/MMBtu) | Test and set limit based on installation of low-NOX burners |

| Glass and Glass Product Manufacturing | Furnaces with PTE > 100 tpy NOX | Pounds per ton of glass produced (lb/ton) | Container Glass Furnace: 4.0 lb/ton

Pressed/Blown Glass Furnace: 4.0 lb/ton Fiberglass Furnace: 4.0 lb/ton Flat Glass Furnace: 9.2 lb/ton |

| Iron and Steel Mills and Ferroalloy Manufacturing; Metal Ore Mining; Basic Chemical Manufacturing; Petroleum and Coal Products Manufacturing; Pulp, Paper, and Paperboard Mills | Fossil Fuel-Fired Boilers ≥100 MMBtu/hr | Lb/MMBtu (30-day average) | Coal: 0.20 lb/MMBtu

Residual Oil: 0.20 lb/MMBtu Distillate Oil: 0.12 lb/MMBtu Natural Gas: 0.08 lb/MMBtu

The limits for multifuel boilers are pro-rated based on heat input. |

| Solid Waste Combustors and Incinerators | Combustors or incinerators ≥ 250 tons of waste/day | Parts per million, dry volume basis (ppmvd) | 110 ppmvd (24-hour average)

105 ppmvd (30-day average) |

Several important changes were made to the originally proposed affected sources and emissions limits between the proposed and final rules based on information obtained during the public comment period, as summarized below:

| Industry | Final Rule Revisions |

| Pipeline Transportation of Natural Gas |

|

| Cement and Concrete Product Manufacturing |

|

| Iron and Steel Mills and Ferroalloy Manufacturing |

|

| Glass and Glass Product Manufacturing |

|

| Iron and Steel Mills and Ferroalloy Manufacturing; Metal Ore Mining; Basic Chemical Manufacturing; Petroleum and Coal Products Manufacturing; Pulp, Paper, and Paperboard Mills |

|

Several additional final rule clarifications regarding the non-EGU provisions of the rule are as follows:

- U.S. EPA finalized a provision that allows a source to request approval of a case-by-case emissions limit based on a showing that an emissions unit cannot meet the applicable standard due to technical impossibility or extreme economic hardship. The request must be submitted within a year of the effective date of the final rule.

- U.S. EPA has provided a process for individual non-EGU sources to seek limited compliance extensions extending no later than 2029 based on a case-by-case demonstration of necessity.

- U.S. EPA will allow sources to rely on enforceable requirements that limit its PTE and is finalizing a regulatory definition of PTE that consistent with the definitions of that term in the Title V and NSR permit programs. However, the applicability criteria for the Cement and Concrete Manufacturing, Iron and Steel and Ferroalloy Manufacturing, and Glass and Glass Product Manufacturing industries only include enforceable PTE limits in effect as of the effective date of the final rule (60 days after it is published in the Federal Register).

- Cogeneration units are not covered under the EGU requirements but are subject to the rule if they meet the applicability criteria for boilers.

- Non-EGUs are not included in the EGU trading program.

- Emissions testing is required no more frequently than once per year and requests for alternate monitoring are allowed.

- Recordkeeping is required for exempt low-use boilers (<10% per year over three years or <20% per year, hourly basis) and emergency engines. If you exceed the 10% per year hours of operation over three years or the 20% hours of operation per year criteria, you must meet the applicable emissions limits and other applicable provisions as soon as possible but not later than one year after you exceeded the low-use boiler criteria.

- U.S. EPA did not exempt temporary boilers.

- The boiler standards apply only to boilers with a design capacity 100 MMBtu/hr or greater burning 90% or more by heat input of coal, oil, gas, or a combination of those fuels. The limit for a combination boiler is prorated based on the amount of coal, oil, gas burned, 30-day average.

- Submittal of monitoring plans, compliance reports, and emissions test data is required via the Compliance and Emissions Data Reporting Interface (CEDRI).

The final rule has not yet been published in the Federal Register, but once it does, legal action is sure to follow. If you have questions on whether your facility is covered under the final rule or need help planning for compliance, please reach out to Amy Marshall or Roy Rakiewicz.

Pennsylvania RACT III Rule – CEMS Compliance Considerations

The “RACT III” rule [25 Pennsylvania Code §§129.111-129.115, Additional Reasonably Available Control Technology (RACT) Requirements for Major Sources of nitrogen oxides (NOX) and volatile organic compounds (VOCs) for the 2015 Ozone National Ambient Air Quality Standards (NAAQS)] was approved and published in the PA Bulletin in November 2022. Facilities should already be in compliance with their applicable RACT III emission limits as the effective date was 1/1/2023. If your facility is using continuous emission monitoring systems (CEMS) for compliance with the RACT III rule, you may be unsure of the next steps or what is required for compliance demonstration. Here are some things you should be evaluating and taking action on immediately:

- Has the Data Acquisition System (DAS) been updated to account for any new averaging periods, validation/calculation changes, data substitution updates, and/or limit changes as a result of RACT III?

It is important that if these changes have not yet been implemented, they are completed as soon as possible to be able to demonstrate compliance with all presumptive and proposed alternative RACT III emission limits. This will also enable timely compliance indication for operators and environmental staff at the facility. Some facilities are submitting hardcopy quarterly compliance demonstrations directly to the Region until the time that electronic data can be submitted. - Does a Phase I Monitoring Plan need to be submitted?

We have been given guidance that Phase I Monitoring Plans will be required for any facilities that either 1) did not use CEMS to comply with RACT II or 2) need to report new information to the PA Department of Environmental Protection (PADEP) via the Continuous Emission Monitoring Data Processing System (CEMDPS) to demonstrate compliance with new RACT III limits (e.g., will need to report hourly heat input, but do not currently report that data via quarterly CEMDPS submittals).If a facility used CEMS to comply with RACT II and is already submitting the hourly data required to demonstrate compliance with the RACT III limit(s), then the changes required in CEMDPS may be able to be accomplished via administrative changes by PADEP. Facilities will need to reach out to the PADEP CEMS Section with the proposed RACT III compliance strategy.

Still unsure? ALL4 can help you evaluate whether a Monitoring Plan will be required. Note that if you are required to submit a Monitoring Plan, there is specific information that PADEP has identified that needs to be submitted related to RACT III. - How to demonstrate compliance using CEMS with alternative RACT III limits that were proposed but not yet approved?

For proposed alternative limits that have not yet been approved, changes will not yet be incorporated in CEMDPS. Facilities will need to continue to comply with and report emissions in CEMDPS in accordance with their most recent permit(s) until a permit incorporating the RACT III limit(s) is issued. If the method of compliance demonstration was not addressed in the RACT III submittal(s), we recommend working with the Region to agree on an acceptable compliance demonstration method in the interim period.

If your facility is demonstrating compliance with RACT III emissions limits using CEMS and you’re not sure of the next steps, want some additional information on the items listed herein, or need help with your next report, please reach out to me at mstroup@all4inc.com or 610-422-1140.

Considerations for Emissions Inventory Reporting in Louisiana

Facilities emitting criteria pollutants and toxic air pollutants (TAP) in Louisiana may be required by the Louisiana Department of Environmental Quality (LDEQ) to submit an annual emissions inventory (EI) using the Department’s web-based Emissions Reporting and Inventory Center (ERIC). The EI data submitted through ERIC is used by LDEQ for a variety of planning, regulatory, and reporting purposes. In addition to the electronic ERIC report, facilities are required to submit a certification statement signed by the responsible official. Emissions inventory submissions in ERIC and the signed certification are due by April 30 each year. This article highlights some things to consider while preparing your annual EI in ERIC to ensure a smooth submittal process.

Verify and Update Facility Information

Most report information can be revised within the template spreadsheet that will be uploaded to ERIC. However, there are some facility details that must be revised prior to submitting the report. These include:

- EI facility contact

- EI billing party

- Facility mailing address or phone number

- Front gate coordinates

- Ownership dates

- North American Industry Classification System (NAICS) or Standard Industrial Classification (SIC) code

Facilities can request revision to these parameters by completing the Facility Update Request Form on the LDEQ website. These updates are passed through to the ERIC platform. This year, LDEQ has indicated that these requests must be submitted before 4:00 PM on Friday April 28, 2023 or they will not be processed prior to the deadline. This information needs to be updated and correct for a complete submission.

Review Emissions Factors

LDEQ requires facilities update emissions factors each year as revised factors are published, even if those factor changes have not been used as part of recent permitting (LAC 33.III.919.G). Facilities should review factors published in AP-42 or by a trade association each year to ensure that emissions are reported correctly in the EI. It is possible that a factor change may result in reported emissions greater than permitted limits; however, LDEQ has indicated that emissions above permitted limits as a result of emissions factor changes alone are not considered a violation (LAC 33.III.501.C.12). Also make sure to apply emissions factors changes to your Toxic Release Inventory (TRI) air emissions to be consistent with what is reported in the EI.

Report the Correct Chemicals in the Correct Format

Emissions inventories in Louisiana cover criteria air pollutants as well as TAP. If an emissions source emits less than 0.005 tons of a pollutant in a year, the pollutant does not need to be reported. For chemicals that require reporting, LDEQ provides guidance for the number of significant figures that must be reported for criteria pollutants and TAP based on the maximum emissions rate and the chemical being reported. Data from facility emissions tracking workbooks may need to be manipulated to satisfy these standards when preparing a bulk upload spreadsheet for ERIC.

Prepare Certification and Potential Notifications

Although the ERIC report is submitted electronically, the certification statement still requires a wet signature. Be sure to coordinate with your facility’s responsible official because both the certification statement and the electronic submission must be completed by April 30 to be considered an on-time submittal. In addition, if there have been changes to emissions factors or estimation methods since the issuance of your Title V Operating Permit which result in a significant change in emissions, a notification should be included as part of the Title V Annual certification per LAC 33:III.501.C.13. You may also consider a permit modification to incorporate any newly published factors.

ALL4 has experience using ERIC and preparing permit applications in Louisiana. If you have questions or need help preparing your facility’s ERIC submittal or follow up permitting, please reach out to your ALL4 project manager or contact info@all4inc.com.

What Do You Need to Know About Starting a Stack Testing Program?

When your facility finds they need to do a stack test on a piece of equipment, there will be a number of questions thrown at you. Being proactive will go a long way toward having a smooth and positive experience. Here are some questions that you should ask.

Why are we testing?

Identifying why is essential. Is there a regulation or permit condition that requires a performance test? Is this a test to determine the peak performance of a unit and/or control device in terms of emissions? A pre-test for a compliance program to determine the optimal rates to run a unit? Answering these basic questions gives an idea of the length of time needed to test and the procedural obstacles that may arise. For example, a test protocol may need to be developed and submitted to the proper regulatory agency prior to any stack testing. The protocol will describe how you will run the unit during the test and how you will use the data gathered during the test. Protocol review takes time, and the reviewing agency may request changes to your test plan as a result of their review.

What pollutants and parameters are listed in the permit?

Once you know why you are testing, you will need to know what pollutants you are testing and how you will have to operate the unit during the testing. Knowing which pollutants and parameters are important, the emissions limits that apply, and how to set operating limits allows you to define the specifics of methods and implementation. The permit and any previous testing/sampling data provide the best information to define the testing scope.

What other information does the stack tester need before testing?

To successfully implement a stack testing program there are details that the stack testing company needs to be efficient and successful. Once the protocol/test plan is prepared, the stack tester will need more information on the source itself. Specifically, they will need at a minimum to know the stack dimensions and if the stack fits the needs of the testing methods. Does the stack meet the length requirements? Are the ports large enough to fit certain probes? Are there enough ports to fit each test method all at once or does the test program need to be split into test phases?

In addition, the stack testing firm will need to know some details about the facility. Will the test team be able to park a trailer near the unit or will they have to run sample lines several hundred feet away? Oftentimes the stack testing company will bring a lab trailer onsite that will need to be powered with a certain voltage. Some facilities have special welding outlets installed near where a stack testing laboratory trailer will be parked. Some trailers can only be powered by the high voltage outlets. Knowing what voltage is available to them prior to their arrival is important.

Another detail to consider – what are your facility’s safety requirements? Each facility is different, some have rigorous safety programs that can require lengthy training and require background checks and/or drug and alcohol screening before testing contractors are allowed to come onsite and do work. Some sites require specialized online training, online classes, or even ID badges before arriving on site. Having all the proverbial ducks in a row up can help prevent any delays to the start of the testing.

What process parameters need to be monitored during stack testing?

One of the trickiest things about stack testing is understanding the link between process operations during the test, permit limits, and how the process operates during non-testing days. Specific process conditions may be required to be maintained throughout the duration of the testing. Collection of data including certain temperatures, feed rates, or loads is often captured through a facility data system and may need to be recorded throughout the testing. However the process is to be run, and the process data is to be collected, details should be figured out prior to any test date, and reviewed the day(s) of the test. Making sure that all stakeholders (stack testers, unit operators, facility environmental team, etc.) are on the same page with how the process needs to be operating during the test, and the implications on operations after the test program, is a crucial part of stack testing and can make or break the success of the testing program. For example, oftentimes a process parameter rate is listed in a permit. If during a performance test that parameter is below the limit listed in that permit, then the regulating agency could either nullify the test or possibly limit the operation of the unit until the next performance test.

How can ALL4 help?

Stack testing is usually a periodic event. Facility test coordinators have a pivotal role in the success of the stack test. They have to meld together the following:

- Permit requirements

- Previous data

- Current facility operations (and operating philosophy)

- Site access

- Stack testing requirements

- Possible future operating limits

ALL4 can be a guide throughout the process of stack testing. It can be a daunting and strange process, but with some guidance, and the right questions, stack testing no longer needs to be a stressful event. Having us guide your facility through the environmental jargon and facilitate the many hurdles involved can relieve the stress stakeholders feel. Please reach out to me at 610-422-1169 or at srathfon@all4inc.com if you have any questions regarding this subject.

Air Permitting Considerations in Kentucky

After a record-setting year of economic growth in 2021 according to the Kentucky Cabinet for Economic Development (KCED), the Bluegrass State continues to experience an industrial boom. KCED indicated the bourbon, automotive, chemical, and primary metals industries are just a few of the top manufacturers in the state, and Kentucky’s enticing economic incentives are attracting more companies. As is the case across the United States, Clean Air Act (CAA) permitting may be required for new and existing facilities in Kentucky that emit regulated air pollutants. Oftentimes, the air permitting process can be difficult to navigate, especially for companies who are new to Kentucky. The goal of this article is to provide a general overview of CAA permitting in Kentucky and highlight a few key considerations.

Who Needs a CAA Permit?

Types of CAA permits include construction and operation. A construction permit may be required prior to commencing construction of a new facility or project, and an operating permit may be required for a facility to operate in compliance with the regulations set forth in the CAA. Note the Kentucky Division for Air Quality (KDAQ) issues combined construction/operating permits to all source categories while the Louisville Metro Air Pollution Control District issues combined construction/operating permits only to non-Title V sources. A facility’s requirement to obtain a CAA operating and/or construction permit depends on its design capacity, type of equipment, and corresponding potential to emit (PTE) regulated air pollutants (defined below).

The four types of CAA permits issued in Kentucky are:

- Registrations – facilities with PTE:

- ≥2 tons per year (tpy) but <10 tpy of a hazardous air pollutant (HAP),

- ≥5 tpy but <25 tpy of combined HAP,

- ≥10 tpy but <25 tpy of a regulated air pollutant, or

- The source is subject to a New Source Performance Standard (NSPS) or National Emission Standards for Hazardous Air Pollutants.

- Minor/State-Origin Permits – sources that exceed registration PTE thresholds but do not exceed major source thresholds.

- Federally Enforceable State Origin Permits (FESOP) or Federally Enforceable District Origin Operating Permit (FEDOOP) also known as synthetic minor – sources that otherwise would exceed major source thresholds but take voluntary operating restrictions so their PTE is below major source thresholds.

- Major/Title V – sources whose PTE is greater than major source thresholds.

Regulatory Agencies in Kentucky

CAA permitting in Kentucky is handled by two regulatory agencies: KDAQ and LMAPCD. LMAPCD regulates sources in Jefferson County while KDAQ regulates sources in the rest of the state. Both KDAQ and LMAPCD follow regulations set forth in the Kentucky Administrative Regulations (KAR), but LMAPCD has additional regulations specific to Jefferson County. According to KDAQ, there are no permit application fees and the maximum regulatory time frames for construction and/or operating permit issuance are:

- Registration – 60 days

- State-Origin – 120 days

- FESOP – 210 days

- Major/Title V – 255 days

A registered source may commence construction immediately upon submittal of a complete registration form to KDAQ.

According to LMAPCD, the following filing fees apply to CAA permit applications submitted during the 2023 fiscal year (July 1, 2022 to June 30, 2023):

- Registration – $622.24

- Minor – $622.24

- FEDOOP – $933.35

- Major/Title V – $1,244.48

LMAPCD does not specify any CAA regulatory timeframes for permit issuance after submittal of an application, and neither KDAQ nor LMAPCD offer a fast-track or expedited program to speed up the application review and permit issuance process. A general rule for facilities that may require a CAA permit is to begin the process as early as possible to help keep planned construction or operation on schedule.

Special Considerations

There are a few considerations that facilities will need to be aware of if they are subject to CAA permitting in Kentucky. Currently eight counties in Kentucky have designated nonattainment areas that, depending on the nonattainment status, could have different CAA permitting thresholds from those in attainment areas.

- Part of Boone County – 8-hour ozone (2015)

- Bullitt County – 8-hour ozone (2015)

- Part of Campbell County – 8-hour ozone (2015)

- Part of Henderson County – Sulfur dioxide (2010)

- Jefferson County – 8-hour ozone (2015)

- Part of Kenton County – 8-hour ozone (2015)

- Oldham County – 8-hour ozone (2015)

- Part of Webster County – Sulfur dioxide (2010)

The areas in nonattainment for sulfur dioxide do not have lower permitting thresholds, and the areas in nonattainment for 8-hour ozone are designated marginal status, so the permitting thresholds for volatile organic compounds (VOC) remain the same as those for attainment areas. However, nonattainment status and permitting thresholds can change depending on the ambient air quality, so it is important for facilities to remain up to date on the attainment status of the area where they are or will be located.

Another key consideration when evaluating CAA permitting in Jefferson County is the Strategic Toxic Air Reduction (STAR) program. LMAPCD has established the STAR program to reduce ambient air concentrations of toxic air contaminants (TAC) in Jefferson County. Facilities located in Jefferson County need to perform additional evaluations to determine if TAC emissions are de minimis. If TAC emissions are not de minimis, LMAPCD may require facilities to take additional actions, such as performing air emissions modeling, and /or implementing an Emissions Reduction Plan. Companies considering constructing and operating in Jefferson County will need to comply with all air quality regulations set forth by LMAPCD.

Summary

CAA permitting varies state by state and navigating the sea of regulations can be difficult. Kentucky’s regulatory agencies closely follow federal regulations, but there are a few additional considerations, such as county-specific nonattainment status and LMAPCD’s STAR program, that facilities will need to evaluate. Finally, it is imperative that facilities begin the CAA permitting process early, and work closely with an air quality permitting expert in order to comply with all applicable regulations and keep the project’s timeline on track. If you have questions about permitting in Kentucky, please reach out to Jason Moore at jmoore@all4inc.com.

EPA Releases Compliance Advisory for Federal Facilities Subject to CAA Chemical Accident Prevention Regulations

Introduction

The 1990 Clean Air Act (CAA) Amendments include Section 112(r), the chemical accident prevention rule, to “provide for the prevention and mitigation of accidental chemical releases”1. The rule requires owners and operators of stationary sources that produce, process, handle, or store regulated hazardous substances in amounts above threshold quantities, as promulgated under Section 112(r), to develop and implement a Risk Management Program (RMP). A RMP includes development of an accident prevention program, an emergency response program, and an offsite consequence analysis (OCA) to evaluate worst-case and alternative release scenarios. A RMP must be established prior to any regulated substances being present on-site above threshold quantities at a facility. Once a RMP is established and submitted to the United States Environmental Protection Agency (U.S. EPA), it is subject to review and renewal every five years, and includes documentation of a five-year accident history at the facility. The purpose of the RMP is to require facilities to:

- Identify the potential effects of an accidental release of a regulated substance,

- Identify the proactive actions established to prevent an accident, and

- Establish emergency response procedures in the event an accident occurs.

Development of a RMP includes consideration of the program level specific to each facility. There are three program levels under the RMP rule, with Program 1 applying to “extremely safe facilities”, Program 2 applying to facilities subject to threshold quantities that trigger Occupational Safety and Health Administration (OSHA) or U.S. EPA planning requirements, and Program 3, which applies to facilities that do not meet Program 1 requirements, but are subject to OSHA Process Safety Management (PSM) requirements. RMP requirements are specific to the applicable program level, but generally include:

- Conducting a hazard assessment,

- Developing a prevention program,

- Establishing an environmental emergency-response program, and

- Operating an overall management system.

Any facility that is required to submit an annual Toxics Release Inventory (TRI) Form R, or is subject to OSHA PSM regulations, is likely to be regulated under the RMP rule. Threshold quantities vary by the specific regulated substance, between 500 and 2,000 pounds onsite for toxic chemicals and 10,000 pounds onsite for flammable substances.

National Enforcement and Compliance Initiative

Section 118 of the CAA requires federal facilities “comply with, all Federal, State, interstate, and local requirements, administrative authority, and process and sanctions respecting the control and abatement of air pollution in the same manner, and to the same extent as any nongovernmental entity” 2, which includes the requirements for accidental releases of regulated substances under CAA Section 112(r).

The U.S. EPA has determined that many regulated federal facilities are not managing the risks associated with the handling of regulated hazardous substances, and therefore, are not adequately protecting the welfare and safety of surrounding communities. The U.S. EPA cites approximately 150 “catastrophic accidents” 3 occur each year at industrial and chemical facilities that store regulated hazardous substances. To reduce the risk to human health and the environment in communities surrounding regulated facilities, the U.S. EPA established the National Enforcement and Compliance Initiative (NECI) in 2017 to conduct inspections and enforcement activities to identify risk management inadequacies and improve safety measures at these facilities.

In February, the U.S. EPA Office of Enforcement and Compliance Assurance released a compliance advisory 4 announcing additional priority to be levied on enforcing NECI policies and associated impacts related to federal facility compliance. The NECI is intended to ensure that all federally regulated entities comply with all CAA requirements associated with handling regulated hazardous substances and, if noncompliance is identified, use enforcement authority to correct facility inadequacies and bring facilities into compliance. The compliance advisory is a notification specifically targeted to federal facilities to “promptly” address any known issues of noncompliance in operations including, but not limited to:

- Water treatment systems,

- Refrigeration systems,

- Controlled temperature laboratories, and

- Animal and plant health inspection services.

Assessing Compliance

The U.S. EPA has established the Enforcement & Compliance History Online (ECHO) tool (https://echo.epa.gov/) to facilitate the review of environmental compliance status for more than 800,000 regulated facilities. In addition, the ECHO Notify system provides weekly email notifications of changes to ECHO enforcement and compliance data, which a facility can use to find specific notifications based on options such as geographic location or facility IDs. It is recommended that federal facilities review their compliance status regularly, and if a noncompliance status occurs, to either report a data error or to take prompt corrective action to resolve the compliance delinquency.

Potential Impacts to Stakeholders

Facilities regulated under CAA Section 112(r) are required to comply with chemical accident prevention regulations – and have the responsibility to take necessary preventative or corrective actions to prevent accidental releases of regulated hazardous substances. This responsibility does not, however, fall solely on federal facilities. Facilities subject to CAA Section 112(r) are located in every state, with the risk of an accidental release of regulated hazardous substances applicable to a significant number of local communities and their populations. Facilities have the responsibility of protecting their surrounding communities and face serious enforcement actions and administrative penalties for failing to do so. In Fiscal Year (FY) 2022 alone, the U.S. EPA increased its number of on-site inspections by over 150% (compared to FY 2021) and concluded 113 administrative penalty actions to address identified violations. With increased NECI priority being placed on enforcing compliance under the February advisory, federal facilities are recommended to take prompt action to correct any compliance inadequacies to avoid costly penalties and subjecting local communities to the risk of an accident.

How Can ALL4 Assist?

ALL4 has a staff of experienced Environmental Consultants familiar with RMP assessments able to provide facilities, regardless of federal status, with evaluations and recommendations to stay current and compliant with CAA Section 112(r) requirements. Please contact ALL4 to evaluate your facility’s RMP status and address any compliance needs.

Contact Ryan Cleary rcleary@all4inc.com (919-230-0716) for more information.

[1] Accidental Release Prevention Requirements; Risk Management Programs Under Clean Air Act Section 112(r)(7); Amendments, 64 Fed. Reg. 964 (January 6, 1999).

[2] 42 U.S. Code § 7418 – Control of pollution from Federal facilities.

[3] U.S. EPA; National Enforcement and Compliance Initiative: Reducing Risks of Accidental Releases at Industrial and Chemical Facilities, https://www.epa.gov/enforcement/national-enforcement-and-compliance-initiative-reducing-risks-accidental-releases (December 22, 2022).

[4] U.S. EPA Office of Enforcement and Compliance Assurance; Federal Facility Compliance Under EPA’s National Enforcement and Compliance Initiative to Reduce Accidental Releases at Industrial and Chemical Facilities; EPA Document #315F23001 (February, 2023).

Recent Revisions to the Miscellaneous Coating Manufacturing NESHAP

On February 22, 2023, the United States Environmental Protection Agency (U.S. EPA) published a final rule that added metal hazardous air pollutant (HAP) emissions standards to the National Emission Standards for Hazardous Air Pollutants (NESHAP) for Miscellaneous Coating Manufacturing (MCM), at 40 CFR Part 63, Subpart HHHHH. Affected existing sources (those that commenced construction or reconstruction on or before June 7, 2022) must comply within one year (February 22, 2024), which includes completion of an initial performance test. New sources must comply as of February 22, 2023, or upon initial startup, whichever is later.

The amended rule requires control of MCM-subject process vessels while these units are being charged with metal HAP-containing solids (excluding solids in paste, slurry, or liquid form). After-control emissions of metal HAP-containing material are limited to no more than 0.014 grains per dry standard cubic foot (gr/dscf) for existing sources, and 0.0079 gr/dscf for new sources. For existing sources, only stationary process vessels are subject to the control requirements; for new sources, both stationary and portable process vessels are subject. Importantly, MCM-affected “process vessels” are units having a capacity of 250 gallons or more.

Facilities must demonstrate initial compliance by conducting a performance test using Method 5, which includes, in some cases, establishing operating limits for the control device. Existing facilities may provide the results of a similar Method 5 test conducted within the past five years. In all cases, facilities must conduct a repeat performance test every five years.

The amended rule requires demonstration of continuous compliance by control device parameter monitoring. Several options are provided, including the following: operation of an alarmed bag leak detection system; operation of an alarmed monitoring device (such as for pressure drop) against limits provided by the control device’s manufacturer; and operation of a continuous parameter monitoring system (CPMS). Facilities that elect a CPMS must additionally meet requirements for data availability, data averaging, etc.

In promulgating the revised rule, U.S. EPA did not extend the one-year compliance period that industry commenters had requested. This deadline is likely unrealistic for any facility that needs to install one or more control devices. Rather, U.S. EPA assumed that all needed control devices already exist at facilities that will be subject to the amended rule. U.S. EPA noted in their February 22, 2023, publication of the final rule that facilities needing to install a control device can request an additional two years to comply under 40 CFR § 63.6(i)(4)(ii). U.S. EPA additionally did not fully address industry concerns about compliance demonstrations, including how to conduct Method 5 testing of process vessels that are charged with HAP-containing dry solids either infrequently or for short durations.

Facilities that are subject to the MCM rule should determine whether dry solid materials containing metal HAP are ever added to an MCM-subject process vessel. You should verify that each such vessel is serviced by a particulate matter (PM) control device, and that it operates while the metal HAP-containing dry solids are being added. Before February 22, 2024, you will need to conduct a Method 5-based performance test of each affected control device (or provide results of a qualifying past test) and set operating parameters or otherwise meet the rule’s requirements for continuous demonstration of compliance. For any affected process vessel that is currently uncontrolled, you will need to install a PM control device or route emissions to an otherwise available PM control device.

For more information or for help assessing how the amended MCM NESHAP will affect your facility, please contact John Metzger (jmetzger@all4inc.com; 612.254.6052).