Electronic Reporting for the Secondary Aluminum Industry

As Chuck described in his January blog, the Subpart RRR amendments include provisions requiring that performance test data to be electronically submitted through the U.S. Environmental Protection Agency (U.S. EPA) Electronic Reporting Tool (ERT). While E-reporting might seem like an easy option at face value, we have found that the ERT is anything but user friendly.

So what do you actually have to do?

The rule requires that performance tests (including any associated fuel analyses) [40 CFR §63.1516(b)(3)(i)(A)] be submitted to U.S. EPA using the ERT. This does not mean just attaching a PDF copy of your test report or submitting your results – the ERT requires a whole host of information, including but not limited to the following:

- Test plan (must be completed before test results can be reported)

- Sampling location information

- Control device parameters

- Calibration gas concentrations

- Process data

Results must be submitted through ERT within 60 days after completing the performance test, so make sure to plan ahead!

If you have any questions or need help using ERT or CEDRI, please contact me at kturney@all4inc.com or (610) 933-5246 x143.

Proposed Information Collection Request for the Plywood and Composite Wood Products NESHAP and Implications for the Industry

On September 8, 2016, the U.S. Environmental Protection Agency (U.S. EPA) published a proposed Information Collection Request (ICR) for the Plywood and Composite Wood Products (PCWP) National Emission Standards for Hazardous Air Pollutants (NESHAP) (available here). U.S. EPA is asking for comments on the proposed ICR to be submitted by November 7, 2016. As it is currently proposed, U.S. EPA estimates that more than 400 facilities will receive an initial survey (Phase I of the ICR), which will request detailed information regarding PCWP facilities and their emissions sources. After evaluating the information received during Phase I, U.S. EPA may send out an additional request (Phase II) requiring that companies conduct emissions testing at selected facilities.

The proposed ICR has both short and longer-term implications. It will require facilities to devote resources in the short-term to responding to the ICR. In addition, the ICR is the first step in what is expected to be the eventual promulgation of additional NESHAP requirements for the PCWP industry. Read on to find out more about the ICR, including:

- Drivers and Goals

- Applicability

- Requested Information

- Looking Ahead

Drivers and Goals

The proposed ICR is driven in part by the requirements of Section 112(d) and Section 112(f) of the Clean Air Act, which obligate U.S. EPA to review existing NESHAP regulations to determine if any residual risk remains and if more stringent standards are needed. These are known as residual risk and technology reviews (RTR). In addition, in 2007, the District of Columbia Circuit Court of Appeals issued a remand that required U.S. EPA to develop standards for all emissions units identified in the PCWP NESHAP that do not currently have emissions limits. The proposed ICR aims to collect the necessary information to conduct the RTR and to develop emissions limits for the sources identified in the 2007 remand.

Applicability

U.S. EPA estimates that approximately 425 facilities that are either major hazardous air pollutant (HAP) sources under the PCWP NESHAP or synthetic minor HAP sources that used technology to avoid this regulation will be affected by Phase I of ICR, including facilities with the following North American Industry Classification System (NAICS) codes:

- 321113 – Sawmills with lumber kilns;

- 321211 – Hardwood plywood and veneer plants;

- 321212 – Softwood plywood and veneer plants;

- 321213 – Structural wood members, not elsewhere classified (engineered wood product plants);

- 321219 – Reconstituted wood product manufacturing; and

- 32199 – All other wood product manufacturing.

Should U.S. EPA decide to issue Phase II of the ICR, it will be sent only to selected major HAP source facilities across the PCWP industry.

Requested Information

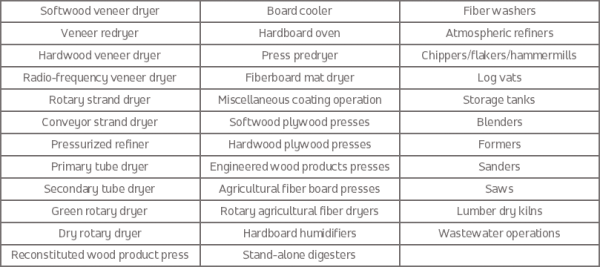

During Phase I of the ICR, U.S. EPA proposes to collect facility-level information, emissions information, compliance data, control information, and information on technological innovations in the industry. The U.S. EPA has made the proposed ICR available for review here. Most of the information is proposed to be collected in a spreadsheet to be filled out for each facility. The information proposed to be collected under Phase I of the ICR includes process flow diagrams, facility emission point maps with coordinates for each release point, and various process and emissions information for emissions units listed in the table below.

Table 1. Emission Units Covered by Phase I of the Proposed PCWP ICR

If U.S. EPA determines that emissions information collected during Phase I is insufficient to conduct the RTR and develop additional PCWP NESHAP standards, U.S. EPA plans to issue Phase II of the ICR, which will require that companies conduct emissions testing at selected major HAP source facilities. Testing would be required for a variety of sources, including dryers, coolers, presses, and other miscellaneous emissions units, and include total hydrocarbons and various hazardous air pollutants.

Looking Ahead

As mentioned above, the deadline for submittal of comments on the proposed ICR is November 7, 2016. After U.S. EPA reviews and considers the comments, a final ICR package will be submitted to the Office of Management and Budget for review and approval, at which time the U.S. EPA will issue another Federal Register notice to provide an opportunity for additional comments.

Once the ICR is finalized and sent to facilities, U.S. EPA expects to provide companies with 90 days to respond to Phase I of the ICR. PCWP facilities should start thinking about, and planning for, the response to the upcoming ICR. U.S. EPA estimates that the total time, effort, and expenditures associated with responding to Phase I of the ICR alone will add up to an average of $30,000 per facility.

In addition to the immediate impact of responding to ICR, it is expected that the data collected by U.S. EPA will ultimately be used as a basis for the promulgation of new regulations for the PCWP industry. It is too early to know what those new regulations will entail but ALL4 will be tracking both the proposed ICR and any subsequent regulatory actions, and we will be updating our blog or newsletter as new information becomes available.

ALL4 has extensive experience assisting clients in responding to ICRs, including those related to rule changes and ICRs received by companies in the context of U.S. EPA enforcement initiatives. If you have any questions about the ICR process, feel free to reach out to Colin McCall at cmccall@all4inc.com or (908) 328-9429.

So You Want to Be a Consultant, Why ALL4? (An Open Letter to College Seniors)

September is upon us and daylight is fading each day, a constant reminder of summer’s inevitable fate. Although summer is coming to a close, it allows for the beginning of something new. For you – the beginning of your final year as a college undergraduate student and the search for your first job. For me – new air quality consulting experiences thanks to the opportunities provided to me at ALL4.

I don’t know about you, but when my final year of college started, I had no idea I’d find a career as an air quality consultant. I didn’t even know what an air quality consultant actually did. What I did know was that I wanted to work as a consultant, and by the time my last year of college was over, I was lucky enough to be offered a job at a large, well-known consulting firm as a staff-level environmental engineer. That large consulting firm was not ALL4, but the year and a half I spent working as a consultant within the structure of that large firm provided me a great opportunity to gain valuable experience and insight into the consulting world. However, within two months of starting that job it was evident that opportunities for me to grow, directly impact the company, and advance within the company were limited by factors outside of my control. Whether it was due to the fact that I worked on the same types of projects day after day or because that next position was occupied by someone there for the long haul, it was evident that opportunities for me within that company were limited.

It has now been two years since I left that first consulting job to join ALL4, and I can say without question that ALL4 is very different than other consulting firms, and different in all the right ways. What makes us so unique? The one thing that stands out the most to me has to be the opportunity and variety offered to the employees at ALL4. The opportunities afforded to employees to grow, advance, and make an impact on our company are endless. If you have an idea to improve ALL4 – not only will ALL4 listen to you, they will act on it. Our principals give us the ability to voice our opinion and impact the company in a tangible way. Performance is recognized within the company and there is a certain amount of intimacy at ALL4 that is comforting in that from the technical staff, to the project managers, to the principals, we are all working together towards the same goals. We are provided opportunities to succeed, and when we do, we celebrate and recognize our individual and company success.

What about opportunities for personal growth? ALL4 trains you on the ins and outs of air quality consulting and exposes you to a variety of industries and processes that you have likely never even thought about. They give you the opportunity to attend relevant trainings and conferences, as well as explore new industries and markets that the company may have not even begun to work in yet. The opportunities at ALL4 seem endless, and as a young consultant still learning and absorbing everything I can in this career, it’s all I can really ask for.

I may not have a two-page resume of consulting experience across multiple jobs and multiple states just yet, but I have worked at different consulting firms and understand what makes ALL4 unique. If you want to learn even more about how refreshing it is to work for ALL4, feel free to reach out to me at (610) 933-5246, extension 139, or at mcarideo@all4inc.com.