Photochemical Modeling

As discussed in my recent blog, there has recently been some buzz surrounding the ozone primary and secondary National Ambient Air Quality Standards (NAAQS). Due to the proposed decrease in the ozone NAAQS and the possibility of them causing more ozone nonattainment areas, it is important to understand how the ozone NAAQS and nonattainment areas may be established using modeling techniques that are not the same as one generally uses for traditional air permitting requirements.

Ozone is a secondary pollutant; it is not generally directly emitted into the atmosphere. Ozone in the lowest levels of the atmosphere is formed through the reaction of sunlight and emissions of nitrogen oxides (NOX) and volatile organic compounds (VOC) directly in a given regional area or many miles downwind. The chemical reaction requires ultraviolet energy from sunlight, and is referred to as a “photochemical reaction.” Photochemical reactions are molecular reactions triggered by exposure to sunlight, and some of these reactions create extremely reactive molecular fragments called “radicals.” These radicals can react with VOC and NOX to form ozone. Due to the complexity of the chemistry involved in the ozone reactions, ozone cannot be evaluated using simple diffusion and dispersion (steady-state plume) algorithms (e.g., U.S. EPA’s AERMOD model). Instead, the ozone pre-cursors, the meteorological conditions, and atmospheric chemistry need to be modeled through a series of intricate equations over much larger spatial scales. As a result of the chemical complexity and the requirement to evaluate the effectiveness of future controls, U.S. EPA’s guidance strongly recommends using photochemical computer models to analyze ozone issues. Computer simulations are the most effective tools to address both the chemical complexity and the future case evaluation.

Photochemical air quality models have become widely recognized and routinely utilized tools by state regulatory agencies for regulatory analysis and attainment demonstrations by assessing the effectiveness of control strategies. The models have not typically entered into the air quality permitting process for individual facilities evaluating specific projects. These photochemical models are large-scale air quality models that simulate the changes of pollutant concentrations in the atmosphere using a set of mathematical equations characterizing the physical and chemical processes in the atmosphere. Photochemical grid models are intended to accurately depict the ways in which air pollution forms, accumulates, and dissipates by simulating the processes that are most essential in generating ozone pollution. These models have emission data from industrial sources, cars, trucks, locomotives, and many other sources that emit chemicals that lead to the formation of ozone and simulate the atmospheric reactions that result in ozone formation. The models are driven by meteorological models that are similar to those relied upon by weather forecasters because they can analyze the winds that carry pollutants to other areas around where the source is.

Ozone modeling involves two (2) major phases, the base case and the future case (with substeps in each phase). The base case evaluates procedures and ensures that the model is performing correctly. The future case evaluates the effectiveness of controls and demonstrates attainment based on how much ozone will be created in the future. A photochemical grid model simulates the atmosphere above a city by dividing it into thousands of boxes, essentially splitting it into individual grid cells that are typically a few kilometers wide. The thickness of the cells varies as the grid cells that are higher in the atmosphere tend to be thicker than the grid cells closer to the ground. The photochemical model calculates concentrations of pollutants, such as ozone, in each cell by simulating the following four (4) parameters: (1) the movement of air into and out of the grid cells, (2) the mixture of pollutants vertically among the layers, (3) the injection of new emissions from sources such as point, area, mobile, biogenic into each grid cell, and (4) the chemical reactions based on chemical equations, pollution precursors, and incoming solar radiation in each grid cell.

The two (2) most popular photochemical models most used by the air quality modeling community are the Comprehensive Air Quality Model with Extensions (CAMx) and the Community Multiscale Air Quality (CMAQ) Modeling System. These models might experience a rise in popularity in the coming years if the proposal to reduce the ozone primary and secondary standards is finalized. If U.S. EPA opts to introduce them into the Prevention of Significant Deterioration (PSD) permitting process for specific projects that trigger PSD permitting requirements for NOX or VOCs, it will add another layer of planning for those projects. ALL4 will continue to track U.S. EPA’s plans relative to photochemical modeling. The final ozone standards are set to be issued by October 1, 2015 and state nonattainment designation will be due in October of 2017.

Sources

TCEQ’s Introduction to Air Quality Modeling: Photochemical Modeling

Six Months at ALL4

Looking back on the past six months of my life, it seems like a total whirlwind. There have been so many changes in such a short period of time it’s hard to wrap my head around sometimes. It seems like just yesterday I was rolling out of bed at the crack of dawn on college time (roughly 10:00am) to head to class. Afterwards I would most likely order a pizza and watch Netflix with my roommates all night. So imagine my surprise to learn that in the real world adults are expected to wake up early, pay bills, AND eat actual meals! Along with these changes, I have also moved away from my hometown in Pittsburgh and started a new chapter of my life, complete with a new job, new apartment, and finally (and most thankfully), a new car that always starts when I turn the key. Although this December marks the terrifying end to the six-month deferral period of my student loans, it also marks six months of the most incredible experience I’ve had thus far; working at ALL4.

Starting a new job is always scary, especially when you’re moving 300 miles from home. Questions plagued my mind like, “Will I like it?”, “Will it be worth the move?”, “Do I really want to do this with my life?”. However, if I’ve learned anything during my 22 years of life it’s that if something scares you, it’s probably a good thing to try. So I went for it. I stepped out of my comfort zone and ended up making the best decision I’ve ever made. ALL4 is not like any other company I’ve encountered. I got the sense of that throughout the interviewing process, but not a day has passed during my time here that hasn’t proven that in one way or another.

The people of ALL4 are one of a kind and have turned out to be much more than just co-workers. It truly is a family here, which is very comforting when you’re far away from your biological family. From the after-work “recess events” like getting to attend my first Philadelphia 76ers game, to the commitment to community service, to just getting through the daily grind, the ALL4 culture really does make it a very special company to be a part of.

The beauty of consulting is the versatility in your projects. So far I have worked with clients that brew beer, create nuclear energy, manufacture cement, and seemingly everything in between. I’ve gotten to see first-hand how fiberboard and wood flooring is made (which was beyond exciting for my nerdy self) and I got a behind-the-scenes look at the massive file rooms of PADEP (not quite as exciting). Although the work can be challenging it always turns out to be a rewarding experience. I have honestly learned something new every day, which is a goal I think everyone should strive for no matter what your experience level is.

Working at ALL4 has given me a variety of opportunities for both career and personal growth. It is a company that I am proud and feel lucky to be a part of. These have been the most fulfilling six months of my life and I can’t wait for many more. Cheers to the next six!

Final Revisions to the GHG Reporting Program for the Oil and Gas Sector

On November 25, 2014, U.S. EPA issued final amendments to 40 CFR Part 98, Subpart W (Mandatory Greenhouse Gas (GHG) Reporting for Petroleum and Natural Gas Systems). The amendments – which were first proposed as described within JP’s March 2014 blog – are aimed at improving the clarity and consistency of the data reported pursuant to Subpart W.

Prior to the final rulemaking, U.S. EPA received and responded to public comments which are included within the final November 25, 2014 rule. In addition, U.S. EPA posted a fact sheet on its “Subpart W Rulemaking Resources” webpage. The final rule, which has an effective date of January 1, 2015, was issued with minor changes from the proposed rule.

So, What’s Been Amended?

Some of the major amendments to Subpart W of the Greenhouse Gas Reporting Program (GHGRP) are as follows:

- Revision of units of measure and terms in certain equations for reporting GHGs. Most notably, GHGs for individual source types will be reported in metric tons of individual GHG, as opposed to metric tons of CO2 equivalent (CO2e). Cumulative GHGs will continue to be reported in metric tons of CO2e.

- Revision of the definitions of “onshore petroleum and natural gas production,” “sub-basin category,” and other terms in the rule.

- Removal of all prior provisions in 40 CFR §98.234(f) for Best Available Monitoring Methods (BAMM). For sources subject to new monitoring or measurement requirements as part of the final revisions, 40 CFR §98.234(f) now provides for transitional BAMM for the 2015 calendar year.

- Clarification of procedures regarding missing data.

- Addition of confidentiality determinations following U.S. EPA’s three (3)-year deferral period for reporting deadlines regarding data that may or may not constitute Confidential Business Information (CBI). These confidentiality determinations were finalized as proposed for all but seven (7) of the new and substantially revised data elements.

Going Forward

These amendments will come into play for the 2015 calendar year (i.e., the first annual reports using the amended requirements will be those submitted March 31, 2016). Therefore, the annual reports due March 31, 2015 will not have to implement these amendments, but reporters will have to begin monitoring and recordkeeping in accordance with the amendments beginning January 1, 2015.

In addition to the final amendments, U.S. EPA has proposed additional amendments to Subpart W which would extend 40 CFR Part 98, Subpart W reporting to:

- Gathering and boosting stations;

- Completions and workovers of hydraulically fractured oil wells; and

- Blowdowns of natural gas transmission pipelines.

ALL4 will keep a close eye (and keep you in the loop!) on implementation of the final rule and the additional proposed amendments. If you have any specific questions, feel free to reach out to me at 678-460-0324 x213 or mgreene@all4inc.com.

Proposed Primary and Secondary Ozone NAAQS Standards

In what is surely to be a hotly contested regulatory action, U.S. EPA proposed to lower the primary (to provide public health protection) and secondary (to provide public welfare protection) National Ambient Air Quality Standards (NAAQS) for ground-level ozone from 75 parts per billion (ppb) to a level between 65 and 70 ppb. U.S. EPA’s November 25, 2014 proposal reflects its conclusions based on research and review of the ozone NAAQS that began in 2008.

Based on the results of the research performed, U.S. EPA has proposed that the current primary ozone standard set at a level of 75 ppb does not protect public health with an adequate margin of safety, and that it should be revised to provide increased public health protection. Specifically, U.S. EPA has proposed to retain the indicator (ozone), averaging time (8-hour), and form (annual fourth-highest daily maximum, averaged over 3 years) of the existing primary ozone standard and has proposed to revise the level of that standard to within the range of 65 ppb to 70 ppb. As part of this action, U.S. EPA is also seeking comments on a proposed NAAQS value of 60 ppb.

Secondary NAAQS provide protection against decreased visibility and damage to animals, crops, vegetation, and buildings. According to U.S. EPA, there is evidence of significant reduction in agricultural yields because of increased ground-level ozone and pollution, which interferes with photosynthesis and stunts overall growth of some plant species. In order to identify the appropriate level of protection, U.S. EPA has proposed to use a seasonal index that scientists often use to assess the impact of ozone on ecosystems and vegetation, known as the W126 index (named for the equation used to calculate it). The unique aspect of this index is the unit of measurement that is used in the analysis: “parts per million (ppm)-hours.” The unit of “ppm-hours” is used to express the sum of weighted hourly ozone concentrations, combined over the 12-hour daylight period (8:00 AM to 8:00 PM). U.S. EPA has proposed that air quality meeting a W126 index value between 13-17 ppm-hours, averaged over three (3) years, would provide the degree of protection that the Clean Air Act requires. U.S. EPA claims that this protection could be achieved by setting an 8-hour secondary standard in the range of 65-70 ppb.

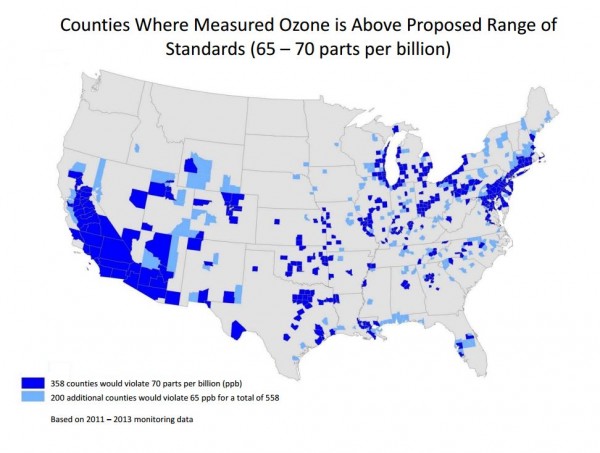

In addition to adjusting the ozone standards, U.S. EPA has also proposed to expand the ozone monitoring season for many states, and update the Air Quality Index (AQI) by setting an AQI value of 100 equal to the level of the 8-hour primary ozone standard in order to ensure people are notified when air quality is unhealthy. U.S. EPA has proposed to extend the monitoring season in 33 states because a review of data shows that ozone can be elevated earlier in spring and later in autumn in many states. In some states, levels have exceeded standards even into the colder winter months. The proposed effective date of the monitoring season extension is January 1, 2017. Based on monitoring data from 2011-2013, and as shown in the figure below, there are currently 358 counties that would violate the 70 ppb standard in the United States. Based on that same monitoring data, there would be 200 additional counties that would violate a 65 ppb standard for a total of 558 counties that would be in danger of violating the attainment standards. Industries within these counties would then be presented with potential air quality permitting challenges associated with Nonattainment New Source Review (NSR).

Nonattainment NSR applies to new major sources or major modifications at existing sources located in areas not attaining the NAAQS. Nonattainment NSR requirements are customized for the nonattainment area and they are more stringent than the Prevention of Significant Deterioration (PSD) requirements that apply to an area that is in attainment. For instance, nonattainment NSR programs have the following three (3) requirements:

- The installation of the Lowest Achievable Emission Rate (LAER)

- Emission offsets

- Opportunity for public involvement

Due to the challenges that these stringent factors present, projects that involve nonattainment NSR are more likely to face permitting obstacles that change the design or permitting feasibility of the project than projects that occur in areas of attainment.

In addition to Nonattainment NSR permitting implications, state agencies will be required to take specific actions in those areas that cannot attain the eventual new ozone NAAQS. These actions typically take the form of more stringent emission limits for existing industry that are written into the State Implementation Plan (SIP) regulations. In these instances, even facilities that are not implementing new permitting projects will be impacted by a more stringent ozone NAAQS.

U.S. EPA is taking comments on the proposed action for 90 days and will be holding three (3) public hearings in January 2015. U.S. EPA will be accepting comments on the standards, including the option of retaining the current standard of 75 ppb or lowering the standard even further to 60 ppb. The final standards are set to be issued by October 1, 2015 and state nonattainment designation will be due in October of 2017 based on ambient monitoring data collected from the 2014 through 2016 calendar years.

Sources

U.S. EPA Ground Level Ozone Actions

Proposed Rule to Update NAAQS Standards for Ground-Level Ozone

Crude Oil and Natural Gas Industry Reduced Emission Completion NSPS Requirements

As 2015 quickly approaches, there is still momentum in the development of domestic unconventional oil and gas resources. Therefore, exploration and production companies utilizing hydraulic fracturing are reminded that the final compliance provisions for reduced emission completions (RECs) pursuant to 40 CFR Part 60, Subpart OOOO (Standards of Performance for Crude Oil and Natural Gas Production, Transmission and Distribution) will become effective with the New Year. In this article we discuss the REC compliance requirements that become effective January 1, 2015, as well as the proposed amendments and their implications to RECs. Before that discussion though, a brief review of the regulatory driver is presented for reference.

The History Of Subpart OOOO

Subpart OOOO regulates emissions of volatile organic compounds (VOC) and sulfur dioxide (SO2) from seven (7) categories of “affected facilities” for which construction, modification, or reconstruction began after August 23, 2011. Subpart OOOO was originally promulgated in July 2012, and was revised in September 2013. In July 2014, additional amendments were proposed that: provide regulatory clarification regarding the handling of liquids and gases during well completion operations; update requirements for storage vessels and reciprocating compressors; provide an opportunity for public comment on the definition of low-pressure wells within the rule; and clarify requirements for leak detection at natural gas processing plants. Key aspects associated with RECs are also clarified in the 2014 proposed amendments. These amendments are expected to be finalized in December 2014.

Subpart OOOO Affected Sources

Before jumping directly into RECs and the implications of the latest proposed amendments, let’s take a step back and do a quick review of the overall requirements for all Subpart OOOO affected facilities.

- A gas well that is constructed, modified, or reconstructed after August 23, 2011 is an affected facility and is subject to Subpart OOOO. Subpart OOOO defines a “gas well or natural gas well” as an onshore well drilled principally for production of natural gas. Each single natural gas well is considered a “gas well affected facility.”

- A centrifugal compressor is considered an affected facility if it uses wet seals and is located between the wellhead and the point of custody transfer to the natural gas transmission and storage segment. If a centrifugal compressor is located at a well site (or an adjacent wellsite) and services more than one (1) well site, it is not considered an affected facility under Subpart OOOO.

- A reciprocating compressor is considered an affected facility if it is located between the wellhead and the point of custody transfer to the natural gas transmission and storage segment. If a reciprocating compressor is located at a well site (or an adjacent wellsite) and services more than one (1) well site, it is not considered an affected facility under Subpart OOOO.

- For both the natural gas and oil production segment, a pneumatic controller is considered an affected facility if it is located between the wellhead and the point of custody transfer, is natural gas driven, and operates at a natural gas bleed rate of greater than six (6) standard cubic feet per hour (scfh).

- For a natural gas processing plant, a pneumatic controller is considered an affected facility if it is driven by natural gas.

- A storage vessel is considered an affected facility if (1) it contains an accumulation of crude oil, condensate, intermediate hydrocarbon liquids, or produced water; (2) is constructed from nonearthern materials (i.e., wood, concrete, steel, fiberglass, or plastic) that provide structural support; and (3) has the potential to emit greater than or equal to six (6) tons per year of VOC.

- Storage vessels for which construction, modification, or reconstruction began after August 23, 2011 or before April 12, 2013, are considered Group 1 storage vessels.

-

- Storage vessels for which construction, modification or reconstructions began after April 12, 2013, are considered Group 2 storage vessels.

The information detailed below will specifically focus on affected gas well facilities and REC requirements.

Why Are Gas Well Facilities Regulated By Subpart OOOO?

The venting or flaring of natural gas from gas well facilities is a source of VOC emissions. Subpart OOOO establishes emission standards and compliance schedules for the control of VOC emissions from affected gas well facilities. In addition, venting or flaring of natural gas from gas well facilities also is a source of methane emissions. Methane is one (1) of the gases included in the definition of greenhouse gases (GHGs), and it has a global warming potential that is 25 times greater than carbon dioxide. Thus, Subpart OOOO, while not directly regulating emissions of methane, establishes de-facto GHG emission standards and compliance schedules that control emissions of GHGs (i.e., methane emissions) from affected gas well facilities.

What Are The Subpart OOOO Standards For Gas Well Affected Facilities?

There are three (3) sets of standards provided at §60.5375 for each affected well completion operation with hydraulic fracturing. These standards can be categorized as follows:

- Well completion operation with hydraulic fracturing begun prior to January 1, 2015

- Well completion operation with hydraulic fracturing beginning on or after January 1, 2015

- Well completion operation with hydraulic fracturing of wells meeting the criteria for a wildcat, delineation, non-wildcat low pressure, or non-delineation low pressure gas well

Note that there is another Subpart OOOO provision at §60.5365(h)(1) for well completions that are hydraulically refractured. This standard specifies that a gas well facility that conducts a well completion operation following hydraulic refracturing is not an affected Subpart OOOO facility, provided the requirements for RECs are met. Any gas well hydraulically refractured on or after October 15, 2012 must meet these REC requirements.

It should be noted that a well completion operation, following refracturing, that is not conducted pursuant to the REC requirements, is considered to be a modification to a gas well that would have been originally exempt from Subpart OOOO. Furthermore, refracturing of a gas well facility does not affect the modification status of other equipment, process units, storage vessels, compressors, or pneumatic controllers located that the well site. Lastly, §60.5365(h)(4) further clarifies that a gas well facility that is initially constructed after August 23, 2011, is considered a Subpart OOOO affected facility and would fall within one (1) of the three (3) categories above.

The primary difference between the various Subpart OOOO standards is the requirement for owner/operators to employ RECs as a method to capture and recover the natural gas (i.e., VOC and methane) that is produced during completion operations. RECs apply to the following gas well facilities:

- Category No. 2 above (i.e., well completion operations with hydraulic fracturing that begin on or after January 1, 2015)

- Well completion operations that were hydraulically refractured on or after October 15, 2012

RECs do not apply to the following gas well facilities:

- Category No. 1 above – well completion operations with hydraulic fracturing that begin prior to January 1, 2015)

- Category No. 3 above – well completion operations with hydraulic fracturing meeting the criteria for a wildcat, delineation, non-wildcat low pressure, or non-delineation low pressure gas well

- Well completion operations that were initially constructed before August 23, 2011 and were hydraulically refractured before October 15, 2012

It should be noted that Subpart OOOO specifies separate requirements for gas well facilities that are not required to comply with the REC requirements or for when RECs are deemed infeasible.

What Are The Non-REC Requirements For Well Completions?

Although the main focus of this article is RECs, a brief review of the regulatory requirements for well completions not requiring RECs is provided below for your reference.

Owner/operators must capture and direct flowback emissions to a completion combustion device, except in conditions that may result in a fire hazard or explosion, or where high heat emissions from a completion combustion device may negatively impact tundra, permafrost or waterways. The completion combustion device must be equipped with a reliable continuous ignition source over the duration of flowback. Owner/operators have a general duty to safely maximize resource recovery and minimize releases to the atmosphere during flowback and subsequent recovery.

What Are RECs?

Subpart OOOO defines RECs as “a well completion following fracturing or refracturing where gas flowback that is otherwise vented is captured, cleaned, and routed to the flow line or collection system, re-injected into the well or another well, used as an on-site fuel source, or used for other useful purpose that a purchased fuel or raw material would serve, with no direct release to the atmosphere.”

In simpler terms, gas flowback that has been historically vented will need to be captured, cleaned, and routed to the sales line, used on-site, or reinjected. Specifically, this process must occur with no direct releases to the atmosphere.

What Does Subpart OOOO Currently Require For RECs?

For those of you who enjoy reading the actual regulation, RECs are specified at §60.5375(a)(1) and (2). For those of you who prefer a paraphrase, RECs are summarized in the bulleted list below:

- RECs are required for the duration of flowback

- Subpart OOOO defines flowback as “the process of allowing fluids to flow from a natural gas well following a treatment, either in preparation for a subsequent phase of treatment or in preparation for cleanup and returning the well to production. The flowback period begins when material introduced into the well during the treatment returns to the surface immediately following hydraulic fracturing or refracturing. The flowback period ends with either well shut in or when the well is producing continuously to the flow line or to a storage vessel for collection, whichever occurs first.”

- Recovered liquids:

- Route into one (1) or more storage vessels or re-inject into the well or another well

- Recovered gas:

- Route into a gas flow line or collection system,

- Re-inject the recovered gas into the well or another well,

- Use the recovered gas as an on-site fuel source, or

- Use the recovered gas for another useful purpose that a purchased fuel or raw material would serve.

- No direct release to the atmosphere may occur.

What REC Revisions Are Proposed Under Subpart OOOO?

The basic requirements for RECs will remain the same if the proposed July 17, 2014 revisions are made final as proposed. The intent of the proposed revisions is to make technical corrections and provide further clarification concerning what owners and operators must do during well completion operations. Specifically, the 2012 NSPS focused mainly on the handling of flowback emissions and did not provide extensive detail concerning requirements for the handling of liquids during well completion operations.

Industry expressed concern that written compliance with the existing language could not be achieved. Some examples presented by industry included the routing of recovered gas into a flow line or collection system and recovered liquids into storage vessels. Specifically, the beginning of flowback consists mainly of water and fracturing materials with virtually no gas present. Gas appears sporadically within the flowback in increasing amounts until a separator can eventually be operated. Routing recovered liquids to a storage vessel, as defined by the rule, would not be feasible because the high volume of solids (e.g., sand and debris) in the fluids would be extremely difficult to remove from storage vessel, typically closed top tanks.

The proposed revisions identify three (3) distinct stages of a well completion operation and the specific requirements for handling of gases and liquids for each stage. The three (3) distinct stages of a well completion operation are as follows:

- Initial flowback stage – begins with the onset of flowback following hydraulic fracturing or refracturing and ends when there is sufficient gas present in the flowback for a separator to operate.

- Separation flowback stage – begins when there is sufficient gas present in the flowback for a separator to operate and ends when the production stage begins or the well is shut it, whichever is first.

- Production stage – when flowback has declined and stabilized sufficiently to allow continuous recovery of the gas and to allow separation and recovery of any crude oil, condensate and produced water.

U.S. EPA provided written clarification that its intent was to allow venting of flowback gasses during certain situations and that fracturing fluids were not required to be routed to storage vessels. The proposed revisions provide key definitions and clarity within the actual rule, which will be located at §60.5430 if the amendments are accepted as proposed. A few of the key proposed Subpart OOOO definitions are as follows:

- Flowback “means the process of allowing fluids and entrained solids to flow from a natural gas well following a treatment, either in preparation for a subsequent phase of treatment or in preparation for cleanup and returning the well to production. The term flowback also means the fluids and entrained solids that emerge from a natural gas well during the flowback process.”

- Recovered gas “means gas recovered through the separation process”

- Recovered liquids “means any crude oil, condensate or produced water recovered through the separation process”

- Well completion vessel “means a vessel that contains flowback during a well completion operation following hydraulic fracturing or refracturing. A well completion vessel may be a lined earthen pit, a storage vessel, or a vessel that is skid-mounted or portable.”

What Will The Proposed Subpart OOOO Require For RECs?

As previously stated, although the regulatory language has changed significantly, the basic requirements for RECs will remain the same if the amendments are made final as proposed.

The first stage in a well completion is the “initial flowback stage”. During this stage, flowback must be routed to a “well completion vessel” (e.g., open top frac tank, a lined pit, or any other vessel), and there is no requirement to control emissions from the “vessel” and any gas can be vented. Gas must be diverted to a separator as soon as a sufficient amount is present. U.S. EPA is seeking to establish objective criteria for determining when there is sufficient gas in the flowback. The proposed requirement has been paraphrased below.

- During the initial flowback stage, route flowback into one (1) or more well completion vessels and operate a separator when sufficient gas is present for a separator to operate. Any gas present in the flowback prior to the separation flowback stage is not subject to control under this section. Initial flowback is the period during a well completion operation when there is insufficient gas in the flowback to operate a separator.

The second stage in a well completion is the “separation flowback stage.” During this stage, flowback gasses and liquids are routed to the separator. With a few exceptions as defined by the rule, the operator is required to route the recovered gas into a gas flow line or collection system, re-inject the gas into the well or another well, use the recovered gas as a fuel, or use the recovered gas for another useful purpose. Where it is technically infeasible to route the recovered gas to a flow line or collection system or reinject the gas or use the gas as a fuel or for other useful purpose, the recovered gas must be combusted using a completion combustion device. Examples of technical infeasibility include: no flow line or other infrastructure available at the site for collection of the gas. Please note that with a few exceptions as defined by the rule, no direct venting of recovered gas is allowed. The proposed requirement has been paraphrased below.

- During the separation flowback stage, route all liquids (i.e., crude oil, condensate or produced water) to one (1) or more well completion vessels or storage vessels, or re-inject the liquids into the well or another well. Route the recovered gas from the separator into a gas flow line or collection system, re-inject the gas into the well or another well, use the recovered gas as a fuel, or use the recovered gas for another useful purpose. If the above items are infeasible, follow the requirements in (a)(3). Comply with the initial flowback stage requirements if at any time the gas present in the flowback becomes insufficient to maintain separator operation.

The final stage in a well completion is the “production stage”. During this stage, gas from the separator is prohibited from being vented or controlled by combustion and all recovered liquids must be routed to a storage vessel. Furthermore, the 30-day period for determining VOC potential to emit for purposes of making a storage vessel affected facility would also begin at the beginning of the production stage. The proposed requirement has been paraphrased below.

- During the production stage, separate and route recovered liquids to storage vessels. Route recovered gas into a gas flow line or collection system, re-inject the gas into a well, use the recovered gas as a fuel, or use the recovered gas for another useful purpose. Recovered gas during the production stage may not be vented or controlled by any combustion device.

Bottom Line

Regulatory definitions and citations aside, the requirement to conduct RECs on January 1, 2015 is not new and is not changing. The proposed July 17, 2014 revisions merely make technical corrections and provide further clarification concerning what owners and operators must do during well completion operations.

There is an exception in the rule to implementing RECs during the separation flowback stage. The exception allows gas that is captured to be directed to a completion combustion device, but only if RECs are deemed infeasible. Whether you plan to utilize this exception or are unsure at this point, you will want to consider how you plan to document that RECs are infeasible. Exception recordkeeping requirements are provided in the rule at §60.5420(c)(iv), which require owner/operators to record the location of the well; the API well number; the specific exception claimed; the starting date and ending date for the period the well operated under the exception; and an explanation of why the well meets the claimed exception.

U.S. EPA Revises Framework for Assessing Biogenic CO2 Emissions

In November 2014, U.S. EPA issued a memorandum and a second draft of its “Framework for Assessing Biogenic Carbon Dioxide Emissions from Stationary Sources” that describes how biogenic carbon dioxide (CO2) emissions will be addressed for the purposes of the Clean Power Plan (CPP) and Prevention of Significant Deterioration (PSD) permitting. The take-home message of this action is that the use of waste-derived feedstocks, as well as certain forest-derived industrial products are likely to have minimal or no net atmospheric contribution of biogenic CO2 emissions, and likely reduces the impact when compared with disposal practices.

The original framework, which was published in September 2011, explored the scientific and technical issues associated with biogenic CO2 emitted from stationary sources and presented a way to estimate biogenic CO2 emissions. The second draft lays out a series of formulas to determine if CO2 emissions from biomass combustion are completely carbon neutral, must be counted in full, or are somewhere in between. Both the original and revised framework, as well as various resources, can be found here.

As for the impacts on CPP, U.S. EPA anticipates that states will incorporate the use of biogenic feedstocks obtained from sustainable practices in their compliance plans. U.S. EPA plans to evaluate the biogenic feedstock components of proposed state plans, provide feedback, and consult experts when needed.

Revisions to the PSD rules that include an exemption from the Best Available Control Technology (BACT) requirement for greenhouse gases (GHGs) from waste-derived or sustainable non-waste biogenic feedstocks are also planned by U.S. EPA. U.S. EPA will propose that for waste-derived feedstocks, biogenic CO2 emissions would be exempt from GHG BACT analyses based on the findings in the framework. U.S. EPA will also propose that for sustainable non-waste biogenic feedstocks, biogenic CO2 emissions would be exempt from GHG BACT analyses if the applicant can show that the feedstocks came from sustainably managed lands. Potential changes to PSD permitting regulations related to GHGs may be necessary to align the recent Supreme Court decision with this proposed accounting framework.

Changes to the Mandatory GHG Reporting Rule and IVT Sandbox Testing (Yes, More Acronyms)

On October 24, 2014, U.S. EPA finalized revisions to the reporting requirements, recordkeeping requirements, and confidentiality determinations of the Mandatory Greenhouse Gas (GHG) Reporting Rule (i.e., 40 CFR Part 98). The October 24, 2014 revisions include new data verification procedures that address industry’s long-standing Confidential Business Information (CBI) concerns. If you’ll recall, reporters have long been concerned that the rule included provisions requiring the reporting of facility-specific process or production data (inputs to equations) that reporters felt could be regarded as business-sensitive information. In order to evaluate these concerns and whether the inputs to equations did in fact constitute CBI, U.S. EPA deferred the reporting deadlines for many inputs to emission equations to either March 31, 2013 or March 31, 2015. The deadline varied per input to equation and afforded U.S. EPA the time it needed to fully evaluate the potential impact of releasing CBI to the public.

Last year, U.S. EPA completed their evaluation of the first set of equation inputs and determined that they did not constitute CBI. Once this determination was made, facilities reporting under certain subparts were required to report inputs to equations that had been historically deferred for the 2010 and 2011 reporting years. U.S. EPA has just completed their second evaluation and will be collecting data this year much like they did during 2013 for the remaining historic inputs to equations that were recently determined not to be CBI.

So what about the data inputs that were determined to be CBI? U.S. EPA has finalized an alternative electronic verification approach that at once (1) allows U.S. EPA to validate information submitted by facilities but (2) protect the confidentiality of inputs to equations for reporters. The data will be kept as records by reporters, rather than be reported to U.S. EPA.

The new data verification procedure is being implemented as an Inputs Verification Tool (IVT) within U.S. EPA’s electronic Greenhouse Gas Reporting Tool (e-GGRT). The IVT will (1) protect the confidentiality of inputs to equations for reporters and (2) allow U.S. EPA to verify emissions and ensure compliance with the reporting program. Two birds with one stone! As indicated in Table 2 of Vol. 79, No. 206, of the Federal Register, most reporters will be required to use the IVT. However, certain Subpart C (General Stationary Fuel Combustion Sources) reporters will have the option to either use the IVT or report their inputs to equations to U.S. EPA. Choosing to actually report the inputs will waive a Subpart C reporter’s right to a confidentiality claim.

U.S. EPA is currently hosting “sandbox testing” of the IVT and details concerning how interested parties can get involved in this sandbox testing can be found here. Deadlines for submitting feedback to U.S. EPA varies per subpart. The November 17, 2014 deadline pertaining to many subparts has just passed but those reporting under Subparts E, F, O, R, V, and Y can still jump in before December 6, 2014, and those reporting under Subparts C and Y (specific to the XML file type) have the ability to submit comments through December 22, 2014.

ALL4 is gearing up to assist our clients with the enhanced reporting that will be required in the upcoming GHG reporting season. If you are actively involved in GHG reporting and are unsure how your upcoming reporting will be impacted by these rule revisions, please give us a call to discuss!

Proposed Boiler MACT Reconsiderations Released

U.S. EPA has released the proposed reconsideration of the National Emission Standards for Hazardous Air Pollutants (NESHAP) for Major Sources: Industrial, Commercial, and Institutional Boilers and Process Heaters (40 CFR Part 63, Subpart DDDDD) and of the NESHAP for Area Sources: Industrial, Commercial, and Institutional Boilers (40 CFR Part 63, Subpart JJJJJJ). The pre-publication versions of the Major and Area Source rules are available on U.S. EPA’s Air Toxics website. The reconsiderations were prompted by submittals from industry, environmental, and state and local regulatory agencies in 2013 that requested U.S. EPA to revise parts of the two (2) rules. In response to the petitions, U.S. EPA identified three (3) items for which comments are requested related to the maximum achievable control technology (MACT) standards contained in Subpart DDDDD (Major Source Boiler MACT rule) and five (5) items for which comments are requested related to Subpart JJJJJJ (Area Source Boiler MACT rule). In addition to the request for comments, U.S. EPA also made technical corrections, fixed typographical errors, and clarified the intent for various requirements in both rules. Comments will be accepted for 45 days after publication of the proposed rules in the Federal Register, or 30 days after a public hearing if one is held, which is likely.

U.S. EPA has also released the proposed reconsideration of the Commercial and Industrial Solid Waste Incineration (CISWI) rules, which can be found here. Stay tuned for a separate blog post addressing the CISWI rules.

The proposed changes for which U.S. EPA is requesting comment for the Major and Area Source Boiler MACT rules are summarized below.

Subpart DDDDD: Major Source Boiler MACT Rule

The three (3) areas for which U.S. EPA is requesting comment related to Subpart DDDDD are:

- Current and revised definitions that affect the startup and shutdown provisions.

- An updated carbon monoxide (CO) emission limit.

- Aspects of the use of particulate matter (PM) continuous parameter monitoring system (CPMS).

A brief summary of the parts of the rules open for comment are provided in the following paragraphs.

- Startup and Shutdown Provisions: U.S. EPA is requesting comment on the original January 2013 format of the startup and shutdown provisions and on proposed alternative provisions for startup and shutdown periods. As part of the alternative provisions, revised definitions that address the terms “startup,” “shutdown,” and “useful thermal energy” are proposed. The revised definitions are reflected in a proposed alternate work practice standard that would apply during periods of startup and shutdown. Finally, U.S. EPA is requesting comment on the recordkeeping requirements during startup periods. Specifically, an alternative definition of startup is proposed as a compliance option, which closely aligns with the recently finalized Mercury and Air Toxics Standards (MATS). Under the alternative definition, startup means:

The period in which operation of a boiler or process heater is initiated for any purpose. Startup begins with either the firing of fuel in a boiler or process heater for the purpose of supplying useful thermal energy (such as steam or heat) for heating, cooling or process purposes, or producing electricity (other than the first-ever firing of fuel in a boiler or process heater following construction of the boiler or process heater), or the firing of fuel in a boiler or process heater for any purpose after a shutdown event. Startup ends four hours after when the boiler or process heater makes useful thermal energy (such as heat or steam) for heating, cooling, or process purposes, or generates electricity, whichever is earlier.

- Updated CO Emission Limit: The petitions to the January 2013 rule included a request to revise the minimum level of 130 parts per million by volume, dry basis (ppmvd) at 3 percent oxygen (% O2) CO emission limit for certain subcategories of boilers. U.S. EPA believes that the CO emission limit is appropriate but also agrees that the public lacked the opportunity to comment on the emission limit. Therefore, U.S. EPA is accepting comment and data regarding the 130 ppm CO emission limit to assess whether an alternate limit is justified or if work practice standards could be more appropriate.

- Use of PM CPMS: Boilers that combust solid fossil fuel or heavy liquid fuel and that have a heat input of 250 million British thermal units per hour (MMBtu/hr) or greater are required to operate a particulate matter (PM) Continuous Parametric Monitoring System (CPMS). U.S. EPA established an allowable number of excursions from operating parameter limits for the PM CPMS before an excursion in a parameter limit is presumed to be an emission violation. In response to comments by the regulated community, U.S. EPA is accepting detailed information from entities that might support a revision to how CPMS excursions should be evaluated.

In addition to the three (3) specific requests for comments, the affirmative defense provisions were removed based on the D.C. Circuit Court’s April 2014 ruling which stated that the Clean Air Act Section 112 rules (i.e., the NESHAPs at 40 CFR Part 63) should apply at all times. The removal of the affirmative defense provisions means that civil penalties can be assessed if an emission limitation is exceeded during a malfunction event.

Subpart JJJJJJ: Area Source Boiler MACT Rule

Sources subject to Subpart JJJJJJ have the opportunity to provide comment on five (5) issues related to the area source requirements:

- Startup and Shutdown Provisions: U.S. EPA is proposing revisions to the definition of startup and shutdown as well as accepting comment on the current regulatory definitions of these two (2) terms. These definitions are consistent with those in Subpart DDDDD. U.S. EPA is also proposing “useful thermal energy” as a new term in conjunction with the startup and shutdown provisions.

- Alternate PM Standards for New Boilers Firing Low Sulfur Oil: U.S. EPA is requesting comment related to an exemption for boilers that combust ultra-low sulfur oil to meet a PM emission limit. In addition, sources firing ultra-low sulfur oil would not be required to conduct initial performance testing to demonstrate compliance with PM emissions limits.

- Establishment of Limited-Use Boiler Subcategory: Environmental groups petitioned U.S. EPA to reconsider the establishment of a limited-use boiler subcategory and require that these limited-use boilers be only subject to tune-up requirements. Environmental groups felt that emission limits and performance testing requirements should be considered for the limited-use boiler subcategory. U.S. EPA agreed that the petition was valid; however, U.S. EPA believes that its regulatory approach is adequate.

- Elimination of PM Performance Testing for Select Sources: Environmental groups petitioned U.S. EPA to reconsider exempting sources demonstrating very low PM performance test results in their emission tests from further testing. As a result of the petition, U.S. EPA is requesting comments and information on PM variability during emission testing.

- Elimination of Fuel Sampling for Select Sources: Environmental groups petitioned U.S. EPA concerning the fuel sampling for mercury (Hg) and the decision to exempt sources from fuel sampling based on a single sample showing low Hg levels. U.S. EPA is requesting comment and data on the variability of Hg in coal as well as alternate Hg fuel sampling programs that include a single annual sampling event requirement for sources demonstrating low Hg levels. For Hg levels that are greater than half of the Hg emission limits, quarterly fuel sampling would be required.

Like Subpart DDDDD, the affirmative defense provisions contained in §63.11226 were removed based on the D.C. Circuit Court’s April 2014 ruling.

The revisions presented here are not intended to be comprehensive, but rather highlight the changes that are most likely to impact regulated entities.

Want to learn even more about Boiler MACT and find out if you’re “on track”? Check out our Major Source Boiler MACT Compliance Checklist and our 4 Rules/Boiler MACT Initiative Page for additional resources.