Hydrogen Sulfide Accounting and Reporting in Advance of this Year’s Toxic Release Inventory Reports

As environmental personnel gear up for the suite of annual reports due each year, 2013 brings an important change to the Toxic Release Inventory (TRI) report. Beginning with the TRI report due July 1, 2013, releases of hydrogen sulfide (H2S), a colorless, flammable, gas with a characteristic “rotten egg” smell, must be reported.

Background

On October 17, 2011, the U.S. Environmental Protection Agency (U.S. EPA) lifted an Administrative Stay of the Emergency Planning and Community Right-to-Know Act (EPCRA) section 313 TRI reporting requirements for H2S [Chemical Abstracts Service Number (CAS No.) 7783–06–4][1]. As detailed in this Federal Register notice, H2S was added to the EPCRA section 313 list of toxic chemicals in a final rule published in the Federal Register on December 1, 1993. However, on August 22, 1994, U.S. EPA issued an Administrative Stay of the reporting requirements for H2S in order to evaluate issues brought to the Agency’s attention after promulgation of the final rule concerning the human health effect basis for the listing and the Agency’s use of exposure analysis in EPCRA section 313 listing decisions. Although the final rule listing H2S under section 313 of EPCRA remained in force, the stay deferred the reporting requirements for H2S while U.S. EPA completed its further evaluation. U.S. EPA has now completed its further evaluation of additional information that has become available since the stay was put in place regarding the human health and environmental effects of H2S, and the Agency published a position that the stay should be lifted in the February 26, 2010 Federal Register document entitled ‘‘Intent to Consider Lifting Administrative Stay; Opportunity for Public Comment.’’ The October 17, 2011 action that lifted the Administrative Stay established that the first TRI reports to include H2S will be due on July 1, 2013 for reporting year 2012 TRI reports.

Sources of H2S

Hydrogen sulfide, also known as sewer gas, stink damp, swamp gas and manure gas, occurs naturally in crude petroleum and natural gas. In addition, H2S is produced by bacterial breakdown of organic materials, and is produced by human and animal wastes. In particular, sanitary and wastewater treatment operations are a primary source of H2S. Hydrogen sulfide typically is formed in wastewater collection systems that are conducive to creating septic conditions. Collection systems in warm climates that have a flat grade or do not have the flow-through velocities [minimum two (2) feet per second] to prevent the stagnation of fluid, allow the septic conditions to occur. In general, septic conditions occur when bacteria use all of the available oxygen while decomposing organic matter in wastewater for energy. Sewers with low velocities encourage the growth of anaerobic bacteria in a slime layer coating the sewer. These bacteria reduce sulfur compounds such as sulfate, thereby producing sulfides. These compounds occur naturally in domestic wastewater but also can be concentrated in industrial waste streams. Under anaerobic (septic) wastewater conditions, sulfides cannot be oxidized. Therefore, they combine with hydrogen to produce hydrogen sulfide gas, creating the “”rotten egg”” odor associated with septic wastewater[2].

Several industrial activities that emit H2S include petroleum/natural gas drilling and refining, food processing facilities (including feeding operations and rendering facilities), coke ovens, tanneries, landfills, and Kraft pulp mills[3]. Hydrogen sulfide is also known to be emitted by certain agriculture operations including those associated with confined animal feeding operations (CAFO).

Releases of H2S for TRI reporting purposes will primarily be in the form of a reaction by-product of a given process (e.g., from the generation of H2S during anaerobic wastewater treatment processes or in a landfill, or in a direct contact evaporator at a Kraft pulp mill, in which the sodium sulfide in the black liquor reacts with the carbon dioxide in the furnace exhaust). However, there are some instances in which H2S is used as a reactant in a process, such as the conversion of H2S to elemental sulfur in the Claus process[4], or as part of a contact process sulfuric acid plant that burns spent acid[5].

Armed with this general understanding of the types of industries that may release H2S, an overview of the TRI reporting basics and the threshold determination process (which establishes if a covered facility must report releases of hydrogen sulfide) is provided below for additional clarification.

Reporting Basics

As described in U.S. EPA’s annual TRI instructions[6], TRI reporting is required if certain activity threshold quantities are exceeded. The activity threshold quantities are specific to each compound and unique to each of the three (3) types of reportable activities (i.e., manufacture, process, and otherwise use).

Let’s first review the current list of compounds that are regulated under the TRI program. The current TRI toxic chemical list contains 593 individually-listed chemicals and 30 chemical categories [including three (3) categories containing 62 specifically-listed chemicals]. If the members of the three (3) categories are counted as separate chemicals, the TRI Program could actually be said to cover 682 combined chemicals and chemical categories [i.e., 593 + (30-3) + 62)][7]. Within this list, H2S is listed without a chemical qualifier; therefore, this means that it is potentially subject to reporting in all forms in which it is manufactured, processed, or otherwise used above its applicable activity thresholds. Since H2S is not a persistent bioaccumulative toxic (PBT chemical), it is therefore subject to the standard activity thresholds of 25,000 pounds for manufacturing, 25,000 pounds for processing, and 10,000 pounds for otherwise using. For purposes of the de minimis exemption, the 1.0% level applies to H2S because it does not meet the Occupational Safety and Health Administration’s (OSHA’s) definition of a carcinogen. Therefore, H2S could be exempt in a mixture at a concentration lower than 1.0 %[1].

What do the terms manufactured, processed, or otherwise used mean for TRI purposes? As stated in the TRI instructions[6], the term “manufacture” means to produce, prepare, compound, or import an EPCRA Section 313 chemical, where the term “import” is defined as causing the EPCRA Section 313 chemical to be imported into the customs territory of the United States. Manufacturing can either be intentional or coincidental, and this is an important distinction, especially for H2S. Coincidental manufacture of a compound can occur as either a byproduct or impurity, in which byproducts are separated from the process stream and further treated or disposed, and impurities stay with the process and end up in the final product. The de minimis exemption applies to the coincidental manufacture of an impurity, but does not apply in the case of the coincidental manufacture of a byproduct. Therefore, the coincidental manufacture of H2S as a byproduct within, for example, a wastewater treatment or other treatment process, would not be eligible for the de minimis exemption. However, H2S could be considered an impurity in the case of a natural gas sweetening plant, in which natural gas from high-pressure wells is sweetened by absorption in an amine solution to remove the H2S [natural gas is considered “sour” if it contains H2S in excess of 0.25 grains per 100 standard cubic feet[8]]. The H2S gas stream recovered by the amine solution may be: (1) vented, (2) flared in waste gas flares or smokeless flares, (3) incinerated, or (4) utilized for the production of elemental sulfur or sulfuric acid. If the recovered H2S gas stream is not to be utilized as a feedstock for commercial applications, the gas is usually passed to a tail gas incinerator in which it is oxidized to sulfur dioxide and is then passed to the atmosphere out a stack. In such cases, as noted in Question 113 of the U.S. EPA’s 1998 EPCRA Section 313 Questions and Answers document, “The removal and destruction of an EPCRA Section 313 toxic chemical from a fuel before it is used by a facility is not considered an activity that falls under the definition of manufacturing, processing or otherwise use. Facilities that use natural gas in production processes sometimes need to remove impurities from the gas before it is used. Such a facility does not coincidentally produce toxic chemicals as byproducts, but merely separates and removes toxic chemicals already present in the gas. These chemicals would not be subject to threshold determinations for reporting under EPCRA Section 313, and would not be subject to release and other waste management reporting unless an activity threshold is exceeded elsewhere at the facility. If the facility exceeds an activity threshold elsewhere, all releases and other waste management activities from the impurity removal process would be reportable.”

The term “process” means the preparation of a listed EPCRA Section 313 chemical, after its manufacture, for distribution in commerce. Processing is usually the incorporation of an EPCRA Section 313 chemical into a product. However, a facility may process an impurity that already exists in a raw material by distributing that impurity in commerce. Processing includes preparation of the EPCRA Section 313 chemicals in the same physical state or chemical form as that received by your facility, or preparation that produces a change in physical state or chemical form. The term also applies to the processing of a mixture or other trade name product that contains a listed EPCRA Section 313 chemical as one component. To revisit the above case of the natural gas sweetening plant as an example, utilization of the recovered H2S for production of elemental sulfur or sulfuric acid constitutes “processing” for the purposes of TRI reporting.

“Otherwise use” means the use of an EPCRA Section 313 chemical, including an EPCRA Section 313 chemical contained in a mixture or other trade name product or waste, which is not covered by the terms manufacture or process. It is unlikely that H2S will be present at a facility in an “otherwise use” manner.

Release Estimation Techniques

Hydrogen sulfide calculations are performed in the same manner as a typical non-metal, non-categorical (e.g., nitrate compounds) TRI compound. Because of the nature in which H2S will be present at most TRI-covered facilities, the process used to perform the threshold determinations will typically provide the quantity of H2S released to the environment. As with most pollutants, the use of analytical data (stack testing or water quality data, for example) is the preferred method to estimate activity quantities and releases. When analytical data are not available, for sources such as wastewater treatment and landfills, computer-based models are the primary means to estimate emissions [e.g., National Council for Air and Stream Improvement’s (NCASI’s) H2SSIM model for wastewater treatment processes, and U.S. EPA’s Landfill Gas Emission Model].

For specific industrial processes, various emissions guidance is available. U.S. EPA offers emissions calculation guidance within AP-42 specific to the solid waste industry, petroleum industry, inorganic chemical industry, food and agriculture industry, and wood products industry. NCASI offers pulp and paper mills not just emission factors within its yet-to-be published Chemical Information Sheet for H2S, but also a site-specific pond profile method which requires extensive field data collection and pond sampling, and a mechanistic model with predictive capabilities that relies on wastewater treatment plant inlet sampling. NCASI also offers emission factors within its air toxics database, and within multiple technical bulletins (e.g., Technical Bulletins No. 956 (September 2008), No. 957 (November 2008), No. 997 (August 2012), and No. 1000 (December 2012).

Regardless of the methodology used, facilities will be required to maintain documentation regarding the source of production or operating data, as well as any analytical data or emission factors used in the calculation process following selection of this approach.

Parting Thoughts

Though H2S emissions are required to be included in TRI reports this year for the first time, some regulated facilities have been performing emission estimates for H2S as part of permit applications and emission and annual emission reports in the past. Hydrogen sulfide is regulated as part of New Source Review (NSR) air permitting requirements. Some states also have ambient air quality standards for H2S, which require facilities to quantify emissions for air dispersion modeling evaluations. State and local water effluent standards are established in terms of H2S itself, or in terms of dissolved sulfides. Lastly, indoor air quality and personal exposure data also may provide a source of emission data for unique or non-typical processes.

So why discuss TRI reporting in February when the report is not due for another five (5) months? Obviously, for facilities that do not routinely quantify H2S emissions as part of current reporting programs, time will be needed to evaluate the numerous calculation methodologies that exist and identify the best methodology to calculate emissions for TRI, particularly if sampling and analysis is required. But even for facilities with some experience reporting H2S emissions, there have been numerous updates to the recommended calculation methodologies that historically existed for this compound which need to be evaluated for both TRI and future permitting purposes. Not to mention the burdensome process of incorporating the selected calculation approach into your existing TRI calculation reporting process. Wouldn’t it be nice to be ahead of the reporting game for once? Don’t let these new reporting requirements catch you by surprise this year.

References

- Federal Register Volume 76, Number 200, pages 64023-64037, October 17, 2011.

- http://www.wwdmag.com/corrosion/hydrogen-sulfide-control-wastewater-collection-systems

- OSHA Fact Sheet for Hydrogen Sulfide, located at www.osha.gov/OshDoc/data…Facts/hydrogen_sulfide_fact.pdf.

- U.S. EPA, AP-42, Compilation of Air Pollutant Emission Factors, Section 8.13, July 1993.

- U.S. EPA, AP-42, Compilation of Air Pollutant Emission Factors, Section 8.10, July 1993.

- U.S. EPA, Toxic Release Inventory Reporting Forms and Instructions, Reporting Year 2011, EPA 260-R-10-001, December 2011, located at http://www.epa.gov/tri/reporting_materials/forms/index.html.

- http://www.epa.gov/tri/trichemicals/

- U.S. EPA, AP-42, Compilation of Air Pollutant Emission Factors, Section 5.3, January 1995.

ALL4’s Is That Your Final Answer?

Last Month’s Answer and Winner:

Our January 2013 “Is That Your Final Answer” question was almost immediately answered by Bridgette Rillema of Zeeland Farms. Bridgette knew that a stimpmeter is the device that is used to measure the speed of a golf green. A number of other respondents also had the correct answer; however, they were just a little bit slower in responding. Congratulations to Bridgette and thanks to everyone for contributing.

Question:

Answer:

Please e-mail your answer to final.answer@all4inc.com. Include in the e-mail your name, answer, and address (to receive your prize).

ALL4’s Final Answer is a monthly feature of our Blog Digest. It is designed to test your knowledge across the environmental field, quiz you on the building blocks of air quality rules, stump you on ALL4 general trivia, and challenge you with brain teasers that have perplexed us. The first correct answer e-mailed to us will qualify the respondent for free ALL4 gear and will enter the winner in our end-of-the year “Final Answer Championship.” The subsequent month’s Final Answer will identify the winner and the correct answer from the previous month’s question. You must be an active subscriber of ALL4’s Blog Digest to win a monthly prize and be eligible for the championship prize. ALL4 employees and family members are not eligible to compete. Hope you enjoy this feature and good luck!

Area Designations and Implementation of the Sulfur Dioxide National Ambient Air Quality Standard

On February 6, 2013, U.S. EPA issued a white paper outlining the agency’s updated strategy for completing initial area designations under the June 2010 1-hour primary sulfur dioxide (SO2) National Ambient Air Quality Standard (NAAQS). The white paper is not intended as final rulemaking or to be legally binding, but rather offers U.S. EPA’s current line of the thinking on the NAAQS implementation process. According to U.S. EPA, their implementation strategy will incorporate input received from air agencies and stakeholders, other NAAQS designation approaches, and the historical presence and importance of SO2 modeling in the past and in the Prevention of Significant Deterioration (PSD) permitting program. U.S. EPA also believes that the strategy will place an emphasis on prioritizing sources based on magnitude of emissions and proximity to large populations, advance an appropriate time scale for developing sufficient data needed to make determinations, and account for responsibilities of state and federal air agencies set forth in the designation process under the Clean Air Act (CAA). Received with mixed reviews, the issuance of the white paper largely represents a shift away from U.S. EPA’s focus on emissions modeling and towards emissions monitoring as the primary method of SO2 NAAQS compliance.

At its surface, the updated strategy revolves around the principal of providing flexibility for air agencies to determine the most appropriate and effective approach for determining NAAQS designations. Specifically, U.S. EPA is proposing that air agencies prescribe to a dual-pathway approach to the designation process in which individual agencies are allowed to use either monitoring, modeling, or some mix thereof for the characterization of SO2 concentrations. U.S. EPA believes that by utilizing such a dual-pathway approach air agencies will benefit from the cost- and time-effectiveness that modeling techniques offer in circumstances that prohibit the more accurate use of ambient monitoring networks. However, as stated in the paper, the U.S. EPA’s preference is for SO2 designations to be made in the same fashion as with other NAAQS designations (i.e., through the use of monitoring networks). Indeed, it appears U.S. EPA’s new strategy will focus on monitoring for emissions categorization as a starting point and use modeling as a secondary means when factors such as funding become an issue.

In addition to introducing the dual-pathway approach, the U.S. EPA’s new strategy places an emphasis on prioritizing which sources should be assessed in regards to attainment of the 1-hour standards. To do so, U.S. EPA proposes to identify sources based on the magnitude of their emissions and their proximity to large populations. U.S. EPA has issued information which indicates that approximately 540 of the 20,000 national SO2 sources nationwide have actual emissions which exceed 1,900 tons per year or, in other terms, account for roughly 90% of all SO2 emissions in the United States. To address these statistics, U.S. EPA is proposing the use of a two-pronged emission threshold for SO2 designation which would place a lower threshold of approximately 2,000-3,000 tons per year for sources located in more densely populated areas and a higher threshold of approximately 5,000-10,000 tons per year for sources located in less densely populated areas. Sources falling within these categories would need to be assessed relative to NAAQS compliance via the installation of ambient monitors of a dispersion modeling evaluation as determined by the applicable state agency. U.S. EPA has identified a number of factors that it intends to consider in selecting the appropriate thresholds for the two-pronged system, including: the comprehensiveness of the total emissions represented; the comparability of source coverage under the two-pronged approach with the typical source coverage of an ambient monitoring network; emission levels for sources in areas with monitored violations; and emission levels associated with sources that are well-controlled.

U.S. EPA has also proposed an implementation timeline for future designations that utilize the dual-pathway and two-pronged approaches discussed above. The proposed implementation timeline is designed to take effect in two stages so that a first round of modeling-based designations takes place prior to a subsequent round of monitoring-based designations. In general, the U.S. EPA would issue final technical assistance documents in July of 2013, identify which sources and areas will deploy new ambient monitors and which will conduct dispersion modeling in 2015, deploy new monitors and require completed dispersion modeling analyses for selected sources and nonattainment areas in January of 2017, require SIP designations for nonattainment modeled areas in 2019, issue final designations for the rest of the country in December of 2020, and require SIP attainment demonstrations for areas designated as nonattainment in 2022.

If you facility’s actual emissions are within or exceed the ranges of emissions referenced above it would be prudent to consider exploratory dispersion modeling and to understand the possible locations and costs of ambient monitors.

ALL4 Seeking Part-Time Administrative Assistant

Do you enjoy having a variety of tasks to spice up your workday?

Do you get personal satisfaction and pride out of making things “just right”?

Do you have a creative side that is aching to get out?

Are you looking to experience what it is like to a part of a “Best in Class” work environment?

If so, then ALL4 has the ideal position for you!

ALL4 is a nationally recognized environmental consulting company with two offices; one in PA & another in GA. We specialize in air quality and our work products are typically permit applications and reports that are sent directly to clients or on behalf of clients to regulatory agencies. Being a small (35+ person) and growing company, we are a group of individuals who juggle many roles and responsibilities. Our Kimberton, PA office currently employs a five-person Administrative Team (most of who are part-time) and we are looking to hire another part-time member of this team to provide general administrative support.

Sound good so far? Great! Now let me give you an idea of some of the things I currently handle that I envision someone might assist me with:

- Processing and formatting Microsoft Word and Excel documents

- Maintenance of company handbook, SOPs, and internal documents

- Entering bills into our accounting system and contacting vendors to resolve billing issues

- Leading our recruiting efforts, which includes preparing recruiting timeline & process each season, attending career fairs, tracking candidates, sending responses, scheduling interviews, filing, etc

- New employee preparation, which includes preparing their welcome letter and HR paperwork, setting them up in our system, preparing their orientation schedule, etc

- Maintenance of our Continuous Improvement Program (CIP) feedback system, which is used for internal and external feedback and includes keeping our employee and client lists up-to-date, as well as running reports

- Training grant reimbursement funding, which includes tracking the internal and external training our employees attend, determining if it may qualify for grant reimbursement, applying for reimbursement, collecting all necessary information and submitting for reimbursement

- Researching new systems as we grow, which will include investigating human resources information management systems, accounting systems, and possibly applicant tracking systems so that we are prepared if/when it comes time to update our current systems

- Customer Relationship Management (CRM) system maintenance, which may include adding/removing contacts, running reports, creating mailing labels, etc

- Marketing support, which includes designing/creating marketing materials, pulling together email invites for in-person and webinar events, acting as the webinar ‘host’ so the ‘presenters’ can focus on presenting their material, helping to track payments for these events, etc

- Project Management support, which includes obtaining and tracking Certificates of Insurance, sending out W-9 Forms, & completing Vendor Setup Forms, as well as general project support such as typing, data entry, proofreading, quality assurance, document production, creating mailing labels, coordinating overnight delivery, etc

- Handling those unexpected requests that “just come up” or “need to be done right away” as well as supporting other Admin Team members with general office support

Are you the person we’re looking for? If you are a hard worker with a keen attention to detail and strong typing & data entry skills in addition to proficiency in Microsoft Word, Excel, & Outlook, then yes!

Will you be the one we hire? If you believe the answer is yes, and you are willing & ready to take ownership of the responsibilities outlined above, then please visit the careers page of our website to view the job posting and submit your resume.

I look forward to hearing from you!

Critical Court Decision Concerning PM2.5 Emissions

In a suit brought by the Natural Resources Defense Council against the U.S. Environmental Protection Agency (U.S. EPA), the U.S. Court of Appeals for the District of Columbia Circuit (Court) on January 4, 2013 ruled that the U.S. EPA had improperly promulgated two rules implementing standards for fine particulate matter less than 2.5 micron in size (PM2.5). This ruling creates a major issue for the U.S. EPA and state air pollution control agencies because it will likely undo 20 area redesignations in five states to attainment for PM2.5 that have already occurred and will definitely delay any pending redesignations.

This ruling determined that Congress required that State Implementation Plans (SIPs) for PM2.5 redesignation must meet the more stringent requirements of Part D, Subpart 4 in its 1990 amendments to the Clean Air Act (CAA). The U.S. EPA had taken the position that the less burdensome requirements of Part D, Subpart 1 should be used in its implementation rules for PM2.5. While it is not clear what additional measures must be met to comply with the full extent of this ruling, it is clear that additional sources of PM2.5 emissions, such as agriculture related sources with ammonia emissions (e.g. from concentrated animal feeding operations), may now have to be addressed for an acceptable SIP revision. Subpart 4 as written in the CAA even requires that uncontrollable natural sources of fine particulate must be addressed in the SIPs.

There are many PM2.5 nonattainment areas of the nation that are currently monitoring attainment for PM2.5, and are about to or were just recently redesignated to attainment with the 1997 and/or 2006 PM2.5 national ambient air quality standards (NAAQS). For major PM2.5 emission sources in these areas with pending attainment designations or recent re-designations, the ability to permit any proposed facility modifications under the Prevention of Significant Deterioration (PSD) requirements applicable to attainment areas prior to the implementation of the new, more stringent annual PM2.5 NAAQS may be lost. For PM2.5 the PSD attainment area requirements (e.g., BACT) are much less burdensome than the nonattainment new source review (NNSR) requirements for nonattainment areas (e.g., LAER and emission offsets). The pending redesignations to attainment with the 1997 and/or 2006 PM2.5 NAAQS are compounded by the recently promulgated, and significantly lower, annual PM2.5 NAAQS, which could create more nonattainment areas.

Why is PM2.5 so significantly affected by this court decision relative to the other regulated pollutants? First, it only takes an emission increase in PM2.5 of 10 tons per year for a major source of PM2.5 to trigger NNSR permitting requirements. Second PM2.5 emission offsets (known in Pennsylvania for example, as emission reduction credits (ERCs)) must be purchased or generated in order for the project to be permitted. Currently there is an extremely limited supply of PM2.5 emission offsets that can be purchased for use anywhere in the nation. Where PM2.5 emission offsets are found, they have sold for more than $10,000 per ton, and sometimes well in excess of that figure. While the Court may have been correct in their assessment of the CAA, their timing could not have been worse. Many clean, economically stimulating, and environmentally sound projects will likely get caught up in this resetting of U.S. EPA’s implementation rules.

What can you do? First, determine if your facility is in one of the PM2.5 redesignation areas or in an area likely to be nonattainment under the new PM2.5 NAAQS. If so, the timing of your projects involving PM2.5 will be critical. Once an area is designated as nonattainment, it is typically several years after the area is again monitoring attainment before it is redesignated for permitting purposes. It is often a decade long process for a state control agency to obtain enough monitoring data, develop a Maintenance Plan and obtain U.S. EPA approval back to attainment. If a facility has to seek PM2.5 ERCs under nonattainment NSR permitting, it could easily upset the viability of any new project in these unforgiving economic times.

Increases in Pennsylvania Title V Emission Fees

For almost 20 years Pennsylvania facilities that are major sources of air pollution have been subject to annual air emission fees. These facilities are about to shell out some additional money for Title V air emission fees. Technically, the base Title V emission fee in Pennsylvania has not increased from the $37 per ton of “regulated pollutant” fee that was established in 1994, with a cap of 4,000 tons for each pollutant each year. However, each year since 1994 the base fee has been “adjusted” by the percentage by which the Consumer Price Index for the most recent calendar year exceeds the Consumer Price Index for the previous calendar year. The current Title V fee for 2012 calendar year emissions is $57.50 per ton. Starting with fees payable by September 1, 2014 for emissions in 2013, the Pennsylvania Department of Environmental Protection (PADEP) has proposed that the emissions fee for “regulated pollutants” will increase by $27.50 to $85 per ton. For 2014 emissions and beyond the $85 per ton fee will again be adjusted based on the Consumer Price Index adjustment described above.

Basically, the fees collected at current rates are no longer sufficient to fund PADEP’s Title V operating permit program costs. PADEP has the responsibility to demonstrate to the U.S. EPA that it has sufficient funds to carry out its Title V Program. Much of the fee collection shortfall that has been experienced by PADEP can be attributed to reduced emissions resulting from better pollution control and the conversions of many major facilities to cleaner fuels. So, while your hard work may have resulted in lower emissions, your fees are not likely to decrease commensurate with your emission decreases.

The revised fee structure does not presently include fees for greenhouses gases (GHGs). While GHG reporting is now part of our lives (including reporting of GHGs for facilities in Pennsylvania starting with your 2012 AIMS reports), Title V air emission fees apply only to “regulated pollutants.” The term “regulated pollutant” means a volatile organic compound; a pollutant regulated under section 111 or 112 of the Clean Air Act; and each pollutant for which a national primary ambient air quality standard has been promulgated (except that carbon monoxide is excluded from this reference). GHGs do not presently meet this definition and therefore are not subject to Title V emission fees. This may not last for long, as U.S. EPA has announced its intention to address new source performance standards for GHGs for some source categories in future rulemaking. Someday GHGs may be part of the Title V fee structure. This would likely introduce some inequity problems among source types. Stay tuned.

After Further Review: The 1-Hour SO2 NAAQS Stands

The request for a hearing of an appeal in the case ASARCO LLC v. EPA has been shot down by the Supreme Court. ASARCO’s original challenge to the 1-hour sulfur dioxide (SO2) National Ambient Air Quality Standard (NAAQS) was rejected by the D.C. Circuit Court, which decided to uphold the 1-hour NAAQS promulgated by U.S. EPA in August 2010. The smelting industry company requested that the Supreme Court review the D.C. Circuit Court’s decision, but that request has now been rejected. ASARCO and other industry groups have challenged the SO2 NAAQS under the pretense that U.S. EPA set a standard that was far too stringent and that has not been demonstrated to be any more protective to sensitive populations than the original SO2 NAAQS levels. U.S. EPA is required to set the NAAQS at a level that will protect public health with an “adequate margin of safety”. According to ASARCO, the 75 parts per billion (ppb) standard selected by U.S. EPA went above and beyond the necessary level of protection. ASCARCO has argued that during research, U.S. EPA selected only carefully selected data points to support a more stringent standard while ignoring other evidence. We submitted comments on the 1-hour SO2 NAAQS and agree with ASARCO’s positions and that of many other commenters on the standard. U.S. EPA continues to stand by the research, claiming that data points were selected with the interest of human health in mind. Smelting industry owners have expressed concern that some facilities may have to shut down, as the cost to comply with the SO2 NAAQS will be excessive. The Supreme Court’s rejection of the SO2 appeal does not bode well for a similar appeal that has been filed by the American Petroleum Institute (API) to address the 1-hour NO2 NAAQS. Stay tuned to ALL4’s blog to see if the court’s EPA-friendly streak continues.

Relationship Advice With John Egan

In the spirit of celebrating the month of love, we’d like to commend John Egan’s dedication and ability to build strong and lasting (business) relationships with his EnviroReview clients. John is a principal of ALL4 and one of the EnviroReview consultants, providing valuable environmental expertise through the EnviroReview consulting call.

John began providing EnviroReview consulting calls one year ago and is excited to celebrate his one year anniversary with his EnviroReview clients. Because of the overwhelming success of the monthly EnviroReview calls, John has agreed to provide his most treasured relationship advice in an exclusive interview.

1. John, our clients have really valued the one-on-one consulting calls with you over the past year. What’s the secret to building such strong relationships?

I try my best to provide them with timely information that’s important for their work. I may have been doing this a long time but it doesn’t make me any smarter than they are, so I work to make the call a sharing experience. They tell me what’s important for them, I tell them what I know or don’t know about it. I work to get them answers or we work through issues together, and I try not to get too serious. Given the typical subject matter the news isn’t always uplifting so it is important to maintain a sense of humor. Since we’re all in this together, it’s good to have someone else to share with and that’s how the relationships develop.

2. Even in the best of relationships and especially over the phone, it can be difficult to keep the conversation going. There can be awkward silences and either party can often run out of things to say. Does that ever happen to you?

Normally that only occurs when there are a number of parties at different locations on the call and people are reluctant to speak up and ask questions. If you stop and think about it, there really are no dumb questions in this business – just consider how illogical some of the rules are. When folks get comfortable with my way of being, they usually don’t hesitate to ask questions or contribute. Anyway, if there’s nothing to talk about we just end the call. Typically though, given the nature of what we all do, there is always something else to talk about. If an EnviroReview call ends early, it is usually because we’ve covered what’s important and my client has other pressing priorities.

3. It’s been a year now and you haven’t had any “break-ups”; how do you keep the spark alive?

I often tell my wife: “You have to continuously water the garden” meaning regular communication is key. The bottom line is that there is tremendous value in sharing information, including opinions, with others who work in the same field. You both learn, you commiserate, you look for humor in what could be considered painful topics, you get to know each other, and you grow personally and professionally.

Many of our clients had subscribed to an automated subscription service in the past; they know what is out there. They may look pretty but there’s no support. ALL4 recognized that need and because environmental consulting is what we do best, it was a natural fit. We work hard to keep the relationships strong and healthy, but it takes two to tango, and we are most thankful to our clients.

EnviroReview is ALL4’s environmental regulatory consulting service.

Training for the Marathon: 4 Rules Compliance

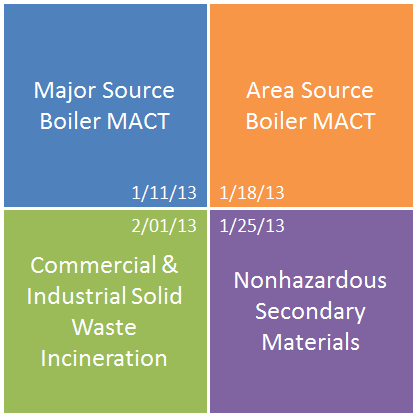

4 Rules Friday is a series of four blog posts highlighting key aspects of the final 4 Rules (i.e., Major and Area Source Boiler MACT, Nonhazardous Secondary Materials, and Commercial and Industrial Solid Waste Incineration). Please refer to the graphic for each blog’s posting date.

In the environmental regulatory arena, it feels like the 4 Rules have been a series of sprints – followed by a pulled hamstring! From the June 2010 proposals to the March 2011 final rules to the December 2011 proposals and to the January/February 2013 final rules, there have certainly been starts and stops along the way. With all four rules now published in the Federal Register, facilities can start preparing for the next race – but this one is a marathon, and it culminates with the finish line being to achieve compliance. The marathon that is the “final 4 Rules” can be found here:

- Major Source Boiler MACT

- Area Source Boiler MACT

- Commercial and Industrial Solid Waste Incineration (CISWI) and Non-Hazardous Secondary Materials (NHSM)

Over the last four Fridays we’ve discussed how each of the final 4 Rules may impact affected facilities. (Miss a post? Don’t worry – links are provided below.) So why have we been providing all of this content? To quote our mission, “ALL4 operates under the premise that the success of our company is measured by the success of our clients.” The answer is simple – we want our current and future clients to be successful. Whether you’re a seasoned expert in the rules or you’re just learning about them now, we want to help you run the 4 Rules marathon and cross the finish line to achieving compliance. If you already know how your facility will comply, we want to help you with the air quality permitting that will likely be necessary to install pollution control equipment. If you need to determine which subcategory your unit falls under or even which rule it will be subject to, we want to help you with the applicability determinations. What specific questions or concerns do you have? We’d love to discuss them with you.

The 4 Rules represent a significant change in the way hundreds of thousands of boilers, process heaters, kilns, and incinerators operate. We’ll continue to train for the marathon by providing valuable content via our blog and 4 The Record newsletter, and we’ll be holding a training webinar series for all in May.

The complete 4 Rules Friday series is provided below:

- Major Source Boiler MACT

- Area Source Boiler MACT

- Non-Hazardous Secondary Materials (NHSM)

- Commercial and Industrial Solid Waste Incineration (CISWI)

Good luck with your 4 Rules marathon and let us know if you need a training partner… our program has already started!

DC Circuit Court Vacates and Remands PM2.5 SILs and SMC

In a decision that could have far reaching permitting implications, the United States Court of Appeals for the District of Columbia Circuit (Court) on January 22, 2013 vacated and remanded portions of the U.S. EPA rule establishing significant impact levels (SILs) and vacated the rule establishing the significant monitoring concentration (SMC) for particulate matter less than 2.5 micrometers (PM2.5). SILs and SMCs are screening tools that are used by regulatory authorities to determine whether a new source or a major modification to an existing source may be exempted from certain requirements (e.g., source impact analysis and pre-construction pollutant monitoring) under §165 of the Clean Air Act (CAA).

Significant Impact Levels

The petitioner (Sierra Club) argued that the U.S. EPA lacked de-minimis authority to promulgate SILs and that the adoption of the SILs is “contrary to the legislative design of the CAA”. The petitioner contended that even minor emissions impacts (e.g. below the SIL) that are associated with a proposed new source or modification could cause or contribute to a violation if the source was in an area that was close to violating a national ambient air quality standard (NAAQS) or PSD increment. Because emissions impacts are below the SIL, the regulatory authority would automatically exempt the source from a NAAQS analysis. The petitioner also contended that a situation could exist where multiple sources with ambient impacts less that the SIL could cause a cumulative violation of the NAAQS or increment.

The U.S. EPA essentially folded on the SIL issue and admitted that the SIL provisions in the rule were indeed “flawed.” It was U.S. EPA’s intent to allow permitting authorities the leeway to seek remedial action from the source in circumstances where an impact below a SIL will cause or contribute to an air quality problem. However, the final regulatory text was structured in such a way that it did not allow regulatory authorities the discretion to require a cumulative impact analysis in such instances. The U.S. EPA ultimately requested that the Court vacate and remand the regulatory text regarding PM2.5 SILs promulgated in the rule at 40 CFR §§51.166(k)(2) and 52.21(k)(2).

The United Air Regulatory Group (UARG) intervened to argue that a vacatur and remand of the SIL rules was not needed. UARG argued that:

- “The premises that an agency’s interpretation of its own regulations is given deference, and that the EPA has interpreted the SIL provisions so that permitting authorities retain discretion in applying the SILs,”

- “A remand is unnecessary because the EPA requires permitting authorities to address violations by revising their SIPs,” and

- If the SIL regulations are remanded, they should not be vacated – referring to a previous Court holding in Fertilizer Institution v. EPA where the Court stated that “when equity demands, an unlawfully promulgated regulation can be left in place while the agency provides the proper procedural remedy.”

The Court disagreed with the intervenors positions and vacated and remanded the §§51.166(k)(2) and 52.21(k)(2) SIL PM2.5 provisions, basing their decision on the U.S. EPA’s lack of authority to exempt sources from the requirements of the CAA. As a consolation prize, the Court ruled that vacatur and remand of the SIL provisions at §51.165(b)(2) was determined to not be necessary because that provision (addressing SILs in nonattainment areas) simply states that a source may be deemed to violate the NAAQS if it exceeds the SILs in certain situations.

Significant Monitoring Concentrations

Similar to the approach taken with regard to SILs, the Sierra Club argued that the U.S. EPA does not have de minimis authority to promulgate an SMC for PM2.5 that can be used to exempt a source or modification from the pre-construction air quality monitoring required by §165(e)(2) of the CAA. The U.S. EPA argued that the Sierra Club challenge was “time barred” because U.S. EPA has been using SMCs as a screening tool since 1980 and petitioners seeking review of a U.S. EPA regulation must file petitions sixty (60) days from their publication in the Federal Register. The Court disagreed with U.S. EPA citing U.S. EPA’s promulgation of new regulation identifying an SMC for PM2.5, a pollutant that was not regulated in 1980. U.S. EPA thereby “exposed” the regulation by establishing a new monitoring exemption (SMC) for a new pollutant (PM2.5).

The Court viewed the preconstruction monitoring requirements of §165(e) of the CAA as “extraordinarily rigid” and cited Congress’s use of the word “shall” in the appropriate sections of §165(e)(2) of the CAA as a “clear legislative mandate” that the preconstruction monitoring requirement applies to prevention of significant deterioration (PSD) permit applicants. The Court was very definitive in their opinion by inferring Congressional reasoning associated with the statutory language and citing several technical reasons why preconstruction monitoring would be mandated.

The Court granted Sierra Club’s petition regarding the parts of the rule establishing a PM2.5 SMC, and vacated them, stating that these parts of the rule exceeded the U.S. EPA’s statutory authority. At present, the vacatur is limited to the PM2.5 SMC because the Court has “not yet decided whether the EPA’s de minimis authority allows it to establish SMCs as a screening tool to determine when to exempt sources from the Act’s preconstruction monitoring requirement.”

What Does It All Mean?

Taking the Court’s decision at face value, a new major source or a major modification at an existing major stationary source involving PM2.5 would need to collect PM2.5 preconstruction monitoring data in advance of a PSD permit application and would also need to complete an ambient air quality impacts analysis including a multi-source NAAQS and increment analysis. The implications to the applicant are significant from both a project timing and cost basis. The implications are also significant from a regulatory agency perspective as state permitting resources, already understaffed in many jurisdictions, will likely be burdened with significant new oversight and technical review responsibilities.

Because of the definitive nature of the Court’s decision (e.g., establishing SMCs for PM2.5 exceeded the U.S. EPA’s statutory authority), it seems fair to assume that the remaining SILs and SMCs will be challenged as well. Overall, the new source review (NSR) process continues to evolve (or devolve depending upon one’s point of view). The NAAQS related changes and interpretations over the past several years are making the permitting of new major sources or major modifications in many locations increasingly onerous from a project timing and cost basis, and even threatening the viability of economically sound projects. It is evident that strategic air quality planning and innovative air quality permitting approaches that seek to avoid triggering NSR are becoming increasingly important considerations for facilities planning new construction or expansion projects.