Post-Inaugural Reflections on the White House and Greenhouse Gases

Within an impassioned second inaugural address, President Barack Obama recently offered the following motivated remarks concerning climate change:

“We, the people, still believe that our obligations as Americans are not just to ourselves, but to all posterity. We will respond to the threat of climate change, knowing that the failure to do so would betray our children and future generations. Some may still deny the overwhelming judgment of science, but none can avoid the devastating impact of raging fires, and crippling drought, and more powerful storms. The path towards sustainable energy sources will be long and sometimes difficult. But America cannot resist this transition. We must lead it. We cannot cede to other nations the technology that will power new jobs and new industries. We must claim its promise. That’s how we will maintain our economic vitality and our national treasure, our forests and waterways, our crop lands and snow capped peaks. That is how we will preserve our planet, commanded to our care by God.”

Strong words, surely. But what exactly lies ahead? Mr. Obama’s specific second-term plans for mitigating climate change are anticipated to be revealed in greater detail within his upcoming State of the Union address scheduled for February 12, 2013. But in the interim, it’s possible to speculate where we may be headed if we take a look at efforts related to climate change executed by the President during his first term.

International Climate Change Efforts

At an international level, the President focused on the following during the period 2009 through 2012:

- International climate negotiations.

- The Major Economies Forum on Energy and Climate.

- The Clean Energy Ministerial.

- The Asia-Pacific Economic Cooperation (APEC) Summit.

- The Climate and Clean Air Coalition to Reduce Short-Lived Climate Pollution.

Throughout his first term, the President joined numerous world leaders first in Copenhagen, then in Cancun, and then in Durban to negotiate resolutions to climate change and clean energy on an international scale. Out of these efforts, the Copenhagen Accord, the Copenhagen Green Climate Fund, and the Cancun Agreement were negotiated. The Copenhagen Accord marked a milestone in which, for the first time, all major developed and developing economies agreed to implement measures to limit their greenhouse gas (GHG) emissions and to do so in an internationally transparent manner. The Copenhagen Green Climate Fund was established to contribute to the United Nations Framework Convention on Climate Change (UNFCCC) by promoting a paradigm shift toward low-emission and climate-resilient development pathways and providing support to developing countries to limit or reduce their greenhouse gas emissions. The Cancun Agreement confirmed and substantially extended the core elements of the Copenhagen Accord in the areas of finance, technology, adaptation, mitigation, and transparency. At the Durban Climate Change Conference in 2011, Obama joined other world leaders in formalizing important steps to make all of the key elements of the Cancun Agreement operational, including a transparency regime to monitor and review mitigation efforts by developed and developing countries.

In April 2009, the President launched the Major Economies Forum on Energy and Climate (Forum) which consists of the following 17 major economies: Australia, Brazil, Canada, China, the European Union, France, Germany, India, Indonesia, Italy, Japan, Korea, Mexico, Russia, South Africa, the United Kingdom, and the United States. The Forum is intended to facilitate dialogue among major developed and developing economies regarding the challenges concerning climate change and clean energy.

In December 2009, the President announced the establishment of the Clean Energy Ministerial (CEM) led by United States Energy Secretary Chu. The CEM is comprised of the Leaders of the Major Economies Forum on Energy and Climate. The goal of the CEM is to drive transformational low-carbon, climate friendly technologies by providing tools and platforms to improve the policy environment for energy efficiency, renewable energy, and clean energy access.

During 2011, President Obama chaired the Asia-Pacific Economic Cooperation (APEC) Summit in Honolulu, where leaders agreed to eliminate non-tariff barriers to environmental goods and services, including local content requirements, and cut applied tariffs on such goods and services to five (5) percent by 2015. The intent of this effort is to lower costs, increase the dissemination of clean technologies, and create jobs. Leaders further committed to the phasing out of inefficient fossil fuel subsidies and aiming to reduce the energy intensity of APEC economies by 45 percent by 2035.

Finally, in February 2012, the United States launched the Climate and Clean Air Coalition to Reduce Short-Lived Climate Pollution (Coalition) in order to initiate rapid progress on climate change and air quality. The coalition believes reducing pollutants that are “short-lived” in the atmosphere, such as methane, black carbon, and hydrofluorocarbons (HFCs), which together account for one (1) third of current global warming, are believed to be able to prevent more than two (2) million premature deaths a year, avoid the annual loss of over 30 million tons of crops, increase energy security, and address climate change. Founding coalition partners include Bangladesh, Canada, Ghana, Mexico, Sweden, and the UN Environment Program.

At a national level, activity related to climate change has occurred rapidly over the past four (4) years, and, as the following timeline will have you recall, our nation’s industry was steadily and directly impacted by each of the actions finalized under Lisa Jackson, Administrator of the U.S. EPA during Mr. Obama’s first term:

- October 2009: U.S. EPA finalized the Mandatory Reporting of Greenhouse Gases Rule.

- December 2009: U.S. EPA issued the “Endangerment Finding” which found that current and projected levels of six (6) GHGs threaten the health and human welfare of current and future generations.

- April 2010: The Endangerment Finding enabled U.S. EPA and National Highway Traffic Safety Administration (NHTSA) to issue the first rule to control emissions of GHG (the Light Duty Vehicle Rule).

- May 2010: U.S. EPA issued the “Prevention of Significant Deterioration (PSD) and Title V Greenhouse Gas Tailoring Rule (GHG Tailoring Rule).” The GHG Tailoring Rule set the timing and established the thresholds for addressing GHG emissions from stationary sources under the Clean Air Act (CAA) permitting programs, tailoring existing air permitting guidelines to apply to only the largest stationary sources of GHGs, excluding smaller factories, restaurants, and farms.

- December 2010: U.S. EPA issued guidance to states on implementing the new GHG Tailoring Rule guidelines.

- January 2011: When the GHG Tailoring Rule took effect on January 2, 2011, GHG officially became “subject to regulation” under the CAA. New GHG air permitting began for facilities that would independently have to go through air permitting for non-GHG pollutants.

- January 2011: U.S. EPA proposed a 3-year deferral of GHG permitting when it relates to biomass combustion.

- July 2011: New GHG permitting began for new facilities that would emit more than 100,000 tons of carbon dioxide equivalent (CO2e) per year and also for facilities that will undergo a major modification that would increase emissions by 75,000 tons of CO2e per year.

- July 2011: U.S. EPA finalized the 3-year deferral of GHG permitting for biomass combustion.

- March 2012: U.S. EPA proposed the first GHG regulations to appear under the “New Source Performance Standards” (NSPS) program. The proposed rule applies to new fossil fuel-fired electric utility generating units (EGUs).

- July 2012: U.S. EPA amended the GHG Tailoring Rule to include Step 3 and certain permit streamlining options.

Of the milestones just listed, we’ve been appreciably affected by the promulgation of the Mandatory Greenhouse Gas Reporting Rule, promulgation of the GHG Tailoring Rule, and the proposal of the first GHG regulations to appear under the NSPS program.

Through the GHG Reporting Program, U.S. EPA has collected and published emissions data from individual facilities within the United States for the last two (2) years. To date, the rule has been amended 20 times since its initial publication in October 2009 to add new source categories and to make clarifying amendments. The rule serves as a bottom-up approach for U.S. EPA to account for the country’s GHG emissions from an industry and geographic perspective. ALL4 has been assisting facilities within numerous source categories to comply with the Mandatory Greenhouse Gas Reporting Rule since data collection began at the facility level in 2010. GHG data reported to U.S. EPA under this mandatory program is accessible to the public through U.S EPA’s website. Today, more than 40 types of source categories are required to report facility-level GHG emissions to U.S. EPA annually, accounting for approximately 90% of the country’s GHG emissions. The first annual reports were submitted to U.S. EPA in September 2011 and the second annual report for these source categories were submitted to U.S. EPA in March 2012. An additional 12 source categories began collecting data in 2011, with their first annual reports submitted to U.S. EPA in September 2012. Reports corresponding to the 2012 Reporting Year are due to U.S. EPA by all affected facilities no later than April 1, 2013. What’s immediately new for the upcoming reporting season? For one, the requirement to report data elements whose reporting deadline from the past reporting years of 2010 and 2011 was deferred until 2013 is upon us.

As Neal Lebo recently explained, reporters under the GHG Reporting Program had historically expressed concerns that certain data elements required to be reported under the Mandatory Greenhouse Gas Reporting Rule were Confidential Business Information (CBI). In response to these concerns, U.S. EPA deferred the requirement to report these specific data elements until 2013 to allow time for U.S. EPA to evaluate the potential impact of releasing this information to the public and to make final determinations with regard to CBI status. U.S. EPA recently completed their evaluation and concluded that the data elements under review were either already publicly available or were not the types of information that would allow competitors to gain competitive advantage if released to the public. Therefore, the data elements that had been deferred are now required to be reported by April 1, 2013. U.S. EPA is currently updating the format of the e-GGRT database to require not just the reporting of the data elements used to calculate 2012 emissions, but also the historically deferred information used to calculate 2010 and 2011 emissions. Since e-GGRT may not allow a complete report submission until requested historic information is completely provided, reporters preparing for the upcoming round of GHG reporting must be mindful of the additional effort that will be required to dust off their historic 2010 and 2011 calculations in order to submit their reports this season.

Is there anything new on the horizon regarding the Mandatory Greenhouse Gas Reporting Rule? Although U.S. EPA managed to finalize a staggering 46 subparts within three (3) short years, for now, active rule proposals are limited to proposed amendments to calculation and monitoring methodologies for the Electronics Manufacturing source category (Subpart I). U.S. EPA is also proposing confidentiality determinations for reporting of the new and revised data elements for this same source category.

Important to note is the fact that the Mandatory Greenhouse Gas Reporting Rule does not require control or reduction of GHG at this time, and it is not anticipated to require it in the future. However, numerous companies are expressing a desire to switch to, or further augment, the use of “inherently cleaner” fuels and process materials as a strategic plan to reduce GHG emissions reported for their company. We warn you that such a project, albeit certainly honorable, does not relieve the applicant of the typical air permitting obligations that would be required for any modification. As Mark Wenclawiak recently explained, U.S. EPA’s focus on energy efficiency projects through the Best Available Control Technology (BACT) process as the means to control emissions of GHGs remains intact. U.S. EPA has published a series of industry-specific white papers that may be useful to a facility preparing a BACT analysis, but the complications associated with the analysis are still numerous given the immature nature of the add-on control technologies that exist. The challenges increase with U.S. EPA’s insistence that technology like carbon capture and sequestration, which has yet to be demonstrated to be a technologically and economically feasible option, should be included in the analysis. Look forward to a subsequent article in which we dig further into the numerous issues concerning the viability of potential GHG control technologies. For the time being, continue to be mindful that permitting energy efficiency and GHG reduction projects at existing major stationary sources would, at a minimum, require a determination regarding the applicability of major New Source Review (NSR) requirements. Such determinations can be quite complex and often are subject to questioning by regulatory authorities, including U.S. EPA.

Relatedly, what kinds of changes might we see with respect to GHG permitting? Right now we are within “Step 3” of U.S. EPA’s phased-in GHG Tailoring Rule. We know that the three (3) year deferral period which relieves biogenic stationary sources of CO2 PSD and Title V permitting requirements is scheduled to conclude during July 2014. U.S. EPA has also committed to completing “Step 4” of the phased-in rule by April 2016. In the interim, we could likely see U.S. EPA encourage sources to control GHG emissions through efficiency improvements or the use of other emission reduction procedures, processes, or equipment as a strategy for reducing the number of sources that require complete PSD permitting. However, as I previously explained, facilities interested in executing these types of efficiency and GHG reduction projects will still incur the air permitting requirements that come along with a modification.

As part of Step 3, U.S. EPA provided a mechanism to streamline the GHG PSD permit program by expanding the existing PSD Plantwide Applicability Limit (PAL) provisions to better implement PALs for GHGs. The expanded PAL provisions allow permitting authorities to establish GHG PALs on either a mass basis (tpy) or a CO2e basis, include an option to use a CO2e-based increase provided in the subject to regulation thresholds in setting the CO2e PAL, include an option to issue a GHG PAL to GHG-only sources that have the potential to become major sources under the Tailoring Rule, and allow GHG PALs to be used as an alternative approach for determining both whether a project is a major modification and whether GHG emissions are subject to regulation. As John Egan recently recommended, obtaining a PAL permit, where appropriate, could be the most strategically advantageous move a facility makes for years to come and it now can be done for GHGs in addition to the other pollutants regulated under NSR.

Beyond the Tailoring Rule, we should anticipate increased regulation of GHG in the realm of New Source Performance Standards (NSPS). As I indicated in a historic blog, U.S. EPA’s March 27, 2012 proposal for an output-based NSPS for emissions of CO2 was a milestone in being the very first time a GHG emission standard was proposed for a stationary source. This still active proposal applies to new affected fossil fuel-fired electric utility generating units (EGUs). But U.S. EPA also committed to proposing GHG standards of performance by July 26, 2011 for new and modified EGUs subject to 40 CFR Part 60, Subpart Da (Electric Utility Steam Generating Units), with final action no later than May 26, 2012, and also committed to proposing standards of performance for GHG for new and modified petroleum refineries subject to the following 40 CFR Part 60 subparts by December 10, 2011, with final action no later than November 10, 2012:

- Subparts J and Ja (Petroleum Refineries, and Petroleum Refineries for Which Construction, Reconstruction, or Modification Commenced After May 14, 2007, respectively).

- Subpart Db (Industrial-Commercial-Institutional Steam Generating Units).

- Subpart Dc (Small Industrial-Commercial-Institutional Steam Generating Units).

- Subpart GGG (Equipment Leaks of VOC in Petroleum Refineries for Which Construction, Reconstruction, or Modification Commenced After November 7, 2006).

- Subpart QQQ (VOC Emissions from Petroleum Refinery Wastewater Systems).

Not too surprisingly, U.S. EPA has fulfilled a piece of that which they committed to in the settlement agreements: the standards of performance for new EGUs. However, as committed to within these settlement agreements, U.S. EPA must still propose standards for the remaining sources – first for existing EGUs, then for new and existing petroleum refineries. Interestingly enough, during a recent interview current U.S. EPA Air Chief Gina McCarthy suggested that while U.S. EPA sets NSPS for new facilities, “it’s really states that develop their own processes” for existing plants. “We are going to respect that and make sure that there is a robust” state role. McCarthy did not reveal the specific timing for when U.S. EPA will fulfill the remainder of the consent decree and finalize its proposed NSPS for new power plants as well as propose NSPS for the existing power plants and new and existing petroleum refineries, as is still required by the consent decree. However, it is clear we can expect there will be activity in this area during Mr. Obama’s second term – it is just a matter of when the news will strike.

In summary, the president has signaled a direction to address climate change. Executing his goals will likely come by U.S. EPA either encouraging, and in certain cases requiring, energy efficiency, clean fuel, or control technology installation projects. However, the projects that can achieve these goals will still need to go through the permitting gauntlet and all the while U.S. EPA will be moving deliberately ahead with new standards that directly limit GHG emissions from specific stationary sources.

Looks Like The Existing Lead NAAQS Is Good – For Now

On January 11, 2013, U.S. EPA released a draft policy paper regarding the agency’s current outlook on the lead national ambient air quality standard (NAAQS). The Clean Air Act (CAA) requires that EPA review each of the NAAQS every five years to confirm that the standards remain sufficient to protect public health in light of newly available data and research. In 2008, after three decades of scientific review, the primary lead NAAQS was lowered one order of magnitude from 1.5 µg/m3 to 0.15 µg/m3, and the averaging time was revised to a rolling three-month period.

In the draft document, U.S. EPA was unable to identify an alternate standard for consideration and recommended retaining the current primary and secondary NAAQS for lead, both levels are 0.15 µg/m3 on a rolling three-month average. At this time, U.S. EPA is unable to scientifically prove that there would be any reductions to public health risk with a lower lead NAAQS. The draft document does identify areas for future research such as the health effects of lead exposure and the relationship between ambient air lead and outdoor dust/surface soil lead concentrations.

What happens next? U.S. EPA will accept comments on the draft policy paper through February 4, 2013. U.S. EPA is scheduled to issue a final rulemaking on whether to retain (or revise) the lead NAAQS in December 2013. Whatever happens, ALL4 will be here to keep you up to date. A link to the January 11, 2013 Federal Register publication can be found here.

A Little Help When You Need It – Georgia’s Expedited Air Permitting Program

To close out 2012, the Georgia Environmental Protection Division (Georgia EPD) rolled out a draft version of its anticipated expedited air permitting program. As it stands today, the program will become effective on July 1, 2013, and though participation in this program would require a fee, it may help facilities that are under a time crunch to implement a change to an existing process or to install a new process. After consideration solicited during two (2) public stakeholder meetings, Georgia EPD has decided to self-execute the expedited permitting process (opposed to using a third-party contractor). For those interested in this option, Georgia EPD has identified the following mandatory procedures as part of the process:

- The program is not designed to address your permitting projects that come to you in the shower. Participation requires a mandatory pre-application meeting at least 30 days prior to submitting the application, except for Prevention of Significant Deterioration (PSD) applications, which require a pre-application meeting at least 90 days in advance.

- You do not always get what you ask for. Submittal of a request for expedited review is not a guarantee that the application will be accepted into the program. Georgia EPD has stated it “expects the highest of quality in applications that are selected for expedited review.” In other words, a technically incomplete application submittal will not be processed under expedited review. Therefore, facilities must carefully consider their available internal resources to prepare the application, and consider the use of a consultant that is experienced in preparing applications in the state of Georgia to avoid impactful delays in the expedited review process.

- Make sure Georgia EPD knows how to get in touch with you. Georgia EPD will contact the applicant within five (5) business day of receipt of an application submittal requesting the expedited process. The applicant has five (5) business days to accept the expedited process, which includes the submittal of the fee within five (5) business days of accepting Georgia EPD’s offer. Responses not provided within the specified timeframes can disqualify you from the expedited program.

- A request for a public hearing would add 60 days to the expedited processing timeframe.

A link to the Georgia EPD draft fact sheet is provided here. In this fact sheet, Table 1 provides the expedited review time frames and Table 2 provides the expedited review fees.

ALL4’s staff is available to discuss the expedited permitting program. Please contact us to review your permitting projects and your available options.

ALL4’s: Is That Your Final Answer?

Last Month’s Answer and Winner:

Well, we decided that our final “Is That Your Final Answer” question for 2012 was too subjective, as we were not able to select a winning response to our December free form question. Regardless, we still have 11 monthly winners of our contest and today we randomly selected a winner of our grand prize $250 gift card. And the winner is…David Constant from Essroc! Watch the video below of David’s name being randomly drawn by ALL4’s Christina Giannascoli. Congratulations to David.

Question:

Our January 2013 “Is That Your Final Answer” question is about a unique measurement device that we happened to read about in a Wall Street Journal article. This device is used to measure a critical “speed” in a common sport. It has also been recently modified and updated. It is 36 inches long and made of aluminum and has two holes with a v-shaped channel leading from both holes. What is the name of this device and to what sport does it belong? Here is a hint: there are only eighteen places where this device needs to be used. Good luck with this month’s question.

Answer:

Please e-mail your answer to final.answer@all4inc.com. Include in the e-mail your name, answer, and address (to receive your prize).

ALL4’s Final Answer is a monthly feature of our Blog Digest. It is designed to test your knowledge across the environmental field, quiz you on the building blocks of air quality rules, stump you on ALL4 general trivia, and challenge you with brain teasers that have perplexed us. The first correct answer e-mailed to us will qualify the respondent for free ALL4 gear and will enter the winner in our end-of-the year “Final Answer Championship.” The subsequent month’s Final Answer will identify the winner and the correct answer from the previous month’s question. You must be an active subscriber of ALL4’s Blog Digest to win a monthly prize and be eligible for the championship prize. ALL4 employees and family members are not eligible to compete. Hope you enjoy this feature and good luck!

A Little Rule for a Big Issue: the Non Hazardous Secondary Materials Rule

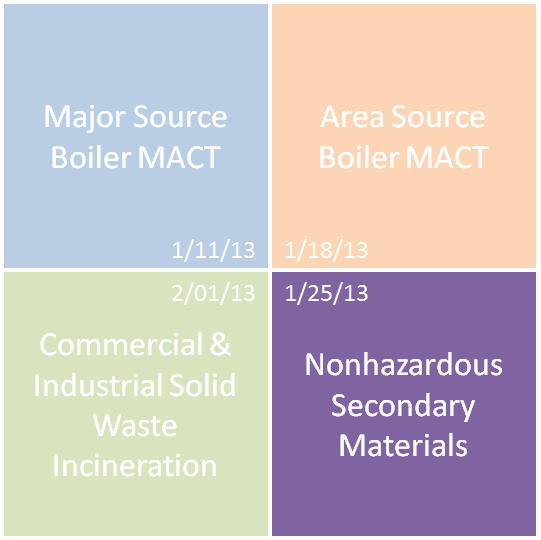

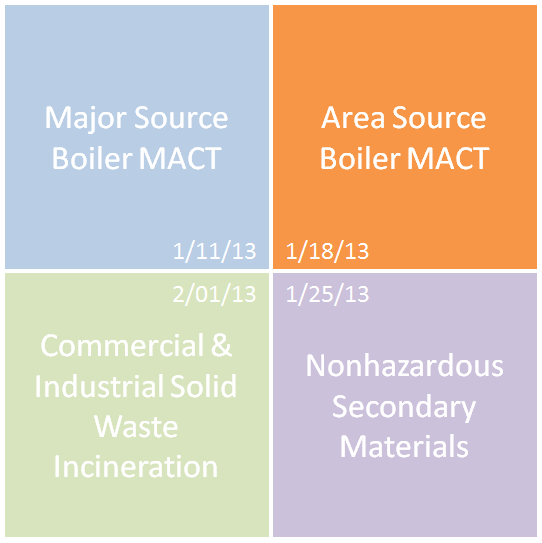

4 Rules Friday is a series of four blog posts highlighting key aspects of the final 4 Rules (i.e., Major and Area Source Boiler MACT, Nonhazardous Secondary Materials, and Commercial and Industrial Solid Waste Incineration). Please refer to the graphic for each blog’s posting date.

Beginning on page 116 and effectively ending on page 329, the Non Hazardous Secondary Materials (NHSM) portion of the 539 page rendering of the Commercial/Industrial Solid Waste Incinerators (CISWI) preamble and final rule make the pages written per page of actual rule ratio the highest of the 4 Rules (Major Source Boiler Maximum Achievable Control Technology (MACT), Area Source Boiler MACT, and the emission standards for new and existing CISWI units being the other three). And while the 4 Rules, including the NHSM rule, are printed out double-spaced, digesting a couple hundred pages of comments, responses to comments, and assessing what the revisions mean is not an inconsequential effort. But that’s why you signed up for ALL4’s blog in the first place, isn’t it?

First, we should refresh our understanding of the intent of the NHSM rule, which is to allow for a determination that a NHSM is not a waste and thus can be used as an alternate fuel or ingredient in a combustion process without triggering the CISWI emission standards. U.S. EPA has provided three processes by which a material can be evaluated against the NHSM criteria:

- A self-implementing NHSM non-waste option, which existed in the previous version of the rule.

- An optional petitioning process for NHSM non-waste status that is submitted at the regional level of U.S. EPA., which existed in the previous version of the rule, but has been slightly revised to allow multiple sources to be covered under a single petition and to assign the review for a NHSM non-waste determination affecting multiple regions to the Office of Solid Waste and Emergency Response (OSWER).

- A categorical NHSM non-waste determination issued by U.S. EPA, which is brand new in the final rule and should prove to be a very valuable mechanism for the regulated community to address common NHSM used as fuel, such as railroad ties.

For all three of these options, a legitimacy criteria documentation process must be undertaken. If the legitimacy criteria documentation for the NHSM non-waste determination is a “slam dunk,” meaning that the NHSM is “processed” (for materials outside the control of the NHSM generator) and meets, with no exceptions, all of the requirements under 40 CFR §241.3(d)(1), then you can self-implement your non-waste determination. If there are any legitimacy criteria that are problematic (e.g., some contaminant levels in the NHSM are greater than the levels of your traditional fuels), then some U.S. EPA involvement is required via the U.S. EPA Regional petitioning process or a categorical U.S. EPA exemption under 40 CFR §241.4 before a non-waste determination can be granted.

U.S. EPA has issued categorical non-waste exemptions for scrap tires, resinated wood, coal refuse, and dewatered pulp and paper sludges that meet certain criteria. Other materials for which categorical exemptions have been proposed, but not issued, include: manure, paper recycling residuals, construction and demolition wood, and creosote-treated railroad ties. Preliminary information has been supplied on these four materials seeking a non-waste determination; however, U.S. EPA will require more information before making a non-waste categorical determination. Remember also, that U.S. EPA has issued multiple “comfort” letters to NHSM users under the self-implementing non-waste option contained in the NHSM non-waste determination process.

It is important to note that even with the categorical exemptions listed above, there are some hidden details in the preamble to the NHSM rule. For example, if you are a pulp and paper mill and you burn dewatered sludge in a boiler, make certain that you qualify for this non-waste exemption. Your mill should be burning a significant portion of your sludge (at least 70% by U.S. EPA’s guidance) to make use of the categorical exemption. A mill can still consider sludge a non-waste if it burns less than 70% of what it generates; however, the mill will need to maintain its own self-implemented non-waste determination on file. Furthermore, all mills would be wise to track their amounts of sludge produced and burned for documentation purposes no matter which approach is used for assessing non-waste status.

U.S. EPA also took the opportunity to revise a few definitions in the NHSM rule. The revisions that affect the definitions of “clean cellulosic biomass,” “tire collection program,” and “resinated wood” are somewhat minor and added clarity where clarity was lacking. The revision to the definition of “contaminants” is a little more important than the other three revisions. Specifically, U.S. EPA introduced precursor pollutants in fuels (chlorine, fluorine, nitrogen, sulfur) and eliminated specific Clean Air Act (CAA) section 112(b) and 129(a)(4) pollutants not expected to be found in an NHSM (e.g., hydrogen chloride). U.S. EPA also grouped total cresols and total xylenes instead of the individual cresol and xylene compounds in the contaminant definition revision.

We offer a final observation about the interrelatedness of the NHSM rule and the Boiler MACT and CISWI rules. The Boiler MACT rule contains requirements to keep records if you combust NHSM that have been determined to be non-waste. Therefore, it can be implied that a facility must know on the effective date of Boiler MACT in 2016 if the NHSM it is using is a waste or non-waste, even if the compliance date for CISWI is later than that. (Yikes Dan, are you hinting that I should be worried about something that is more than 3 years out on the regulatory timeline?)

Well, there are always reasons for putting off the effort to address an issue with a long lead time. However, once you begin to look at the timelines associated with some of the effort around complying with Boiler MACT (e.g., control equipment design, air permitting, and actual construction time), just planning for Boiler MACT compliance, without considering any NHSM issues, needs to begin sooner rather than later. Does it make any sense to leave the NHSM determination as the last item to address in early 2016? If you are looking for certainty around how your fuel profile is going to look in 2016 and what impact it has on your Boiler MACT compliance scenario, finding out at the last minute that your alternate fuel does not qualify as a non-waste, thereby either triggering CISWI requirements or saying good-bye to a valuable fuel, is not conducive to an environmental manager’s peace of mind. The advice here is to arrange for your non-waste determination sooner rather than later.

February 2016 May As Well Be Tomorrow: Major Source Boiler MACT and Timing

Consultants and environmental personnel at industrial facilities are used to spreading the warning “plan now, this compliance date will be right around the corner.” Although we say it often, the warning is rarely without merit. Here we are again reviewing the Major Source Boiler MACT regulations and we will say it again: now is the time to plan for compliance. The compliance date for existing sources is likely to be in February 2016 (depending on when the final rule is published in the Federal Register). Although February 2016 seems like the distant future, there are several considerations that will compress the compliance timeline and create the need for immediate action between now and then:

- Capital Costs: Many facilities have struggled to set plans for future expansion amidst the uncertainty of how much capital expenditure will be required to comply with the Boiler MACT regulations. Now that we have the final rule in place, we can define the compliance costs of the rule. However, the process of defining that cost isn’t always simple because controlling certain pollutants (like carbon monoxide (CO) regulated under Boiler MACT) could increase emissions of other pollutants (like nitrogen oxides (NOX)) and bring New Source Review (NSR) permitting regulations into play. In rare cases, modifications made for Boiler MACT purposes could trigger NSR permitting and control requirements for other pollutants and complicate the process of defining required capital costs. Understanding how these rules play together now will be critical in planning for other projects.

- Resource Access: Many facilities will be required to install new particulate matter (PM) emissions controls or upgrade existing controls. These installations and upgrades will be resource intensive. They will require access to the equipment, access to engineering resources, and access to stack testing firms to measure PM emissions in support of the engineering efforts. These resources are not unlimited, particularly when many facilities are drawing from them at the same time, as they likely will to comply with Boiler MACT. Once again, the earlier these resources are addressed the better.

- Construction Permitting Timelines: There are very few Boiler MACT modifications that will not require some level of Clean Air Act construction permitting. Most states require permit application submittals for control device installations and air system modifications, particularly since with those modifications will come the regulatory provisions of Boiler MACT that will be incorporated into facility operating permits. Like any other construction permitting process, it will take time to receive the appropriate permits authorizing installation and construction of control devices from state agencies. Further, there are some facilities that have limited windows of time (shutdowns, rampdowns in production, etc.) during which these projects can be implemented. When you overlay state permitting timelines with the available windows to complete the physical changes and consider the items mentioned above, February 2016 may not look so far away.

Given the time necessary to prepare engineering studies for control device options, to conduct testing programs, and to prepare and submit permit applications, the three (3) year timeframe for compliance now may be a challenge for some facilities. Though the rule has provisions for a one (1) year extension, the message is clear: now is the time for action.

RICE MACT Update – U.S. EPA Finalized Amendments to the RICE MACT Late on January 14, 2013

U.S. EPA finalized proposed amendments to 40 CFR Part 63, Subpart ZZZZ – National Emissions Standards for Hazardous Air Pollutants for Stationary Reciprocating Internal Combustion Engines, the so called RICE MACT, late on Monday, January 14, 2013. Taking advantage of a last minute extension granted on December 14, 2012, U.S. EPA snuck the finalized rule in just under the wire posed by the 30-day extension. In their final rulemaking, U.S. EPA addressed petitions for reconsideration, legal challenges, and new technical information submitted by stakeholders, including industry and environmental groups, brought to the attention of U.S. EPA after publication of the August 2010 standards. The final amendments affect the following:

- Stationary spark ignition (SI) RICE at area sources with capacities greater than 500 HP.

- Engines located in remote areas of Alaska.

- Engines scheduled to be replaced in the next few years due to State or local rules.

- Engines installed in 2006 (certain subgroups).

- Engines located on offshore vessels on the outer continental shelf, specifically stationary compression ignition (CI) RICE.

- Emergency engines.

The finalized RICE MACT includes the controversial provisions expanding the duration that emergency engines can operate under demand response programs from 15 to 100 hours per year. Engines used in such a capacity will need to collect and submit an annual report including the location, dates, and times of such operation. The finalized rule expands the situations in which an emergency engine can operate in a non-emergency situation (for up to 100 hours per year) to include the following:

- Maintenance and testing.

- Emergency demand response for Energy Emergency Alert Level 2 situations [i.e., situations when there is at least a five (5) percent or more change in voltage].

- Heading off potential voltage collapse, or line overloads, that could result in local or regional power disruption (for up to 50 of the available 100 hours per year).

Proponents of such provisions tout the electric grid stabilization impacts of the expanded “bank” of demand response operating hours. Opponents of the provisions point instead to the perceived potential for increased emissions associated with the expanded demand response operation of uncontrolled diesel generators.

A copy of the pre-publication notice of this action can be found here, and a copy of U.S. EPA’s Fact Sheet on the finalized rule can be found here. Question pertaining to the finalized RICE MACT rules should be directed to Ron Harding at (610) 933-5246 ext. 19 or rharding@all4inc.com.

Final Area Source Boiler MACT: The Gift That Keeps on Giving

4 Rules Friday is a series of four blog posts highlighting key aspects of the final 4 Rules (i.e., Major and Area Source Boiler MACT, Nonhazardous Secondary Materials, and Commercial and Industrial Solid Waste Incineration). Please refer to the graphic for each blog’s posting date.

In part two of ALL4’s 4 Rules Friday series, we take a look at the Final Area Source Boiler MACT (40 CFR Part 63, Subpart JJJJJJ) and how the final rule may impact facilities. As we all are well aware by now, U.S. EPA issued pre-publication versions of the final rules, including Area Source Boiler MACT, on December 20, 2012. A number of the revisions to the final rule address the comments that U.S. EPA received regarding the December 23, 2011 proposed reconsideration of the Area Source Boiler MACT. In particular, U.S. EPA established four new subcategories since the March 21, 2011 final version of the rule. The subcategories for the final rule are as follows, with new categories noted in bold:

- Coal

- Biomass

- Oil

- Seasonal boilers – boilers that do not operate for at least seven consecutive months for each 12-month period and that fire only oil or biomass

- Small oil-fired boilers – boilers with a heat input capacity of less than or equal to 5 MMBtu/hr

- Boilers with an oxygen trim system – boilers that operate a continuous oxygen trim system and maintain an optimum air-to-fuel ratio

- Limited-use boilers – boilers that fire solid or liquid fuels with an average annual capacity factor less than or equal to 10 percent

The final rule also identifies additional boilers that are excluded from the source categories above and, therefore, are not subject to the Area Source Boiler MACT. These additional excluded boilers include electric boilers, residential boilers, and temporary boilers. U.S. EPA also clarified language around exclusions for boilers with Section 3005 permits and boilers used as control devices. To qualify as a boiler used as a control device, 50 percent or more of the heat input to the boiler must be provided by the gas stream being controlled, and the purpose of controlling the gas stream must be to comply with a requirement under 40 CFR Parts 60, 61, or 65.

The final rule also revised the applicability for dual-fuel fired boilers. Any existing dual-fired boiler (i.e., commenced construction on or before June 4, 2010) that meets the definition of a gas-fired boiler per 40 CFR §63.11237 and meets the applicability criteria of Subpart JJJJJJ after June 4, 2010 due to a fuel switch from gaseous fuel to solid, biomass, or liquid fuel will be considered an existing source as long as the boiler was designed to accommodate the alternate fuel. Similarly, any new or reconstructed boiler that meets the definition of a gas-fired boiler and meets the applicability criteria of Subpart JJJJJJ after June 4, 2010 due to a fuel switch from gaseous fuel to solid, biomass, or liquid fuel will still be considered a new source.

Mercury (Hg) and carbon dioxide (CO) emission limits for new and existing coal-fired boilers have been revised based on new information provided to U.S. EPA. The Hg emissions limit for coal-fired boilers greater than or equal to 10 MMBtu/hr has been increased from 4.8E-6 to 2.2E-5 lb/MMBtu and the CO emissions limit has been increased from 400 to 420 ppmvd corrected to 3% oxygen. Additionally, coal-fired boilers subject to a CO emission limit now have the option to comply using continuous emissions monitoring system (CEMS) data based on a 10-day rolling average.

The final rule also contains a number of changes related to work practice and management practice requirements. For the new subcategories added to the final rule (i.e., seasonal boilers, small oil-fired boilers, boilers with oxygen trim systems, and limited-use boilers), U.S. EPA has established tune-up requirements. However, the tune-ups are only required every five (5) years as opposed to the biennial tune-up requirements for coal-, biomass-, and oil-fired boilers. The methodology for conducting tune-ups has also been updated in the final rule to provide more detail around the previously vague tune-up requirements. This includes allowing for the use of portable CO analyzers to measure the concentration of CO in the effluent stream. Additionally, the burner and air-to-fuel ratio inspections can be delayed until the first scheduled shutdown, and until the first outage for units that sell electricity so long as the time between inspections does not exceed 36 months. Tune-ups shall be conducted within 30 days of startup for units that are not operating by the time the inspection is required. The final rule has also been revised so that initial tune-ups are not required for new or reconstructed boilers.

U.S. EPA has also revised the definition of energy assessment for those facilities that are subject to the one-time energy assessment requirements. The final rule clarifies that the energy assessment is limited to only those energy systems located on-site, associated with the affected boilers. U.S. EPA further clarifies that the scope of the energy assessment is based on energy use by individual areas of the facility (i.e., production areas, lines, or buildings) and not by the total aggregation of all individual energy areas of a facility. Also, all energy assessor approval and qualification requirements are waived for those energy assessments that were completed on or after January 1, 2008 to meet, or are amended to meet, the energy assessment requirements in the final rule by March 21, 2014. If, by March 21, 2014, a facility is operating under an energy management program established through energy management systems compatible with ISO 50001 which includes the affected boilers, the energy assessment requirement is satisfied.

Fuel sampling requirements were revised for coal-fired units, in that if the Hg constituents of the fuel or fuel mixture are measured to be less than or equal to 50 percent of the Hg emission limit during the initial compliance demonstration, no further sampling is required. If the constituents are measured to be greater than 50 percent of the emission limit, then quarterly sampling is required. Performance testing requirements were similarly revised, in that if the particulate matter (PM) initial performance test results demonstrate that emissions are less than or equal to 50 percent of the PM emission limit, no further performance testing is required. If the test results demonstrate that emissions are greater than 50 percent of the emission limit, then ongoing performance tests are required pursuant to 40 CFR §63.11220(a).

The initial compliance date of the final rule for existing affected boilers subject to an emissions limitation has not been revised and remains March 21, 2014. Initial notification for existing affected boilers is now due by January 20, 2014. The initial tune-up, previously required by March 21, 2012, is now required by March 21, 2014. The Notification of Compliance Status (NOCS) regarding the initial tune-up requirement, previously due by July 19, 2012, is now due by July 19, 2014. New sources (which remain defined as those that began operating on or after June 4, 2010) must be in compliance upon startup, except for new sources that began operation on or before May 20, 2011, which must have been in compliance by May 20, 2011.

As mentioned above, all existing boilers subject to Subpart JJJJJJ must demonstrate initial compliance by March 21, 2014. This means that there is not much time left for those facilities that must install a control device to comply with the Area Source Boiler MACT. However, in the preamble of the final rule, U.S. EPA states that the Clean Air Act “allows Title V permitting authorities to grant sources, on a case-by-case basis, extensions to compliance time of up to 1 year if such time is needed for the installation of controls.” So fear not, all hope is not lost if you are still a little late to the party. However, all facilities must begin to act now because the compliance date will be here before we know it.

The pre-publication version of the final rule can be found here. Please refer to Susie’s blog post for information related to the final Major Source Boiler MACT.

Pennsylvania Expands Scope of Greenhouse Gas Reporting to Smaller Facilities

If you happen to be a facility located in Pennsylvania and are required to submit an Annual Inventory and Emission Statement to the Pennsylvania Department of Environmental Protection (PADEP) by March 1 of each year, you will likely receive the 2012 reporting notice in which PADEP informs that reporters must include greenhouse gas (GHG) emissions in their upcoming March 1, 2013 submittal.

We’ve spoken to PADEP and the new data is being requested due to GHG being considered “subject to regulation” under the Clean Air Act (CAA). Whether this brand new requirement will affect your facility is not at all dependent on whether or not your facility is subject to any Federal requirements for GHG due to exceeding a major source GHG threshold. In fact, a facility does not even have to be a major source subject to Title V to be required to report GHG to PADEP this year, since facilities with minor source State Only Operating Permits are receiving similar letters. It is also not dependent on whether you are subject to Federal reporting requirements under 40 CFR Part 98 (Mandatory Reporting of Greenhouse Gases). The requirement will apply to any facility located in Pennsylvania that is already required to submit an annual emissions inventory.

Until now, you may not have calculated GHG emissions due to falling below applicable 40 CFR Part 98 reporting thresholds, or not having gone through any permitting activities since GHG became subject to regulation. PADEP has attempted to alleviated some of this new burden for you by pre-populating your 2012 reporting forms to at least include placeholder fields for combustion-related carbon dioxide (CO2), nitrous oxide (N2O), and methane (CH4), thereby pointing out the most likely sources of GHG at your facility. PADEP also recommends utilizing 40 CFR Part 98 calculation methodologies to identify contributing sources of emissions and develop your corresponding calculations. However, it is important to note that PADEP’s recommendation to utilize 40 CFR Part 98 calculation methodologies does not include a recommendation to necessarily exclude emissions from sources that are exempted under 40 CFR Part 98 but included in your permit, or, on the contrary, to include sources of GHG emissions that are required under 40 CFR Part 98 but which are currently not included in your permit. PADEP is indicating that you must provide GHG data for all applicable sources of GHG that you currently report either combustion or process-related emissions for as part of your typical annual report.

Facilities that must now include GHG in their annual Pennsylvania report should reconsider their plans for preparing required submittals and adjust their schedules accordingly. If you haven’t previously calculated GHG emissions, you’ll want some extra time to identify appropriate equations, emission factors and operating data, and to do the additional math. If you need guidance, reach out to resources such as ALL4 well in advance of the deadline. On the other hand, if you are required to report your facility’s GHG at the Federal level by April 1, 2013, it will now behoove you to complete those calculations well in advance of the March 1 deadline for Pennsylvania so that you will be reporting consistently at both the State and Federal levels.

Air Permitting Gets Less Complicated Each Year…Said No One Ever: How the Aggregation Test Just Got More Complicated

For those involved in Title V or New Source Review (NSR) permitting, the concept of aggregation and the three-pronged litmus test to define a “single source” has long (over 30 years) been based on the following three (3) concepts:

- Whether emission units are under the common control of the same person;

- Whether emission units are in a single major industrial grouping (i.e., the same two-digit SIC Code); and

- Whether the emission units are located on one (1) or more contiguous or adjacent (emphasis added) properties.

You can look up “adjacent” in Merriam-Webster (www.m-w.com) and find definitions such as “not distant,” or “having a common endpoint or border.” For the most part I’m confident that we would agree these definitions seem fairly straight-forward and self-explanatory. However, for over 30 years, U.S. EPA has produced numerous applicability determinations and issued guidance around the concept of “adjacent,” which included not only a physical distance criterion, but also a “functional interrelatedness,” or dependency on criterion when evaluating if two (2) (or more) sources (or entire facilities) are one (1) source.

Flashback to August 2012, when the 6th Circuit Court of Appeals (comprising Michigan, Ohio, Tennessee, and Kentucky) vacated and remanded U.S. EPA’s historical approach for “adjacent” in the Summit Petroleum Corp. v EPA et al. decision. Note that in this case, Summit’s wells and sweetening plant were deemed by U.S. EPA to be a single source (thus triggering the need to apply for a Title V operating permit) due to their functional interrelatedness despite the wells being approximately seven (7) miles away from the sweetening plant. By the vacatur and remand, the Court unqualifiedly rejected U.S. EPA’s functional interrelatedness test for determining whether facilities are “adjacent” for air aggregation purposes (See a 4 The Record Guest Article regarding the decision here).

In a December 21, 2012 memo (available here) from U.S. EPA’s Office of Air Quality Planning Standards to its Regional Air Division Directors, U.S. EPA has decided it will no longer consider interrelatedness as a factor for adjacency when making single source determinations in Michigan, Ohio, Tennessee, and Kentucky. Outside of these states (i.e., outside of the jurisdiction of the 6th Circuit Court of Appeals), U.S. EPA will continue to consider interrelatedness in permitting actions.

Aggregation has received a lot of attention in the oil and gas sector, particularly in the Northeast and Midwest U.S. However, the concepts are the same regardless of industry, and are becoming more common as projects related to energy savings, such as the co-location of co-generation plants at industrial sites, or Facility A providing a waste or off-spec product to its neighbor Facility B for its use a raw material in its process (i.e., the concept of interrelatedness, including an economic dependency) receive more consideration in this economic climate. Consider the single-source factors as part of your planning process and use resources such as your state agency or ALL4 for guidance.