Waste Not: Why You Need a Waste Minimization Program

Posted: November 6th, 2025

Authors: Kelly D.When was the last time you took a close look at your waste streams?

If you’re like many other companies, you may be relying on your hazardous waste vendor to handle waste determination and profiling. But here’s the catch: as the generator, you’re ultimately responsible for the accuracy of waste characterization and documentation for your site. Is storing your waste profiles in the vendor’s client portal enough? Do you have a written waste minimization program in place or just a vague idea that one exists?

What the Regulations Say:

40 CFR §262.11(d)(1) lists acceptable methods for generator waste determination, which includes:

- Process knowledge (e.g., information about chemical feedstocks and other inputs to the production process).

- Knowledge of products, by-products, and intermediates produced by the process.

- Chemical or physical characterization of wastes.

- Information on the properties of the chemicals used or produced by the process.

- Analytical testing that illustrates the properties of the waste.

- Other reliable and relevant information about the properties of the waste or its constituents.

When waste generator knowledge isn’t enough to make an accurate waste determination, the generator must test the waste according to the applicable methods set forth in subpart C of 40 CFR part 261.

Section 262.11(f) specifically mandates that Small Quantity Generators (SQG) and Large Quantity Generators (LQG) maintain records supporting their hazardous waste determinations and that the records are maintained for at least three years. While not required for Very Small Quantity Generators (VSQGs) of hazardous waste, it is recommended that VSQGs maintain these same records to support their waste determinations.

The required documentation includes:

- The results of any tests, sampling, waste analyses, or other determinations made; records documenting the tests, sampling, and analytical methods used to demonstrate the validity and relevance of such tests,

- Records that demonstrate the process by which the waste was generated,

- The composition and properties of the waste; and

- Records which explain the knowledge basis for the generator’s determination

A lot of facilities get their waste tested but the rest of the requirements are forgotten and recordkeeping efforts often end there. Even if testing is not required and the generator can make waste determinations based on knowledge, they are still required to document additional information on the waste generation process and how the determination was made.

But That’s Not All:

The U.S. Environmental Protection Agency (U.S. EPA) takes waste recordkeeping one step further by requiring Large Quantity Generators (LQGs) to sign a certification on the uniform hazardous waste manifest. This certification states the following:

“I am a large quantity generator. I have a program in place to reduce the volume and toxicity of waste generated to the degree I have determined to be economically practicable, and I have selected the practicable method of treatment, storage, or disposal currently available to me which minimizes the present and future threat to human health and the environment;”

The generator is required to sign this official document stating that they have a program in place to reduce the amount of waste generated. While U.S. EPA doesn’t explicitly require this program to be written, some states require written pollution prevention or waste minimization programs, which typically include hazardous waste reduction information. If you aren’t sure if your state requires a written program, we can help!

What is a Waste Minimization Program?

Waste Minimization means reducing the hazardous waste generated before it is treated, stored, or disposed of. An effective waste minimization program can lower costs and reduce environmental impact.

A strong waste minimization program should include:

- Leadership Support: Clear goals, training, and integration into company policy

- Waste Characterization and Management: Accurate inventory and cost management

- Financial Support: Allocating costs required for program success

- Assessments: Identifying opportunities to reduce waste

- Procurement Policies: Favoring less hazardous materials

- Implementation and Evaluation: Regular program reviews and improvement implementation

- Training and Recordkeeping

- Sharing Best Practices: Across departments or among peer organizations

How Does it Work?

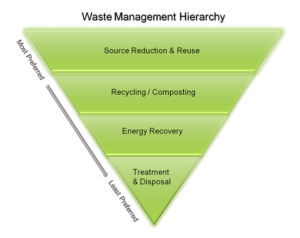

The use of source reduction and recycling methods prior to treatment or disposal of wastes is the best place to start.

Source reduction, also known as pollution prevention (P2), refers to any action that will reduce or eliminate hazardous material at its source and significantly decrease or eliminate the amount of waste exiting a process.

This can include:

- Process changes (e.g., reducing cleaning operations)

- Product redesign or reformulation (e.g., removing per- and polyfluoroalkyl substances (PFAS) or lead)

- Material Substitution (e.g., switching to lead-free solder)

- Equipment or technology upgrades

- Better housekeeping, maintenance, inventory control, and training

If source reduction isn’t feasible, recycling is the next best option. This is a broad term that encompasses the use, reuse, or reclamation of a resource, byproduct, or residual material in original or changed form rather than discarding it as waste. It includes:

- Removing contaminants from waste to allow reuse (e.g., triple-rinsing waste containers, metals recovery)

- Reclaiming useful ingredients: (e.g., solvent recovery and distillation systems)

- Reusing spent materials as a substitute for new material (e.g., reusing purge solvents)

- Using waste as a substitute for a new commercial product. (e.g., recycled mercury in fluorescent lamps)

Some recycling may require a permit and you should be sure to comply with any applicable hazardous waste requirements when recycling. This includes proper identification, handling, storage, and transportation of the materials, even when they are destined for recycling. For more information on P2 and waste management, check out the U. S. EPA website.

Figure 1

Waste Management Hierarchy

Benefits of a Waste Minimization Plan:

A well-executed waste minimization plan:

- Reduces costs and inefficiencies

- Demonstrates environmental responsibility and helps meet sustainability goals

- Increases ability to qualify for International Organization for Standardization (ISO) certifications

- Can increase business from companies that have environmental requirements for their vendors and business partners

- Improves relationship with regulators, employees, investors, and the public

Need Help Getting Started?

Navigating hazardous waste regulations and building an effective waste minimization program can be complex—but you don’t have to do it alone. Whether you need help characterizing your waste, developing a written program, or identifying practical reduction strategies, our team is here to support you. We offer expert guidance tailored to your operations to help you stay compliant, reduce costs, and meet your sustainability goals. For more information, reach out to your ALL4 project manager or contact Kelly Di Stefano at kdistefano@all4inc.com. Let’s work together to turn your waste challenges into opportunities.