Turning Exposure Data Into Safer Workplaces

Posted: October 23rd, 2025

Authors:Understanding Workplace Airborne Hazards

In many workplaces employees handle chemicals that can cause both immediate and long-term health effects. Whether it be in a research and development laboratory or a manufacturing environment, airborne contaminants can pose risks if not properly controlled. Some examples of these contaminants are particulates (dusts), chemical vapors, and mists. To protect workers, employers need real exposure data capturing the specific tasks employees perform, local ventilation, nearby operations, and variations throughout the workday. This information provides a more accurate picture of what employees are truly breathing.

This is where occupational exposure assessments utilizing personal air monitoring badges and air sampling pumps come in. By measuring actual exposures during typical work activities, these tools provide the information needed to protect employees, ensure compliance, and design safer workplaces.

Occupational Exposure Assessments

Occupational exposure assessments are a crucial step in a comprehensive industrial hygiene (IH) program. Conducting occupational exposure assessments can provide employers with key information regarding the health and safety of their employees.

- Short-Term Safety: Monitoring can identify acute overexposures that may lead to immediate effects such as dizziness, eye and throat irritation, or even chemical burns. For example, comparing data against Short-Term Exposure Limits (STELs) helps ensure employees are not harmed by high-concentration exposures.

- Long-Term Safety: Many chemicals cause health issues after repeated, long-term exposure. Personal sampling helps ensure employees are not exceeding eight-hour time-weighted average (TWA) limits, reducing the risk of chronic diseases such as asthma, organ toxicity, or certain cancers.

- Regulatory Compliance: The Occupational Safety and Health Administration (OSHA) requires employers to evaluate employee exposures to hazardous chemicals under standards such as 29 CFR 1910.1000 (Air Contaminants) and substance-specific rules. Personal monitoring provides defensible data to demonstrate compliance with OSHA Permissible Exposure Limits (PELs) or recommended exposure limits such as the American Conference of Governmental Industrial Hygienists (ACGIH) Threshold Limit Values (TLVs).

A Brief Occupational Exposure Assessment Roadmap

An effective occupational exposure assessment typically begins with a process review, where the work areas and tasks are observed to understand what chemicals are used, how they are used, and what controls are in place. From there, a sampling plan is created by reviewing chemical information and determining which substances to test and how many samples to collect. Some substances, such as respirable crystalline silica, lead, and benzene, have specific OSHA requirements that mandate exposure monitoring when employees may be exposed above action levels. For operations that warrant sampling, employees are often grouped into similar exposure groups, with monitoring focused on those tasks and job roles most likely to experience the highest exposures.

How Air Monitoring Works

There are two common approaches to personal air sampling:

- Badges (Passive Samplers): Lightweight devices worn on the lapel, designed to absorb chemical vapors or gases over the course of a shift or task. These are often used for volatile organic compounds (VOCs) and are valued for being simple and unobtrusive.

- Pumps (Active Samplers): These devices actively draw measured volumes of air through a collection medium, allowing for precise measurement of air sampled. Pumps are ideal for particulates like dust, metals, or acid mists.

Selecting the right method depends on the hazardous substance of concern, the work environment, and the accuracy required for regulatory or internal standards. Guidance from agencies such as OSHA, California State Plan (Cal/OSHA), other state plan equivalents, National Institute for Occupational Safety and Health (NIOSH), and ACGIH should also be considered, as each provides validated sampling methods for different contaminants. Factors such as expected concentration ranges, duration of sampling, potential interferences, and analytical sensitivity all play a role in determining whether a passive badge or an active pump-based method is most appropriate. Additionally, each analytical method has a defined Limit of Quantitation (LOQ), the lowest concentration of a substance that can be measured reliably with acceptable precision and accuracy, which should be considered when selecting a method to ensure that results are both meaningful and compliant.

Controls That Follow Monitoring

Collecting exposure data is important, but what you do with that data is even more important.

- Compare air sampling results to applicable occupational exposure limits: Results are evaluated against current occupational exposure limits including OSHA PELs, ACGIH TLVs, and the NIOSH Recommended Exposure Limits (RELs).

- Identify Trends: Data often highlight specific operations, shifts, or tasks with elevated exposure risks.

- Communicate Results: Sharing outcomes with employees demonstrates transparency and supports Right-to-Know obligations under OSHA’s Hazard Communication Standard. Certain substances, such as hexavalent chromium and lead, also have specific notification requirements when exposure results exceed regulatory limits.

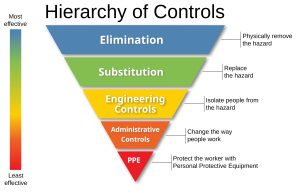

Controls solve the issues that monitoring identifies. Through the collected exposure data and following the hierarchy of controls, employers can implement strategies such as:

- Elimination: Finding ways to completely eliminate the use of the hazardous substance from the process.

- Substitution: Replacing the hazardous substance with a lesser or non-hazardous substance.

- Engineering Controls: Local exhaust ventilation, enclosed systems, or improved fume hood performance.

- Administrative Controls: Job rotation, limiting time spent on high-exposure tasks, or adjusting production schedules.

- Personal Protective Equipment (PPE): Respirators and other PPE worn when exposures cannot be reduced below limits through engineering or administrative means alone.

Once controls are in place, follow-up monitoring verifies their effectiveness and supports continuous improvement.

Moving Forward

Occupational exposure assessments are a foundational tool for protecting worker health. By collecting exposure data, employers gain the insights they need to reduce risks, prevent illness, and create a culture of safety.

If your facility uses or produces hazardous chemicals, ask whether you truly understand employee exposure. Even with existing controls such as local exhaust ventilation, respirators, gloves, or other forms of PPE, unknown or underestimated exposures can still occur due to changes in processes, chemical formulations, or work practices. Regular exposure assessments help verify that PPE is effective, ensure engineering controls are performing as intended, and identify opportunities for improvement.

For assistance on conducting occupational exposure assessments or any IH related questions, please contact Joe Grosse at JGrosse@all4inc.com or John Kelleher at JKhelleher@all4inc.com.

1https://en.wikipedia.org/wiki/Hierarchy_of_hazard_controls