Five Considerations of Being a CISWI Unit

Posted: August 1st, 2013

Author: All4 Staff

With so much talk of boilers and heaters since the 4 Rules were published in early 2013, most facilities are focused on developing an understanding and strategy to comply with the Maximum Achievable Control Technology (MACT) standards for Boilers (commonly referred to as Boiler MACT). However, one of the 4 Rules is the Commercial and Industrial Solid Waste Incineration (CISWI) rule, and facilities may want to consider this rule as a compliance alternative to Boiler MACT. The CISWI rules are codified at 40 CFR Part 60, Subpart CCCC for new, modified, or reconstructed units (i.e., New Source Performance Standards) and Subpart DDDD for existing units (i.e., Emission Guidelines). This concept of choosing to be regulated under the CISWI regulations may not be as far-fetched as one might think. In fact, from an emission limit, fuel flexibility, and timing perspective, a case can be made that some boilers could be better off regulated under CISWI rather than Boiler MACT. Let’s look at the following five (5) considerations when deciding whether to go down the CISWI path or the Boiler MACT path:

- Fuel flexibility

- Compliance schedule

- Compliance requirements

- Emission limits

- Public perception

Before we dive into the specific considerations of being a CISWI unit as opposed to a Boiler MACT unit, let’s review the basics of CISWI. A CISWI unit is any distinct operating unit of any commercial or industrial facility that combusts, or has combusted in the preceding six (6) months, any solid waste. The CISWI rule applies to 106 existing units (according to U.S. EPA estimates) in four (4) subcategories: incinerators, energy recovery units (ERUs), waste-burning kilns, and small, remote incinerators. ERUs are further broken down into three (3) subcategories: ERU liquids and gases, ERU biomass, and ERU coal. Waste-burning kilns have two (2) subcategories, which are differentiated based on carbon monoxide (CO) emission limits: long kilns and preheater/precalciner categories.

Since the combustion of solid waste is what distinguishes a CISWI emissions unit from a Boiler MACT emissions unit, it is important to understand the definition of solid waste. For rule applicability, 40 CFR Part 258.2 defines the term solid waste. Solid waste is defined as any garbage, or refuse, sludge from a wastewater treatment plant, water supply treatment plant, or air pollution control facility and other discarded material, including solid, liquid, semi-solid, or contained gaseous material resulting from industrial, commercial, mining, and agricultural operations, and from community activities. Solid waste is not a non-hazardous secondary material (NHSM) that meets the “legitimacy criteria” as outlined at 40 CFR Part 241.3(b).

The CISWI rule has many components including increments of progress and control plans, preconstruction siting analysis (for new sources), waste management plans, operator training and qualification, air pollution control inspections, emission and operating limits, performance testing, initial and continuous compliance requirements, and monitoring, recordkeeping, and reporting requirements. It is noteworthy that there are no major and area source distinctions in the CISWI rule. Since the effective date of the CISWI rule for existing sources (February 2013), most facility operators have been exposed to some type of webinar, conference, or other training that provided the basic requirements of CISWI and Boiler MACT rules. In lieu of going through the details of each component of two rules, let’s look at those components that should be evaluated as part of the CISWI/Boiler MACT comparison.

1. Fuel Flexibility

Fuel flexibility is probably the most important consideration when comparing CISWI to Boiler MACT. Boiler MACT fuel categories are clearly defined, and any fuel outside of those categories must be proven to be a non-waste NHSM following the legitimacy criteria contained at 40 CFR Part 241.3(d). Under the CISWI rule, facilities can combust traditional fuels along with solid wastes. For example, a facility that combusts biomass along with a pre-consumer NHSM (e.g., off-spec plastic parts) may want to evaluate becoming a CISWI unit in lieu of being a Boiler MACT unit. Under the current Boiler MACT rules, the example facility would need to cease firing that valuable and cheap alternate fuel in order to be classified as a Boiler MACT unit, since off-spec plastic parts are considered a solid waste pending a viable non-waste determination. However, the unit could continue to fire any NHSMs under the CISWI rule.

2. Compliance Schedule

Another benefit of falling under the CISWI category is the potentially extended compliance schedule. Existing CISWI units have to comply with the standards no later than three (3) years after U.S. EPA approves a State Plan or five (5) years after the February 7, 2013 publication date (i.e., February 7, 2018), whichever is earlier. It is highly likely that the compliance date will ultimately be five (5) years after the CISWI rule publication date, thus, the February 7, 2018 compliance date. The Boiler MACT units are facing a March 21, 2014 compliance date for area sources and a January 31, 2016 compliance date for major sources, and thus the CISWI compliance date gives existing facilities between two (2) and four (4) more years to implement a compliance strategy. These Boiler MACT dates are fast approaching. The CISWI compliance date allows facilities a little more breathing room to determine compliance strategy and implementation time. The Boiler MACT sources, especially area sources, are on a compressed timeline to get their compliance strategy implemented, especially once air permitting activities are taken into account.

3. Compliance Requirements

Both rules have compliance requirements (and plenty of them). The common requirements include performance testing, emission and operating limits, monitoring, recordkeeping, and reporting. Let’s focus on the requirements that are different:

- Increments of Progress

- Waste Management Plan

- Operator Training and Qualification

State Plans (i.e., state rules developed to implement the Subpart DDDD Emission Guidelines) must include at least two (2) increments of progress for regulated CISWI units. Increments of progress requirements become applicable if you plan to achieve compliance more than one (1) year following the effective date of the State Plan. If this path is chosen, facilities must submit a final control plan and achieve final compliance by a specific date in the State Plan. The final control plan must include the measures that will be taken, including a description of any process changes or air pollution control device changes, to comply with the CISWI emission limits. A facility must notify, no later than 10 days after the increment compliance date, that they have achieved the increment of progress. A facility must complete all of the process changes and retrofit of control devices, if needed, that are specified in their final control plan to achieve the final compliance increment of progress.

Another different compliance component to the CISWI rule is the requirement to write and maintain a Waste Management Plan (WMP). This is a plan that identifies the feasibility and methods used to reduce or separate certain toxic components of a solid waste in order to reduce or eliminate their emissions due to being incinerated. The WMP would rank the practical and feasible contaminant reduction options by effectiveness, costs of separation measures, emissions reductions expected, and any other environmental or energy impacts for each option. The facility would only implement those measures that are considered practical and feasible. The WMP must be submitted to U.S. EPA or the delegated enforcement authority no later than the date required to submit the final control plan discussed above.

Yet another requirement that is different from the Boiler MACT rules is operator training and qualification. A CISWI unit can only be operated when a fully trained and qualified CISWI unit operator is accessible. What does this mean? It means that a trained and qualified operator is either on-site at the time of operation or can be at the facility within one (1) hour. The operator can be someone who operates the CISWI unit directly or supervises plant personnel who operate the unit. The training must include the following elements: environmental concerns (including types of emissions), basic combustion principles (including products of combustion), operation of the facility’s specific type of incinerator (including proper startup, waste charging, and shutdown procedures), combustion controls and monitoring, operation of air pollution control equipment, inspection and maintenance of the incinerator and air pollution control device(s), corrective actions to prevent and correct malfunctions, ash characteristics and handling procedures, all applicable workplace standards, pollution prevention, and waste management practices. The training program must include an exam and written material that can be referenced after the course is over. An operator needs to maintain his qualification by completing an annual review or refresher course.

3. Compliance Requirements

Both rules have compliance requirements (and plenty of them). The common requirements include performance testing, emission and operating limits, monitoring, recordkeeping, and reporting. Let’s focus on the requirements that are different:

- Increments of Progress

- Waste Management Plan

- Operator Training and Qualification

State Plans (i.e., state rules developed to implement the Subpart DDDD Emission Guidelines) must include at least two (2) increments of progress for regulated CISWI units. Increments of progress requirements become applicable if you plan to achieve compliance more than one (1) year following the effective date of the State Plan. If this path is chosen, facilities must submit a final control plan and achieve final compliance by a specific date in the State Plan. The final control plan must include the measures that will be taken, including a description of any process changes or air pollution control device changes, to comply with the CISWI emission limits. A facility must notify, no later than 10 days after the increment compliance date, that they have achieved the increment of progress. A facility must complete all of the process changes and retrofit of control devices, if needed, that are specified in their final control plan to achieve the final compliance increment of progress.

Another different compliance component to the CISWI rule is the requirement to write and maintain a Waste Management Plan (WMP). This is a plan that identifies the feasibility and methods used to reduce or separate certain toxic components of a solid waste in order to reduce or eliminate their emissions due to being incinerated. The WMP would rank the practical and feasible contaminant reduction options by effectiveness, costs of separation measures, emissions reductions expected, and any other environmental or energy impacts for each option. The facility would only implement those measures that are considered practical and feasible. The WMP must be submitted to U.S. EPA or the delegated enforcement authority no later than the date required to submit the final control plan discussed above.

Yet another requirement that is different from the Boiler MACT rules is operator training and qualification. A CISWI unit can only be operated when a fully trained and qualified CISWI unit operator is accessible. What does this mean? It means that a trained and qualified operator is either on-site at the time of operation or can be at the facility within one (1) hour. The operator can be someone who operates the CISWI unit directly or supervises plant personnel who operate the unit. The training must include the following elements: environmental concerns (including types of emissions), basic combustion principles (including products of combustion), operation of the facility’s specific type of incinerator (including proper startup, waste charging, and shutdown procedures), combustion controls and monitoring, operation of air pollution control equipment, inspection and maintenance of the incinerator and air pollution control device(s), corrective actions to prevent and correct malfunctions, ash characteristics and handling procedures, all applicable workplace standards, pollution prevention, and waste management practices. The training program must include an exam and written material that can be referenced after the course is over. An operator needs to maintain his qualification by completing an annual review or refresher course.

4. Emission Limits

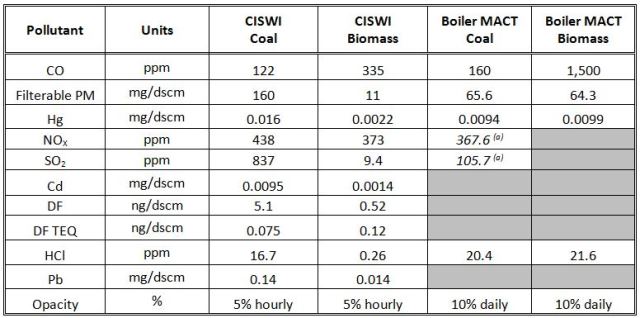

Let’s look at a biomass fuel and coal example and compare the Boiler MACT and CISWI emission limits. Note that the emission limits presented in the CISWI rule are corrected to seven (7) percent oxygen whereas the Boiler MACT emission limits are presented as corrected to three (3) percent oxygen. For comparison purposes, we have presented all emission limits as corrected to three (3) percent oxygen.

By U.S. EPA’s estimate, the major source Boiler MACT will regulate 14,000 boilers and process heaters that burn solid, liquid, and gaseous fuels. U.S. EPA designated nine (9) different boiler designs to be regulated. Similarly, the CISWI rules regulate several different combustion units all of which combust a solid waste; however, emission limits for “energy recovery units” are the most appropriate to compare with Boiler MACT emission limits, as these units “would be considered boilers and process heaters if they did not combust solid waste.” Shown below is a table that provides a side-by-side comparison of the emission limits that would apply under Boiler MACT for existing coal and biomass boilers (stoker and stoker with sloped grate, respectively) and under CISWI for existing energy recovery units. For reference purposes, the New Source Performance Standards (NSPS) Subpart Db oxides of nitrogen (NOX) and sulfur dioxide (SO2) coal emission limits are included in the table.

Note: All values are at 3% O2.

(a) NSPS Subpart Db values are italicized and provided for reference purposes, as there are no Boiler MACT limits for SO2 and NOX.

As shown in the table, the comparison tells a different story for biomass and coal units. For biomass units, the CISWI biomass emission limits are more restrictive than the Boiler MACT emission limits for carbon monoxide (CO), filterable particulate matter (PM), mercury (Hg), and hydrochloric acid (HCl). In addition, the CISWI biomass SO2 emission limit could represent an issue for boilers that co-fire limited amounts of high sulfur fuels (e.g., coal or high sulfur oil). For coal fired units, the CISWI emission limits are higher for PM and Hg and are lower for CO and HCl relative to the Boiler MACT emission limits. For SO2 and NOX, the CISWI emission limits are higher than those for the NSPS Subpart Db.

A facility should consider the degree of fuel flexibility desired with the amount of effort required to meet emission limits. Facilities would need to do some preliminary evaluations when considering the CISWI path to ensure their fuels fired meet the CISWI emission limits. Similarly, if a facility is contemplating going down the Boiler MACT path, preliminary engineering testing needs to be completed to determine how the facility fares against the Boiler MACT emission limits.

5. Public Perception

Public perception of units firing solid wastes versus traditional fuels can also play a role in a facility’s decision regarding CISWI and Boiler MACT. Firing solid wastes tends to have a negative connation even if a facility may be subject to more stringent emission limits than a non-waste combusting source. If a facility does decide to comply with the CISWI rule, the public perception can be influenced through education and outreach to the community surrounding the facility. The public perception will depend on each facility’s location and community situation. A facility should definitely keep public relations in mind when deciding which path to choose. It could be a deciding factor. Depending on one’s community, there could be a lot of opposition to being a CISWI unit.

When choosing a compliance strategy for your boiler, heater, or incineration unit, take into account the considerations described herein. Weigh the pros and cons of each for your particular facility, community, and situation. There is no clear cut answer. It is facility-specific. The operations of one facility may lend itself to becoming a CISWI unit while another may not. How could you realize a business and compliance advantage by operating under the CISWI rule? What would an environmental compliance advantage mean for you and your business? If you think that the CISWI rule might be an alternative to Boiler MACT for you or you want to learn more, contact us to discuss your specific concerns.