Cement Manufacturing – Balancing Growth with Air Quality Requirements

Posted: September 27th, 2013

Author: All4 Staff

In most areas of the U.S., it appears that the recession is a bad memory and the signs of recovery are all around us. As described by the Portland Cement Association (PCA) on its website[1], “following the strongest cement consumption gains in seven (7) years in 2012, cement consumption growth will continue in 2013 with a 6.2% increase.” PCA continues to explain that “the accelerated consumption predicted during the second half of 2013 should carry into the following year, with an increase of 9.2% for 2014.” PCA also upwardly revised its long-range projections for 2015-2017, with annual growth during that period expected to be as high as 11.1%. PCA predicts cement consumption levels will reach 120 million metric tons by 2017.

With this good news for U.S. cement plants, as well as similar projects across key construction sectors, the cement industry will need to balance this growth with challenging air quality requirements. A given cement manufacturing process can simultaneously be subject to multiple air quality regulations with varying requirements and compliance deadlines. Specifically, these requirements include the National Emission Standards for Hazardous Air Pollutants (NESHAPs) for the Portland Cement Manufacturing Industry (40 CFR Part 63, Subpart LLL; “PC MACT”); the Commercial and Industrial Solid waste Incinerator (CISWI) Rule (40 CFR Parts 60, Subparts CCCC or DDDD), the NESHAP for Major Sources: Industrial, Commercial, and Institutional Boilers and Process Heaters (40 CFR Part 63, Subpart DDDDD, “Boiler MACT”), and New Source Performance Standards (NSPS) for Portland Cement Plants (40 CFR Part 60, Subpart F). Since both CISWI and Boiler MACT have been given an enormous amount of attention in 2013, in this article we will explore PC MACT in some more detail and then discuss the relationship between these separate but inexorably connected rules.

Brief History of PC MACT[2]

Similar to Boiler MACT, PC MACT has existed for several years, beginning with the promulgation of standards in 1999. Following iterations of comments, reconsiderations, and amendments, revised standards were promulgated on February 12, 2013. PC MACT applies to both major and area sources of HAPs. One (1) of the primary drivers of the revised PC MACT was the impact of the U.S. Environmental Protection Agency’s (U.S. EPA’s) nonhazardous secondary materials (NHSM) rule, which resulted in the reclassification of 23 cement kilns as CISWI units. This required U.S. EPA to recalculate the floors that establish the PC MACT emission standards. With the recalculation of the floor came revisions to the standards for particulate matter (PM); the standards for mercury, total hydrocarbons (THC), and hydrogen chloride (HCl) remained the same as the 2010 version of PC MACT. PC MACT also includes an emission standard for dioxins and furans (D/F). In addition, startup and shutdown emission limits were replaced with work practice standards, and the monitoring requirements for the PM and THC pollutants were modified. Lastly, and potentially most importantly, the compliance date to meet the PC MACT emission standards was extended to September 9, 2015 for existing sources. A more near-term compliance date of February 12, 2014 was established for existing open clinker storage piles.

Affected Sources Under PC MACT

The affected sources in PC MACT consist of kilns, clinker coolers, raw material dryers, and open clinker storage piles. Emission standards and work practice standards are provided for new (post-May 6, 2009) sources and existing sources in normal, as well as startup and shutdown operating modes, that are located at major and area sources of HAPs. Emissions from open clinker piles must be effectively controlled through the use of an enclosure, installing and operating a water spray or chemical dust suppressant, or use of a wind barrier or tarpaulin.

Summary of Performance Testing and Monitoring Requirements

The compliance basis for the PM standards for kilns has been revised to a manual three-run stack test conducted annually. The opacity limits and the requirement for opacity monitoring of kilns and clinker coolers at major sources has been removed from PC MACT (effective September 2015), since facilities will now be required to use a PM continuous parametric monitoring system (PM CMPS) to demonstrate continuous compliance with PM emission limits. For raw material, clinker, or finished product storage bins; conveying system transfer points; bagging system; bulk loading or unloading system; raw and finish mills; and raw material dryers, a 10% opacity limit remains, with the option to use a continuous opacity monitoring system (COMS) or U.S. EPA Method 22. A continuous emissions monitoring system (CEMS) must be used to demonstrate compliance with THC emission standards. Kilns also have operating limits related to the temperature of the gas at the inlet to the kiln PM control device or to the sorbent injection rates, where employed. The operating limits are used as the continuous compliance demonstration methodology for D/F emissions. For mercury, THC, and HCl, initial performance tests using U.S. EPA reference methods are required, followed by the use of CEMS (or a sorbent trap monitoring system for mercury) as the on-going continuous compliance demonstration method. Monitoring of clinker production must be performed on an hourly basis.

Based on these requirements, the cement industry will be burdened with significant performance testing, CEMS installation, and operation and maintenance requirements for compliance purposes, particularly compared to other industries.

Is Your Kiln Subject to PC MACT or CISWI?

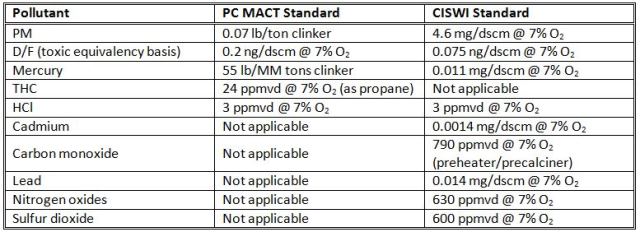

Because of the high temperatures required for the Portland cement manufacturing process, cement plants are continually searching for alternative fuels to supplement traditional fossil fuels. According to PCA, the average energy input required to make one (1) ton of cement is 4.7 million British thermal units (MMBtu), which is the equivalent of about 418 pounds of coal.[3] Today, many plants meet between 20 to 70% of their energy requirements with alternative fuels through consumer wastes or byproducts from other industries. Traditional Fuels like coal, coke, natural gas, and fuel oils contain carbon and release tremendous quantities of heat when they are burned. However, these “primary” fuels are not the only fuels that contain carbon. Tires, which typically have a higher heat input than coal, are also a great source of hydrocarbons (carbon and hydrogen). Using tires for combustion in a cement kiln produces 25% more energy than coal and it can also result in lower emissions. Many materials with high carbon content are used as fuels, such as paper, packaging, plastics, wood/saw dust, and solvents. Burning alternative fuels in cement kilns can be viewed as beneficial from a cost and sustainable operating perspective (e.g., reducing the amount of waste otherwise sent to a landfill). However, doing so can introduce the possibility of a kiln being classified as a solid waste incinerator (more appropriately, a waste-burning kiln), and therefore, subject to the CISWI regulations. Given the process temperature requirements and the cost of fossil fuels, the flexibility to use solid wastes in a kiln might be an opportunity worth considering (or continuing, for those units that already use such fuels). Therefore, one place to begin your evaluation of PC MACT versus CISWI would be to compare the applicable emission standards. The table below summarizes the pollutants include in PC MACT and CISWI, based on the assumption of an existing kiln located at a major source and under normal operating mode (for the purposes of PC MACT) as defined under each regulation.

ng/dscm @ 7% O2 = nanograms per dry standard cubic meter corrected to 7% oxygen

ppmvd = parts per million by volume, dry basis

mg/dscm @ 7% O2 = milligrams per dry standard cubic meter corrected to 7% oxygen

Because of the various units of measure of the emission standards and the range of operating conditions for cement kilns, an “apples to apples” comparison of the emission standards between PC MACT and CISWI is beyond the scope of this document. However, a qualitative discussion on the implications of complying with the emission standards in the PC MACT and CISWI is presented below.

According to PCA,[4] the CISWI standards present the cement industry with two (2) options: 1) continue to burn alternative fuels that are solid wastes and invest in air pollution control devices to comply with CISWI emission standards, or 2) discontinue using alternative fuels that are solid wastes to avoid CISWI and remain subject to PC MACT. The more beneficial option for a given cement plant will be based in part on a comparison of the incremental costs to install the necessary control devices and monitoring equipment to comply with CISWI over PC MACT, as well as the potential fuel cost savings resulting from the continued burning of solid wastes in lieu of fossil fuels.

PCA evaluated the emission control technologies[5] that are applicable to achieve compliance with the CISWI and PC MACT standards:

- Baghouses and electrostatic precipitators (ESPs) for particulate control for CISWI and PC MACT. Baghouses and ESPs also will control lead and cadmium emissions for CISWI purposes.

- Activated carbon injection (ACI), wet scrubbers, or a combination of both for mercury control for CISWI and PC MACT.

- ACI, a regenerative thermal oxidizer (RTO), or a wet scrubber combined with an RTO system for the control of THC for PC MACT.

- Wet scrubber systems to control HCl emissions for CISWI and PC MACT.

- Wet scrubber systems, lime injection and hydration systems, and calcinatory slip stream systems to control SO2 for CISWI. It is noted that the inherent process design of a kiln provides an alkaline internal environment that absorbs potential SO2 emissions; therefore, add-on pollution control devices to control SO2 from kilns for CISWI are likely to be polishing devices, if required at all.

- Selective non-catalytic reduction (SNCR) systems to control NOX emissions for CISWI.

- Burner enhancements and good combustion practices to control CO for CISWI.

- Achieving cooler exhaust temperatures to the kiln’s control devices to control D/F emissions for CISWI and PC MACT.

Based on PCA’s estimates for a 1.2 million ton dry kiln with a pre-calciner and pre-heater, the total industry investments to comply with PC MACT are estimated at $3.4 billion and are estimated at $2.0 billion for CISWI.[6] These data are limited to kilns. PC MACT also includes requirements for other processes at a cement plant, which introduces the complexity of a given plant with a CISWI-regulated kiln also obliged to comply with PC MACT for other regulated processes.