Georgia EPD Tightens Timeline for 2025 Emissions Inventory

The Georgia Environmental Protection Division (GEPD) has announced a new deadline of May 31, 2026 for the submission of calendar year (CY) 2025 Emissions Inventory (EI) Reports. This change shortens the reporting period by one month compared to previous years, when the deadline was June 30. In accordance with the U.S. Environmental Protection Agency’s (U.S. EPA) Air Emissions Reporting Requirements (AERR) and Georgia Rule 391-3-1-.02(6)(b)1, Title V facilities are required to report air emissions on a periodic basis.

Do I need to submit my Facility’s data for 2025?

All Title V facilities are required to report emissions triennially. However, certain larger Title V facilities are required to report annually. The potential emissions thresholds that determine if reporting is required annually or triennially are found in Appendix A to 40 CFR Part 51, Subpart A. CY2025 is an annual reporting year and the next triennial reporting year will be CY2026.

If your Title V Facility is not required to submit a 2025 EI, your Facility must “opt-out” of the 2025 EI through the Georgia Environmental Connections Online (GECO) portal.

How do I submit my Facility’s Emissions Inventory?

Georgia Facilities must report air emissions using the Combined Air Emissions Reporting System (CAERS), an online platform that streamlines both annual and triennial reporting in accordance with the AERR Rule. If you currently prepare your annual emissions inventory in a spreadsheet, ALL4 can enhance it with added functionality that allows you to bulk-upload your data directly into CAERS.

For more details on how Georgia uses CAERS for emissions reporting, see our earlier blog post: Georgia Facilities – Get Ready for CAERS 2.0!

What are the next steps?

GEPD will open GECO on December 1, 2025 for facilities to review facility information, update preparer and certifier contact information, and opt in or out of annual emissions reporting. With the tightened deadline, it is important to make sure your GECO EI contacts are accurate so you can access CAERS without delay. CAERS will open on January 5, 2026 for CY2025 reporting.

In addition, GEPD offers trainings and virtual help sessions throughout December and January to assist facilities with EI reporting and navigating CAERS. Facilities are encouraged to attend these sessions to ensure they are prepared for the new reporting timeline. GEPD has not indicated that this new deadline is temporary, so facilities should plan for the May 31st deadline to remain in effect for future reporting years.

With the tightened reporting window for the 2025 EI, we’re here to help! ALL4 has extensive experience assisting facilities with EI preparation and submission in CAERS. Time and again we’ve found that beginning the process early and carefully reviewing the data submitted to CAERS can significantly reduce the time spent addressing GEPD questions and comments. If there are any questions about the EI process and how your Facility may be affected, or if you’d like assistance with your air emissions inventory, please reach out to me at cgregory@all4inc.com or your ALL4 project manager for more information.

Vermont Department of Environmental Conservation Issues 2025 NPDES Multi-Sector General Permit

The Vermont Department of Environmental Conservation (DEC) issued the National Pollutant Discharge Elimination System (NPDES) Multi-Sector General Permit (MSGP) for Stormwater Discharges Associated with Industrial Activity (MSGP 3-9003) on July 14, 2025. The final permit is available for review on the DEC Vermont.gov MSGP Landing Page.

Major Changes to MSGP 3-9003

Substantial changes have been made to the MSGP 3-9003 that include but are not limited to:

- Reports and submittals are to be submitted electronically via the Vermont Agency of Natural Resources Online Services Portal (ANR Online),

- Updates to the copper, selenium, and aluminum benchmark monitoring parameters to align with the U.S. Environmental Protection Agency (U.S. EPA) 2021 MSGP,

- Requirements for each facility’s Notice of Intent (NOI) and Stormwater Pollution Prevention Plan (SWPPP) to be posted to the Environmental Notice Bulletin (ENB) by the DEC for a public comment period,

- Updates to the monitoring requirements for facilities discharging to impaired waters,

- Additional control measures for benchmark monitoring exceedances,

- Permittees must consider structural improvements or develop strategies for their pollution prevention measures to minimize the impact of a major storm event (hurricane, flood event, etc.) as follows:

- This new subpart requires that the permittee must consider Part 2.1.A. when selecting and designing control measures to minimize pollutant discharges via stormwater. This subpart does not require nor prescribe specific control measures to be implemented; however, the permittee must document in their SWPPP the considerations made to select and design control measures at their facility to minimize pollutants discharged via stormwater.

- Sector-specific updates:

- Adding discharge from uncontaminated spray down or intentional wetting of logs at wet deck storage areas as an allowed non-stormwater discharge for Sector A,

- Removing coverage for earth disturbing activities for Sector G and H,

- Adding construction permit requirements for Sector J,

- Adding requirements for deicing operations for Sector S, and

- Creation of a new industrial sector (Sector AD-1) for facilities that produce biogas through the anaerobic digesting and processing of organics.

What Actions do you Need to Take?

If your facility has coverage under this permit, the electronic NOI (eNOI) and an updated SWPPP must be submitted via ANR Online by January 10, 2026 to ensure the facility’s stormwater coverage is uninterrupted. If your facility will become a new discharger of industrial stormwater, then coverage must be approved prior to commencement of discharge.

Facilities with a Conditional Exclusion for No Exposure (NOX) of the industrial activities at their site must submit a No Exposure Certification via ANR Online by January 10, 2026 to ensure the facility’s stormwater coverage is uninterrupted.

If you have any questions regarding what your next steps should be to apply for coverage or to maintain for coverage under the MSGP 3-9003, please reach out to me at jfantone@all4inc.com. ALL4 is here to help with any of the above actions your facility may need to take, along with any other aspects of stormwater compliance your facility may need.

Recap of the CAPCA 2025 Fall Technical Workshop and Forum

This year’s fall Carolinas Air Pollution Control Association (CAPCA) technical workshop and forum included a wide range of technical topics of interest to those located in the Carolinas and beyond. In addition to the regulatory update highlights presented by the North Carolina and South Carolina Chambers of Commerce and the air directors from the South Carolina Department of Environmental Services (SC DES) and the North Carolina Department of Environmental Quality (NC DEQ), conference sessions were divided into three primary technical sessions.

Wednesday afternoon was filled with informative presentations on the lifecycle of air quality regulations as well as practical applications for Environmental, Health, and Safety (EHS) managers for facility incident investigation, root cause analysis, and management of change. Thursday afternoon was dedicated to environmental hot topics including energy sector policies and permitting, per- and polyfluoroalkyl substances (PFAS), Toxic Substance Control Act (TSCA) updates, and revisions to the South Carolina and North Carolina air permit application review process, which highlighted the importance of submitting administratively complete air permit applications. Finally, the conference concluded with an insightful look at artificial intelligence (AI) from both transformative compliance opportunity and ethics in the workplace perspectives. Highlights from these program presentations are provided below:

Integrated Safety Management: Investigation, RCA, and MoC

Following an event, two critical activities must occur. The event itself must be managed, and parties must be notified within the required timelines. Timelines are established by company policy and regulatory requirements. As a best practice, facilities should establish and maintain a flow chart to assist with the initial response. A fact-finding investigation is critical to the root cause analysis (RCA) and management of change (MoC). The investigation should be conducted in the first 24 hours. Documentation is vital including:

- Photos, which will allow the event to be reconstructed to aid the RCA,

- Witness statements,

- Training records of the individuals involved,

- Equipment maintenance logs, and

- Examination of equipment and parts including overtightening, wear and tear, and labeling.

When completing the RCA, there are several methods that can be used, and no single method is better than another, but it is critical to stick with the methodology selected. Every incident begins with a risk, a perception of that risk, and what risk is acceptable. Investigators should be careful how a question is asked to not guide the response. Presenters emphasized looking beyond human error when identifying the root cause. Human error is often a symptom but, in many instances, not the underlying cause. Finally, MoC can be equated to management of risk and is an effective tool even if a facility is not subject to Process Safety Management (PSM) or other driving regulatory requirements. Every change can be analyzed to understand the impact to operations, quality, environment, safety, and hygiene. Either administrative or engineering controls can be designed to mitigate risk. The critical steps to MoC are asking the right questions and identifying the responsible parties.

Revised Air Permit Application Procedures: Ensuring Administrative Completeness

In North Carolina, for an air permit application to be deemed complete, the application must be both administratively and technically complete. Administrative completeness includes:

- All required application forms per the NC DAQ Matrix (filled out completely),

- Appropriate signature,

- Zoning consistency determination (when in doubt, a zoning consistency determination is required),

- Professional engineer seal, if required,

- Appropriate number of copies,

- Application fee,

- Financial qualification or substantial compliance statement, if required.

Technical completeness includes:

- Comprehensive applicable and non-applicable regulatory requirement review and summary,

- Project description,

- Process schematics and parameters,

- Emissions calculation spreadsheet (unlocked) including sample calculations and sources of emissions factors,

- Modeling, if required.

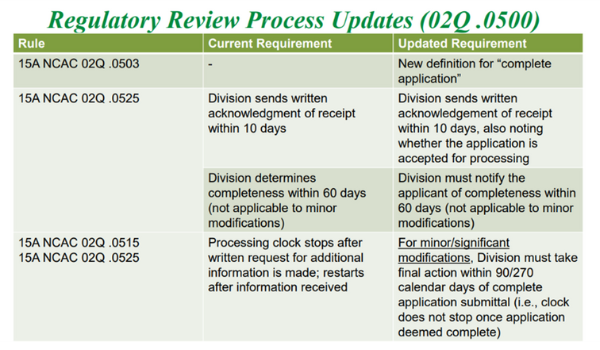

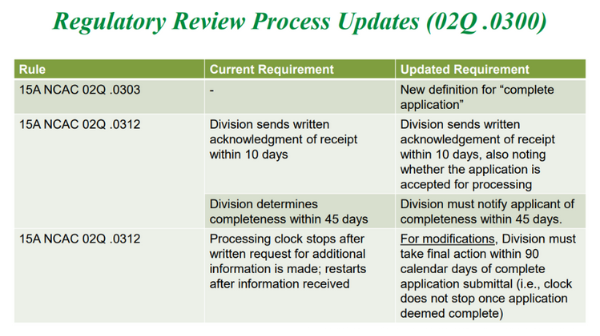

NC has proposed revisions to the permit application review process for both Title 15A of the North Carolina Administrative Code (NCAC) 02Q .0300 (minor and synthetic minor facilities) and 15A NCAC 02Q .0500 (major “Title V” facilities). The following tables summarize the revisions to the process that will become effective 60 days following United States Environmental Protection Agency’s (U.S. EPA) approval of the State Implementation Plan (SIP) revisions.1 U.S. EPA approval is pending.

In South Carolina, revisions to permit application review timelines have been proposed for approval in the State fiscal year (FY) 2025-2026 Budget. Except for Energy Infrastructure Projects (EIP), to which a separate timeline applies, SC must issue a decision on a permit application within 90 calendar days of receiving a complete application or an alternative timeline established via Mutual Agreement between the agency and applicant. The agency will have 10 calendar days to make a completeness determination, which will be a significantly more comprehensive review. In July 2025, SC DES published an Air Permit Application Checklist to assist applicants in submitting an administratively and technically complete construction permit application. Pre-application meetings will be required for Prevention of Significant Deterioration (PSD), 112(g), synthetic minor, and applications of public interest.

Artificial Intelligence in the Workplace

AI offers numerous benefits in the workplace including:

- Enhanced productivity,

- Data analysis and decision support,

- Communication and collaboration, and

- Strategy and innovation.

AI also presents risks including:

- Data vulnerability,

- Over reliance, and

- Verification challenges.2

There can be a reluctance to put data in the hands of AI and data management programs are needed to responsibly govern the design and implementation of AI. Strong data security measures as well as continuous monitoring and testing of all components are recommended to protect a company’s data and reputation.

With responsible oversight, environmental digital solutions, coupled with AI, offer improvements and enhancements to operational performance and environmental compliance. Presentations highlighted digital platforms using AI to create digital forms from paper logs, such as inspection logs, as well as access and extract data from documents that are not already digitized such as waste manifests or from electronic analytical or stack test reports. Industrial internet of things (IoT) solutions, specifically wireless solutions, enable real time data collection of data from remote locations. This monitoring not only enhances visibility but also facilitates safer working conditions when data can be collected from physically restrictive locations, such as data from wastewater treatment systems or remote outfalls. IoT sensors also monitor and assess the health of sensors systems used for environmental compliance such as pneumatic devices and continuous emissions monitoring systems (CEMS). The data collected enables improvements to process reliability and compliance. Finally, examples of how digital systems are transforming the onboarding process and teammate collaboration highlighted the multifaceted success of these systems when designed and implemented well.

Summary

As we heard at the CAPCA meeting, there are many air regulatory developments to keep track of at both the state and federal level and ALL4 staff are following them. ALL4 looks forward to seeing you in the spring at the CAPCA technical workshop and forum in Asheville, NC or sooner at a young professionals event! If you need support with one or more of these topics or need help with air permitting and compliance in North or South Carolina, please reach out to Jenny Brown at jbrown@all4inc.com or 678-293-9432.

U.S. EPA Prepares New Revisions to CWA Section 401: What Industrial Project Teams Should Know Going Into 2026

On November 5, 2025, U.S. Environmental Protection Agency (U.S. EPA) quietly advanced a significant Clean Water Act (CWA) action to the White House Office of Management and Budget (OMB) for review. The proposal would revise the Biden administration’s 2023 Section 401 water quality certification rule. According to the current Unified Agenda, U.S. EPA intends to propose the revised rule in 2025. The stated objective is to “clarify the scope of certification” and address “implementation challenges and regulatory uncertainty associated with the 2023 Rule.” Translation: U.S. EPA is moving toward a narrower interpretation of what states may evaluate when determining whether a project will comply with applicable water quality requirements.

What Section 401 of the CWA Actually Does

Section 401 certifications play a pivotal role in federally permitted projects because they give states and tribes the authority to confirm that a proposed activity will comply with state water quality standards before a federal permit can be issued. The certification requirement applies to a range of activities requiring federal approvals, including U.S. Army Corps of Engineers Section 404 dredge-and-fill permits and authorizations issued by the Federal Energy Regulatory Commission (FERC) for projects that may result in a discharge to Waters of the U.S. In practice, a project cannot move forward until the certifying authority either issues the certification or waives it. Because federal authorization hinges on the Section 401 process, even modest adjustments to the scope of review or timing requirements can affect project feasibility, costs, and overall schedules.

Why U.S. EPA Is Revisiting the 2023 Rule

U.S. EPA’s stated goal is to “clarify the scope of certification” and reduce the implementation challenges that emerged following the 2023 rule. That rule centered review on the entire project “activity,” which many states and environmental groups supported because it allowed for a broader consideration of potential impacts. Industry groups and other states, however, argued that the 2023 rule opened the door to conditions – or outright denials – based on issues only indirectly connected to water quality.

U.S. EPA previewed its shifting position in a May 2025 memorandum that encouraged certifying authorities to focus on whether a project would comply with applicable water quality requirements rather than evaluating broader project-level impacts. This narrower interpretation resembles the approach taken under the 2020 rule.

Signals on the Direction of the New Proposal

U.S. EPA Administrator Lee Zeldin has emphasized that narrowing the states’ review authority is necessary to prevent states from using Section 401 to block energy infrastructure. At the same time, environmental organizations have urged U.S. EPA to maintain the broader interpretation embedded in the 2023 rule, arguing it aligns more closely with both statute and longstanding practice.

With these competing pressures, the upcoming proposal will likely aim for a more defined, discharge- or water-quality-focused scope paired with clearer procedural steps – elements industry groups have been requesting for several years.

What This Means for Industrial and Manufacturing Projects

If U.S. EPA reinstates a narrower, more discharge-focused scope of the rule:

- States may have fewer opportunities to impose broad conditions, reducing the likelihood of project delays unrelated to water-quality compliance.

- Expect clearer timelines and application requirements, which could reduce administrative burden for complex capital projects.

- Litigation risk may shift. A narrower rule is likely to be challenged by environmental groups, creating potential future uncertainty even if short-term clarity improves.

- Projects in states that historically exercised broad Section 401 authority – particularly in the Northeast and Pacific Coast – can expect federal pressure to ensure their Section 401 certification approvals toe the line of federal expectations.

Bottom Line

Projects entering early-stage planning now may benefit from a more predictable federal-state review process, but only if the proposal survives the next regulatory and litigation cycle. If you’re planning capital improvements, expansions, linear infrastructure, or new discharges that require federal approvals, now is a good time to reassess permitting timelines and stakeholder engagement strategies. ALL4 will continue to track this rule as it moves through the regulatory process. If you have questions or would like to discuss whether this rule impacts your project, please reach out to Cody Fridley at 269.716.6537 or cfridley@all4inc.com or Paul Hagerty at phagerty@all4inc.com.

U.S. EPA and Workplace Exposure: Air Toxics and Worker Health in Texas Industries

Introduction

Texas manufacturing, refining, and petrochemical sectors are a significant component of American industry. These production facilities sit at the intersection of worker protection and environmental regulation. The U.S. Environmental Protection Agency (U.S. EPA) air toxics standards are designed to safeguard surrounding neighborhoods but the same chemical contaminants can create risks for facility workers behind the fence line.

Why is it important? It protects the workforce that drives operations and production. Industries should look ahead and expect more scrutiny by U.S. EPA and the Occupational Safety and Health Administration (OSHA) in the future.

U.S. EPA’s Role in Workplace Exposure

The National Emission Standards for Hazardous Air Pollutants (NESHAP), as administered by the U.S. EPA through the Clean Air Act, mandates the installation of strict controls to lower air emissions of hazardous air pollutants (HAPs) like benzene, chromium, nickel, and manganese. These substances can also cause cancer, brain damage, and other chronic illnesses. NESHAP targets emissions to ensure air quality is preserved, while other regulations like the Toxic Substances Control Act (TSCA), control the handling of chemicals to prevent exposure of workers and safeguard public health in industrial facilities. Overall, these regulations work towards minimizing the occupational and environmental hazards which workers and nearby communities are exposed to daily.

OSHA’s Perspective: Protection of the Individual Worker

OSHA’s focus is on protecting the worker rather than the community. They set Permissible Exposure Limits (PELs) for many of the same hazardous substances regulated by U.S. EPA.

For example:

- OSHA limits the concentration of benzene a worker can be exposed to within an eight-hour day.

- OSHA requires engineering controls such as ventilation to be in place if a worker is exposed to a contaminant, such as benzene, above the PEL. Additional controls such as respiratory protection may also be required depending on exposure levels.

Texas industries frequently have to comply with both standards simultaneously: U.S. EPA with emissions and OSHA with concentrations in the workplace.

Texas Industry Examples: Where the Overlap Counts

Refineries and Petrochemicals: U.S. EPA’s Refinery Sector Rule requires fence line monitoring of benzene concentrations. While the rule benefits surrounding neighborhoods, that same data can also be used to identify hazards for refinery workers who are repeatedly exposed to benzene.

Metal Fabrication and Welding: U.S. EPA emissions standards placed on chromium, nickel, and manganese are interdependent from OSHA limits for welder and maintenance staff exposure. Emissions controls can prevent regulatory risks and maintain workers’ health.

Chemical Production and Storage: U.S. EPA is extremely strict with volatile organic compound (VOC) emissions regulations. However, the VOCs may also be present in operators’ and maintenance worker locations, which could trigger OSHA compliance with ventilation and air contaminant standards.

Why You Should Pay Attention

This is not simply a matter of ‘compliance fatigue’ affecting Environmental, Health, and Safety (EHS) managers and facility owners. It reflects a broader need to recognize that:

- U.S. EPA compliance can also function as protection for workers. By becoming environmentally compliant, you may be avoiding workplace dangers from occurring in the first place.

- Regulatory pressure is increasing. U.S. EPA and OSHA have both stepped up enforcement in Texas—especially in refining and manufacturing activities.

Employees are an organization’s most valuable asset. Employees recognize when companies are investing in keeping them healthy. Effective compliance programs can aid retention, safety culture, and credibility with the community.

What’s Ahead

U.S. EPA is accelerating its air toxics programs through risk and technology reviews (RTRs). OSHA, in turn, is under pressure to modernize outdated PELs and enhance workplace chemical safety standards. To the Texas industry, this translates into the regulatory intersection of environmental and occupational regulations being on the rise.

What should you do now?

- Verify emissions inventories to both U.S. EPA and OSHA considerations—seeing how air toxics impact not only the environment, but also workers inside the facility.

- Dual-use compliance data: Fenceline monitoring results, stack tests, and emissions modeling can also inform the development of worker exposure control strategies.

- Get ahead of changing standards. Don’t wait for an inspection, complaint, or citation to examine your comprehensive responsibilities when it comes to worker exposures.

How ALL4 Can Help

At ALL4, our focus is to assist facilities and bridge the regulatory impact gap to the workplace. Whether interpreting benzene fence line data, worker exposure assessments (industrial hygiene), or NESHAP compliance assurance, we partner with facilities to turn regulatory requirements into usable strategies that safeguard communities and employees alike. If you have any questions or would like assistance in evaluating how U.S. EPA air toxics standards intersect with workplace exposures at your facility, contact Kevin Chaplin at kchaplin@all4inc.com or Molly Vaziri at mvaziri@all4inc.com. ALL4 will continue to track updates to additional guidance or rulemaking regarding U.S. EPA and OSHA worker exposure requirements.

Waste Not: Why You Need a Waste Minimization Program

When was the last time you took a close look at your waste streams?

If you’re like many other companies, you may be relying on your hazardous waste vendor to handle waste determination and profiling. But here’s the catch: as the generator, you’re ultimately responsible for the accuracy of waste characterization and documentation for your site. Is storing your waste profiles in the vendor’s client portal enough? Do you have a written waste minimization program in place or just a vague idea that one exists?

What the Regulations Say:

40 CFR §262.11(d)(1) lists acceptable methods for generator waste determination, which includes:

- Process knowledge (e.g., information about chemical feedstocks and other inputs to the production process).

- Knowledge of products, by-products, and intermediates produced by the process.

- Chemical or physical characterization of wastes.

- Information on the properties of the chemicals used or produced by the process.

- Analytical testing that illustrates the properties of the waste.

- Other reliable and relevant information about the properties of the waste or its constituents.

When waste generator knowledge isn’t enough to make an accurate waste determination, the generator must test the waste according to the applicable methods set forth in subpart C of 40 CFR part 261.

Section 262.11(f) specifically mandates that Small Quantity Generators (SQG) and Large Quantity Generators (LQG) maintain records supporting their hazardous waste determinations and that the records are maintained for at least three years. While not required for Very Small Quantity Generators (VSQGs) of hazardous waste, it is recommended that VSQGs maintain these same records to support their waste determinations.

The required documentation includes:

- The results of any tests, sampling, waste analyses, or other determinations made; records documenting the tests, sampling, and analytical methods used to demonstrate the validity and relevance of such tests,

- Records that demonstrate the process by which the waste was generated,

- The composition and properties of the waste; and

- Records which explain the knowledge basis for the generator’s determination

A lot of facilities get their waste tested but the rest of the requirements are forgotten and recordkeeping efforts often end there. Even if testing is not required and the generator can make waste determinations based on knowledge, they are still required to document additional information on the waste generation process and how the determination was made.

But That’s Not All:

The U.S. Environmental Protection Agency (U.S. EPA) takes waste recordkeeping one step further by requiring Large Quantity Generators (LQGs) to sign a certification on the uniform hazardous waste manifest. This certification states the following:

“I am a large quantity generator. I have a program in place to reduce the volume and toxicity of waste generated to the degree I have determined to be economically practicable, and I have selected the practicable method of treatment, storage, or disposal currently available to me which minimizes the present and future threat to human health and the environment;”

The generator is required to sign this official document stating that they have a program in place to reduce the amount of waste generated. While U.S. EPA doesn’t explicitly require this program to be written, some states require written pollution prevention or waste minimization programs, which typically include hazardous waste reduction information. If you aren’t sure if your state requires a written program, we can help!

What is a Waste Minimization Program?

Waste Minimization means reducing the hazardous waste generated before it is treated, stored, or disposed of. An effective waste minimization program can lower costs and reduce environmental impact.

A strong waste minimization program should include:

- Leadership Support: Clear goals, training, and integration into company policy

- Waste Characterization and Management: Accurate inventory and cost management

- Financial Support: Allocating costs required for program success

- Assessments: Identifying opportunities to reduce waste

- Procurement Policies: Favoring less hazardous materials

- Implementation and Evaluation: Regular program reviews and improvement implementation

- Training and Recordkeeping

- Sharing Best Practices: Across departments or among peer organizations

How Does it Work?

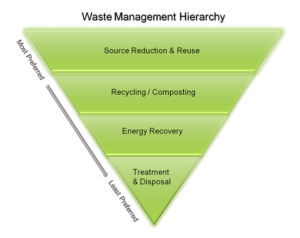

The use of source reduction and recycling methods prior to treatment or disposal of wastes is the best place to start.

Source reduction, also known as pollution prevention (P2), refers to any action that will reduce or eliminate hazardous material at its source and significantly decrease or eliminate the amount of waste exiting a process.

This can include:

- Process changes (e.g., reducing cleaning operations)

- Product redesign or reformulation (e.g., removing per- and polyfluoroalkyl substances (PFAS) or lead)

- Material Substitution (e.g., switching to lead-free solder)

- Equipment or technology upgrades

- Better housekeeping, maintenance, inventory control, and training

If source reduction isn’t feasible, recycling is the next best option. This is a broad term that encompasses the use, reuse, or reclamation of a resource, byproduct, or residual material in original or changed form rather than discarding it as waste. It includes:

- Removing contaminants from waste to allow reuse (e.g., triple-rinsing waste containers, metals recovery)

- Reclaiming useful ingredients: (e.g., solvent recovery and distillation systems)

- Reusing spent materials as a substitute for new material (e.g., reusing purge solvents)

- Using waste as a substitute for a new commercial product. (e.g., recycled mercury in fluorescent lamps)

Some recycling may require a permit and you should be sure to comply with any applicable hazardous waste requirements when recycling. This includes proper identification, handling, storage, and transportation of the materials, even when they are destined for recycling. For more information on P2 and waste management, check out the U. S. EPA website.

Figure 1

Waste Management Hierarchy

Benefits of a Waste Minimization Plan:

A well-executed waste minimization plan:

- Reduces costs and inefficiencies

- Demonstrates environmental responsibility and helps meet sustainability goals

- Increases ability to qualify for International Organization for Standardization (ISO) certifications

- Can increase business from companies that have environmental requirements for their vendors and business partners

- Improves relationship with regulators, employees, investors, and the public

Need Help Getting Started?

Navigating hazardous waste regulations and building an effective waste minimization program can be complex—but you don’t have to do it alone. Whether you need help characterizing your waste, developing a written program, or identifying practical reduction strategies, our team is here to support you. We offer expert guidance tailored to your operations to help you stay compliant, reduce costs, and meet your sustainability goals. For more information, reach out to your ALL4 project manager or contact Kelly Di Stefano at kdistefano@all4inc.com. Let’s work together to turn your waste challenges into opportunities.

U.S. EPA Processes Renewable Fuel Standard Small Refinery Exemption Backlog

November 20, 2025 Update: As of Nov. 7, the U.S. Environmental Protection Agency (EPA) has ruled upon 16 more Small Refinery Exemption (SRE) petitions, granting full exemptions for two, granting partial exemptions for 12, and denying two petitions. Notice of these rulings was published in the Federal Register on Nov. 20. The U.S. EPA stated that they are committed to addressing new petitions within the 90-day statutory review period and ask that small refineries that receive exemptions contact the U.S. EPA Fuels Program Helpdesk to begin the RINs return process, which can be reached at FuelsProgramSupport@epa.gov.

Under the Energy Policy Act of 2005, the Renewable Fuel Standard (RFS) requires that all transportation fuel contain at least a minimum volume of renewable fuels to reduce greenhouse gas emissions. Since its establishment, enforcement of RFS has varied greatly, ranging from blanket exemptions to complete denial of all petitions. While the current goals of the RFS include boosting the domestic renewable fuel industry, these requirements can also result in disproportionate economic hardship for small refineries. These small refineries may petition to be exempted from certain RFS requirements as allowed for in 40 CFR 80.1441(a)(1).

Exemption Applications Processed

On August 22, 2025, the U.S. Environmental Protection Agency (U.S. EPA) provided determinations on the backlog of Small Refinery Exemption (SRE) petitions for the 2016 to 2024 compliance years, 93 of which were denied but remanded to U.S. EPA for reconsideration. Of the 175 SRE petitions reviewed by U.S. EPA and the U.S. Department of Energy (U.S. DOE), 63 were granted full exemptions, 77 were granted partial exemptions, 28 were denied, and seven were determined to be ineligible. U.S. EPA reaffirmed that the 2020 Renewable Volume Obligation (RVO) Rulemaking will grant partial relief to eligible small refineries that face partial hardship from the RFS requirements.

The refineries granted partial or full exemptions will be granted relief for certain requirements for fuels produced during the exempted compliance years. However, exemptions are granted for individual years, and refineries desiring an exemption must petition U.S. EPA annually or they will be subject to RFS requirements.

Returning RFS Compliance credits

U.S. EPA has also reaffirmed a policy to return Renewable Identification Numbers (RINs) that were previously retired to fill RVOs when a small refinery is retroactively granted an exemption for a past compliance year. Because RINs must be used within a two-year window, only RINs returned for 2023 may be used to meet compliance requirements for 2024. RINs returned for years prior to 2023 may be used for past compliance years that fall within the two-year window. These vintage RINs could potentially result in refineries retroactively fulfilling previously unfulfilled RVOs for non-exempt compliance years. On the other hand, small refineries that fulfilled their compliance obligations yet received a retroactive exemption become effectively penalized for their efforts since their recovered RINs will have expired.

Reallocation of Exempted Volumes

In addition, U.S. EPA recently proposed a supplemental rule for the RFS that reallocates exempted renewable volumes. Due to exemptions granted on August 22, 2025 for the 2023 and 2024 compliance years, the number of RINs available to fulfill compliance obligations increased, with additional exemptions expected for the 2025 compliance year. The rule proposed by U.S. EPA would reallocate a percentage of the RINs for years 2023 through 2025 to years 2026 and 2027 instead to maintain demand for renewable fuels in the wake of an influx of available compliance credits. As a result, small refineries may be able to use their returned RINs to fulfill RVOs for years outside of the two-year period. More information on the proposed rule can be found on the U.S. EPA website.

Why does this matter?

U.S. EPA proposed RFS for 2026 and 2027 in June 2025 that reduced the cellulosic biofuel volume requirement for 2025 but doubled the biomass-based diesel volume requirements for 2026 and 2027 compared to historical data. Moreover, the proposal includes reducing the number of RINs for imported renewable fuels and renewable fuels produced from imported goods. Coupled with the intention to remove renewable electricity from the RFS program, this proposal clearly aims to increase demand for domestically produced biofuel. However, industry groups posit that these new standards are unrealistic, impossible to fulfill with domestic production alone, and will cause compliance costs for the refining industry to reach over 70 billion dollars annually.

How ALL4 Can Help

Because the proposed RFS for 2026-2027 could result in historically high compliance costs, preemptively understanding their effects on small refineries is crucial to their economic health. As small refineries look towards the future, ALL4 can help navigate regulatory applicability and the RFS scoring matrix, prepare exemption petitions, and assess compliance. To learn more, contact Meghan Skemp at mskemp@all4inc.com or your local ALL4 staff.

Under the Energy Policy Act of 2005, the Renewable Fuel Standard (RFS) requires that all transportation fuel contain at least a minimum volume of renewable fuels to reduce greenhouse gas emissions. Since its establishment, enforcement of RFS has varied greatly, ranging from blanket exemptions to complete denial of all petitions. While the current goals of the RFS include boosting the domestic renewable fuel industry, these requirements can also result in disproportionate economic hardship for small refineries. These small refineries may petition to be exempted from certain RFS requirements as allowed for in 40 CFR 80.1441(a)(1).

Exemption Applications Processed

On August 22, 2025, the U.S. Environmental Protection Agency (U.S. EPA) provided determinations on the backlog of Small Refinery Exemption (SRE) petitions for the 2016 to 2024 compliance years, 93 of which were denied but remanded to U.S. EPA for reconsideration. Of the 175 SRE petitions reviewed by U.S. EPA and the U.S. Department of Energy (U.S. DOE), 63 were granted full exemptions, 77 were granted partial exemptions, 28 were denied, and seven were determined to be ineligible. U.S. EPA reaffirmed that the 2020 Renewable Volume Obligation (RVO) Rulemaking will grant partial relief to eligible small refineries that face partial hardship from the RFS requirements.

The refineries granted partial or full exemptions will be granted relief for certain requirements for fuels produced during the exempted compliance years. However, exemptions are granted for individual years, and refineries desiring an exemption must petition U.S. EPA annually or they will be subject to RFS requirements.

Returning RFS Compliance credits

U.S. EPA has also reaffirmed a policy to return Renewable Identification Numbers (RINs) that were previously retired to fill RVOs when a small refinery is retroactively granted an exemption for a past compliance year. Because RINs must be used within a two-year window, only RINs returned for 2023 may be used to meet compliance requirements for 2024. RINs returned for years prior to 2023 may be used for past compliance years that fall within the two-year window. These vintage RINs could potentially result in refineries retroactively fulfilling previously unfulfilled RVOs for non-exempt compliance years. On the other hand, small refineries that fulfilled their compliance obligations yet received a retroactive exemption become effectively penalized for their efforts since their recovered RINs will have expired.

Reallocation of Exempted Volumes

In addition, U.S. EPA recently proposed a supplemental rule for the RFS that reallocates exempted renewable volumes. Due to exemptions granted on August 22, 2025 for the 2023 and 2024 compliance years, the number of RINs available to fulfill compliance obligations increased, with additional exemptions expected for the 2025 compliance year. The rule proposed by U.S. EPA would reallocate a percentage of the RINs for years 2023 through 2025 to years 2026 and 2027 instead to maintain demand for renewable fuels in the wake of an influx of available compliance credits. As a result, small refineries may be able to use their returned RINs to fulfill RVOs for years outside of the two-year period. More information on the proposed rule can be found on the U.S. EPA website.

Why does this matter?

U.S. EPA proposed RFS for 2026 and 2027 in June 2025 that reduced the cellulosic biofuel volume requirement for 2025 but doubled the biomass-based diesel volume requirements for 2026 and 2027 compared to historical data. Moreover, the proposal includes reducing the number of RINs for imported renewable fuels and renewable fuels produced from imported goods. Coupled with the intention to remove renewable electricity from the RFS program, this proposal clearly aims to increase demand for domestically produced biofuel. However, industry groups posit that these new standards are unrealistic, impossible to fulfill with domestic production alone, and will cause compliance costs for the refining industry to reach over 70 billion dollars annually.

How ALL4 Can Help

Because the proposed RFS for 2026-2027 could result in historically high compliance costs, preemptively understanding their effects on small refineries is crucial to their economic health. As small refineries look towards the future, ALL4 can help navigate regulatory applicability and the RFS scoring matrix, prepare exemption petitions, and assess compliance. To learn more, contact Meghan Skemp at mskemp@all4inc.com or your local ALL4 staff.