Lead Copper Rule Improvements Update

The Lead and Copper Rule Improvements were finalized in October 2024 with Federal requirements as a national baseline including, but not limited to:

- Lead Service Line Replacement (LSLR) by 2037,

- Submitting an updated sampling plan to their State,

- Updated monitoring requirements,

- Prioritization on tap sample collection based on which sampling sites have the greatest likelihood of capturing the highest lead levels at the tap, and

- A reduction in the action level of lead from 15 parts per billion (ppb) to 10 ppb.

Since then, the rule has faced Congressional Review Act (CRA) attempts and litigation. The CRA attempt earlier this year failed due to grassroots efforts and public pressure. A critical deadline was missed, the submittal of initial lead service line inventories for water systems nationwide by October 16, 2024, with an estimate of less than half of the inventories received for some states. However, litigation brought by the American Water Works Association (AWWA) over the feasibility of LSLR is still pending.

The lawsuit had been on pause for months to allow the U.S. Environmental Protection Agency (U.S. EPA) time to consider options in defending the rule. In early August, U.S. EPA signaled that they were ready to move forward with the case.

U.S. EPA has stated that they are working on providing clarity and are working on developing tools to help support implementation of the LCRI. Under the U.S. Department of Justice’s revised schedule for the case, U.S. EPA’s brief is due by December 5, 2025. It is possible we will see additional resources and updates regarding the rule prior to that deadline (though this has undoubtedly been delayed by the ongoing federal government shutdown).

In the meantime, LCRI remains in effect while the litigation runs its course. For additional information on the 2024 LCRI, please refer to ALL4’s previous blog posts on the differences between the Lead Copper Rule Revisions (LCRR ) and the LCRI, and Changes to U.S. EPA PFAS Drinking Water Standards Under the Trump Administration, highlighting changes that may affect your system and facility. If you have any questions or would like assistance in evaluating how your facility is impacted by LCRI, please reach out to me at cnagel@all4inc.com. ALL4 will continue to track updates to additional guidance or rulemaking regarding the LCRI.

Water Regulatory Update: U.S. EPA’s Latest Agenda

The Spring Unified Agenda of Regulatory and Deregulatory Actions was (finally) published in early September at reginfo.gov and it brought some anticipated but abbreviated insights into the water regulatory priorities of the U.S. Environmental Protection Agency (U.S. EPA). Some key items of interest to ALL4’s readers are summarized below, and of course in the short time since the agenda was published we’ve seen a government shutdown that may impact the (in some cases, fairly aggressive) timetables noted in the agenda. We should see a Fall agenda that updates these items before the end of 2025.

- Effluent Limitation Guidelines (ELGs) for Per- and Polyfluoroalkyl Substances (PFAS) Manufacturers Under the Organic Chemicals, Plastics, and Synthetic Fibers Point Source Category – Under Effluent Guidelines Plan 15, U.S. EPA is moving forward with revising ELGs at 40 CFR Part 414 to address PFAS discharges from facilities manufacturing PFAS. An Advanced Notice of Proposed Rulemaking was issued in March 2021, and a Notice of Proposed Rulemaking (NPRM) is targeted for January 2026.

- PFAS Requirements in National Pollutant Discharge Elimination System (NPDES) Permit Applications – We’ve seen this coming for a few years now but were curious as to whether this would stay on the docket for this administration. U.S. EPA still plans to update the list of pollutants at 40 CFR 122.21 that NPDES permit applicants must report to the permitting authority in their NPDES renewal or modification applications to include PFAS for several types of existing NPDES permit applications. An NPRM is targeted for November 2025 with a final rule in May of 2027.

- Steam Electric ELG Reconsideration Rule – U.S. EPA is reconsidering the technology-based effluent limitations (TBELs) and standards for this point source category that were promulgated in 2024, including technology-based requirements for coal combustion residual (CCR) leachate. This reconsideration was part of S. EPA’s March 12, 2025 deregulatory announcement. The NPRM is targeted for November 2025 with a final action targeted for May 2026.

- ELGs and Standards for the Oil and Gas Extraction Category – U.S. EPA is proposing rulemaking to increase opportunities for discharge of treated produced water by expanding the geographic area where such discharges occur (currently limited to west of the 98th meridian, which is essentially the western half of the U.S.) and evaluate increased opportunities to discharge for other uses (currently limited to agriculture and wildlife propagation with possible expansion to critical minerals extraction and industrial cooling water).

- Final Clarifying Definition of “Waters of the United States” (WOTUS) – U.S. EPA and U.S. Department of the Army are undertaking rulemaking to revise the WOTUS definition to align with the 2023 Sackett v. U.S. EPA decision, including continuous surface connection, “relatively permanent,” and jurisdictional vs. non-jurisdictional ditches. The goal, as stated, is to establish a clear and simple definition that will “stand the test of time.” See ALL4’s recent blog on WOTUS for more information. An NPRM was targeted for August 2025 but the proposal is at the White House Office of Management and Budget (OMB) for review and has not been released, so U.S. EPA will not meet its target for final action of January 2026.

- Multiple entries regarding drinking water, including revisions to microbial and disinfection byproducts rules, the drinking water method update rule, establishing the sixth unregulated contaminant monitoring rule (UCMR 6), and changes around PFAS including extending the compliance deadline for the PFAS National Primary Drinking Water Regulation Rulemaking and withdrawal of regulatory determinations and removal of related provisions for certain PFAS (see our previous blog for the latest on PFAS in drinking water).

- And last but not least, Clean Water Act (CWA) Hazardous Substances Facility Response Plans (FRP) – As anticipated (see our most recent blog), U.S. EPA will propose to extend the compliance deadline (currently June 2027) and make “administrative changes.” The NRPM was originally targeted for July 2025, which has now come and gone, with final action by December 2025. Since the agenda was published, an “Amendment Reconsideration” categorized as a “prerule” and a proposal to delay the compliance dates and make changes to reflect the current administration’s policy went to OMB for review.

ALL4 is tracking these and other regulatory and deregulatory developments and will keep our readers up-to-date as we learn more. For any water regulatory questions or for help strategizing on how to deal with regulatory uncertainty, please reach out to our Water Tech Team Lead, Lizzie Smith, at lsmith@all4inc.com or 770-999-0269.

CTDEEP Industrial Stormwater General Permit Reissuance

The Connecticut Department of Energy and Environmental Protection (DEEP) reissued the industrial stormwater general permit (IGP) on October 1, 2025 with an effective date of November 1, 2025. The previous DEEP National Pollutant Discharge Elimination System (NPDES) General Permit for the Discharge of Stormwater Associated with Industrial Activities, also known as the IGP, expired on September 30, 2024 and coverage has been administratively continued. The IGP re-issuance has been in progress for over a year, with multiple draft iterations and public comment periods. A public hearing was held in May 2025 where a majority of public concerns surrounding bulk de-icing storage were heard. DEEP has responded to these comments and others in an October 2025 update with the final IGP re-issuance.

Existing permittees are covered under interim permit coverage during the transition to the newly issued IGP provided that a complete and timely application for coverage under the reissued permit is submitted by the deadline of April 1, 2026. Registration will open on November 1, 2025 and registration will require a fee, an electronic copy of the facility’s updated Stormwater Pollution Prevention Plan (SWPPP), and completed online registration form. The proposed IGP contains more substantive changes than the previous re-issuances in 2016 and 2021, including updated effluent limit guidelines, new SWPPP requirements, and annual reports due in April for the previous calendar year.

ALL4 published a blog on August 1, 2024 discussing the modifications from the previous permit compared to the draft permit. Facilities seeking coverage under the new IGP will need to update their SWPPP in accordance with the new requirements including the “Resiliency Measure” element similar to the U.S. Environmental Protection Agency (U.S. EPA) multisector general permit issued in 2021. The facility must consider various stormwater control measures (SCM) defined in the permit. The permit “does not require nor prescribe specific SCMs to be implemented; however, the permittee must document in their SWPPP the considerations made to select and design control measures at their facility to minimize pollutants discharged via stormwater.” These SCMs include structural improvements, enhanced/resilient pollution prevention measures, and other mitigation measures to minimize impacts of stormwater discharge from major storm events such as hurricanes, storm surge, extreme precipitation, and flood events. The template SWPPP provided on DEEP’s website provides a tabular format for presenting this information in the SWPPP.

The IGP lists additional SCMs that may be considered, but are not limited to the following:

- Reinforce materials storage structures to withstand flooding and additional exertion of force.

- Prevent floating of semi-stationary structures by elevating to the Base Flood Elevation (BFE) level of securing with non-corrosive device.

- When a delivery of exposed materials is expected, and a storm is anticipated within 72 hours (three days), delay delivery until after the storm or store materials as appropriate (refer to emergency procedures).

- Temporarily store materials and waste above the BFE level.

- Temporarily reduce or eliminate outdoor storage.

- Temporarily relocate any mobile vehicles and equipment to higher ground.

- Develop scenario-based emergency procedures for major storms that are complementary to regular stormwater pollution prevention planning and identify emergency contacts for staff and contractors.

- Conduct staff training for implementing the permittee’s emergency procedures at regular intervals.

ALL4 recommends that permittees allow sufficient time to consider these “Resiliency Measures” and other site-specific measures while making the required SWPPP updates.

If you have any questions regarding the scheduled IGP reissuance in October 2025 or what your next steps should be to prepare your facility (and SWPPP) for the issuance of the IGP, please reach out to Shane Galloway, at sgalloway@all4inc.com or 215-372-0865.

Turning Exposure Data Into Safer Workplaces

Understanding Workplace Airborne Hazards

In many workplaces employees handle chemicals that can cause both immediate and long-term health effects. Whether it be in a research and development laboratory or a manufacturing environment, airborne contaminants can pose risks if not properly controlled. Some examples of these contaminants are particulates (dusts), chemical vapors, and mists. To protect workers, employers need real exposure data capturing the specific tasks employees perform, local ventilation, nearby operations, and variations throughout the workday. This information provides a more accurate picture of what employees are truly breathing.

This is where occupational exposure assessments utilizing personal air monitoring badges and air sampling pumps come in. By measuring actual exposures during typical work activities, these tools provide the information needed to protect employees, ensure compliance, and design safer workplaces.

Occupational Exposure Assessments

Occupational exposure assessments are a crucial step in a comprehensive industrial hygiene (IH) program. Conducting occupational exposure assessments can provide employers with key information regarding the health and safety of their employees.

- Short-Term Safety: Monitoring can identify acute overexposures that may lead to immediate effects such as dizziness, eye and throat irritation, or even chemical burns. For example, comparing data against Short-Term Exposure Limits (STELs) helps ensure employees are not harmed by high-concentration exposures.

- Long-Term Safety: Many chemicals cause health issues after repeated, long-term exposure. Personal sampling helps ensure employees are not exceeding eight-hour time-weighted average (TWA) limits, reducing the risk of chronic diseases such as asthma, organ toxicity, or certain cancers.

- Regulatory Compliance: The Occupational Safety and Health Administration (OSHA) requires employers to evaluate employee exposures to hazardous chemicals under standards such as 29 CFR 1910.1000 (Air Contaminants) and substance-specific rules. Personal monitoring provides defensible data to demonstrate compliance with OSHA Permissible Exposure Limits (PELs) or recommended exposure limits such as the American Conference of Governmental Industrial Hygienists (ACGIH) Threshold Limit Values (TLVs).

A Brief Occupational Exposure Assessment Roadmap

An effective occupational exposure assessment typically begins with a process review, where the work areas and tasks are observed to understand what chemicals are used, how they are used, and what controls are in place. From there, a sampling plan is created by reviewing chemical information and determining which substances to test and how many samples to collect. Some substances, such as respirable crystalline silica, lead, and benzene, have specific OSHA requirements that mandate exposure monitoring when employees may be exposed above action levels. For operations that warrant sampling, employees are often grouped into similar exposure groups, with monitoring focused on those tasks and job roles most likely to experience the highest exposures.

How Air Monitoring Works

There are two common approaches to personal air sampling:

- Badges (Passive Samplers): Lightweight devices worn on the lapel, designed to absorb chemical vapors or gases over the course of a shift or task. These are often used for volatile organic compounds (VOCs) and are valued for being simple and unobtrusive.

- Pumps (Active Samplers): These devices actively draw measured volumes of air through a collection medium, allowing for precise measurement of air sampled. Pumps are ideal for particulates like dust, metals, or acid mists.

Selecting the right method depends on the hazardous substance of concern, the work environment, and the accuracy required for regulatory or internal standards. Guidance from agencies such as OSHA, California State Plan (Cal/OSHA), other state plan equivalents, National Institute for Occupational Safety and Health (NIOSH), and ACGIH should also be considered, as each provides validated sampling methods for different contaminants. Factors such as expected concentration ranges, duration of sampling, potential interferences, and analytical sensitivity all play a role in determining whether a passive badge or an active pump-based method is most appropriate. Additionally, each analytical method has a defined Limit of Quantitation (LOQ), the lowest concentration of a substance that can be measured reliably with acceptable precision and accuracy, which should be considered when selecting a method to ensure that results are both meaningful and compliant.

Controls That Follow Monitoring

Collecting exposure data is important, but what you do with that data is even more important.

- Compare air sampling results to applicable occupational exposure limits: Results are evaluated against current occupational exposure limits including OSHA PELs, ACGIH TLVs, and the NIOSH Recommended Exposure Limits (RELs).

- Identify Trends: Data often highlight specific operations, shifts, or tasks with elevated exposure risks.

- Communicate Results: Sharing outcomes with employees demonstrates transparency and supports Right-to-Know obligations under OSHA’s Hazard Communication Standard. Certain substances, such as hexavalent chromium and lead, also have specific notification requirements when exposure results exceed regulatory limits.

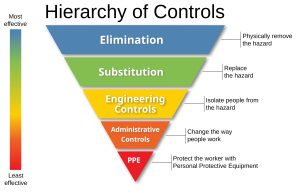

Controls solve the issues that monitoring identifies. Through the collected exposure data and following the hierarchy of controls, employers can implement strategies such as:

- Elimination: Finding ways to completely eliminate the use of the hazardous substance from the process.

- Substitution: Replacing the hazardous substance with a lesser or non-hazardous substance.

- Engineering Controls: Local exhaust ventilation, enclosed systems, or improved fume hood performance.

- Administrative Controls: Job rotation, limiting time spent on high-exposure tasks, or adjusting production schedules.

- Personal Protective Equipment (PPE): Respirators and other PPE worn when exposures cannot be reduced below limits through engineering or administrative means alone.

Once controls are in place, follow-up monitoring verifies their effectiveness and supports continuous improvement.

Moving Forward

Occupational exposure assessments are a foundational tool for protecting worker health. By collecting exposure data, employers gain the insights they need to reduce risks, prevent illness, and create a culture of safety.

If your facility uses or produces hazardous chemicals, ask whether you truly understand employee exposure. Even with existing controls such as local exhaust ventilation, respirators, gloves, or other forms of PPE, unknown or underestimated exposures can still occur due to changes in processes, chemical formulations, or work practices. Regular exposure assessments help verify that PPE is effective, ensure engineering controls are performing as intended, and identify opportunities for improvement.

For assistance on conducting occupational exposure assessments or any IH related questions, please contact Joe Grosse at JGrosse@all4inc.com or John Kelleher at JKhelleher@all4inc.com.

1https://en.wikipedia.org/wiki/Hierarchy_of_hazard_controls

EHS Considerations in the Paperboard Converting Industry

While the process of converting paperboard into corrugated sheets and containers seems rather straightforward, there are a wide array of environmental, health, and safety (EHS) challenges faced when manufacturing these products. As experts in both the converting process and EHS permitting and compliance, here are a few things ALL4 recommends you consider.

Emissions Sources and Air Permits

Have each of the units that emit regulated pollutants to the atmosphere been accounted for in your air permit? Including that diesel-fired fire pump engine sitting in the back corner of the warehouse? Is that parts washer exempt, or does that need to be on the permit too?

Many converting plants can be classified as minor sources of criteria and hazardous air pollutants, which means that the permitting requirements vary greatly from state to state. What could be exempt from permitting in one state may require a state operating permit and air dispersion modeling in another. Emissions reporting for minor sources can also vary greatly and may not be required on an annual basis. Irregular reporting deadlines can lead to confusion and missed reports if a robust compliance calendar is not in place.

The primary pollutants of concern for most converting facilities are generated at the converting equipment and the wastepaper handling system, which respectively emit Volatile Organic Compounds (VOC) and Particulate Matter (PM). Although facilities may have boilers or emergency engines, emissions from these units are typically small and may only result in regular tuning or maintenance requirements. Watch out for state air quality requirements around replacing burners or other combustion equipment, however. Your new burner may need to meet a certain emissions level.

VOC emissions, including hazardous air pollutants (HAP), come from residual VOC in the paper as well as the adhesives or additives used in the converting process, whether that’s for the corrugator or a specific color of ink. VOC emissions come with their own challenges as many states can regulate the toxic air pollutants/contaminants (TAP/TAC) at the state level, and those restrictions arise from health-based studies of these pollutants in the environment. In addition, some states require potential emissions be based on fairly unrealistic assumptions around ink and coating usage. You may be able to reduce your permitting burden by evaluating whether alternative inks with lower VOC or HAP/TAP content can be used.

While we certainly have to consider particulate emissions with respect to air quality requirements, there are other media to consider.

- PM emitted from a roof vent can collect on surfaces and later be washed off during a rain event. It then becomes part of the plant’s stormwater, contributing to the total suspended solids (TSS) loading of the discharge. A starch silo can also contribute PM to air and stormwater emissions if it is not maintained properly.

- Because the PM emitted from a converting plant originates from paper, it is defined as a combustible dust. While external emissions of paper dust do not pose a combustion risk, enclosed spaces with high concentrations of dust (e.g., a baler or hogger) should be assessed for hazard risks.

Discharges to a POTW

The majority of converting plants will discharge wastewater to their municipality’s publicly owned treatment works (POTW). Depending on the municipality requirements and the site’s specific wastewater, pretreatment may be required to meet discharge limits. All POTWs will require sampling on some frequency and will monitor discharge status. Discharge limits often include pH, TSS, chemical oxygen demand (COD), and color. Changes to the inks and additives used on-site can impact wastewater quality. As POTW permits change or as regulatory agencies request information from POTW on emerging contaminants such as PFAS, impacts may be felt upstream by industrial dischargers including converting operations. Changes may come in the form of new or reduced discharge limits, data collection, or additional monitoring requirements.

Chemical Storage

In addition to the actual physical chemical storage requirements, there are several regulations to keep in mind. Spill Prevention, Control, and Countermeasure (SPCC) plans are required for certain volumes of oil storage. Reporting and tracking is required for certain chemicals stored above their listed thresholds under the Emergency Planning and Community Right-to-Know Act (EPCRA) and Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) requirements. This can open your site to requirements to maintain a Facility Response Plan (FRP) or fall under Risk Management Plan (RMP) guidelines, especially if you are co-located with a paper mill.

Stormwater

Many converting operations have the potential to impact stormwater discharge, requiring them to obtain and maintain stormwater permit coverage, most often in the form of coverage under a state general permit. These permits often require sampling, inspections, training, reporting, recordkeeping, and implementing and maintaining a Stormwater Pollution Prevention Plan (SWPPP). When general permits renew, sites are required to register for continued coverage and update their SWPPP and onsite practices, as required, to comply with the renewed permit.

Safety

In addition to the combustible dust concerns mentioned above, another key safety program at converting plants is lockout/tagout. The converting equipment contains knives to cut the paperboard, as well as multiple pinch points due to the large amount of rollers. Also, these plants will certainly have powered industrial trucks (PIT) inside the manufacturing and warehouse areas. Therefore, a robust pedestrian safety program is necessary for each facility. You also want to make sure your safe work procedures are well laid out and easy to follow so your expectations for workers are clear.

EHS Staff Turnover

Typically, the EHS Department at a converting plant consists of only one or two employees. When the department changes hands, knowledge can easily be lost. The following best practices can prevent a critical knowledge gap when roles change.

- Document decisions made internally or by a regulatory agency (e.g., memo to file).

- Maintain an organized file system – both electronic and physical.

- Use a compliance calendar to track all reporting and compliance due dates.

- Prepare a quick reference sheet for environmental permits and plans.

- Document all assumptions and emissions factors in air emissions calculations.

- Have at least two individuals who can access online reporting systems within the organization.

How Can ALL4 Help?

Do EHS concerns at your converting plant keep you up at night? ALL4 can help – from air permitting to SPCC plans to lockout/tagout programs and everything in between. Reach out to your ALL4 contact or Anna Richardson at arichardson@all4inc.com for more information.

New Stormwater Permit to Impact The Los Angeles And Los Alamitos Area

The Los Angeles Regional Water Board (LA Water Board) has issued a revised draft General National Pollutant Discharge Elimination System (NPDES) permit (Permit) that will cover stormwater discharges from certain privately owned commercial, industrial, and institutional (CII) sites within two Los Angeles County watersheds: the Dominguez Channel/Greater Los Angeles and Long Beach Harbor Watershed and the Los Cerritos/Alamitos Bay Watershed. This draft Permit has been issued in response to petitions, a 2018 District Court Order, and the United States Environmental Protection Agency (U.S. EPA) using it’s residual designation authority under the Clean Water Act. U.S. EPA has reported that the two watersheds require a reduction in copper and zinc pollutants to restore water quality.

Who Will be Impacted?

Coverage from this Permit will be mandatory for the following CII sites in these watersheds that have five or more acres of total area:

- Sites not covered by other NPDES permits with five or more acres of impervious surface.

- Sites entirely or partially covered by other NPDES permits.

- Sites covered by a No Exposure Certification.

- Sites covered by a Notice of Non-Applicability.

Sites with an individual NPDES permit are not required to obtain coverage under the Permit unless the individual NPDES permit does not have equally stringent requirements.

Compliance Options

Stormwater dischargers will be required to submit Compliance Option Documents with their Notice of Intent (NOI), a Stormwater Pollution Prevention Plan (SWPPP), and laboratory analytical results.

There will be three compliance options available:

- Agreement with local watershed management group to fund regional project(s).

- Facility-specific design standards to reduce stormwater runoff.

- Direct demonstration of compliance with effluent limitations.

Option 1 is an off-site compliance option where funding is sent to an approved downstream regional project in a Watershed Management Program (WMP). To meet the requirements of this option, a copy of an agreement between the CII site and WMP must be submitted.

Option 2 is an on-site compliance option where structural and/or non-structural controls are implemented for stormwater runoff control. The required documentation to demonstrate compliance includes reports confirming design standards meet with the requirements and reports of installation of the approved controls.

Option 3 is an on-site compliance option where a site-specific Monitoring and Reporting Plan (MRP) is required to meet the requirements. The site-specific MRP includes descriptions of sampling methods and analysis. These reports are required to be submitted within 30 days of the sampling event.

With these three compliance options, submittal of an updated site-specific SWPPP is necessary. With each compliance option, reports will be due annually on December 15.

Existing dischargers and new dischargers will have different requirements for when Permit registration documents are required to be submitted. Existing dischargers will be required to submit an NOI and SWPPP within one year and Compliance Option Documents within three years of the effective date. New dischargers will be required to submit an NOI, SWPPP, and Compliance Option Documents at least 45 days before an authorized discharge occurs.

What’s next?

LA Water Board is currently considering the adoption of the draft Permit. A public hearing to consider the adoption of the draft Permit is scheduled for November 20, 2025.

If this applies to you, now is the time to start strategizing compliance. ALL4 can work with your site to develop an action plan. If you’re not sure if this Permit applies to you, speak to your point of contact at ALL4 or reach out to Meredith Pedraza at mpedraza@all4inc.com or 909.477.7132.

EU Delays CSRD Sustainability Reporting Standards for Non-EU Companies: What It Means for Your Organization

The European Commission (EC) recently announced a delay in the adoption of the European Sustainability Reporting Standards (ESRS) for non-European Union (EU) companies under the Corporate Sustainability Reporting Directive (CSRD). This decision, part of the EC’s broader simplification agenda, has implications for multinational organizations and presents an opportunity to strengthen sustainability reporting practices.

Key Updates and Timeline

- Original Schedule: Adoption of the ESRS for non-EU companies was initially planned for June 2024.

- Previous Delay: European Union (EU) lawmakers postponed the adoption to June 2026.

- Current Status: The EC’s recent de-prioritization letter indicates that the adoption will not occur before October 2027.

The delay impacts large non-EU companies operating in the EU that were scheduled to begin sustainability reporting under the ESRS framework in 2028. The postponement aligns with the EC’s ongoing regulatory changes proposed through the Omnibus I initiative, which aims to reduce administrative burdens and refine the scope and reporting requirements of the CSRD.

For reference, the CSRD overview provides further details.

Implications for Non-EU Companies

While the delay may ease immediate reporting pressures, it offers a valuable opportunity for organizations to:

1) Enhance sustainability reporting processes

- Organizations can refine internal data collection, governance, and reporting frameworks to ensure alignment with ESRS requirements.

2) Aligning corporate strategy with ESG objectives

- The additional time allows companies to integrate sustainability into business strategy, risk management, and decision-making.

3) Strengthen compliance readiness

- By adopting robust reporting practices early, organizations can gain a competitive advantage and be fully prepared when CSRD obligations take effect.

ALL4 Expertise: Guiding Clients Through Regulatory Change

At ALL4, we help clients navigate the evolving landscape of sustainability reporting by providing strategic and technical expertise across every stage of compliance. Our services include:

- Assessing the applicability of CSRD and ESRS standards to non-EU operations, providing clarity on obligations and timelines.

- Developing reporting frameworks that meet regulatory expectations and align with corporate ESG objectives.

- Leveraging digital solutions to streamline data collection, validation, and disclosure processes.

- Providing expert insight into emerging and evolving EU and international sustainability regulations, helping organizations stay ahead of change.

Our team helps organizations remain proactively prepared, turning regulatory changes into opportunities for operational excellence and enhanced ESG credibility.

Takeaway

The EU’s delay of the ESRS adoption for non-EU companies underscores the importance of strategic sustainability planning. Rather than viewing the postponement as a setback, companies can use the extra time to strengthen reporting frameworks, integrate ESG strategy into business operations, and ensure compliance readiness.

For tailored guidance on how your organization can leverage CSRD updates to enhance sustainability reporting, contact Teresa Flores at tflores@all4inc.com (EMEA) or James Giannantonio at jgiannantonio@all4inc.com (U.S.).

Spanish Translation:

La Comisión Europea (CE) anunció recientemente un retraso en la adopción de los Estándares Europeos de Reporte de Sostenibilidad (ESRS, por sus siglas en inglés) para empresas no pertenecientes a la Unión Europea (UE), bajo la Directiva de Reporte de Sostenibilidad Corporativa (CSRD). Esta decisión, que forma parte de la agenda de simplificación de la CE, tiene implicaciones para las organizaciones multinacionales y representa una oportunidad para fortalecer las prácticas de reporte en materia de sostenibilidad.

Actualizaciones Clave y Cronograma

- Calendario original: La adopción de los ESRS para empresas no europeas estaba prevista inicialmente para junio de 2024.

- Retraso previo: Los legisladores de la UE pospusieron la adopción hasta junio de 2026.

- Estado actual: Según la carta reciente de despriorización emitida por la CE, la adopción no se producirá antes de octubre de 2027.

Este retraso afecta a las grandes empresas no europeas que operan en la UE y que debían comenzar a reportar bajo el marco ESRS en 2028. La postergación se alinea con los cambios regulatorios en curso propuestos mediante la iniciativa Omnibus I, cuyo objetivo es reducir las cargas administrativas y ajustar el alcance y los requisitos de reporte establecidos por la CSRD.

Para obtener más información, puede consultar la visión general de la CSRD, que ofrece detalles adicionales.

Implicaciones para las Empresas No Europeas

Aunque el aplazamiento ofrece un respiro a corto plazo, también abre una ventana de oportunidad para que las empresas se preparen mejor:

1) Mejorar la calidad del reporte de sostenibilidad

- Este tiempo adicional puede aprovecharse para perfeccionar los procesos internos de recopilación de datos, gobierno corporativo y reporte, asegurando que estén alineados con los futuros requisitos de los ESRS.

2) Integrar la sostenibilidad en la estrategia del negocio

- Las organizaciones pueden avanzar en la incorporación de criterios ambientales, sociales y de gobernanza (ESG) dentro de su planificación estratégica, su gestión de riesgos y la toma de decisiones.

3) Fortalecer la preparación para el cumplimiento

- Las empresas que adopten buenas prácticas de reporte con antelación estarán en una mejor posición competitiva cuando los requisitos del CSRD entren en vigor.

Experiencia de ALL4: Guiando a Nuestros Clientes a Través del Cambio Regulatorio

En ALL4, ayudamos a nuestros clientes a navegar el panorama en constante evolución del reporte de sostenibilidad, brindando experiencia estratégica y técnica en cada etapa del proceso de cumplimiento. Nuestros servicios incluyen:

- Evaluar la aplicabilidad de los estándares CSRD y ESRS para operaciones fuera de la UE, proporcionando claridad sobre obligaciones y plazos.

- Desarrollar marcos de reporte que cumplan con las expectativas regulatorias y se alineen con los objetivos ESG corporativos.

- Implementar soluciones digitales para optimizar la recopilación, validación y divulgación de datos.

- Ofrecer asesoramiento experto sobre regulaciones emergentes y en evolución, tanto en la UE como a nivel internacional, ayudando a las organizaciones a anticiparse al cambio.

Nuestro equipo garantiza que las organizaciones se mantengan proactivamente preparadas, transformando los cambios regulatorios en oportunidades para alcanzar la excelencia operativa y fortalecer su credibilidad en materia ESG.

Conclusión

El retraso en la adopción de los ESRS por parte de la UE para empresas no europeas subraya la importancia de una planificación estratégica en sostenibilidad. Más que un retroceso, este aplazamiento debe verse como una oportunidad para reforzar los marcos de reporte, integrar la estrategia ESG en las operaciones empresariales y asegurar una preparación sólida para el cumplimiento futuro.

Para obtener asesoramiento personalizado sobre cómo su organización puede aprovechar las actualizaciones del CSRD para mejorar sus reportes de sostenibilidad, comuníquese con: Teresa Flores por medio de l correo tflores@all4inc.com (EMEA) o con James Giannantonio por medio del correo jgiannantonio@all4inc.com (EE. UU.)

Sunsetting Paper Manifests – Is It Finally Happening?

The Hazardous Waste Electronic Manifest Establishment Act (e-Manifest Act) was signed into law over 13 years ago in October 2012. However, the United States Environmental Protection Agency (U.S. EPA) reports that over 99.5% of the over two million manifests received annually do not fully utilize the electronic manifest system. The Hazardous Waste e-Manifest System Advisory Board met in September 2025 with the goal of laying a path towards the complete sunsetting of paper manifests. A white paper detailing the plan, background, and obstacles can be found here.

December 2025 Requirements

Beginning on December 1, 2025, all generators (except for Very Small Quantity Generators (VSQGs) or PCB generators) must submit all Exception Reports through e-Manifest. Similarly, all receiving facilities must submit all Discrepancy Reports through e-Manifest; paper copies can no longer be mailed to the U.S. EPA Regional Administrator after December 1, 2025. Users completing these reports must be registered and have at least the Certifier role within e-Manifest for their site. Export manifests must be submitted by domestic exporters via e-Manifest beginning on December 1, 2025, as well.

Barriers to e-Manifest

U.S. EPA recognizes that there are a range of barriers that still exist and will need to be addressed before paper manifests are fully phased out. These include:

- Legacy Workflows

- S. DOT Shipping Paper

- Access to Manifest Tracking Numbers

- Variability of Pickup Volumes

- Office and Field Hours

- Legacy Industry Systems

- Cell Service and Internet Access

U.S. EPA is proposing system updates that will address access to manifest tracking numbers, variability of pickup volumes, office and field hours, and internet service access. These changes are intended to further address the legacy workflow of manifest preparation and signatures to ease the burden on generators, transporters, and receiving facilities. They are also engaging the U.S. DOT to ensure the transition from paper manifests still maintains allowances to meet U.S. DOT’s requirements.

System Updates

One of the most challenging barriers to the current e-Manifest system is the signatures required to transfer custody of waste between the generator and transporter. To address this, U.S. EPA is proposing a signature method that will allow for short message system (SMS) signatures. In short, a user would be able to text a manifest tracking number to e-Manifest to begin a message exchange that will end with the user texting their full name as a signature. This would make access more convenient and not as dependent on internet access.

Another barrier is the current process to update shipment details which requires the updates be made by a registered user in the RCRAInfo Industry Application and be associated with the site. U.S. EPA is proposing to use a combination of SMS editing and Quick Response (QR) codes that will allow a user to be make updates without needing to be granted access to a site within e-Manifest. The updates will be automatically pushed through the system and into the manifest itself. The intent is to make the process nearly as convenient as just updating a paper form on a clipboard.

Expected Regulatory Changes and Timeline

While there have already been three rulemakings to implement the use of e-Manifests, none have fully sunset the use of paper manifests. A new proposed rule will need to be published that will include a date by which paper manifests can no longer be used. U.S. EPA currently anticipates publishing the rule to the Federal Register for public comment in early 2026 and a final rule is expected to be issued in 2027. U.S. EPA is still weighing their options as to how soon compliance will be required and if there will be a staggered approach or not.

The new rule will likely require many additional waste handlers to register with e-Manifest. These include:

- Episodic VSQGs operating under 40 CFR part 262, subpart L

- Handlers of pharmaceutical wastes subject to 40 CFR part 266, subpart P

- RCRA transporters

- PCB generators and transporters subject to the manifest under 40 CFR 761, subpart K

In addition to the new rule, several existing regulations (40 CFR Parts 260, 262-267, 271, and 761) need to be updated to remove language pertaining to the use of paper manifests. These current Resource Conservation and Recovery Act (RCRA) and Toxic Substances Control Act (TSCA) regulations may also be updated to remove paper recordkeeping requirements as all necessary records would be accessible through e-Manifest

After over 40 years of tracking hazardous waste shipments with paper manifests, a full phaseout is imminent. Overhauling such an extensive recordkeeping system has come with many obstacles, and there are surely more to come. ALL4 is following these changes and is available to assist your company with the e-Manifest system. Please reach out to Meredith Pedraza at mpedraza@all4inc.com or your ALL4 project manager with questions.

D.C Circuit Court Restores Title V Affirmative Defense

In a September 5, 2025 decision, the D.C. Circuit reinstated the affirmative defense provisions under Title V operating permits. The court found that the July 1, 2023 rule, which removed the affirmative defense provisions from Title V permits, was arbitrary and capricious. A key point in the court’s decision is that an affirmative defense to liability is not an exemption from an emissions standard that applies on a continuous basis. The court reiterated that “[a]n affirmative defense allows a defendant to avoid liability, but it does not alter the underlying legal requirements,” which assume that a legal standard remains in force. The court also stated “the Title V affirmative defense for emergencies does not lift applicable standards. Because the emission standards are never lifted, they apply “on a continuous basis” as required by the Clean Air Act.”

The Title V affirmative defense provisions were first promulgated in 1992 under 40 CFR §70.6(g) to provide a defense for sources that exceed emissions limitations as a result of an emergency. The rule created an affirmative defense regarding actions as a result of noncompliance with an emissions standard during an emergency. Emergency was defined as “any situation arising from sudden and reasonably unforeseeable events beyond the control of the source, including acts of God…” and that results in unavoidable emissions in excess of a standard attributed to the emergency. A permit holder would not be in violation of the Clean Air Act (CAA) if the affirmative defense provision applied. To qualify for the defense, the permittee was required to prove that an emergency occurred, the facility was being properly operated, and that all reasonable steps had been taken to minimize excess emissions during the emergency.

The affirmative defense provisions were removed from the Title V regulations by U.S. EPA on August 21, 2023 because they were deemed inconsistent with the U.S. EPA’s CAA enforcement structure and removal “would harmonize the EPA’s treatment of affirmative defenses across different CAA programs.” The U.S. EPA also concluded that the affirmative defense provisions provided an exemption from emissions limits that otherwise applied continuously. They also stated that the affirmative defense encroached on the judiciary’s role to impose appropriate penalties.

In addition to reinstating the affirmative defense provisions that can be used by stationary sources, as applicable, in the event of unavoidable exceedances of emissions standards due to emergencies, the D.C. Circuit court ruling could provide additional leeway for the reinstatement or continuation (as applicable) of similar provisions under other regulatory programs. For example, U.S. EPA has been removing affirmative defense provisions added to Part 63 standards (National Emission Standards for Hazardous Air Pollutants for Source Categories, or NESHAPS) as they are conducting their periodic reviews.

ALL4’s air quality experts have significant experience developing Title V permitting and compliance strategies, and Title V air permit applications. Please reach out to me at rrakiewicz@all4inc.com or a familiar ALL4 resource should you have any questions about Title V permitting or compliance or for assistance in evaluating or permitting your next project.

Novel Approach Included in U.S. EPA’s Recent Secondary Lead Smelting Proposal

On October 1, 2025, the U.S. Environmental Protection Agency (U.S. EPA) proposed amendments to the National Emission Standards for Hazardous Air Pollutants (NESHAP) for the Secondary Lead Smelting source category (40 CFR Part 63, Subpart X). The proposal addresses multiple items: the required technology review, unregulated hazardous air pollutants (HAP), and outstanding petition issues. U.S. EPA is also proposing revisions related to startup, shutdown, and malfunction (SSM), electronic reporting, monitoring requirements, and other minor technical issues. The novel approach hinted at in the title of this article relates to their analysis of unregulated HAP.

Technology Review

U.S. EPA is required to perform a one-time risk review of each NESHAP eight years after promulgation and an ongoing technology review every eight years after promulgation. The risk review is performed to determine if any changes are needed to address remaining risk associated with HAP emissions from the source category. The technology review is performed to assess whether there have been cost-effective developments in practices, processes, or control technologies that should be incorporated into the rule. These deadlines are often missed; U.S. EPA originally promulgated the NESHAP in 1996 and finalized its risk and technology review of Subpart X in 2012.

This proposal represents the second technology review. U.S. EPA has determined that wet electrostatic precipitators (WESPs) and fenceline monitoring were the most relevant potential developments for consideration in its review. The review determined that requiring a WESP at the outlet of a facility’s existing particulate control (e.g., baghouse) was not cost effective and WESPs are therefore not proposed as a requirement. U.S. EPA also determined that the 2012 Subpart X amendments reduced fugitive HAP metal emissions and ambient concentrations at facility fencelines. Because of these reductions, the additional monitoring programs already required by the rule, and the fact that there has been no fenceline monitoring method proposed or promulgated for HAP metals, U.S. EPA is not proposing to require fenceline monitoring as part of the technology review.

Unregulated HAP

As a result of the D.C. Circuit Court’s 2020 decision in the LEAN case, U.S. EPA has been reviewing NESHAPs to determine if they adequately address all sources of HAP in the source category and all HAP known to be emitted from affected sources. As a result of that review for Subpart X, emissions of hydrochloric acid (HCl), chlorine (Cl2), and carbonyl sulfide from all furnace types and emissions of total hydrocarbon (THC) and dioxin/furan (D/F) from rotary furnaces were identified as unregulated. Therefore, emissions testing was required as part of an information collection request and based on the collected emissions data, U.S. EPA proposes to:

- Add THC and D/F emissions limits for co-located rotary and reverberatory furnaces,

- Use THC as a surrogate for carbonyl sulfide (COS) emissions (thermal controls used for THC control also control COS), and

- Not require standards for emissions of hydrochloric acid (HCl) and chlorine (Cl2) because emissions are so minimal as to be considered de minimis.

This is not the first NESHAP where U.S. EPA has added THC and D/F limits to sources or applied THC as a surrogate for non-D/F organic HAP. However, this is the first time since the LEAN decision that U.S. EPA has articulated a position that HAP emitted in “de minimis” amounts do not require either numeric emissions limits or work practice standards. U.S. EPA estimates that HCl and Cl2 emissions have been reduced to 1.5 and 0.2 tons per year (tpy), respectively, from the 11 facilities covered by Subpart X because polyvinyl chloride (PVC) has been phased out as a separator material in the batteries processed at secondary lead smelters. Their reasoning in determining that these levels of emissions do not require additional controls is that Congress did not intend to subject trivial levels of emissions to controls under Clean Air Act Section 112. Various court decisions are cited in the proposal preamble that revolve around the principle that the law does not concern itself with trifling matters and that a general statutory requirement does not encompass de minimis concerns unless otherwise indicated. U.S. EPA supports its position by pointing out that Section 112 establishes a major source as one that emits 10 tpy or more of any HAP or 25 tpy of total HAP, and that area sources are only regulated if they present a threat of adverse effects to human health or the environment. Also mentioned is the Supreme Court’s admonition in one case that no statute yet known pursues its purpose at all costs. U.S. EPA contends that because Congress required them to establish priorities for promulgating NESHAP that included the effects of HAP on public health and the environment and the quantity and location of HAP that each source category emitted, thus supporting the treatment of HAP with trivial emissions and low impacts as de minimis.

Specific to the secondary lead smelting category and HCl/Cl2 emissions, U.S. EPA points out that the emissions levels per source are nowhere near the thresholds that trigger major source regulation and do not amount to a level that presents an adverse effect to human health or the environment (the 2012 risk review found that the NESHAP provides an ample margin of safety to protect public health). In addition, neither of these two HAP persist in the environment for long periods of time, transform into other HAP, or bioaccumulate and they are not non-threshold carcinogens. U.S. EPA states that this analysis differs from its prior decision to reject de minimis treatment for these two pollutants under the cement kilns source category because HCl was emitted by each kiln at major source levels.

Finally, it is noted by U.S. EPA that the decision to apply this treatment to these pollutants for this NESHAP is highly fact specific. While U.S. EPA could use the de minimis criteria in future NESHAP reviews, it remains uncertain exactly what emissions level constitutes de minimis. However, in this proposal, de minimis seems to be an amount less than the major source threshold. U.S. EPA’s future use of the de minimis principle is most likely to occur in other gap-filling exercises where emissions are small, risks are low, and there is no indication that emissions of the HAP(s) from the source category are likely to increase over time. While the use of the de minimis criteria by U.S. EPA is discretionary, it will not likely occur for a HAP such as mercury because of its associated risks but could occur for certain trace HAP associated with combustion systems or HAP that pose minimal health risk.

Although U.S. EPA considered a health-based standard for HCl as part of its review of the Lime Manufacturing NESHAP in 2024, they estimated reductions of 884 tpy from application of the numeric emissions limit that was ultimately finalized, which is much higher than HCl emissions levels in the secondary lead smelting source category. The Lime Manufacturing NESHAP is one of several NESHAP where the previous administration added HAP emissions limits that are currently being reconsidered, so it will be interesting to see for which rules and pollutants U.S. EPA applies a novel approach to avoiding or removing standards.

Other Proposed Changes

Other proposed changes to Subpart X include:

- Revisions to building differential pressure monitoring requirements,

- Automatic approval of 24-month performance test extensions under certain circumstances,

- Changes to SSM provisions,

- Updates to the General Provisions applicability table,

- Expansion of electronic reporting requirements, and

- Removal of the affirmative defense provisions.

Comments on the proposal are due November 17, 2025.

Summary

ALL4 is tracking proposed and final revisions to several U.S. EPA air regulations and the approaches the agency is using to justify those revisions. We’re following the reviews and reconsiderations of NESHAP, so stay tuned for future articles. We have extensive experience preparing technical comments on regulations, evaluating final regulations, preparing compliance strategies, and helping facilities implement and sustain compliance approaches. If you need help developing comments or understanding how changes to regulations affect you, please reach out to your ALL4 Project Manager.