Lead Service Line Replacement Plans – Does Your Facility Need One?

The United States Environmental Protection Agency (U.S. EPA) published the Lead and Copper Rule (LCR) in 1991 to protect the public from potentially contaminated drinking water coming from water pipes using copper or lead materials. Since the initial rule in 1991, the EPA has modified the rule as needed such as the 2021 Lead and Copper Rule Revisions (LCRR). These ongoing modifications have been catalyzed by President Biden’s Bipartisan Infrastructure Law and are set to make great strides in reducing public exposure to lead and copper in drinking water.

Is the LCRR applicable to your industrial facility?

Of these ongoing rule changes packaged with in the LCRR, one of the most impactful regulations is the “Lead Service Line Inventory and Replacement Reporting Requirements” codified in 40 CFR 141.90(e). This regulation affects community water systems and non-transient, non-community water systems under 40 CFR 141.80(a)(1). Non-transient, non-community water systems (NTNCWS) are defined as a public water system that regularly serves at least 25 of the same persons over 6 months per year. NTNCWS includes industrial facilities, schools, office buildings, or hospitals that supply potable water for employees.

Lead Service Line Replacement Plan

The “Lead Service Line Inventory and Replacement Reporting Requirements” sets the date of October 16, 2024, for facilities to create, and submit to the state, a lead service line inventory as well as a lead service line replacement plan.

The lead service line inventory requires facilities to identify the materials of service lines connected to the water distribution system. The lead service line replacement plan requires facilities with lead, galvanized requiring replacement, or lead status unknown service lines to create a lead service line replacement plan. The plan is required to detail a strategy to determine the presence of lead in service lines as well as replace them if need be.

What’s The Next Step

The lead service line inventory and replacement plan are comprehensive reports that will set up a framework to do away with lead-based piping systems. These reports will require a detailed look at current systems and possible modifications. With only a little over a year left until the compliance deadline there is no time like the present to start building your inventory and plan. If you have questions or want to discuss your compliance strategies, reach out to Evan Mia at emia@all4inc.com.

TCEQ Sunset Bill

This year, the representatives of the Texas Legislature met in Austin for the 88th Regular Session. In this Legislative Session, which ran from January 10th and adjourned May 29th, there were over 11,000 bills introduced. This article addresses Senate Bill (SB) 1397 or the Texas Commission on Environmental Quality’s (TCEQ) Sunset Bill which has major implications on the operation of TCEQ going forward.

A “Sunset Bill” is the vehicle to take the recommendations from the Sunset Advisory Commission and pass them through the legislative process. In Texas, the Sunset Advisory Commission is a government entity that is responsible for evaluating the effectiveness and efficiency of other state agencies and programs. This commission will perform periodic (about every 12 years) and comprehensive reviews of state agencies, including the TCEQ, with the goal of evaluating how these agencies utilize funds and provide services to the public. At the completion of their review, the Sunset Advisory Commission provides recommendations to improve, change, or abolish these agencies.

On the docket for last year’s Sunset Advisory Review was the TCEQ. In their review, the Sunset Advisory Commission ultimately determined that the TCEQ should live on as a necessary regulatory entity in Texas; however, the agency should have some changes. The main findings were two-fold: The TCEQ was found to have lacked adequate transparency with the public which prohibited Texans from appropriate participation in the permitting process. Additionally, TCEQ received a ‘Needs Approvement’ in their Compliance Monitoring and Enforcement procedures.

To address this review, representatives of the Texas Legislature introduced SB 1397. This bill was unanimously approved in the Texas Senate and received little sparring in the House. Currently, the Bill has been passed in the Texas Legislature and on its way to Governor Abbott’s desk. Below is a high-level summary of changes that are coming to TCEQ based on SB 1397:

- TCEQ will post all permit applications on its website.

- TCEQ will be required to publish notice of permit applications on its website and will be required to make accommodations for residents without access to the internet.

- The maximum daily penalty that the TCEQ can enforce for a violation will increase from $25,000 to $40,000 per day. These must be repeated violations with detrimental effect on human health and the environment that TCEQ determines could have been reasonably avoided.

- TCEQ will establish a small business and local government enforcement division to provide compliance and technical resources for these businesses.

- TCEQ will establish a Standard Permit for temporary concrete plants that support public work projects.

If you have any questions on how this Bill could affect you or your future permitting projects reach out to me, Wesley Hill, at whill@all4inc.com.

Kentucky Division of Water to Renew KYR00 Industrial Stormwater General Permit

The Kentucky General Permit for Stormwater Discharges Associated With Industrial Activity From Other Facilities, also known as the KYR00 Industrial Stormwater General Permit (KYR00 General Permit), expires on July 31, 2023. The current version of the permit became effective on August 1, 2018, and requires reissuance by the regulatory agency every five years. Prior to issuance, the KYR00 General Permit will go out for a 30-day public notice period. Industrial facilities, members of the public, and other interested parties will be able to review the draft permit and submit comments to KYDOW for agency review.

What do you need to know?

KYDOW will likely try to minimize the time between expiration and issuance of the renewed permit because, once the permit has expired, coverage for new facilities cannot be issued until the renewed permit is issued. If the number of comments received during the public notice period is significant, there could be a delay in issuing the renewed permit. Therefore, it is recommended that any new facility seeking coverage submit an application to KYDOW at least several weeks prior to July 31, 2023; otherwise, the only available option for facilities with unpermitted stormwater discharges will be to obtain an individual Kentucky Pollutant Discharge Elimination System (KPDES) permit. Frequency of sampling for stormwater discharges under an individual KPDES permit is typically monthly as opposed to semi-annually for the general permit.

Substantial changes are not expected in the renewed KYR00 General Permit. KYDOW indicated that (1) additional industrial facility types will be covered under the KYR00 General Permit, and (2) existing permittees will not see any changes in requirements. For reference, the most significant change to the KYR00 General Permit following the previous reissuance in 2018 was the addition of a 100 milligram per liter (mg/l) trigger for Total Suspended Solids (TSS), which required evaluation of existing Best Management Practices (BMPs) if the trigger value was exceeded in two consecutive reporting periods.

What actions do you need to take?

A renewal application will be required to renew coverage this year. However, no action is required for existing permittees prior to expiration; the Kentucky Division of Water (KYDOW) cannot process any applications until they renew the permit. Once the renewed permit has become effective, KYDOW will send solicitation letters to all existing permittees with instructions on how to renew coverage. Existing permittees will then have 90 days to submit an electronic renewal application through the Kentucky Online Gateway website at https://kog.chfs.ky.gov. In an effort to streamline the application process, the solicitation letter will contain a Transaction ID that can be used to recall the previous application.

Facilities covered under a conditional exclusion for no exposure (i.e., No Exposure Certification) will also be required to renew coverage following the same timeline as permit holders with existing coverage under the KYR00 General Permit.

Finally, it is recommended to use the renewal process as an opportunity to review and update the facility’s Stormwater Pollution Prevention Plan (SWPPP). The SWPPP is required for all facilities with KYR00 General Permit coverage. Some facilities may find that their SWPPP hasn’t been updated since KYR00 General Permit coverage was initially granted. A review of the facility and operations will often identify changes to outdoor material storage, updates to BMPs, and administrative revisions such as changes in site contacts. These changes should be reflected in an updated SWPPP, and reissuance of the KYR00 General Permit is an ideal time to review site drainage, stormwater controls, and management practices.

If you have any questions about stormwater permitting and how ALL4 can help, please contact William Shane (wshane@all4inc.com).

U.S. EPA Issues Proposed Revisions to SOCMI NESHAPs and NSPS and the NESHAPs for Group I and II Polymers and Resins

On April 25, 2023, the U.S. Environmental Protection Agency (U.S. EPA) proposed revisions to several National Emission Standards for Hazardous Air Pollutants (NESHAP) and New Source Performance Standards (NSPS) applicable to facilities in the Synthetic Organic Chemical Manufacturing Industry (SOCMI) and Group I and II Polymers and Resins (P&R) Industries. U.S. EPA has proposed these changes in response to several consent decrees where they agreed to complete the NESHAP risk and technology reviews (RTR) required by the Clean Air Act (CAA) and the NSPS review required by the CAA within a specified timeframe. In addition to updates associated with these statutorily required reviews, U.S. EPA has also proposed revisions to NSPS Subparts VV and VVa to address an outstanding reconsideration petition from January 2008, removed the startup, shutdown, and malfunction (SSM) exemptions from the SOCMI NESHAPs, and proposed several other miscellaneous changes. This article includes a summary of the changes U.S. EPA has included in the proposal.

Changes to NESHAPs due to U.S. EPA’s Technology Review

U.S. EPA is required to complete a technology review of each NESHAP no less than every eight years and revise the standards as necessary, taking into account developments in practices, processes, and control technologies. U.S. EPA has proposed the following changes to 40 CFR Part 63, Subparts F, G, H, I (HON), 40 CFR Part 63, Subpart U (P&R I), and 40 CFR Part 63, Subpart W (P&R II) as a result of its technology review.

| Source Type | Rule | Proposed Change |

| Heat Exchange Systems | HON

P&R I |

|

| Storage Vessels | HON

P&R I |

|

| Process Vents

|

HON |

|

| P&R I |

|

|

| Equipment Leaks | P&R II |

|

| Fenceline Monitoring | HON

P&R I |

|

Changes to NESHAPs due to U.S. EPA’s Risk Review

U.S. EPA is required to complete a risk review following promulgation of NESHAPs to determine whether additional standards are needed to provide an ample margin of safety to protect public health or to prevent an adverse environmental effect. Initial risk reviews for HON, P&R I, and P&R II were completed in 2006, 2008, and 2011. However, U.S. EPA determined that another risk review was necessary due to changes to the Integrated Risk Information System (IRIS) that have occurred since they were conducted. Specifically, the IRIS inhalation Unit Risk Estimate (URE) for ethylene oxide was lowered and an IRIS value for chloroprene was added. The following changes have been proposed to HON, P&R I, and P&R II in response to U.S. EPA’s risk review.

| Source Type | Rule | Proposed Change |

| Heat Exchange Systems in Ethylene Oxide Service | HON |

|

| Storage Vessels in Ethylene Oxide/Chloroprene Service | HON |

|

| P&R I |

|

|

| Process Vents in Ethylene Oxide/Chloroprene Service | HON |

|

| P&R I |

|

|

| Equipment in Ethylene Oxide Service | HON |

|

| Wastewater in Ethylene Oxide/Chloroprene Service | HON |

|

| P&R I |

|

|

| Maintenance Vents in Ethylene Oxide/Chloroprene Service | HON |

|

| P&R I |

|

|

| Flares | HON |

|

| PRDs in Ethylene Oxide/Chloroprene Service | HON |

|

| P&R I |

|

|

| Source Cap | P&R I |

|

Changes as a Result of U.S. EPA’s NSPS Reviews

U.S. EPA is required to review NSPS every eight years and revise the standards as necessary. U.S. EPA has proposed the creation of four new subparts under 40 CFR Part 60: VVb (SOCMI Equipment Leaks), IIIa (SOCMI Air Oxidation Unit Processes), NNNa (SOCMI Distillation Operations), and RRRa (SOCMI Reactor Processes). The following are some of the key changes from the existing subparts:

Proposed Subpart VVb

- Same as current VVa requirements, except for the following changes:

- The leak definition for gas and light liquid valves has been lowered from 500 ppm to 100 ppm; and

- Annual connector monitoring with a leak definition of 500 ppm has been added.

Proposed Subparts IIIa / NNNa / RRRa

- The option to comply based on the total resource effectiveness (TRE) value has been removed.

- Flares used to comply with the emissions standard are subject to the requirements in 40 CFR Part 63, Subpart CC (Refinery MACT), with certain clarifications and exemptions.

- The definition of vent stream has been revised so that it no longer excludes relief valve discharges, thus making any release from a PRD a violation of the rule.

- Language expressly prohibiting the bypass of any air pollution control device has been added as a deviation.

- Addition of requirements for adsorbers used as air pollution control devices that cannot be regenerated or must be regenerated offsite.

- Addition of maintenance vent requirements, similar to those proposed for the SOCMI NESHAPs.

Other Proposed Changes

U.S. is proposing the following additional changes to HON, P&R I, and P&R II:

| Source Type | Rule | Proposed Change |

| Flares | HON

P&R I |

|

| PRDs | HON

P&R I |

|

| Bypass Lines | HON

P&R I |

|

| Maintenance Activities | HON

P&R I |

|

| Dioxins Furans | HON

P&R I P&R II |

|

| Pressure Vessels | HON

P&R I |

|

| Surge Control Vessels and Bottoms Receivers | HON

P&R I |

|

| Transfer Operations | HON |

|

| Heat Exchange Systems | P&R II |

|

| Equipment Leaks | P&R II |

|

Finally, the following minor changes have also been proposed:

- Changes to 40 CFR Part 60, Subparts VV and VVa related to the 2008 Reconsideration petition: removal of the method for assigning shared storage vessels from both Subparts VV and VVa, removal of connector monitoring from Subpart VVa, and revising the definition of capital expenditure in Subpart VVa.

- Changes associated with startup, shutdown, and malfunction: The new NSPS (VVb, IIIa, NNNa, and RRRa) do not include SSM exemptions and the affirmative defense provisions for malfunctions in P&R I will be removed.

- Electronic reporting requirements using the Electronic Reporting Tool (ERT) and CEDRI.

- Other technical and editorial changes to improve clarity.

What do I need to do?

The comment period for the proposed rule ends on June 26, 2023. The final rule is expected in Spring 2024. The proposed changes to the SOCMI NESHAP and NSPS rules add many new requirements for new and existing sources in the SOCMI source category. This article only provides an overview of some of the key changes associated with the proposed rule and is not intended to provide a complete inventory of all the requirements or revisions. If you have additional questions or would like to gain an understanding of how the new rules could affect your facility’s compliance program, please reach out to me at cward@all4inc.com. We will also be hosting a webinar on July 12, 2023 where we will discuss the proposed changes in more detail. ALL4 is monitoring all updates published by the U.S. EPA on this topic, and we are here to answer your questions and assist your facility with any aspects of regulatory compliance.

U.S. EPA’s Proposed Updates to the Wood Products NESHAP

The U.S. Environmental Protection Agency (U.S. EPA) proposed significant amendments to the National Emission Standards for Hazardous Air Pollutants (NESHAP) for Plywood and Composite Wood Products (PCWP) on May 18, 2023. The current NESHAP requirements focus primarily on organic hazardous air pollutant (HAP) emissions from certain types of wood products dryers and presses. The proposed amendments address the 2007 partial remand and vacatur of portions of the original 2004 PCWP NESHAP (U.S. EPA had not set any standards for several types of emissions units that had no HAP controls) and a petition for reconsideration that U.S. EPA received on the 2020 Risk and Technology Review (RTR) of the NESHAP. Basically, U.S. EPA is proposing to (1) set emission standards for several types of process units that are part of the affected source but do not currently have standards (including lumber kilns) and (2) set emission standards for several new pollutants for biomass direct-fired wood products dryers. Major proposed amendments to the rule are discussed below.

Work Practice Standards for Lumber Kilns

Lumber kilns are part of the affected source under the PCWP NESHAP but are not currently subject to any standards. U.S. EPA is proposing to establish work practice standards for lumber kilns. The proposed work practice has four elements:

- An operation and maintenance plan for all types of kilns,

- Annual burner tune-ups for direct-fired kilns,

- Work practices to limit over-drying of lumber using temperature and/or moisture,

- A definition of over-dried lumber based on the variance from the target moisture content of the lumber grade.

The third element of the work practice proposed by U.S. EPA involves the facility selecting between three options to limit HAP emissions from lumber kilns: (1) limiting the 3-hour block average temperature in the kiln based on the type of kiln being used (batch indirect fired, batch direct fired, or continuous), (2) limiting the semiannual average in-kiln moisture content of the wood being dried, or (3) establishing a site-specific plan that contains both temperature and lumber moisture content limitations, where the moisture of the lumber may be measured at a location other than in the kiln. These options are necessary because not all species of wood can be efficiently dried at the temperatures proposed in option 1 and not all facilities measure in-kiln lumber moisture per option 2. U.S. EPA proposes to require that the site-specific plan be incorporated into the facility’s Title V permit if option 3 is selected.

Additional Standards for Direct-Fired Dryers

U.S. EPA has proposed to add work practice standards for all direct-fired dryers and numeric standards for emissions of filterable particulate matter (PM), mercury, hydrochloric acid (HCl), and polycyclic aromatic hydrocarbons (PAH) from biomass direct-fired dryers. U.S. EPA proposes to define a natural gas direct-fired dryer as one where greater than 90 percent of the direct heat results from gas combustion and a biomass direct-fired dryer as one where at least 10 percent of the direct heat comes from biomass combustion.

The proposed work practice standards include annual tune-ups (similar to the Industrial Boiler NESHAP) to ensure good combustion (and limit emissions of dioxins/furans) and monitoring of bypass stack use during startup or shutdown. The proposed numeric standards for biomass direct-fired dryers are subcategorized according to dryer type (rotary strand, green rotary, dry rotary, tube, and softwood veneer) and compliance must be demonstrated via continuous monitoring and 5-year stack testing. Two options are provided for compliance with the new numeric standards: production based or concentration based.

Standards for Resinated Material Handling (RMH) Process Units

RMH process units are resin tanks, softwood and hardwood plywood presses, engineered wood products presses and curing chambers, blenders, formers, finishing saws, finishing sanders, panel trim chippers, reconstituted wood products board coolers (at existing affected sources), hardboard humidifiers, and wastewater operations. These process units handle resin or resinated wood material downstream of the point in the PCWP process where resin is applied. U.S. EPA is proposing work practice standards for these RMH process units because they do not currently have any requirements in the rule and are generally fugitive sources of organic HAP. The proposed standards are:

- Vapor pressure limit of 5.2 kPa (0.75 psia) for resin storage tanks storing resins that do not qualify as non-HAP resins.

- Use only a non-HAP resin OR use a resin with a maximum true vapor pressure less than or equal to 5.2 kPa (0.75 psia) OR use a combination of resins meeting the first two options.

- Process wood material that was purchased pre-dried to a moisture content of no more than 30 weight percent, dry basis or that has been dried in a dryer located at the PCWP facility. This requirement does not apply to wet formers or wastewater operations.

- Four options for reducing HAP emissions from wastewater operations.

A non-HAP resin is defined as resin with HAP contents below 0.1% for carcinogens and below 1.0% for non-carcinogens. Not all resins used at PCWP facilities can qualify as non-HAP resins so U.S. EPA has provided options for limiting HAP emissions from RMH process units.

Other Proposed Requirements

Other requirements U.S. EPA is proposing to add are:

- Numeric standards for dry and green wood atmospheric refiners,

- Work practice standards for stand-alone digesters and fiber washers,

- Numeric standards for fiberboard mat dryers and press predryers at existing sources,

- Work practice standards for log vats,

- Numeric standards for process units with methylene diphenyl diisocyanate (MDI),

- Standards for mixed process streams,

- Repeat testing and parameter monitoring requirements for the added numeric standards.

U.S. EPA is also proposing to remove the emissions averaging provisions, update the electronic reporting template, and make various corrections/clarifications to rule text.

The Path Forward

Comments on the proposed amendments to the PCWP NESHAP are due July 3, 2023, and U.S. EPA is currently under a court-ordered deadline to sign the final rule by November 11, 2023. A 45-day comment period is not a lot of time to read and understand the proposed changes and to prepare comments providing feedback to U.S. EPA, so you will want to get started now if this rule amendment will affect you. Note that the regulatory text was not included in the Federal Register notice, but a redline/strikeout version of the rule is located in the rulemaking docket at regulations.gov for review.

U.S. EPA is proposing to give existing facilities three years to comply with the amended requirements, although any facility with a lumber kiln that chooses the site-specific work practice option will likely need to prepare the plan within 180 days of the final rule. The new standards could result in the need for process changes, so it will be important to gather data as early as possible to determine the need for any modifications to comply with the new standards. ALL4 is reviewing the proposed rule and preparing technical comments; let us know if your company requires assistance reviewing the proposed rule and preparing a compliance strategy. Feel free to reach out to Amy Marshall at amarshall@all4inc.com with questions.

Data Quality Part 2: What Are the Components of Data Quality?

In the first article of this series we started with this thought: Defining data quality and implementing a data quality program furthers the goal that the data collected serve the intended purpose, i.e., informed decision making. We walked through an example of different methods to make a measurement; the upshot of that was that we needed to match the measurement to the end use of the result. If we need better, tighter numbers, we need to use a better, tighter tool (and in this context, tool means both the physical tool and the procedure). In this article, we will discuss the questions that help us frame our decision making around methodology. (And we’re going to put fancy words around the questions.)

- Does the data need to be repeatable? Of course it does, right? But how repeatable? In the extension cord example in the first article of this series, it just needs to be repeatable enough that I don’t have to string together two extension cords. When considering data quality, repeatability is called PRECISION.

- Does the data need to be right? Again, of course it does. But how tightly does it need to agree with the actual value? In the lumber estimation example in the first article of this series, it just needs to be close enough to avoid another trip to Home Depot. When considering data quality, agreement with the correct value is called ACCURACY.

- Under what conditions are we making the measurement? For my overall deck case, did I lay out the deck in the right place, and did I start from the right points on the house? Or did I lay out the deck and measure planning to use 2×8 boards, and then bought 2×6 boards? When considering data quality, making sure that the data reflects the intended physical state is called REPRESENTATIVENESS.

- Is my measurement something someone else can use (and vice versa)? If we are sharing, combining, or comparing our data with someone else’s data, we need to have used similar (or near identical) methodologies. I built my deck out of wood and my neighbor built his out of concrete. We’re comparing notes ─ I bought 700 board feet of decking and he bought 4 tons of concrete. We can’t compare. When considering data quality, similarity between measurements is called COMPARABILITY.

- Did I get all the data I need? To stretch my deck analogy, did I forget anything? Yes, I did; while I covered the decking material itself, I forgot anything that had to do with raising or lifting the deck off the ground and making it level. I didn’t measure the drop over the dimensions of the deck, so I didn’t buy any risers or in‑ground support for my risers (back to Home Depot I go…). When considering data quality, getting enough data is called COMPLETENESS.

As we set up a measurement program, we want to define the data quality objectives. We want to identify and define all the specifications to get the quantity and quality of data necessary to answer the underlying question. To do that, we address all the things mentioned above: precision, accuracy, representativeness, comparability, and completeness.

For a small measurement event, the identification and assessment of many of those data quality components needs to be external to our own measurements. For example, three stack test measurements are insufficient to assess precision. Instead, we must assess precision using any of a number of tools: repeat measurements, repeat analysis of known standards, and multiple spiked samples. There are also procedural approaches to data quality; examples here include training, use of standardized procedures, implementation of published methods, and robust and standardized systems. The ribbon that wraps up our data quality assessment and helps make sure that the data collected will address our underlying question is our selection and assignment of data quality objectives.

Next time: Into the Weeds on Precision and Accuracy

Until then, feel free to contact either of us:

- Gene Youngerman, gyoungerman@all4inc.com, 512.649.2571

- Aditya Shivkumar, ashivkumar@all4inc.com, 281‑201-1239

Links to other blogs from our Data Quality Series:

Scope 1 & 2, and Sometimes Scope 3 GHG Emissions Disclosures Are Becoming Required for Many Market Actors

Here are some answers to questions we hear the most from our clients.

What does Scope 1, 2 & 3 mean?

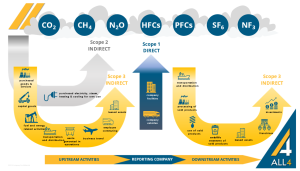

The GHG Protocol was developed by World Resources Institute (WRI) and the World Business Council for Sustainable Development (WBCSD) to “establish comprehensive global standardized frameworks to measure and manage greenhouse gas (GHG) emissions from private and public sector operations, value chains and mitigation actions”.

The GHG Protocol categorizes GHG emissions thusly:

Scope 1 Direct GHG Emissions

Direct GHG emissions occur from sources that are owned or controlled by an organization. These emissions are a result of activities or processes that release GHGs into the atmosphere such as emissions from combustion in owned or controlled boilers, furnaces, vehicles, etc., and emissions from chemical production in owned or controlled process equipment. This also includes company vehicles or unintentional releases of GHGs such as leaks or flares.

Scope 2 Utility Indirect GHG Emissions

Indirect GHG emissions from the generation of electricity, heat or steam purchased by or otherwise brought into the organizational boundary of an organization. Scope 2 emissions physically occur at the facility where electricity is generated, such as a power plant owned by your utility provider. Your Scope 2 emissions are Scope 1 emissions for your utility provider.

Scope 3 Other Indirect GHG emissions

Other Indirect GHG emissions that occur throughout an organization’s supply chain are categorized as Scope 3. These include upstream and downstream GHG emissions which are a consequence of the activities or products of the company but occur from sources not owned or controlled by the company. Scope 3 emissions are typically the largest and most complex category to measure and manage. Examples of Scope 3 GHG emissions include purchased goods and services, upstream transportation and distribution, waste disposal and treatment, business travel and employee commuting.

The following chemical compounds are considered GHG’s according to the GHG Protocol and the Kyoto Protocol:

Carbon Dioxide – CO2

Sulfur Hexafluoride – SF6

Methane – CH4

Nitrous Oxide – N2O

Hydrofluorocarbons – HFCs

Perfluorocarbons – PFCs

Nitrogen Trifluoride – NF3

Other greenhouse species, which are produced in smaller quantities, or which have lower global warming potential (GWP), such as water, some VOCs or NOX are not typically required for Scope 1,2 & 3 disclosures.

Figure 1 Scope 1,2 3 Emissions – GHG Protocol

What makes a molecule a greenhouse gas?

If you want to find the secrets of the universe, think in terms of energy, frequency and vibration – Nikola Tesla

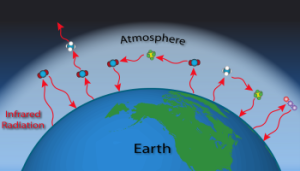

At the risk of oversimplification greenhouse gas molecules have radiative properties, which means they absorb, hold and eventually reemit heat in the form of Infrared Radiation (IR). Solar energy enters the atmosphere at shorter wavelengths that allow the photons to pass through GHGs in the atmosphere and reach Earth’s surface. The photons are absorbed by the Earth and reflected back into the atmosphere at longer wavelengths, which correspond to the frequency at which the molecules vibrate, allowing GHG molecules to trap the heat for a while.

Without the greenhouse effect human life could not survive on earth. However, the more molecules with radiative properties the more heat is trapped in the atmosphere, causing an enhanced greenhouse effect leading to global warming. The concentration of CO2 in the atmosphere has increased nearly 150% since the Industrial Revolution.

Figure 2 NOAA Global Monitoring Lab

I report according to 40 CFR Part 98. Do I need to do more for Scope 1, 2 & 3?

Yes. Part 98, aka EPA Greenhouse Gas Reporting Program Mandatory Greenhouse Gas Reporting Rule includes only a subset of Scope 1, direct emissions. There are other direct emissions, such as mobile sources, which need to be captured for Scope 1. Scopes 2 & 3 are not covered at all by Part 98 reporting obligations.

Why would I need to disclose GHG emissions if there is not a compliance obligation?

Depending on the locations of your facilities and your emissions rates, you may be subject to compliance obligations now or soon. Aside from the EPA regulation, which is triggered by GHG emissions more than 25,000 tons, currently 24 states and the District of Columbia have GHG emissions targets. California and Washington state have broad GHG cap and trade programs (WA’s Cap and Invest legislation takes effect this year) and 11 states in the Regional Greenhouse Gas Initiative have cap and trade programs for the power sector.

Even if you aren’t subject to state or federal laws, there may be market access requirements or other stakeholder pressures to disclose. For example:

- It is anticipated that the SEC will release rules on GHG emissions disclosure for issuers this summer. This will mean that companies whose stocks trade on US exchanges will need to disclose at least Scope 1 and 2 emissions. How the final rules play out – for example the role of Scope 3 disclosures, is yet to be seen.

- If you do more the €150m annually of business in the EU, you may be subject to CSRD disclosure requirements.

- Many large companies such as Walmart, Microsoft and Nike are part of the CDP Supply Chain Program and so require certain suppliers to disclose to CDP. The CDP Supply Chain Program has over 280 members with combined $6.4 trillion in purchasing power. The program resulted in 40,000 requests to suppliers for CDP disclosure.

- GSA policy adopted in January 2023 offers 3,500 points for emission disclosures, out of the 94,700 maximum points available for government wide IT contracts. The 60 suppliers with the highest number of points overall will receive the contracts.

- $7.5 million from the federal government to inventory and disclose greenhouse gas emissions from their own operations and from the energy they use — known as Scope 1 and 2 emissions. The same rule would create additional requirements for companies with contracts totaling $50 million or more. Those “major” contractors would have to tally and report emissions from their suppliers, known as Scope 3 emissions. The proposed rule would also require them to develop net-zero emissions goals that align with the temperature goals of the Paris Agreement, and to get those goals validated by a voluntary scientific integrity body known as the Science-Based Targets initiative.

When would I need to get started?

It depends on what your stakeholder’s requirements are, or your regulatory obligations, or SEC or Fed procurement final rules, but the sooner the better. Developing a baseline inventory from scratch, or even with Part 98 data as a starting point, can take several weeks to several months depending on complexity, data availability, people availability and other factors.

Now that I have a baseline, what next?

Once your baseline year is established you should leverage the momentum to calculate all years forward from baseline for which you have data. This will be helpful for identifying trends and anomalies, revealing inconsistencies, setting goals, identifying performance paths and meeting stakeholder requirements for current data.

We are a privately held company, so the SEC and EU requirements don’t apply to us, right?

The SEC rules will not directly apply to companies which are not traded on US exchanges. However, if your customers are subject to the disclosure rules they may be knocking on your door. For the EU rules, at present they do include companies which do over €150m of business in the EU annually.

How can ALL4 help?

All4 is a CDP Accredited Climate Consultancy and can help you where you stand. Whether you are just getting started and need to define operational or organizational boundaries, figure out what your obligations are, or develop a baseline accounting All4’s experienced team can help. If you are further along and need to have your calculations third party verified, set reduction targets, develop a transition plan, identify climate and transition risks according to TCFD, or develop a communications strategy and transition plans, All4 can offer strategic advisory services and tactical support.

Contact: Connie Prostko-Bell, Director, ESG & Sustainability Practice, cprostko-bell@all4inc.com, 610-422-1110.

References:

Greenhouse Gas Protocol https://ghgprotocol.org/

GHG Corporate Standard https://ghgprotocol.org/corporate-standard

Part 98 https://www.ecfr.gov/current/title-40/chapter-I/subchapter-C/part-98?toc=1

SEC Climate Disclosure Rule https://www.sec.gov/rules/proposed/2022/33-11042.pdf

CDP Supply Chain Program https://www.cdp.net/en/supply-chain

Federal Supplier Climate Risks and Resilience Proposed Rule https://www.sustainability.gov/federalsustainabilityplan/fed-supplier-rule.html

NOAA Global Monitoring Laboratory https://gml.noaa.gov/ccgg/trends/

Recap of the CAPCA 2023 Spring Technical Workshop and Forum

A long time ago in a galaxy far, far away Darth Vader, C-3PO, R2-D2, Chewbacca, and the Mandalorian attended the Carolinas Air Pollution Control Association (CAPCA) technical workshop and forum. This unexpected band of Star Wars visitors enjoyed the space-themed exhibitors social on Thursday night and the technical sessions, including but not limited to a regulatory update from the United States Environmental Protection Agency (U.S. EPA) and a fireside chat with the air directors from South Carolina Department of Health and Environmental Control (SC DHEC) and the North Carolina Department of Environmental Quality (NC DEQ). The galactic travelers learned about a variety of technical topics and heard the latest air permitting and compliance news. Highlights of air regulatory changes on the horizon are below.

PM2.5 NAAQS

The comment period closed on March 28, 2023 on the proposed changes to the particulate matter of less than 2.5 microns (PM2.5) National Ambient Air Quality Standard (NAAQS). Comments were requested on a range of 8 ug/m3 to 11 ug/m3 for the annual standard. As we anxiously wait to learn where the standard will be set, the presenters reviewed limitations of the current air dispersion models and guidelines and suggested improvements and strategies for dealing with a lower NAAQS. Multiple layers of conservatism are built into the models and guidelines and with a lower standard these conservative elements cause increased difficulty with modeling demonstrations. Emissions factor refinement and working closely with the state agencies will be key for upcoming air permitting projects.

Electronic Permitting and Reporting

SC DHEC is internally testing the ePermitting system under the air quality program and is closer to taking the program live externally. Electronic submittal of compliance reports and air permit applications will be available and the system will provide notifications when items are due.

NC DEQ is currently working on a permitting transformation project. The air program is expected to be the last one implemented due to complexity; however, NC Division of Air Quality’s (DAQ) Electronic Public Records Management System (Laserfiche) is now available, making public records more accessible.

Minor New Source Review

U.S. EPA has been evaluating the sufficiency of state implementation plan minor New Source Review (NSR) programs with the focus on public noticing procedures and if permitting procedures are protective of the NAAQS. Currently NC DEQ does not require NAAQS modeling for minor NSR air permit applications. SC DHEC requires criteria pollutant modeling under Regulation 61-62.5, Standard No. 2 but allows modeling exemptions and deferrals under the current “Modeling Guidelines for Air Quality Permits.” At this time, it is unknown how either program will be impacted. U.S. EPA anticipates a notice of proposed rulemaking later this year.

“Once In, Always In”

U.S. EPA withdrew the “once in, always in” policy and promulgated the Major MACT to Area Source (MM2A) rule on January 19, 2021. This rule allows facilities that emit hazardous air pollutants and were previously classified as major sources to be reclassified as area sources when the facility’s potential to emit is limited to below major source thresholds. Details of the rule changes expected to be proposed this summer were not shared; however, possible recission of the MM2A rule and reinstatement of the “once in, always in” policy is a concern.

ALL4 is tracking regulatory developments on these topics and looks forward to seeing you in the fall at the CAPCA technical workshop and forum in Myrtle Beach, SC! We’ll put our space outfits away and get out the tailgating gear. If you have questions about how these regulatory changes might affect you or need help with air permitting and compliance in North or South Carolina, please reach out to Claire Corta at ccorta@all4inc.com or 919-578-4195.

30th Annual U.S. Greenhouse Gas Inventory

The 30th Annual U.S. Greenhouse Gas (GHG) Inventory is a report that provides information on the sources and sinks of greenhouse gases in the U.S. The newest version was published on April 13, 2023 and compiles the GHG data from 1990 to 2021. The report is produced by the U.S. Environmental Protection Agency (U.S. EPA) and is used to inform policy decisions related to climate change.

What are the Key Findings from the Report?

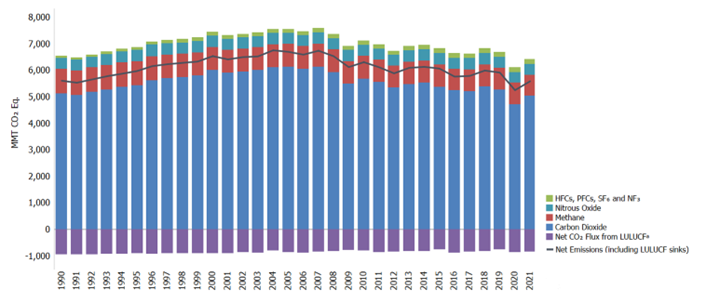

The report found that in 2021, greenhouse gas emissions in the United States were 6,340 million (6.34 billion) metric tons of carbon dioxide equivalent (CO2e), an increase of 5.2% from 2020. This increase from 2020 was primarily due to the economic rebound in transportation and industrial sectors emissions as a result of the COVID-19 pandemic that occurred in 2020. Net CO2e emissions have decreased by 16.6% from 2005 levels, which is consistent with the overall downward trend. This trend is mostly due to the use of renewable energy in the electric power sector. Figure 1 shows the U.S. GHG emissions trends from 1990 to 2021 (U.S. EPA Document No. 430-F-23-001).

Figure 1

U.S. Greenhouse Gas Emissions and Sinks by Gas

In 2021, carbon dioxide emissions from natural gas increased slightly by 0.5% compared to 2020, while emissions from coal increased significantly by 14.6%, which is the opposite of recent trends. The rise in natural gas emissions was seen across all sectors except for Electric Power and U.S. Territories, while the increase in coal emissions was mainly observed in the Electric Power sector. These increases are due to the economic and traveling rebound after the COVID-19 pandemic in 2020, the overall carbon dioxide emissions are still less than pre-pandemic levels in 2019, as shown in Figure 1. Additionally, emissions from petroleum use increased by 8.6%, and the total CO2 emissions from fossil fuel combustion in 2021 were 1.9% lower than emissions in 1990.

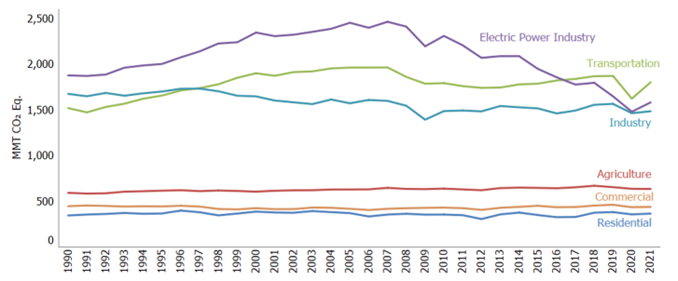

The report also provides information on the sources and sinks of specific greenhouse gases, including carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), and fluorinated gases. CO2 accounts for the majority of U.S. greenhouse gas emissions, with transportation, electricity generation, and industrial activities being the three largest sources. Transportation accounts for the largest portion of GHG emissions with 28.5% with the lowest sector being residential. The full trends from the GHG emissions by sector are shown in Figure 2 (U.S. EPA Document No. 430-F-23-001).

Figure 2

U.S. Greenhouse Gas Emissions Allocated to Economic Sectors

The Land Use, Land-Use Change and Forestry (LULUCF) sector offset 12% of total emissions in 2021. These activities include reducing deforestation and ecosystem restoration since these activities help in carbon sequestration. An important driver in improving in the LULUCF sector is due to forest management practices.

What is the Direction for the Future?

The U.S. GHG Inventory provides important information for policymakers as they work to address climate change. The report highlights the need to reduce GHG emissions from the transportation and industrial sectors, which are the largest contributors to GHG emissions. It also demonstrates that economic growth and emissions reductions can be achieved simultaneously.

Moving forward, the U.S. will continue to prioritize policies and actions that reduce GHG emissions. This includes transitioning to clean energy sources, promoting energy efficiency, and supporting the development of low-emissions transportation options. Additionally, the U.S. will work with other countries to address global emissions and promote international cooperation on climate change. The President’s Inflation Reduction Act (IRA) of 2022 is also expected to assist in further reductions in GHG emissions.

Conclusions

The 30th Annual U.S. Greenhouse Gas Inventory provides important insights into the sources of GHG emissions in the U.S. While there has been progress in reducing emissions, there is still much work to be done to address climate change. Contact us or your ALL4 Project Manager to discuss how we can help reduce your GHG footprint.

North Carolina NPDES Industrial Stormwater General Permit Updates – What You Need to Know General Background of North Carolina Stormwater Permits

Federal regulation 40 CFR §122.26 requires facilities with industrial stormwater discharges to apply for a National Pollutant Discharge Elimination System (NPDES) permit; either an individual permit or a general permit from an authorized state, such as North Carolina, that has promulgated NPDES authority. In North Carolina, facilities that wish to seek general permit coverage do so through the North Carolina Department of Environmental Quality (NCDEQ) NPDES General Permit No. NCGXXXXXX for Stormwater Discharges Associated with Industrial Activities.

General Permit Updates

The Division of Energy, Mineral, and Land Resources (DEMLR) is currently seeking public comment on the proposed revisions and re-issuance of NPDES Industrial Stormwater General Permits for the following industry groups:

- NCG050000 – Apparel, Printing, Leather, Rubber

- NCG070000 – Stone, Clay, Glass

- NCG110000 – Treatment Works

- NCG130000 – Nonmetal Waste and Scrap

- NCG210000 – Timber Products

The public comment period began on April 17, 2023, and ends at 5:00 pm on May 17, 2023. The proposed issuance date for permits in each industry group is no later than June 1, 2023, and the effective date will be June 1, 2023.

Solvent Management Plan

Each General Permit includes a Solvent Management Plan (SMP) requirement. The SMP shall be incorporated into the facilities stormwater pollution prevention plan (SWPPP). The SMP needs to include the following:

- An annually updated and quantified inventory of solvents present on site during the previous three years

- A narrative description of the facility locations and uses of solvents

- The method of disposal, including quantities disposed on-site and off-site

- The management procedures and engineering measures for assuring that solvents do not spill or leak into stormwater

PFAS Monitoring

Each General Permit also includes the following language for PFAS monitoring:

“If notified by the Director, the permittee shall monitor for Emerging Contaminants such as Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS) in accordance with written notification.”

Analytical Monitoring

As a part of the General Permit updates, all facilities associated with any of the five industry groups must start conducting quarterly sampling for the following parameters in the table below.

Permittees part of the industry group NCG050000 will be allowed a 4-month grace period to prepare for analytical monitoring requirements; analytical monitoring shall begin in Quarter 3 (July 1st – September 30th) of 2023.

Permittees part of the industry groups NCG070000 and NCG130000 will be allowed a 4-month grace period to prepare for analytical monitoring requirements; analytical monitoring shall begin in Quarter 4 (October 1st – December 31st) of 2023.

| Summary of Quarterly Baseline Sampling Requirements | |||||

| NCG050000 | NCG070000 | NCG110000 | NCG130000 | NCG210000 | |

| Total Suspended Solids (TSS)1 | 100 mg/L | 100 mg/L | 100 mg/L | 100 mg/L | 100 mg/L |

| Chemical Oxygen Demand (COD) | 120 mg/L | N/A | N/A | 120 mg/L | 120 mg/L |

| pH2 | 6-9 s.u. | 6-9 s.u. | 6-9 s.u. | 6-9 s.u. | — s.u.3 |

| Non-Polar Oil and Grease4 | 15 mg/L | 15 mg/L | 15 mg/L | 15 mg/L | 15 mg/L |

| Fecal Coliform | N/A | N/A | 1,000 count per 100ml | N/A | N/A |

General Monitoring Requirements

A minimum of thirty (30) days must separate sampling events. The total rainfall amount for each sampling event shall be recorded in inches. Total rainfall shall be determined from an on-site rain gauge or a regional rain gauge located within one (1) mile of the facility. The average monthly usage of new motor and hydraulic oil used for vehicle maintenance at the facility shall be tracked and recorded.

Electronic Discharge Monitoring Reporting (eDMR)

Facilities are required to register for Electronic Discharge Monitoring Reporting (eDMR) within 30 days of the Certificate of Coverage issuance date. The NC Stormwater Electronic Discharge Monitoring Reports (eDMR) page can be found here. Submit the discharge monitoring report (DMR) within 30 days after the end of the monitoring period. When results are below detection limit, report in the format, “<XX mg/L,” where XX is the numerical value of the detection limit.

Qualitative Monitoring

Qualitative monitoring must also be conducted concurrently with analytical monitoring. The qualitative monitoring visual inspections shall be recorded on the DEMLR’s Stormwater Discharge Outfall Qualitative Monitoring Report (QMR) form. The completed qualitive monitoring visual inspection forms need to be filed onsite, and only submitted to the Division upon request.

If you have questions about how the draft General Permit updates could affect your NPDES stormwater compliance, or what your next steps should be when the General Permit updates become effective, please reach out to me at agolding@all4inc.com or Matt Dabrowski at mdabrowski@all4inc.com. ALL4 is monitoring all updates published by NCDEQ on this topic, and we are here to answer your questions and assist your facility with any aspects of industrial general stormwater compliance.

- TSS benchmark for High Quality Waters (HQW), Outstanding Resource Waters (ORW), Trout Waters (Tr), and Primary Nursery Areas (PNA) is 50 mg/L. NC surface water classifications can be determined using the NC DWR Surface Water Classifications Website map.

- The saltwater benchmark pH range is 6.8-8.5 s.u.

- Grab samples shall be analyzed for pH within 15 minutes of collection.

- Non-Polar Oil and Grease is only monitored for vehicle or equipment maintenance areas in which more than 55 Gallons of motor oil and/or hydraulic oil is used per month.