Navigating Kentucky’s Nonattainment Status

In October 2015, the U.S. Environmental Protection Agency (EPA) revised the primary and secondary ozone standards to a level of 70 parts per billion (ppb). Based on the new National Ambient Air Quality Standards (NAAQS), U.S. EPA uses national air quality data to designate an attainment status for all areas in the U.S. As of 2018, various areas in Kentucky have been designated as marginal non-attainment. This designation can lead to changes in regulations and more stringent air permitting requirements for individual facilities. This blog will explore the upcoming changes to Kentucky air quality regulations based on this designation and can serve as a resource for facilities as they navigate these changes.

U.S. EPA’s 2015 Ozone Standard

On October 26, 2015, U.S. EPA revised the primary and secondary ozone standards to 70 ppb. Data from air quality monitors are used to calculate “design values” and determine if an area is in attainment. Areas meet the standards if the fourth-highest daily maximum 8-hour ozone concentration per year, averaged across three consecutive years, is equal to or less than 70 ppb. .

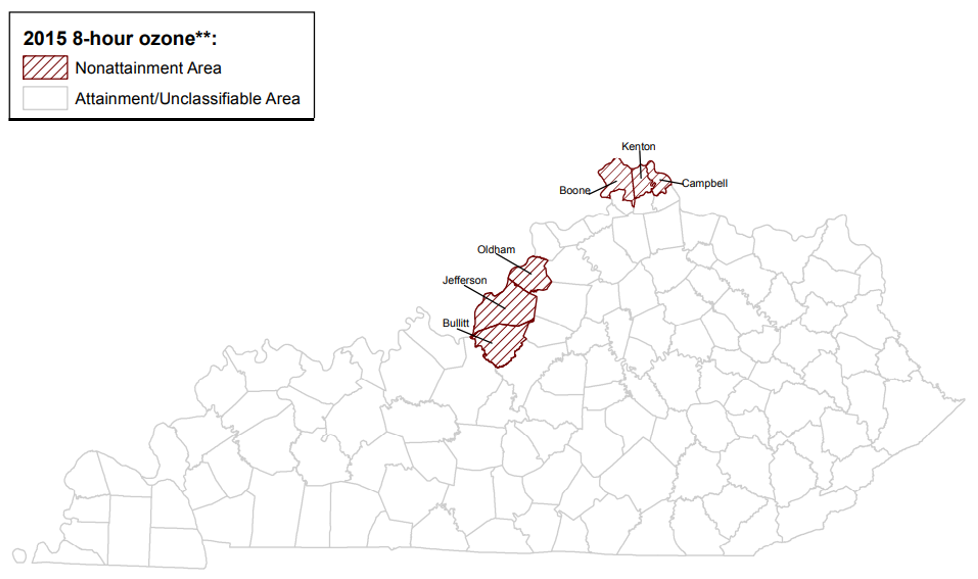

For the years 2018-2020, air quality monitors recorded exceedances of the 2015 ozone standard for Jefferson county in Kentucky, Butler county in Ohio, Hamilton county in Ohio, and Warren county in Ohio. Based on these violating monitors, EPA designated Bullitt, Jefferson, and Oldham counties as marginal nonattainment areas in June 2018 (Figure 1). Similarly, Boone, Campbell, and Kenton counties were designated as marginal nonattainment areas in 2018 (Figure 1).

Now, you may be wondering why Ohio monitors are used to determine attainment status for Kentucky. Well, this is because U.S. EPA determined that emissions from sources in Boone, Campbell, and Kenton counties were affecting the monitors in the Cincinnati, OH area right across the Ohio River. This is enough to designate these counties as marginal nonattainment areas, according to U.S. EPA.

Figure 1: Areas of Nonattainment for 2015 Ozone Standard in Kentucky

Levels of Nonattainment and Their Requirements

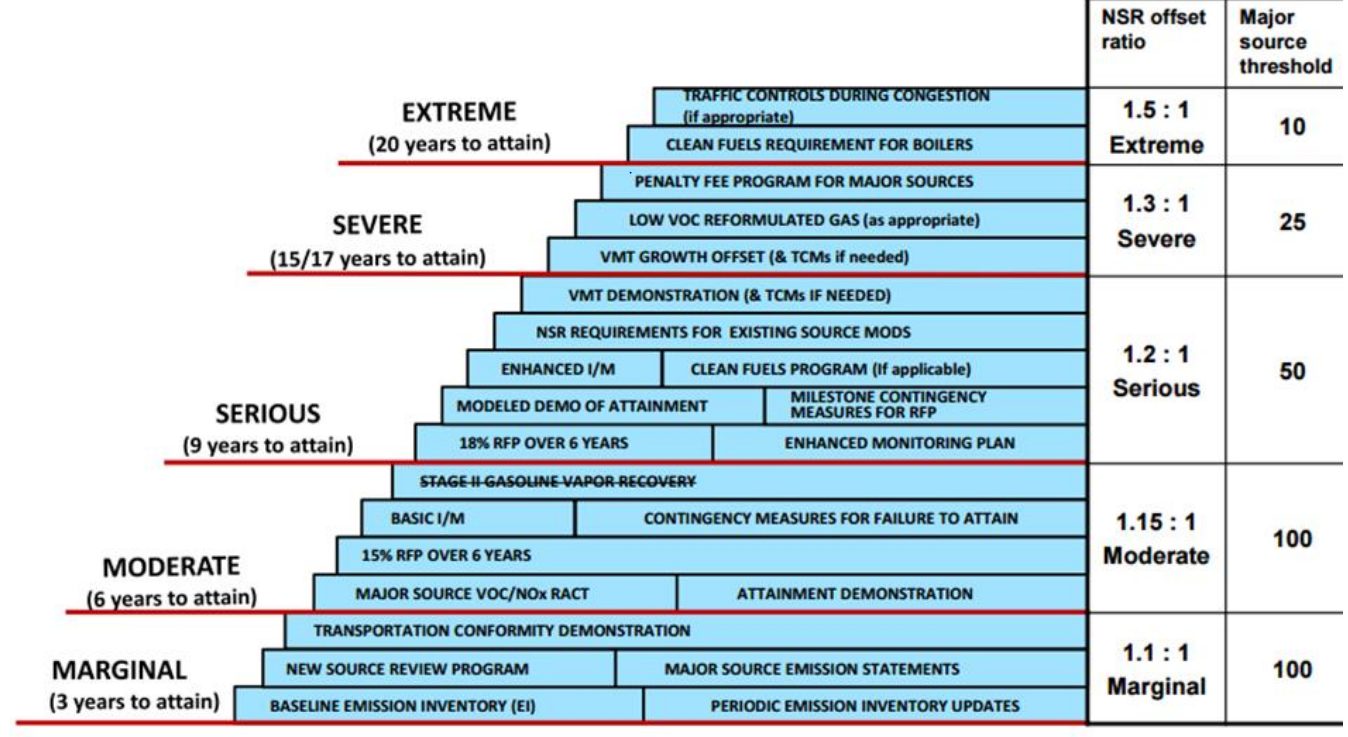

As stated above, the nonattainment areas in Kentucky are “marginal nonattainment.” Marginal nonattainment is the lowest level (ozone range: 71 to less than 81 ppb) with the least stringent requirements. Currently, the only requirements for Kentucky to address marginal nonattainment areas are to submit revisions to their State Implementation Plan (SIP) and to submit a current inventory of actual emissions for all sources.

Areas designated as marginal nonattainment have 3 years to reach attainment status before they are “bumped up” to moderate nonattainment status. Unfortunately, since the current marginal nonattainment counties failed to attain the ozone NAAQS during 2018-2020, they will be bumped up to “moderate nonattainment” in 2022.

Unlike marginal, a moderate nonattainment designation (ozone range: 81 to less than 93 ppb) comes with a few more strings attached. Although the counties in Kentucky are not within the range mentioned above, the “bump up” automatically occurs if attainment is not achieved. Moderate nonattainment areas are required under the Clean Air Act to implement:

- Nitrogen Oxides (NOx) Reasonably Available Control Technology (RACT).

- Volatile Organic Chemicals (VOC) Control Techniques Guidelines (CTGs).

- New offset ratio of 1.15:1 for New Source Review (NSR).

- Vehicle Emissions and Inspection Management Program.

These requirements are in addition to those for marginal nonattainment, and the areas have 6 years to reach attainment. Figure 2 below shows the different nonattainment levels and their requirements.

Figure 2: Levels of Nonattainment

What Does This Mean for Your Facility?

The ozone nonattainment areas in Kentucky have not yet been designated as moderate nonattainment; however, EPA has already notified Kentucky that the bump up will occur in Fall of 2021. Therefore, implementation of moderate nonattainment requirements will begin within the next year.

Overall, the main impact of this new designation will be to future construction projects. New emission sources with the potential to emit VOC and NOx will be strictly regulated since those are the components of ozone. Additionally, the NSR offset will require facilities to reduce 1.15 tons of emissions for every 1 ton of emissions added. Fortunately, most facilities will not need to worry about the vehicle emissions and inspection management program.

In addition to the requirements mentioned above, Kentucky is required to submit revisions to their State Implementation Plan (SIP). This could lead to new regulations and requirements for existing facilities with emissions of VOC and/or NOx. This has already begun at Louisville Metro Air Pollution Control District (LMAPCD) and the Kentucky Energy and Environment Cabinet (KY EEC).

The following revisions to the Kentucky SIP have already been submitted to the EPA:

- Ambient Air Quality Standards (7/2017):

- The air quality standards for carbon dioxide (CO), lead (Pb), nitrogen dioxide (NO2), ozone, particulate matter (PM10 and PM5), and sulfur dioxide (SO2) were changed to reflect the new NAAQS. These new standards can be found in 401 KAR 53:010.

- Infrastructure SIP (3/2020):

- An “infrastructure” SIP contains provisions that ensure the new NAAQS will be implemented, enforced, and maintained in KY.

- Prevention of Significant Deterioration and Modeling Infrastructure Requirements (9/2020):

- New major sources and major modifications in attainment areas of KY are subject to federally-approved PSD permitting program.

- Modeling based on EPA’s guidelines in 82 FR 5182 is the most appropriate, but alternative modeling can be used in KY.

In addition, LMAPCD has revised their regulations to reflect the new nonattainment status. As of May 2020, Regulation 1.06 requires all stationary sources that emit greater than 25 tons per year of VOC and/or NOx under Louisville Metro to submit a statement to the District of actual ozone precursor emissions for the previous calendar year of operation.

With all that said, navigating this new nonattainment status will be tricky. Luckily, ALL4 is here to help! Our consultants can keep you informed on the latest air regulatory and policy developments as they happen, so you can consider how your facility may be impacted. Contact me at pbarreto@all4inc.com or (502) 509-7999 for more information or to discuss a strategy.

Recap of the Kentucky Chamber 24th Annual Environmental Permitting and Reporting Conference

The Kentucky Chamber hosted a hybrid (virtual and in-person) conference on August 12 -13, 2021 that included updates from the Kentucky Environmental and Energy Cabinet, consultants, lawyers, and corporate managers. A few notable items we heard are shared below.

Air Update

The Division of Air Quality was well represented by Melissa Duff, Director, and other staff that co-presented during the conference. Key takeaways during the conference included:

- Facilities should plan to integrate application preparation and review with DAQ to develop schedules to meet construction schedules. New builds and expansions are a priority, but the Division is seeing more development activity and has limited review capacity with current staffing levels.

- The Division has updated forms and use of the new form DEP7007C, Incinerators and Waste Burners is required if applicable to your facility.

- Ozone monitoring data in the non-attainment areas in Metropolitan Louisville and Northern Kentucky/ Cincinnati are being evaluated. These two areas may step up to moderate non-attainment, depending on the results of the data evaluation. Watch for U.S. EPA determinations and possible changes to the State Implementation Plan as a result of a designation change. A future 4 the Record Article details possible changes to the Kentucky State Implementation Plan (SIP) that may be required if the areas are reclassified.

- The 2021 ozone season was on track to be in attainment with the ozone standard, which could keep the state at marginal non-attainment with the 2015 ozone standard.

Renewable Energy

The conference also had presentations on solar energy deployment in Kentucky. There has been an uptick in solar projects across the state for both off-setting energy used in manufacturing and merchant solar power farms adding capacity to the grid. While expanding our alternative energy portfolio in Kentucky, don’t worry, there will continue to be more horse farms than solar farms in the Bluegrass State for the foreseeable future.

Water Update

Presentations and an update from the Division of Water focused on new legislation, Kentucky’s triennial review, and changes within the Division of Water. Look for more in the upcoming months including workshops from the Division of Compliance Assistance on wastewater and stillage from the bourbon industry. The state would like additional input from industry on best practices for the treatment of stillage that cannot be used by the farming community for feed.

Environmental Justice

While Kentucky has not adopted new regulations or policies around the Biden Administration’s Environmental Justice Executive Orders, the Cabinet expressed that policies were being developed internally. Cabinet Personnel suggested that Cabinet wide environmental justice policies could be presented during 2022. ALL4 is keeping a close eye on environmental justice policy and regulatory development across the country and can help facilities plan and respond.

If you have any questions regarding air, water, or waste permitting and compliance in Kentucky or would like more detail on any of these items, please reach out to Karen Thompson at kthompson@all4inc.com or 859-281-1664.

WOTUS WOES – Litigation, Legislation, or Regulation?

Where to begin? The 1972 amendments to the Clean Water Act (CWA) established federal jurisdiction over the navigable waters defined as the “waters of the United States” (WOTUS). However, the text of the CWA does not define WOTUS but provides discretion for the United States Environmental Protection Agency (U.S. EPA) and the U.S. Department of the Army (Corps of Engineers) to define WOTUS within regulations. In the 1980s, U.S. EPA and Corps of Engineers created a definition for WOTUS. In 2015, after multiple court cases, U.S. EPA and Corps of Engineers revised the definition to clarify what waters upstream from the traditional navigable waters were included in the definition and therefore can be regulated by federal and state programs. In June 2020, the definition was revised again. On June 9, 2021, U.S. EPA and Corps of Engineers announced their intent to initiate new rulemaking “that restores the protections in place prior to the 2015 WOTUS implementation and develops a new rule to establish a durable definition of WOTUS.” Of course, it is not everyone’s opinion that the 2015 rule is flawed. On August 4, 2021, U.S. EPA and Corps of Engineers started the latest rulemaking process by publishing in the Federal Register, Notice of Public Meetings Regarding ‘‘Waters of the United States’’; Establishment of a Public Docket; Request for Recommendations. Throughout August and September, public meetings were scheduled to gather pre-proposal input.

In the meantime, several lawsuits have been filed against the 2020 WOTUS rule. On August 30, 2021, the U.S. District Court for the District of Arizona ruled the Trump administration’s Navigable Waters Protection Rule (NWPR) was too flawed to keep in place. Immediately following the decision, the U.S. EPA and Corps of Engineers announced that they would be following the Pre-2015 regulatory definition and practices until further notice. Other district courts have also remanded the rule.

What programs does the decision affect?

The federal CWA sections that are affected by the definition of WOTUS include Water Quality Standards, Impaired Waters and Total Maximum Daily Loads (TMDLs), Oil Prevention and Preparedness Programs, 401 Certifications, National Pollutant Discharge Elimination System (NPDES) permitting, and permitting discharges of dredged or fill material.

What does this mean for the regulated community?

For states with primacy for their water programs, the “waters of the state” or “waters of the commonwealth” will continue to apply to industrial wastewater and stormwater permits. For states without definitions of state waters, the pre-2015 WOTUS definitions may be applicable. For federal programs such as Corps of Engineer permitting, National Environmental Policy Act (NEPA) determinations, and CWA programs such as the oil spill prevention control and countermeasure (SPCC) plan and facility response plan (FRP), all current and future work will be reviewed based on the pre-2015 WOTUS rules. Affected sites should re-evaluate affected applications, plans, and projects in terms of the pre-2015 WOTUS for the foreseeable future.

U.S. EPA and Corps of Engineers will continue through the regulatory process to update the WOTUS definition and additional cases are making their way through the courts; however, in the meantime, we will be operating under the pre-2015 rules and interpretations. ALL4 will continue to watch the regulatory development. If you have questions on WOTUS or other water issues, contact Karen Thompson at kthompson@all4inc.com or other technical experts in any one of our offices.

Proposed Changes to New Hampshire Air Toxics Rules and Potential Ramifications to Stakeholders

ALL4 is pleased to continue providing updates regarding changes to New Hampshire air toxics rules and the impacts to stakeholders responsible for compliance. In April 2021, ALL4 presented, “Changes to the New Hampshire Air Toxics Rule: What Could it Mean for You”, the first in a series of articles detailing proposed revisions to the New Hampshire Code of Administrative Rules Part Env-A 1400 (Rule). This article serves as the second part in the series, intended to provide updates to recent developments associated with the proposed revisions and to provide a high-level overview of one implication of the revisions: considerations for conducting air dispersion modeling at a facility.

Introduction

In 1987, the New Hampshire Legislature established its Air Toxic Control Act to promote public health and reduce human exposure to toxic chemicals. The act regulates releases of Regulated Toxic Air Pollutants (RTAP) into ambient air and requires any facility that uses substances containing RTAP to conduct an Air Toxics Compliance Demonstration to determine compliance with ENV-A 1400.

Env-A 1400 is applicable to facilities that use products containing RTAP and therefore applies even if an air emissions permit is not required for a facility. Examples include manufacturing facilities, facilities burning a non-exempt fuel, such as landfill gas and resinated wood products for heat or power, and facilities producing a renewable fuel, such as dried wood chips, pellets, and Renewable Natural Gas (RNG), the biogas product of the decomposition of organic matter.

Proposed changes to Env-A 1400

On August 16, 2021, the New Hampshire Department of Environmental Services (NHDES) provided notice of rulemaking for Env-A 1400. As part of the notice, a public hearing has been scheduled for September 29, 2021, and written public comments will be accepted through October 8, 2021. The public hearing will be held in person at NHDES offices in Concord, New Hampshire and will be made accessible virtually.

The intent of the proposed changes to Env-A 1400 is to clarify aspects of the Rule to make it easier to understand and follow. Sections have been reorganized and renumbered, and terminology has been added or redefined. Several noteworthy changes to the Rule that could potentially necessitate compliance activities, including air pollution dispersion modeling, are:

- Addition, or incorporation of, 121 RTAP,

- Removal of 21 RTAP,

- Modification to aspects of over 150 RTAP (e.g., compound description, de minimis and Ambient Air Limits (AAL) thresholds, toxicity class), and

- Redefinition of the compliance boundary for leased properties and inclusion of a provision for proposing an alternate compliance boundary other than the boundary in which an emissions source is located.

Overview of Env-A 1400

Env-A 1400 defines the applicability of air emissions sources and exemptions to the Rule, permit requirements and application procedures, and the classification of RTAP. Under the Rule, NHDES established de minimis levels and AAL for over 700 RTAP, including lead. The Rule applies to a stationary source with new, modified, or an existing process or device that emits RTAP, unless exempted under Env-A 1402.01 (e.g., normal agricultural operations and emissions of RTAP from mobile sources or resulting from combustion of virgin petroleum products) or Env-A 1402.2 (e.g., combustion of certain fuels, gasoline dispensing, and spray coating operations).

Compliance with the Rule can be demonstrated based on a sequence of evaluation methods specified in the Rule, in the following order:

- De minimis emission level method,

- In-stack concentration method,

- Adjusted in-stack concentration method, and

- Air dispersion modeling analysis.

The Rule also provides the option for an applicant to submit a request for approval of an alternative compliance demonstration using air dispersion modeling to NHDES.

Requirements for performing compliance demonstrations vary across the methods. The de minimis emission level method requires emissions rates when airflow exiting the stack is vertical and unobstructed. Both the in-stack concentration and adjusted in-stack concentration methods require the emissions rate, in pounds per hour, of each RTAP from each stack. The in-stack method also requires volumetric flow rates for each stack, whereas the adjusted in-stack methods requires distances from each stack’s associated building to the nearest compliance boundary. The air dispersion modeling analysis method has specific procedural requirements specified by NHDES, and has additional data requirements, including emissions rates, stack parameters, meteorological data, and terrain data. Regardless of the selected method, compliance must be demonstrated relative to the de minimis or AAL levels defined in the Rule.

Modeling Associated with Env-A 1400

Under the proposed Env-A 1404.02, if an air dispersion modeling analysis is performed, the owner or operator must conduct the analysis in accordance with Env-A 606 requirements to demonstrate that the concentration of emissions of each RTAP is equal to, or below, the corresponding AAL at and beyond the compliance boundary.

In addition, NHDES modeling guidance requires the use of one of the United States Environmental Protection Agency (U.S. EPA) recommended models, AERMOD or AERSCREEN, in conformance with the “Guideline on Air Quality Models” (Appendix W to 40 CFR Part 51). For any compliance demonstration associated with a permit application, NHDES requires, by rule, submittal of a modeling protocol documenting the proposed modeling methodology and input parameters, prior to submittal of the compliance demonstration. Following acceptance of an approved protocol, results of the compliance demonstration, in the form of a report and associated modeling files, must also be submitted to NHDES. Even if the compliance demonstration is not associated with an air emissions permit, it is recommended that the final report be kept on-site, in the event the facility is inspected in the future.

Potential Impacts and Benefits to Stakeholders

The proposed changes to Env-A 1400 could have significant impacts on existing facilities that emit RTAP. The addition of RTAP may require an updated compliance demonstration, possibly including modeling for facilities that have previously demonstrated compliance, whereas the removal of one or more RTAP or the increase in de minimis threshold or AAL may present facilities with an opportunity to remove or relax permit limits on some processes. The modification of RTAP thresholds may require updated analyses, either to demonstrate compliance with more restrictive limits, or to increase permit limits due to more lenient limits. Similarly, the redefinition of the compliance boundary may impact compliance or offer the opportunity to modify permit limits.

In addition to updating previous compliance demonstrations for existing facilities, the proposed Rule changes may prompt a change in a facility’s compliance demonstration strategy. A different approach may become more cost-effective or offer a facility additional operational flexibility. Facilities, and the individuals responsible for maintaining their compliance, should review the Rule revisions and carefully consider their impacts on costs and production flexibility, to realize effective and efficient operations.

Stakeholders – Actions to Consider

Stakeholders should begin the evaluation process to determine how they may be impacted by the proposed Rule changes. The evaluation should include:

- Determining if Env-A 1400 applies to a facility. If a facility is not exempt, perform a compliance demonstration.

- While performing the compliance demonstration, evaluating the most effective compliance strategy, such as initiating a product substitution, changing production goals, installing an emissions control device, requesting an alternative compliance boundary, or performing air quality dispersion modeling.

- Assessing if Env-A 1400 will require an air emissions permit. Compliance must be evaluated and demonstrated, with supporting documentation kept on-site, even if an air emissions permit is not required.

Contact John Hinckley at jhinckley@all4inc.com (802-359-7295), Dan Dix at ddix@all4inc.com (610-422-1118), or Ryan Cleary at rcleary@all4inc.com (919-230-0716) for more information.

Meet Sheryl Watkins

Sheryl Watkins// Senior Technical Manager // Florida Regional Support

What are some of the things that you’ve been working on lately that have you energized?

TRI reporting comes to mind. This is such a great learning exercise for junior-level engineers as it allows them to work and get trained across multi-media including air, water, and waste. Gaining experience as a young engineer across multi-media can be so impactful in shaping you into a well-rounded consultant.

What types of project work has been impactful to you throughout your career as a consultant?

Working alongside clients on large-scale projects has served me well in teaching me how to be an effective communicator not only with my client contacts, but also project team members and members of the regulatory community. These are such valuable skillsets for a consultant to have in their toolbox. I’ve also gotten a lot of enjoyment collaborating with trade groups, NCASI being one such group, on project work. This type of collaboration is a wonderful learning experience as we gain additional perspective from NCASI research and then how to apply that to real life experiences/projects.

For engineers and scientists starting their career and aspiring to be a Senior Technical Manager, can you share the types of projects that you’re typically working on?

My expertise lies in air permit applications, regulatory strategy, compliance support, audits, and coordination/negotiation with state and EPA regulators.. Most of my experience is in the pulp and paper, wood products, and chemical manufacturing industries. I enjoy providing compliance support to facilities as it requires not only knowledge of the regulations, but also a detailed understanding of facility operations and emissions. I’ve particularly enjoyed the auditing work because you’re on-site seeing things first-hand, which deepens your understanding of the processes, as well as the relationship between processes. This is where you can provide a lot of value as a consultant. Compliance audits also require ‘big picture thinking’ because you cover compliance with all regulations and that is both challenging and rewarding to me. Anytime that a consultant gets an opportunity to be on-site at their client’s facility it provides an opportunity to see exactly what activities and efforts the client performs to demonstrate compliance and that real-time connection and experience can lead you to being “an extension of the client” when addressing compliance issues.

As someone who lives along the coast of Florida you have an atypical morning routine, tell us about that.

I’m a life-long swimmer and take advantage of incorporating living near the ocean into my morning routine. You could say that I like to “swim with the dolphins”! As someone who competes in swimming competitions I like to start my day training, whether it is swimming in our year-round outdoor community pool under the moon and stars, or actually getting out for a 2-3 mile ocean swim along the coast with teammates. There is something magical and meditative doing the ocean swims. It’s my happy place!

Rumor has it you’ve been doing some guest appearances at ALL4’s AQ101 training webinars?

I’m enjoying presenting – it’s something I’ve done quite a bit of at NCASI conferencing events but this is my first run at hosting the AQ101 webinars. I’ve found it rewarding as a consultant to be on both sides of knowledge transfer…the receiving end when I get to learn from senior resources internally at ALL4 and at the opposite end when I provide training to the AQ101 audience. For this audience you’re trying to find that balance of distilling complex technical content in a manner that can be easily understood by an audience who may be learning about this particular technical content for the first time.

Observations and Reminders from RY2020 TRI Reporting

With Toxic Release Inventory (TRI) reporting deadlines having passed on July 1st, now is the time to reflect on what went right, what went wrong, and how you can improve for next year’s reports.

Here are some noteworthy observations from this reporting season, as well as some reminders for next year:

- Double check reporting requirements and exclusion criteria for the chemical. Remember that for certain TRI-reportable chemicals, you are not required to report the full amount depending on the substance, or you only need to report when the chemical is released in a specific form or based on the activity of the chemical; details on the specific conditions under which some TRI-reportable chemicals must be reported (known as “chemical qualifiers”) can be found in Table II of U.S. EPA’s annual TRI guidance document. For example, when reporting ammonia, you are required to report 100% of anhydrous ammonia, but only 10% of aqueous ammonia compounds. When reporting sulfuric acid, you are only required to report if the sulfuric acid at your facility is in an aerosol form (mists, vapors, gas, fog, and other airborne forms) because aqueous solutions are not covered by the sulfuric acid listing. Isopropyl alcohol, which is only reportable if it is manufactured by the strong acid process, is an example of where reporting a TRI chemical is based solely on the activity. Facilities that manufacture isopropyl alcohol as a byproduct or that process or otherwise use isopropyl alcohol are not covered and should not perform release calculations nor file a report; rather, they should document the activity and associated exemption.

- Metal compounds must be checked for specific exclusion and releases quantified properly based on the metal portion of the compound. When reporting metal compounds be sure to check U.S. EPA’s Consolidated List of Lists to confirm which compounds of that metal are actually reportable and which ones are not. An example related to zinc compounds: initially zinc pyrithione was conservatively included in threshold calculations for a facility and upon further review it was determined that zinc pyrithione was not a reportable zinc compound. Also, when filing a combined form for a metal and a metal compound containing the same elemental metal, remember that while threshold quantities for metal compounds are based on the total weight of the compound, only the metal portion of the compound needs to be considered in release and waste management calculations. Further information on how to report metal compounds can be found in Section B.5 of U.S. EPA’s annual TRI guidance document.

- Make sure emissions calculations are consistent across reporting obligations. While preparing release calculations, we’ve encountered situations in which air emissions of some TRI-reportable chemicals were being double-counted in information supplied as the basis for preparing a TRI report. Regardless of an error, typo, or inadvertent emission, it’s important that the best possible information available at the time is used. It is a best practice to double check assumptions and foundational information, rather than relying (for efficiency’s sake) on the fact that this was previously prepared and submitted and assuming that it is 100% accurate. When preparing your TRI calculations, make sure to check your final numbers against what you have reported in your other obligations to ensure there are no discrepancies, or that you have a valid explanation for any discrepancies you do see (e.g., differences in regulatory requirements). If possible, I recommend consolidating your reporting obligations that utilize similar data into one spreadsheet or location to better assure consistency with data that is being used for various reports.

- Remember that beneficial reuse is not required to be reported. When performing release calculations for waste discharges and transfers off-site, consider the ultimate fate of the release when deciding whether or not it needs to be reported: byproducts and waste materials that are reused or sent off-site for beneficial reuse are not required to be reported. Examples of beneficial reuse include incorporating waste ash into concrete and land-applying sludge for use as a soil amendment.

- Check that you are using N/A and zero in the correct places. N/A should only be entered if it is not possible for a particular chemical to be emitted/released to the environment. If the chemical is present in some years and is absent in other years a value of zero should be entered. This is especially important when documenting waste streams and discharges to water bodies and it is not an uncommon situation for certain types of waste streams.

- Remember to double-check your article exemptions. TRI-reportable chemicals contained in certain articles that are processed or otherwise-used are exempt from reporting. The TRI guidance states that to be covered under an article exemption, the item containing your chemical must be a manufactured item formed to a specific shape, which has end-use functions dependent on its shape, and does not release a toxic chemical under normal use. Examples that qualify for article exemption are copper wire, the nickel contained in doorknobs, lead batteries, and stainless steel pipe that is cut to length. When reviewing your facility’s purchase records and beginning to perform threshold calculations, be sure to keep the article exemption in mind to determine eligibility to your specific situation.

If you have any questions, feel free to contact me at kwalburn@all4inc.com or at (678) 599-9011.

Pennsylvania Updates Air Permitting Exemption Document

On June 26, 2021, the Pennsylvania Department of Environmental Protection (PADEP) published a notice in the Pennsylvania Bulletin, finalizing amendments to the Air Quality Permit Exemptions document (guidance or exemption document), PADEP ID: 275-2101-003, which was last updated in 2018. This exemption document is commonly used to evaluate whether a permit or other authorization under 25 Pa. Code Chapter 127 (Construction, Modification, Reactivation, and Operation of Sources) is required for new projects or for changes at an existing facility. PADEP published draft revisions to the exemption list on July 11, 2020, opened a public comment period through August 24, 2020, and on July 1, 2021, published the revised exemption document as well as a Comment and Response Document pertaining to the comments received. These documents can be found on PADEP’s eLibrary under the Technical Guidance Final Documents folder.

PADEP states that the revised guidance document is applicable to sources that are constructed or modified after July 1, 2021. As with previous updates, it is not retroactively applicable. In other words, if a historically applicable exemption was removed, an affected source is not retroactively required to obtain a permit. Conversely, a source that previously did not qualify for an exemption cannot now qualify for a new exemption unless the source is modified.

In addition to updating, removing, and adding specific exemptions, the changes to the exemption document can be summarized in a few categories:

- Baghouse exemptions:

- All original language that stated “Appropriately designed” has been updated to “Designed using good engineering practices”

- Emissions must not exceed 0.01 gr/dscf of particulate matter (PM), 1,000 lb/yr of a single hazardous air pollutant (HAP) and 1 tpy of total HAP

- Turbine/engine clarification:

- Exemption does not apply to newly installed sources of a model year that is not within 5 years of installation date unless they meet New Source Performance Standards (NSPS) for the new sources.

- HAP emissions cannot include Polychlorinated Biphenyls (PCBs), Chromium (Cr), Mercury (Hg), Lead (Pb), Polycyclic Organic Matter (POM), Dioxins or Furans.

- A new section was added to specify certain exemptions that will now require a Request for Determination (RFD) of Changes of Minor Significance.

The rest of this blog highlights a few of the more notable updates to specific exemptions from the 2018 Air Quality Permit Exemptions document. Where noted, the regulatory references are within 25 Pa. Code.

The following exemptions were removed:

- 14(a)(8) Item 1: Incinerators < 75 lb/hr

- Trivial Activities Item 19: Portable electrical generators

- Trivial Activities Item 31: Natural gas pressure regulator vents

- Trivial Activities Item 39: Certain bench-scale laboratory equipment

The following exemptions were added:

- 14(a)(8) Item 49: Certain bulk material storage bins (requires RFD)

- 14(a)(9) Item 16: Turbine core replacements with certain conditions

The following exemptions were moved and updated to now require an RFD:

- 14(a)(8) Item 25 and new Item 45:

- There are two categories for exemptions in Research and Development facilities. Item 25 provides the exemption thresholds for facilities that do not require an RFD, and Item 45 provides higher thresholds which do require an RFD.

- 127.14(a)(8) Item 37 (new Item 46): Sources exhausting to a filter/baghouse with particulate loading (before control) below limits in Chapter 123 now require an RFD and previously did not.

- 127.14(a)(8) Item 41 (new Item 47): Powdered metal sintering furnaces used to require an RFD if using organic lubricants and operating outside the specified limitations of the exemption. All powdered metal sintering furnaces now require an RFD.

- 127.14(a)(8) Item 43 (new Item 48): Remediation of gasoline or fuel oil contaminated soil, groundwater, or surface water by specified equipment used to require an RFD only if emissions were greater than 1 tpy volatile organic compounds (VOC) or HAP. All specified remediation equipment now require an RFD.

The following exemptions were updated (Note that this list is not exhaustive, and items discussed above are not repeated):

- 14(a)(8) Item 2: This exemption category was revised from only shot blast and sand blast units to all sources which only emit PM. In addition, the concentration of PM emissions may not exceed 0.01 gr/dscf.

- 14(a)(8) Item 6: The internal combustion engines exemption criteria are based on actual emissions and do not include emissions from sources which are approved by the Department in plan approvals or the general plan approvals/general operating permits at the facility. This category does not apply if an add-on air-cleaning device is installed.

- 14(a)(8) Item 12: The 150 tons per hour threshold for portable crushers has been removed.

- 14(a)(8) Item 15: The storage vessels for VOC exemption criteria does not apply if the source is subject to 25 Pa. Code 129.57.

- 14(a)(8) Item 30: This exemption no longer applies to solvents with less than 5% VOC by weight.

- 14(a)(8) Item 39: Combustion units with a rated capacity of 10 MMBtu/hr of heat input continue to be exempt through the use of pipeline quality natural gas, and now also include the use of liquified petroleum gas (LPG) and propane.

- 14(a)(9) Item 12: Owners and operators installing an air-cleaning device when there is no obligation to install an air-cleaning device must provide a 30-day prior written notification to PADEP.

- Trivial Activities Item 33: PM was added to VOC and HAP as pollutants that cannot be emitted for equipment used for surface coating, painting, dipping, or spraying operations.

The changes to the exemption list encompass a wide variety of industries and sources; even if you are very familiar with the exemption list, much has changed, so we encourage you to review the applicable exemptions for possible projects at your facility. For example, 25 Pa. Code §127.14(a)(8) Item 6 pertaining to the nitrogen oxides (NOx) exemption criteria for internal combustion engines is a commonly used exemption category that has been revised.

On the other hand, two major revisions that were added to the 2018 Air Permitting Exemption Document have not been revised further in the July 2021 update. These categories are 127.14(a)(8) Item 33 which pertains to compressed natural gas dispensing, and 127.14(a)(8) Item 38 which pertains to oil and gas exploration, development, production facilities, and associated equipment.

ALL4 will continue to track updates to this exemption document and provide updates to help you prepare and strategize for your next project. If you have questions about how this change may affect you, please contact your ALL4 Managing Consultant at info@all4inc.com.

Compliance History Proposed Rule – Texas Edition

The Texas Commission on Environmental Quality (TCEQ) published a proposed rulemaking for consideration on July 23, 2021 regarding the ability to make immediate adjustments to a site’s compliance history classification. The proposed rule will be published under 30 TAC Chapter 60: Compliance History and added as a new section of §60.4. Read on for more information or jump to the docket containing the proposed rulemaking.

Sites are rated using a compliance history score that evaluates the previous five years and classifies them as one of the following:

- High performers

- Satisfactory

- Unsatisfactory

- Unclassified

These classifications are evaluated annually, but with the proposed rule under 30 TAC §60.4, the Administrator would have the power to immediately reclassify a site as “suspended” in the event of a “significant emergency,” which has implications on permitting and compliance in multiple TCEQ programs, such as air permitting. This classification is temporary and would be followed by a true reclassification into one of the categories above. A significant emergency isn’t explicitly defined but includes a list of potential results of the type of emergencies being discussed here. A few examples include situations which:

- Result in a significant disruption to one or more local communities;

- Cause emergency response by a federal or state governmental authority.

The above criteria would capture situations where there is a fire or explosion at a facility.

The ability for immediate reclassification can have a big effect on a site. For example, if a site is reclassified as unsatisfactory, the agency has the right to deny, amend, or hold hearings to discuss permits under various programs, including general permits under chapter 205 and flexible permits under chapter 116. Just as an annual reclassification can affect permitting, a reclassification to “suspended” prohibits permitting actions to be taken unless they are evaluated in light of the recent emergency event. Additionally, fines will be considered on a case-by-case basis.

There is an opportunity for a site to provide additional information during the review process. Although there is not a formal procedure, the Executive Director will accept additional materials and withdraw the reclassification, if warranted. The site reclassification would end if the event is accounted for in the annual classification or three years after the effective date of reclassification unless identification and corrective actions were taken by the site and presented to the Executive Director.

In light of many recent events in the Houston area, it’s clear that the goal of the proposed rule is to have real-time understanding of a sites compliance history when evaluating permitting and provide the public with increased transparency. The TCEQ opened public comment on this topic, and it will remain open until October 30, 2021. If you have any questions or want to get in touch, please reach out to Rachel Henn at 281-937-7553 or rhenn@all4inc.com.

U.S. EPA Enforcement Alert Regarding Metal Recycling Facilities

In July 2021, the U.S. Environmental Protection Agency (U.S. EPA) issued an enforcement alert for metal recycling facilities that operate auto and scrap metal shredders. The enforcement alert is intended to inform facilities of potential excess emissions of volatile organic compounds (VOC) from facility operations that may not be quantified or permitted. VOC are ozone pre-cursors and are regulated under the Clean Air Act as well as by state and local air pollution control regulations.

What are we talking about?

Scrap metal and automobile recycling facilities are located in almost all 50 states, and U.S. EPA’s alert states that there are more than 250 metal recycling facilities currently operating shredders. Metal recycling facilities with shredders typically receive a combination of automobiles, construction materials, and appliances that are prepared for shredding by removing hazardous fluids and non-metallic materials. The metal is then processed by a shredder, which tears it into smaller pieces, that are then sent off for recycling to manufacturers or steel foundries. Metal recycling facilities are often located in or adjacent to cities and urban areas, potentially impacting overburdened communities.

Why is this enforcement alert important?

In recent years, U.S. EPA has evaluated and investigated several metal recycling facilities by issuing Clean Air Act (CAA) Section 114(a) letters and responding to complaints and enforcement violations. U.S. EPA has found that shredding operations are sources of VOC emissions through the volatilization of residual fluids and fuels that are not completely removed from the prepared scrap metal. The lack of reliable emissions test data may have resulted in an underestimation of VOC emissions industry-wide. Rates of VOC emissions vary widely, and are dependent on the size of the shredder, the type of material processed and if it is properly drained, and whether the shredder is enclosed and operates existing control equipment. This is especially concerning for facilities located in ozone non-attainment areas (where permitting thresholds are low and VOC emissions standards can be stringent) or facilities that are subject to VOC emissions limits (and may be under-reporting their emissions).

What does this enforcement look like?

Enforcement activity for the industry sector has increased. In the alert, U.S. EPA identifies three facilities that were assessed state and federal penalties, along with requirements to make significant operational changes and to implement VOC control technologies. Additionally, citizen action and environmental groups are engaged in communities with environmental justice considerations. The most significant action was the 2019 U.S. EPA administrative consent order (ACO) issued to General Iron Industries’ Chicago facility. U.S. EPA and the Chicago Department of Public Health had received numerous complaints about air emissions and non-compliance at the facility. After conducting several inspections and requiring emissions testing, U.S. EPA determined that emissions of VOC exceeded allowable limits and that the facility was incorrectly permitted. With this enforcement action, U.S. EPA also required emissions testing for metal hazardous air pollutants (HAP) and particulate matter (PM).

Associated costs with these enforcement actions are significant: litigation resulting from regulatory agency actions, emissions testing, financial penalties, installation of air pollution control equipment, obtaining air permits, and developing compliance strategies.

What does this mean for my facility now?

ALL4 is recommending affected facilities take a few preliminary steps to get started:

- assess the process for accepting materials and implement pollution prevention/minimization practices;

- use recent emissions test data from other, similar facilities, to estimate potential VOC emissions; and

- evaluate the potential emissions and compare to state requirements and New Source Review (NSR) or Prevention of Significant Deterioration (PSD) significant emissions rates.

In the meantime, stay tuned for Part 2 of the “scrap metal recycling series” while the ALL4 team is reviewing and summarizing state responses to the U.S. EPA enforcement alert – and they’re coming in fast.

If you have any questions or would like to discuss assistance the ALL4 team can provide to your facility, please reach out to Merritt McGlynn at (610) 422-1133 or mmcglynn@all4inc.com.

State-Specific Considerations for SPCC Plans in North Carolina and South Carolina

This blog is part of a series that covers key state-specific requirements for petroleum containing aboveground storage tanks (ASTs) with respect to Spill Prevention, Control, and Countermeasure (SPCC) compliance with 40 CFR Part 112.7(j).

In this edition, ALL4 will continue our series with key SPCC and tank requirements in North Carolina (NC) and South Carolina (SC).

North Carolina

The North Carolina Department of Environmental Quality (NC DEQ), generally does not regulate the installation, construction, permitting or monitoring of aboveground storage tanks (ASTs) except for those ASTs that are located at an Oil Terminal Facility as defined by the North Carolina General Statue (NCGS), Chapter 143, Article 21A. NC DEQ defines an Oil Terminal Facility as any facility on land or water which has transferred, stored, processed, or refined oil, excluding any facility with a storage capacity of less than 500 barrels (21,000 gallons) of oil and excluding any public retail gasoline operations. An Oil Terminal Facility must be registered within 30 days of the start of operations as required at NCGS 143-215.96. The definition of oil at NCGS 143-215.77(8) does not include animal or vegetable fats, which are included in the definition of oil for SPCC Plans in 40 CFR Part 112.2. The key takeaway is that NC DEQ AST requirements focus on registration of the larger ASTs at oil terminals, not retail containers, and some industrial facilities with oil storage. Animal and vegetable oil storage tanks – however large – are not covered by this requirement.

NC DEQ requires that all petroleum discharges into the environment are immediately collected and removed within 24 hours. In addition to this requirement, any petroleum discharge that meets the following thresholds must be reported to the NC DEQ Underground Storage Tank (UST) Section Regional Office within 24 hours as required at NCGS 143-215.85(b):

- 25 gallons or more of petroleum as defined at NCGS 145-215.94A;

- Where oil sheen is present on a surface water; or

- 100 feet or less from a surface water body.

If a petroleum discharge does not meet the thresholds listed above but the petroleum discharge cannot be collected and removed within 24 hours, NC DEQ must be notified immediately.

All SPCC Plans in NC must be certified by a professional engineer (PE) licensed by the North Carolina Board of Examiners for Engineers and Surveyors (NCBELS). NC DEQ does not require PE certification for qualified facilities, defined in 40 CFR Part 112.3(g), for which the U.S. Environmental Protection Agency (U.S. EPA) does not require PE certification of tiered SPCC Plans. However, NCBELS Policy Number BP-1709-2 states that only PEs are allowed to write SPCC Plans. The result is that a preparer of a qualified plan is considered to have “practiced engineering” and thus needs to be licensed.

South Carolina

The South Carolina Department of Health and Environmental Control (SC DHEC) does not regulate ASTs. The South Carolina Department of Agriculture (SC DA) regulates petroleum products at the South Carolina Code of State Regulations, Chapter 5, Article 10. SC DA requires under R.5-447(2)(A-C) that all fill connections of a retail storage tank are clearly labeled and the volume of each regulated product and total volume of the retail storage tank can be determined by a calibration chart or other means. In general, the SC DA requirements affect your SPCC facility’s equipment, but the state regulations do not have a significant impact on your SPCC plan itself.

SC DHEC’S website does highlight important guidelines for ASTs, including:

- Common causes of AST failures, including improper installation, construction failures, corrosion, and improper operations.

- Best practices including routine maintenance, safety measures during deliveries, and inspection of overfill devices.

- Signs of potential spills including rusted equipment, misshapen tank walls, strong odors, oil sheens, or dead vegetation or animals in the surrounding area.

SPCC Plans in SC must be certified by a PE licensed by the South Carolina State Board of Registration for Professional Engineers and Surveyors except for qualified facilities for which the U.S. EPA does not require PE certification.

Up Next

Stay tuned for upcoming articles that will continue to cover additional AST requirements in states across the country. If you have any questions on AST compliance in North Carolina, South Carolina, or another state, please feel free to reach out to Mark Robinson at mrobinson@all4inc.com or 470-893-2880.