U.S. EPA to Reconsider PM2.5 NAAQS

On June 10, 2021 U.S. EPA announced that it would reconsider the previous administration’s decision to retain the particulate matter less than 2.5 microns (PM2.5) National Ambient Air Quality Standard (NAAQS). The previous administration made its final decision to retain both the annual and 24-hour PM2.5 NAAQS even though U.S. EPA’s 2019 Integrated Science Assessment (ISA) concluded that there was scientific evidence that supported lowering the annual PM2.5 NAAQS. The current annual PM2.5 NAAQS is 12 micrograms per cubic meter (µg/m3) and was last lowered from 15 µg/m3 to 12 µg/m3 in 2012. The 24-hour PM2.5 NAAQS is 35 µg/m3 and hasn’t been changed since initially being established in 2006.

The Clean Air Act (CAA) requires U.S. EPA to re-evaluate the NAAQS every 5 years. The process involves the development of an ISA which evaluates peer-reviewed literature published since the last assessment on the health and welfare effects of the NAAQS under review and the development of a Risk/Exposure Assessment (REA). The Clean Air Scientific Advisory Committee (CASAC) then provides an independent review of both the ISA and REA. Finally, a Policy Assessment (PA) is developed by U.S. EPA which considers both the ISA, REA, and policy implications and makes a recommendation on whether to retain or revise the NAAQS. The 2019 particulate matter (PM) ISA included recommendations for lower of the annual PM2.5 NAAQS to between 8 and 10 µg/m3, although the final PA concluded that there was not enough evidence to support lowering the annual PM2.5 NAAQS.

As part of the reconsideration, U.S. EPA intends to develop a supplement to the 2019 PM ISA that will consider the most up-to-date science. This approach means that the NAAQS review process will not be restarted and as a result U.S. EPA expects to finalize a proposal to retain or lower the PM2.5 NAAQS by Summer of 2022, following up with a final rule by Spring of 2023.

How Would a Reduced PM2.5 NAAQS Impact My Facility?

The current measured annual PM2.5 concentration average across all state operated ambient monitors in the country is 7.8 µg/m3 for the 2018-2020 time period. As a result, there is little “headroom” available below the current annual PM2.5 NAAQS of 12 µg/m3 for new projects and facilities or for areas to remain in attainment with the NAAQS. There are two critical ways that lowering the PM2.5 NAAQS could impact your facility. First, for projects that trigger Prevention of Significant Deterioration (PSD) permitting air quality modeling requirements, the available headroom could shrink from already very restrictive levels to a level that would make it nearly impossible to model below the PM2.5 annual NAAQS for even the smallest increases in PM2.5 emissions. Second, due to current monitored concentration levels many areas across the country could see newly established nonattainment areas. If your facility is located in a newly established PM2.5 nonattainment area, nonattainment new source review (NNSR) permitting would be required instead of PSD permitting. While the air quality modeling is not required as a part of NNSR permitting, Lowest Achievable Emissions Rate (LAER) is required instead of Best Avaiable Control Technology (BACT). The main difference between BACT and LAER is the removal of the economic consideration (i.e., if means to reduce emissions are technically feasible, they are required no matter the cost). In addition, Emissions Reductions Credits (ERCs) are required to be purchased to offset emissions increases as part of the NNSR permitting program. ERCs can be difficult to procure and expensive in some situations. This adds cost and can delay implementation of a project. Additionally, states that have newly designated nonattainment areas are required to develop a State Implementation Plan (SIP) to bring the area back into attainment with the NAAQS. This process could require your facility to install control equipment or otherwise take new, more restrictive permit limits even if your facility is not currently engaged in an air permitting project. This could even occur if your facility is not the one that is primarily responsible for the creation of the nonattainment area in the first place.

CLEAN Future Act Implications

While not directly tied into the reconsideration of the annual PM2.5 NAAQS, one piece of draft legislation that is out there related to the new administration’s focus on Environmental Justice is the CLEAN Future Act. One of the two criteria that would determine whether a census tract would be considered overburdened for the purpose of the law would be “Has been determined to have an annual mean concentration of PM2.5 of greater than 8 µg/m3, as determined over the most recent 3-year period for which data are available”. As discussed above, the national annual-average PM2.5 concentration is 7.8 µg/m3. This means that if the Clean Future Act passes as currently proposed, nearly half of the United States would be considered overburdened not even considering the other criteria in the law, that being a cancer risk of greater than 100 in 1,000,000. The implications of your facility being in such an area would be significant:

- After the date of enactment of the CLEAN Future Act, no permit shall be granted by a permitting authority for a proposed major source that would be in an overburdened census tract.

- After January 1, 2025, no permit for a major source in an overburdened census tract shall be renewed.

Thus, regardless of whether or not the annual PM2.5 NAAQS is revised, should the CLEAN Future Act pass, no permit action that triggered New Source Review (NSR) permitting would be allowed in an area with an ambient annual PM2.5 concentration over 8 µg/m3, and existing major stationary sources in such areas could not renew their permits starting in 2025!

The Good News

You’ve still got time on your side if you start soon to complete and obtain a permit under the existing PM2.5 annual NAAQS and before any version of the CLEAN Future Act is finalized. If you’re considering a project that could increase PM2.5 emissions from your facility that could trigger PM2.5 air quality modeling, now is the time to evaluate that project. PSD permitting (typically the longest permitting program) is typically a 12-18 month process from application development to receipt of a final permit from the agency. This would put your permit in hand before any potential revision of the PM2.5 NAAQS. Once a permit has been finalized you have been grandfathered into the regulations promulgated at that time. As long as you don’t need to make any additional changes to your permit you wouldn’t have to re-evaluate your project under any potential reduced PM2.5 NAAQS. While the PSD permitting program is the Federal program that impacts most major facilities across the country be aware that the same recommendations can be made for states that have air quality modeling requirements for minor modifications or minor facilities that don’t trigger Major PSD permitting, as states that do require modeling for minor source projects typically use the current NAAQS as the thresholds for demonstrating compliance.

If you have any questions about a potential project that includes PM2.5 emissions or want to see how close your area’s ambient PM2.5 concentration is to the current PM2.5 NAAQS is, please contact Dan Dix at ddix@all4inc.com or at 610.422.1118.

PFAS: State-by-State Regulatory Update

Given the current lack of all-encompassing federal environmental regulation around per- and polyfluoroalkyl substances (PFAS), states are taking it upon themselves to set their own standards amid growing public scrutiny. With proposed house bills, rejections of bills, and other PFAS news popping up seemingly every day, it can be difficult to keep track of the regulatory climate and obligations. ALL4 is here to help.

Note: This information is current as of July 16, 2021.

First to level-set, the following are several key PFAS regulations currently at the federal level:

- Water

- Drinking Water: Health Advisory Level (HAL) of 70 parts per trillion (ppt) for perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS), combined. HALs are not enforceable. Note that U.S. Environmental Protection Agency (U.S. EPA) is moving forward to implement enforceable drinking water maximum contaminant levels (MCLs) for PFOA and PFOS, but a limit does not exist at this time.

- Air

- There are no proposed or promulgated standards at this time.

- Other

- Toxic Release Inventory (TRI): Section 7321 of the National Defense Authorization Act for Fiscal Year 2020 (NDAA), which was passed in December 2019, immediately added 172 per- and polyfluoroalkyl substances (PFAS) to the list of chemicals covered by the TRI and provided a framework for additional PFAS to be added to TRI on an annual basis. This list became effective January 1, 2020, with the first PFAS Form Rs required by July 1, 2021. Three additional PFAS have been added to the TRI list in 2021, bringing the current total to 175.

- Aqueous Film Forming Foam (AFFF): The Department of Defense (DOD) is phasing out of AFFF and prohibition of the use of AFFF during training exercises at military sites.

- Significant New Use Rule (SNUR): Finalized for PFOA and PFOA-related chemicals. The SNUR requires notification from anyone who begins or resumes the manufacturing, including importing, or processing of these chemicals. The SNUR addresses risks from products like carpets, furniture, electronics, and household appliances.

- Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA): Proposing to designate PFOA and PFOS as “hazardous substances”.

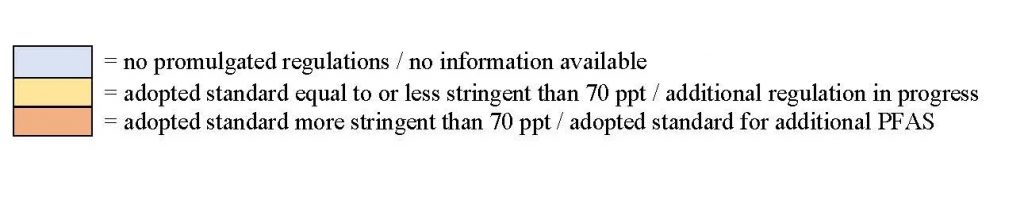

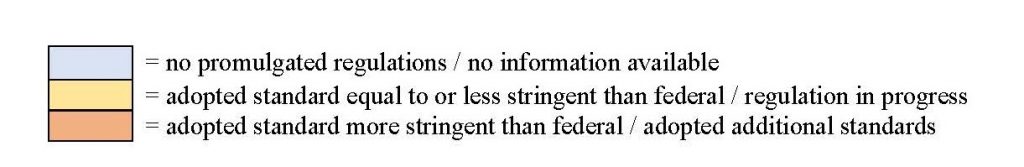

The following maps provide a high-level summary of what states are currently doing in terms of water, air, and other (e.g., AFFF, waste, consumer goods, remediation) PFAS-related regulations. This does not include any litigation or consent decrees.

WATER REGULATIONS

The color key is as follows:

Highlights:

- California: Drinking water notification levels for PFOS (6.5 ppt), PFOA (5.1 ppt), and perfluorobutane sulfonic acid (PFBS) (500 ppt). Drinking water response levels for PFOS (40 ppt), PFOA (10 ppt), and PFBS (5,000 ppt). The State Water Board has also requested notification levels for perfluorohexane sulfonic acid (PFHxS), perfluorohexanoic acid (PFHxA), perfluoroheptanoic acid (PFHpA), perfluorononanoic acid (PFNA), perfluorodecanoic acid (PFDA), and 4,8-dioxia-3H-perflourononanoic acid (ADONA).

- Colorado: Surface water/groundwater translation levels for PFOA (and parent constituents), PFOS (and parent constituents), and PFNA (70 ppt, combined), PFHxS (700 ppt), and PFBS (400,000 ppt). The policy also includes monitoring and permitting considerations for entities that discharge to state waters.

- Connecticut: Drinking water action levels for PFOA, PFOS, PFNA, PFHxS, and PFHpA (70 ppt, combined).

- Illinois: Health advisories for PFBS (2,100 ppt), PFHxS (140 ppt), PFOS (14 ppt), PFOA (2 ppt), and PFHxA (560,000 ppt). Illinois is also in the process of introducing groundwater quality standards and evaluating the need to introduce drinking water MCLs for several PFAS.

- Maine: Interim drinking water MCLs for PFOS, PFOA, PFHpA, PFNA, PFHxS, and PFDA (20 ppt, combined) and monitoring requirements.

- Massachusetts: Drinking water MCLs for PFOS, PFOA, PFHxS, PFNA, PFHpA, and PFDA (20 ppt, combined). Massachusetts is also introducing monitoring obligations for these PFAS under National Pollutant Discharge Elimination System (NPDES).

- Michigan: Drinking water MCLs for PFNA (6 ppt), PFOA (8 ppt), PFHxA (400,000 ppt), PFOS (16 ppt), PFHxS (51 ppt), PFBS (420 ppt), and hexafluoropropylene oxide dimer acid (HFPO-DA) (370 ppt).

- Minnesota: Health advisories for PFOS (15 ppt), PFOA (35 ppt), PFHxS (47 ppt), PFBS (2,000 ppt), and PFBA (7,000 ppt).

- New Hampshire: Drinking water MCLs and ambient groundwater quality standards (AGQS) for PFOA (12 ppt), PFOS (15 ppt), PFNA (11 ppt), and PFHxS (18 ppt).

- New Jersey: Drinking water MCLs and groundwater quality standards for PFNA (13 ppt), PFOA (14 ppt), and PFOS (13 ppt).

- New York: Drinking water MCLs for PFOA (10 ppt) and PFOS (10 ppt).

- North Carolina: Drinking water health goal for GenX (150 ppt). Proposed groundwater quality standard for PFOA and PFOS (70 ppt, combined).

- Ohio: Drinking water action levels for PFOA and PFOS (70 ppt, combined), GenX (700 ppt), PFBS (140,000 ppt), PFHxS (140 ppt), and PFNA (21 ppt).

- Pennsylvania: Proposing (pre-draft rule) drinking water MCLs for PFOA (14 ppt) and PFOS (18 ppt).

- Vermont: Drinking water MCLs for PFOS, PFOA, PFHxS, PFNA, and PFHpA (20 ppt, combined).

- Wisconsin: Proposing drinking water MCL and groundwater standards for PFOA and PFOS (20 ppt, combined). Additional regulations in progress to address 16 other PFAS.

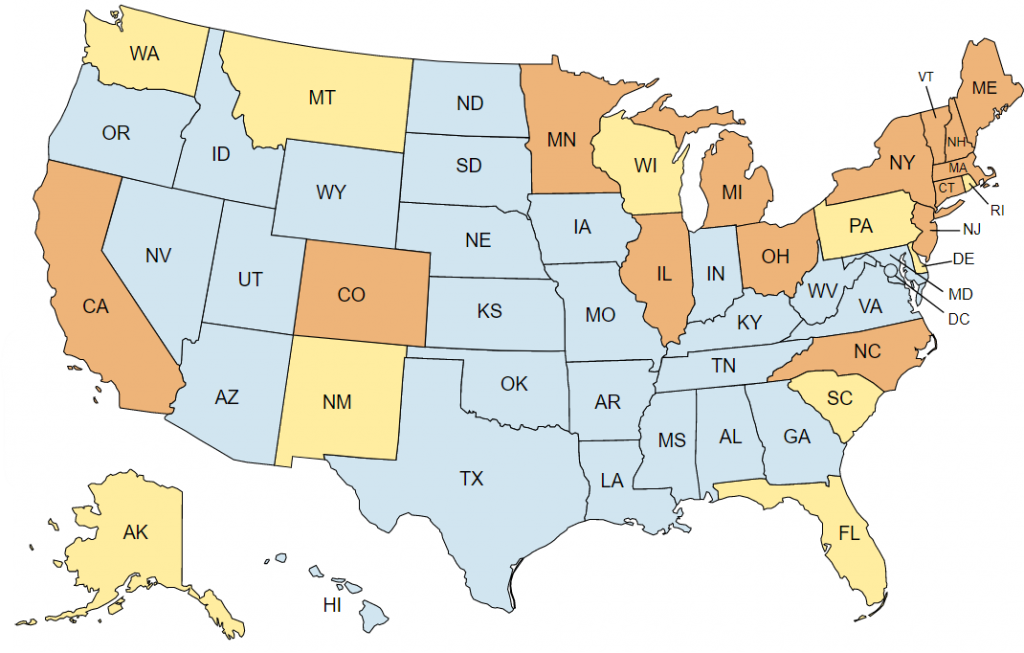

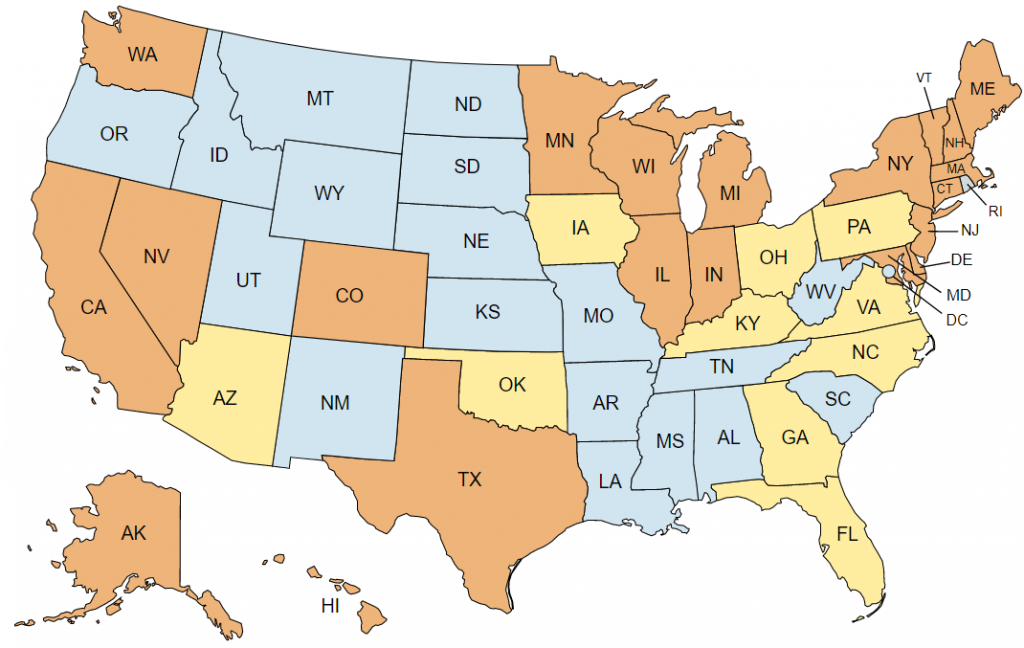

AIR REGULATIONS

The color key is as follows:

- Michigan: Air toxics rule set allowable concentration levels (ACLs) for PFOA and PFOS of 0.07 micrograms per cubic meter (µg/m³), 24-hour average, individually or combined. New or modified sources that are required to obtain an air use permit are subject to Michigan’s air toxics rules, unless otherwise exempt.

- New Hampshire: Air toxics rule set ambient air limits (AAL) for ammonium perfluorooctanoate (APFO) of 0.05 µg/m³ (24-hour) and 0.024 µg/m³ (annual). New, modified, and existing processes are subject to the air toxics rule. In addition, New Hampshire promulgated a Best Available Control Technology (BACT) requirement for any facility that may cause or contribute to an ambient groundwater quality standard (AGQS) or surface water quality standard (SWQS) exceedance of perfluorinated compounds (PFCs) or precursors, which includes certain PFAS.

- New York: Air toxics program set an annual guideline concentration (AGC) for PFOA of 0.0053 µg/m3. Any facility regulated under Part 212 must evaluate air contaminants, including PFOA, as applicable.

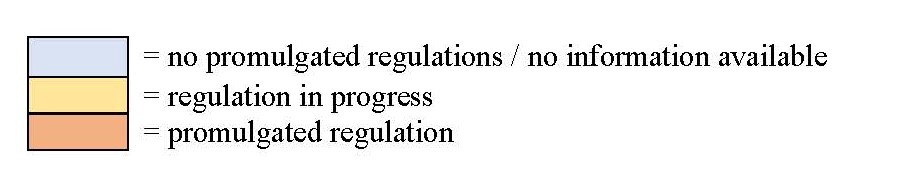

OTHER REGULATIONS

The color key is as follows:

Highlights:

- California:

- Proposition 65: Warning required for PFOA/PFOS.

- AFFF: Reporting, notification, usage, and manufacturer requirements.

- Consumer Goods: Notification for personal protective equipment (PPE) containing PFAS. Ban on cosmetics containing PFOA or PFOS. Proposal to regulate plant-fiber-based food packaging containing PFAS.

- Illinois:

- AFFF: Usage and manufacturer requirements.

- Incineration: Proposed bill to prohibit incineration of PFAS.

- Maine:

- Remediation: Soil remedial action screening levels and water remedial action guidelines for PFBS, PFOS, and PFOA.

- AFFF: Proposed reporting, notification, and usage requirements.

- Consumer Goods: Prohibition of PFAS additions in packaging. Reporting requirements for PFOS-containing children’s products. Prohibition of sale of any product containing PFAS that were intentionally added.

- New York:

- Hazardous Substances: PFOS and PFOA classified as hazardous substances.

- AFFF: Usage, notification, and incineration requirements.

- Consumer Goods: Prohibition of PFAS additions in food packaging materials. Notification requirements for PFOS- and PFOA-containing children’s products.

- Pennsylvania

- Biosolids: Revised Biosolids General Permits to include PFOA and PFOS monitoring requirements (pre-draft issued/public comment anticipated Fall 2021)

- Texas:

- Remediation: Protective concentration levels (PCLs) set for 16 PFAS in groundwater and soil.

- Washington:

- AFFF: Usage, notification, and manufacturer requirements.

- Consumer Goods: Notification for PPE containing PFAS. Prohibition of PFAS additions in food packaging materials.

ALL4 continues to track the regulatory movements and maintains a database of current state PFAS activity. If you have any questions about your specific state or would like any additional information, please reach out to Kayla Turney at kturney@all4inc.com.

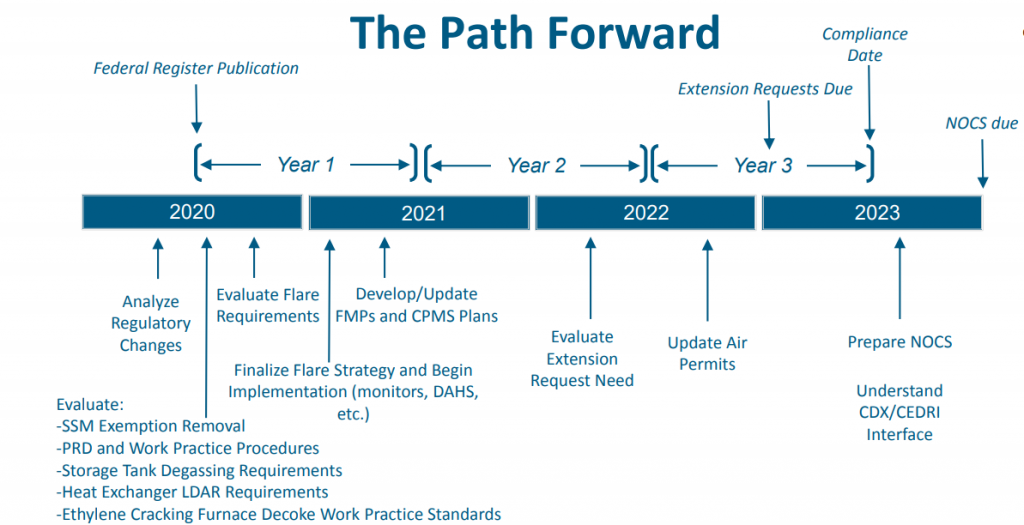

My Facility is Subject to the EMACT – What Should I be doing Now?

The U.S. Environmental Protection Agency (U.S. EPA) finalized amendments to the National Emission Standards for Hazardous Air Pollutants (NESHAP): Generic Maximum Achievable Control Technology Standards for Ethylene Production, otherwise known as “EMACT” on July 6, 2020. Is your facility on the right path to complying with the new requirements?

WHAT CHANGED?

Major regulatory changes include the following:

- Changes to address treatment of startup, shutdown, and malfunction (SSM) events consistent with the 2008 vacatur of the SSM exemptions in 40 CFR Part 63 General Provisions.

- Work practices for decoking

- Revised flare monitoring requirements to ensure flares meet the EMACT standards at all times.

- Changes to leak monitoring methodology for heat exchangers.

- Additional restrictions on maintenance vents, bypasses, pressure relief devices, and in-situ sampling systems.

- Existing facilities must comply with the changes starting 3 years after publication of the final rule in the Federal Register (July 6, 2023).

- New facilities (facilities that commenced construction or reconstruction after October 9, 2019) must comply with the changes upon initial startup or July 6, 2020, whichever is later.

WHAT SHOULD MY FACILITY BE DOING NOW?

ALL4 recommends the following:

- Read the final rule, preamble, and U.S. EPA’s response to comment document and understand the impacts on your business and facilities. Evaluate the following:

-

- Changes to the definition of an “ethylene process vent,” which will cover maintenance vents in-situ sampling systems and the changes to using fuel gas

- SSM Exemption Removal

- PRD and Work Practice Procedures

- Storage Tank Degassing Requirements

- Heat Exchanger LDAR Requirements

- Ethylene Cracking Furnace Decoke Work Practice Standards

- Identify what additional internal and external resources you need to implement the rule.

- Develop your EMACT compliance approach.

- Identify any capital projects that will be required for compliance.

-

- Develop a timeline and schedule highlighting milestones.

- Can you accommodate these projects into an already planned outage such that the compliance deadline can be met?

- Identify what air permitting, if any, will need to be completed to support possible capital projects.

- Determine what additional information must be monitored and recorded to comply with the revised monitoring, recordkeeping, and reporting requirements.

-

- For example, depending on a facility’s current configuration, the flare monitoring requirements in 40 CFR Part 63, Subpart CC may require the installation of a gas chromatograph, a hydrogen analyzer, or a calorimeter.

- New flare gas, air, fuel, or steam monitoring and control equipment may also be required.

- Facilities should also consider any necessary upgrades to their data acquisition systems.

- Monitoring that may be required for temporary flares, in addition to temporary control devices used to control storage tank degassing emissions.

- Determine what internal procedures and plans need to be updated as a result of the rule changes.

-

- Flare Management Plans

- Continuous Parametric Monitoring Plans

- Site Standard Operating Procedures (SOPs) to conduct and document root cause analysis for PRDs and flares.

ALL4 has a variety of chemical sector experience, including ethylene. We are well versed in the Refinery RTR flare requirements and can assist EMACT facilities with the new flare requirements including developing monitoring plans, identifying required monitoring systems, and/or preparing procurement specifications for equipment suppliers. We can also help facilities analyze, plan for, and comply with the new requirements for heat exchange systems, PRDs, and other emissions sources. Contact Meghan Skemp at mskemp@all4inc.com or 281.937.7553 ext 307.

Cement and Concrete: What’s the Difference? What Effects Do They Have on Sustainability?

There are some age-old questions out there: What’s the difference between bourbon and whiskey? A calzone and a stromboli? A fiddle and a violin? What about the difference between cement and concrete?

To keep it short and sweet, cement is a binding agent in powder form and is a component used for concrete, mortar, stucco, grout, and even some adhesives. Once combined with water, cement will eventually set and harden. The subsequent building material name depends on what is mixed with the cement. For example, concrete is cement mixed with sand and gravel (or other mixture of fine/coarse aggregate) as a tried-and-true, complete building material.

OK – that’s a great start. Cement is the “glue” that holds concrete together. Where does sustainability come in? For that, we need to go into how cement is made. Cement is made from a variety of feeds, with the most-common feed being limestone. Other materials (such as sand, iron, aluminum, and clay) are added to the limestone, as needed, to ensure that the raw material contains the right components to become cement. This material is then fed into a kiln and “baked” at around 2,700 degrees Fahrenheit. After exiting the kiln, the material, now called clinker, is cooled, ground up, mixed with gypsum to regulate the time it takes the cement to set (and potentially other additives depending on the type of cement), and then packaged for use. Its usefulness in construction makes it one of the most widely used materials in the world.

So what? With hints to a massive infrastructure bill in the news, cement and its building material derivatives (including, but not limited to concrete) may have a significantly increased demand with a corresponding increase in production. Cement production has its fair share of environmental challenges and cement plants must continue to monitor their effect on the surrounding environment. With increased production due to the infrastructure bill, there may be more attention directed towards the environmental effects of cement production, not least of which are greenhouse gas (GHG) emissions.

Manufacturing cement produces a significant amount of carbon dioxide (CO2) both through the process (limestone + heat -> calcium oxide and CO2) and through the burning of fuel to maintain the high temperatures required in the cement kiln for the baking process. Fossil fuels are the type of fuel most often utilized in kilns since a high temperature must be maintained, and fossil fuels are the most available and economically feasible fuel for such operations. Due to the scale of production of cement, these sources contribute a significant portion of GHG emissions [e.g., according to U.S. EPA’s GHG Reporting Program for large-emitting facilities, the cement industry accounted for 58% of the CO2 equivalent (CO2e) emissions in the U.S. minerals sector, and 2.4% of total U.S. CO2e emissions in 2019].

Therefore, there is some pressure on the cement industry to mitigate GHG emissions through a sustainable reduction in GHG emissions, primarily CO2. CO2 emissions can potentially be reduced from an operational standpoint in several ways: by increasing the efficiency of production (less energy spent to create the same amount of clinker), replacing clinker with an alternative material or filler (less clinker required to make the same amount of cement), and by using alternative and/or waste fuels to reduce CO2 emissions from kiln combustion. Of course, reducing CO2 emissions in these ways comes with their own set of disadvantages (e.g., a potential drop in cement quality or installation of expensive equipment), but are good approaches to reduce CO2 emissions from cement kilns.

In addition to sustainable reductions in GHG emissions from process changes, post-combustion GHG emissions controls continue to be evaluated. In the cement industry, however, there are several technical issues that prevent the current control technologies from being implemented on a wide scale (e.g., high temperatures, excess material in the exhaust gas, and continuous wear and tear of the control equipment). Developing a reasonably affordable and technically feasible post-combustion GHG emissions control technology for widespread use in the cement industry will take time to complete.

ALL4 will continue to track both the pressure of sustainability on the cement industry as well as the development of CO2 control technologies for sustainable cement production. If you have any questions, please contact me at scunningham@all4inc.com or (610) 422-1144.

New Landfill Air Regulations May Inspire a Round of Tic Tac Toe

If it seems like you’ve been hearing a lot about air quality regulations for landfills over the last few years, that’s because there are seven different Subparts under Parts 60, 62, and 63 to Title 40 of the Code of Federal Regulations (CFR) that pertain to landfill air emissions. In addition, four of those rules have been subject to 11 regulatory actions since 2014. These rules generally require landfills to collect and control landfill gas (LFG) if and when they reach a certain capacity of waste and a certain emissions rate of non-methane organic compounds (NMOC). Before getting into the details of the most recent rulemakings, and why they might inspire a round of Tic Tac Toe, let’s first revisit the seven different 40 CFR Subparts that pertain to landfill air emissions.

The Landfill Regulations

Many of the rules applicable to a landfill depend on when the landfill was constructed, modified, or reconstructed, which dictates whether the landfill is considered “new” or “existing.” New landfills are regulated by Standards of Performance for New Stationary Sources, commonly referred to as New Source Performance Standards (NSPS) under 40 CFR Part 60. Under Part 60, Subparts WWW and XXX may be applicable depending on when the landfill was constructed, modified, or reconstructed.

Existing landfills are indirectly regulated by Emission Guidelines, which are also codified under 40 CFR Part 60. Under Part 60, Subparts Cc and Cf may be indirectly applicable depending on when the landfill was constructed, modified, or reconstructed. Rather than applying directly to landfills, Emission Guidelines direct state, local, and tribal agencies (herein referred to as states) to develop their own State Plans to implement the Emission Guidelines. If a state does not develop a State Plan, or the U.S. Environmental Protection Agency (U.S. EPA) does not approve a submitted State Plan, U.S. EPA will develop a Federal Plan. Federal Plans are codified under 40 CFR Part 62. Under Part 62, Subparts GGG and OOO may be applicable depending on when the landfill was constructed, modified, or reconstructed.

While the six NSPS and Emission Guidelines regulate emissions of criteria and other pollutants pursuant to Section 111 of the Clean Air Act (CAA), the seventh rule is a National Emission Standard for Hazardous Air Pollutants (NESHAP) under 40 CFR Part 63, which regulates emissions of hazardous air pollutants (HAP) pursuant to Section 112 of the CAA. Under Part 63, Subpart AAAA may be applicable depending on the landfill’s size, NMOC emissions rate, and HAP emissions rate.

Rule History

Prior to 2014, Emission Guideline Subpart Cc, NSPS Subpart WWW, Federal Plan Subpart GGG, and NESHAP Subpart AAAA were potentially applicable to a landfill. NESHAP Subpart AAAA was amended on March 26, 2020 and remains an applicable rule for landfills. However, rather than amending Emission Guideline Subpart Cc, NSPS Subpart WWW, and Federal Plan Subpart GGG, U.S. EPA promulgated new Emission Guideline Subpart Cf, NSPS Subpart XXX, and Federal Plan Subpart OOO over the span of approximately five years, effectively making the three previous rules obsolete once the new rules became effective, and potentially changing the regulation to which a landfill had been subject. For example, a landfill that was modified on or before July 17, 2014 that had been subject to NSPS Subpart WWW under 40 CFR Part 60 may now be subject to Federal Plan Subpart OOO under 40 CFR Part 62, or the State Plan (if developed by their state and approved by U.S. EPA).

NSPS Subpart XXX was proposed on July 17, 2014 and finalized on August 29, 2016, with an effective date of October 28, 2016. Therefore, any affected landfills that commenced construction, modification, or reconstruction after July 17, 2014 became subject to NSPS Subpart XXX on October 28, 2016. Emission Guideline Subpart Cf was proposed on August 27, 2015 and finalized on August 29, 2016 (the same day as the final NSPS Subpart XXX). The newest rule, Federal Plan Subpart OOO, was proposed on August 22, 2019, signed on May 10, 2021, and published in the Federal Register just 11 days later on May 21, 2021 with an effective date June 21, 2021. The relatively quick turnaround for implementing a regulation was likely due to U.S. EPA’s recent focus on climate change, to which landfills contribute due to their emissions of methane. U.S. EPA acknowledged the short timeline, stating in the preamble to the Federal Register notice that Emission Guideline Subpart Cf was published “over 3 years prior to the publication of the proposed Federal plan;” in other words, these requirements shouldn’t come as a surprise.

Subparts XXX and OOO (Tic Tac Toe!)

NSPS for new sources are generally more stringent than Emission Guidelines (i.e., State or Federal Plans) for existing sources. In this case, however, NSPS Subpart XXX and Federal Plan Subpart OOO are fairly consistent. For example, both Subparts XXX and OOO reduced the NMOC applicability threshold from 50 megagrams per year (Mg/year) to 34 Mg/year (Subpart OOO retained the 50 Mg/year threshold for closed landfills), removed the corrective action requirements for wellhead oxygen and nitrogen operating parameters, and added a Tier 4 option to demonstrate surface methane emissions are less than 500 parts per million (ppm) via surface emissions monitoring (SEM) before triggering the requirement to install a gas collection and control system (GCCS).

Subparts XXX and OOO also added an option to comply with the “major compliance provisions” of NESHAP Subpart AAAA “in lieu of complying with the analogous provisions in the NSPS and EG.” As implied by this option, NESHAP Subpart AAAA is also very similar to Subparts XXX and OOO. While it has a less stringent (i.e., higher) temperature parameter limit, it has additional corresponding enhanced monitoring and reporting requirements. Subpart AAAA also has additional requirements for landfills with bioreactors.

Newly effective Federal Plan Subpart OOO contains provisions for existing “legacy controlled landfills” that already have a GCCS in place (i.e., they are not expected to redo certain specified previously completed compliance obligations), as well as increments of progress for previously uncontrolled existing landfills to meet the requirements (i.e., they are not expected to comply on day one). Uncontrolled landfills now subject to Federal Plan Subpart OOO must submit a design capacity report (and an NMOC emissions rate report if the capacity equals or exceeds 2.5 million Mg and 2.5 million cubic meters) by September 20, 2021. Future requirements will depend on the NMOC emissions rate; once greater than 34 Mg/year (50 Mg/year for closed landfills), and if surface methane emissions exceed 500 ppm for those choosing to utilize the new Tier 4 option, the landfill will be required to install a GCCS according to specified increments of progress. The first increment is due one year after the NMOC emissions rate report in which NMOC emissions equaled or exceeded 34/50 Mg/year, and the last increment (i.e., achieving final compliance) is due 30 months after that report.

Applicability & Permitting Considerations

U.S. EPA issued a finding of failure on March 12, 2020 for 42 states to submit State Plans in response to Emission Guideline Subpart Cf, which were due by May 30, 2017; therefore, the Federal Plan is expected to impact many landfills that would otherwise be subject to a State Plan. Indeed, U.S. EPA states in the preamble to the Federal Register notice that “there are an estimated 1,590 landfills covered by this final Federal plan.” While previously unregulated landfills may not be looking forward to their new compliance obligations, previously regulated landfills have been waiting almost five years for Emission Guideline Subpart Cf to be implemented, which relaxes certain requirements like the oxygen and nitrogen operating parameter limits compared to the previously applicable rule(s). However, a previously regulated landfill’s operating permit will still reflect the previously applicable rule(s) until it is amended, so landfill operators should make sure to demonstrate compliance with all requirements until they are able to complete the permit amendment process.

Additionally, until a state requests delegation of authority to implement Federal Plan Subpart OOO, U.S. EPA remains the Administrator. Even after delegation, U.S. EPA “will continue to hold enforcement authority along with the state or tribe,” but the state will have responsibility for “administration and oversight of compliance, reporting, and recordkeeping requirements, MSW landfill inspections, and preparation of draft notices of violation.” There are also certain other authorities that cannot be delegated to a state, which generally include alternatives and waivers for certain requirements.

If you would rather play a round of Tic Tac Toe than try to keep all of the landfill air regulations straight, please contact Lindsey Kroos at lkroos@all4inc.com or 610.933.5246 x122 so she can answer your questions about how NSPS Subpart XXX, Federal Plan Subpart OOO, or any of the other landfill regulations may impact your facility.