Meet JP Kleinle

JP Kleinle // Project Management Director // Philadelphia Office

Any pandemic projects currently in the works at the Kleinle house?

The ‘Paver Project’ is currently in full swing! This is my first time doing one and it’s going well. In fact, I’d give myself an A-/B+ on this inaugural project. Cutting and securing the wall caps is the only task remaining. We’re looking forward this fall to enjoying the outdoors and having some fires.

What inspired you to become an environmental consultant?

I really enjoy meeting people and problem solving. Environmental consulting has a lot of variety and you’re working with multiple clients at any given time who are in different market segments. For me it keeps the role challenging and fresh.

At ALL4 what’s the superpower(s) that you’re known for?

Structure. Feedback that I consistently receive from peers is that I have very structured systems in place. This is true, I find it enables me to keep myself feeling ‘in balance’.

As the CMS Practice Area Leader, you are growing that business unit. What are the top 3 traits that you look for in team members?

1) Accountability: As a leader, there is a peace of mind in knowing team members are taking the initiative to do what is needed and strive to exceed expectations; 2) Curiosity: Someone who has an appetite for learning new things; raising the bar to continually challenge themself; and 3) Entrepreneurial: Ability to see a gap or risk for their clients and effectively lead a team in the creation of a solution; contribute to the sustainable-productivity of the growing practice area.

What are some of your interests outside of work?

A few come to mind – our family really enjoys being outdoors, so you’ll find us camping, exercising, doing yard work together… I guess I can now add ‘sitting on our new paver patio’ to the list! An upside to the pandemic is that I’ve started woodworking again. Our family recently built a chicken coop. You can also find me coaching wrestling for my son’s team – that’s something I’ve really enjoyed the past several years and it allows me to stay connected to my days as a college wrestler.

What are your favorite things about working at ALL4?

Three come to mind: 1) There is a perpetual drive as individuals and an organization to improve, become better, and increase efficiency 2) Ability to chart your path at ALL4, seek new opportunities, and be supported by team members/leadership in making opportunities that you’ve identified come to fruition; and 3) The family vibe, my co-workers feel more like a work family.

To learn more about JP, please visit his profile. You can reach him at jkleinle@all4inc.com // 610.422.1120

TCEQ Inspections in the Time of COVID-19

Life is far from normal these days. Virtual game nights and networking events have become semi-routine in my life, as I try and figure out the best way to stay connected throughout these social distancing times. Similar to how I’ve adjusted, the Texas Commission on Environmental Quality (TCEQ) has also adjusted. Specifically, TCEQ has tweaked the method in which site inspections may be performed. As the new normal, let’s go and take a look, virtually.

What is TCEQ’s approach regarding site investigations and inspections during this time of COVID-19?

I have spoken with a few TCEQ Regional Office representatives and have learned that TCEQ is continuing to conduct scheduled site investigations as well as unannounced inspections. At the time of my conversations with TCEQ (in mid-September 2020), virtual audits in lieu of in-person audits were being determined on a case-by-case basis. For example, in-person inspections may occur in less densely populated counties, while more densely populated counties may see their inspectors opt to perform virtual inspections instead. The Regional Office inspector will work with each site to determine what makes the most sense in each situation.

You received a notice that TCEQ will be performing a virtual environmental compliance inspection. Now what?

A virtual inspection in many ways is very similar to an in-person inspection and sites should prepare for them as they normally would. To start, the TCEQ typically reviews each permit condition and requests associated records which demonstrate compliance with those permit conditions. Instead of physically being onsite and visually reviewing such records, files can be sent to the site inspector via email. However, during these virtual inspections, the records request turn-around time is more condensed: that is, in most cases you will only have two days to respond to each inspectors’ requests, thus limiting the flexibility of environmental personnel. Large records requests can take a few days to prepare, so it is important that adequate preparation is done prior to each virtual audit. Feeling lost or overwhelmed? ALL4 is here to help you prepare for an agency virtual audit.

What Can you do to Prepare?

First, especially for the planned virtual inspections, organize your electronic and hardcopy records to make them easily accessible. Understand where such files are saved on your site network so you’ll be able to send them to the TCEQ quickly. Have conversations with your TCEQ contact leading up to the inspection to understand their expectations. In some cases, a TCEQ inspector may ask a site to take pictures or provide video footage of an area or location. It is helpful also to prepare your environmental staff for the upcoming inspection, especially if onsite information is needed from employees working remotely. Preparing environmental staff may look like reviewing permit compliance documentation or reviewing possible interview questions to ensure they are ready for TCEQ’s questions.

If a visual component is anticipated for site interviews, know which platform (e.g., Zoom, Teams, etc.) is preferred to ensure both parties can access video sharing capabilities without spending additional time troubleshooting IT issues. For example, one TCEQ representative shared that it was helpful to have a phone available so an environmental staff member could easily walk around the site to demonstrate that proper signage was posted for emission points throughout the site. Besides facilitating TCEQ to see into the site, another challenge that has arisen included the transferring of hardcopy materials (e.g., logbooks, compliance documents) into digital scans. This can be time consuming.

Next Steps

Virtual inspections are new to TCEQ and to the regulated community. As such, those participating in inspections require a level of understanding and flexibility while working with TCEQ. Who knows, depending on how effective these virtual inspections are, they very well could become the “new normal.” ALL4 is here as a resource and extension of your environmental department. Before TCEQ inspections, we can perform gap analyses, perform independent third-party compliance audits, or prepare staff members for the upcoming audit. During the inspection we can participate in agency calls to facilitate discussions, track down information, respond to agency inquiries, and organize electronic files and site photos. Now is as good of a time as any to ensure your site is ready for an inspection. If you have questions or need help preparing for a virtual inspection, please reach out to our Houston Office, or me at fdougherty@all4inc.com or 281-937-7553 x302.

TCEQ Now Accepting Applications for TERP Rebate Grants Program

The Texas Commission on Environmental Quality (TCEQ) provides grants to eligible individuals, businesses, and local governments to reduce emissions from vehicles and equipment through the Texas Emissions Reduction Plan (TERP). Some of the TERP programs have been operating since as early as 2001. In the fiscal year 2019, the TERP fund awarded over $77,300,000.

The TERP program is comprised of ten different grant programs:

- Alternative Fueling Facilities Program (AFFP)

- Seaport and Rail Yard Areas Emissions Reduction (SPRY) Program

- Emissions Reduction Incentive Grants (ERIG)

- New Technology Implementation Grant (NTIG) Program

- Rebate Grants Program

- Texas Clean Fleet Program (TCFP)

- Texas Clean School Bus (TCSB) Program

- Light-Duty Motor Vehicle Purchase or Lease Incentive Program (LDPLIP)

- Texas Natural Gas Vehicle Grant Program (TNGVGP)

- Government Alternative Fuel Fleet (GAFF) Grant Program

Applications for grants open at the beginning of each year and close either on a specific date or once funding has been fully awarded. This year, the deadline for applications is at 5:00 p.m. on November 12, 2020. The programs that are still accepting applications as of September 2020 are the: SPRY Program; NTIG Program; LDPLIP Program; TNGVGP; and the GAFF Program.

Program descriptions, eligibility requirements, project applications, form requirements, and example contracts are provided on the TCEQ TERP Website, .

Programs grant that are still available in 2020:

- The SPRY Program – the program is for seaports or Class I Rail Yards in a Texas nonattainment area and can replace older drayage trucks.

- The following counties in Texas are designated as nonattainment areas: Anderson County, Bexar County, Brazoria County, Chambers County, Collin County, Dallas County, Denton County, El Paso County, Ellis County, Fort Bend County, Freestone County, Galveston County, Hardin County, Harris County, Jefferson County, Johnson County, Kaufman County, Liberty County, Montgomery County, Orange County, Panola County, Parker County, Rockwall County, Rusk County, Tarrant County, Titus County, Victoria County, Waller County, and Wise County.

- The NTIG Program – the program is for facilities or stationary sources and for implementing new technologies to reduce pollutant emissions. Eligible project categories include advanced clean energy, new technology (stationary sources), new technology (oil and gas), and electricity storage.

- The LDPLIP Program – the program is for purchased or leased vehicles, in Texas, that qualify as a new light-duty motor vehicle powered by compressed natural gas, liquefied petroleum gas, or hydrogen fuel cells or other electric drives (plug-in or plug-in hybrid). Only vehicles purchased in Texas are eligible for the incentive.

- The TNGVGP Program – the program is for heavy-duty or medium-duty motor vehicles and can be used to repower a vehicle with a natural gas engine or replace the vehicle with a natural gas vehicle. A minimum of $1,000,000 is reserved for TERP Small Businesses, which are businesses operating five or less diesel-powered vehicles or pieces of equipment.

Programs to look for in 2021:

- The AFFP Program – applies in the Clean Transportation Zone and can construct or expand a natural gas or other alternative fuel fueling station. The Clean Transportation Zone covers 83 counties in Texas, mostly in the south and east. Applications are due every March.

- The ERIG Program – applies if you reduce your nitrogen oxides emissions by 25% by replacing or upgrading on-road vehicles, non-road equipment, stationary equipment, marine vessels, locomotives, on-vehicle electrification and idle reduction infrastructure, or rail relocation and improvement projects.

- The Rebate Grants Program – applies for the replacement or upgrade of diesel heavy-duty vehicles and/or non-road equipment. Applications available until funds are fully awarded.

- The TCFP Program – applies for the replacement of heavy-duty or light-duty on-road diesel vehicles with alternative fuel or hybrid vehicles.

- The TCSB Program – applies for reduced emissions from diesel. Applications available until funds are fully awarded.

- The GAFF Grant Program – Applications for the GAFF Grant Program have not yet been made available. Once they are, it applies to those who purchase or lease new motor vehicles that operate primarily on compressed natural gas, liquefied natural gas, liquefied petroleum gas, hydrogen fuel cells, or electricity. Additionally, it applies to refueling infrastructure for grant-funded vehicles.

If the grant program that applies to you has closed this year, be sure to check back in next year in 2021. For more information about the grant application process, visit www.terpgrants.org, call 800-919-TERP (8377) or send an email to terp@tceq.texas.gov, or contact me at (678) 460-0324 ext. 215 or mjones@all4inc.com.

CFATS Regulatory Update

Over the summer, there have been several key developments with regards to the Department of Homeland Security’s (DHS) Chemical Facility Anti-Terrorism Standards (CFATS) program, including a Federal Register Notice, Reauthorization, Personnel Surety Program (PSP) Rollout, and COVID. Read on to see how these developments could impact your facility.

June Federal Register Notice and Potential Impacts

On June 22, 2020, DHS Cybersecurity and Infrastructure Security Agency (CISA) published Federal Register Notice (Vol. 85, No. 120) regarding a retrospective analysis of the data, assumptions, and methodology used to support the 2007 interim final rule for the Chemical Facility Anti-Terrorism Standards (CFATS) program. This analysis reviewed the actual costs of the CFATS program over its first 10 years and determined that the actual cost of the program was about 83 percent lower than the original 2007 estimate. Comments on the retrospective cost analysis were due by September 21, 2020.

Retrospective Analysis

This dramatic overestimation by the 2007 regulatory impact analysis (RIA) was primarily driven by DHS’s uncertainty on two fronts:

- The total number of facilities that would ultimately be affected by the program, and

- The security measures chemical facilities had already put into place prior to the program’s implementation.

Fewer facilities ended up being affected, and more security measures were already in place at affected facilities than CISA initially predicted. As a result, of the originally estimated roughly $9.8 billion the agency expected CFATS to cost, only about $1.7 billion was actually required to implement the program.

Potential Regulatory Outcomes

According to the June 22 Notice, CISA will use the RIA:

- “To improve the accuracy of cost estimates incurred by regulated facilities since 2007;

- as a basis for future regulatory changes to the CFATS program; and

- to perform cumulative impact analysis on the full costs of the program as it evolves.”

Based on discussions with DHS, ALL4 understands that changes in the CFATS program will likely be related to the chemicals of interest (COI) listed in Appendix A to 6 CFR Part 27 and their respective threshold quantities. To date, there have been no changes to the COI list (or to the threshold quantities described therein) since its publication in 2007, less than a year after CFATS first appeared on the Federal Register. Since that time, DHS has gained experience regarding the true threats posed by chemicals onsite at regulated facilities and their threshold quantities.

Although the June 22 Notice does not suggest specific updates to the COI list, future updates to Appendix A could result both in additional facilities becoming “Tiered” CFATS facilities and in additional chemicals at already “Tiered” CFATS facilities becoming “Tiered” COI. To gain insight into what potential changes DHS may propose to Appendix A, ALL4 investigated the development of Appendix A. The Federal Register Proposed Rule 6 CFR 27 (Vol. 71, No. 249, December 28, 2006) listed information to be reviewed by the Vulnerability Assessment (VA) Team as appropriate for determination of critical assets and development of Appendix A, including:

- Regulatory lists of hazardous chemicals, such as Clean Air Act 112(r) list of flammable and toxic substances for the U.S. EPA Risk Management Program (RMP) or the Occupational Safety and Health Administration (OSHA) Process Safety Management (PSM) list of highly hazardous chemicals,

- Inhalation poisons,

- Chemical Weapons Convention list,

- Federal Bureau of Investigation (FBI) Community Outreach Program for Weapons of Mass Destruction materials and precursors,

- The Australia Group list of chemical and biological weapons, and

- Chemicals susceptible to reactive chemistry.

A review of this information against your facility’s chemical inventory may provide insight into how potential changes to Appendix A may affect your facility. DHS may also adjust (increase or decrease) the threshold quantities for chemicals currently listed in Appendix A. Any future changes to 6 CFR Part 27, including Appendix A, would be subject to rulemaking, including a public comment period.

Reauthorization

Following years of Congressional inaction on a reform package for CFATS, the Trump Administration issued a series of short-term extensions to the program between 2018 and 2020, the most recent of which was slated to expire on July 23, 2020. On July 22, one day before the program expired, President Trump signed a reauthorization to extend the current CFATS program by three years.

PSP Rollout

As discussed in our previous article on the CFATS PSP Process, pursuant to Federal Register Notice (84 FR 32768) issued on July 9, 2019, Tier 3 and 4 facilities are being contacted by DHS and notified of the requirement to comply with RBPS 12(iv). DHS is taking a phased approach to the rollout, sending approximately 80 notifications a month beginning in May of 2020. Following notification, a facility will have 30 days to submit an updated Site Security Plan (SSP) or Alternative Security Plan (ASP), indicating how the facility intends to comply with the requirements of RBPS 12(iv). The updated ASP should address the following questions:

- Who does the facility define as an affected person (e.g. persons with access to the COI, all employees, all individuals entering the facility)?

- How will affected individuals be notified of their personally identifiable information (PII) being provided to DHS (such as by letter or in-person)?

- Will the facility update DHS when individuals no longer have access to the COI (e.g. change in job assignment, termination)? (Note: Facilities do not have to notify DHS, but it is recommended)

- Who will safeguard the PII of employees being submitted to DHS (this is typically someone in the Human Resources Department)?

Although no action is required until the facilities have been notified, voluntary participation prior to notification is allowed.

COVID Impacts

Due to complications and travel restrictions related to COVID-19, DHS has postponed over 200 compliance inspections and several authorization inspections. This affects both the format and expected frequency of inspections going forward.

DHS is taking a two-pronged approach to its modified inspections of facilities:

- Remote Documentation Audits – DHS will request that facilities send (typically, electronic) copies of their compliance documentation to their inspector a few weeks prior to the scheduled inspection for review. The inspector may follow-up with questions or request a conference call to review the documentation.

- Modified In-Person Inspection – The inspector will come onsite for a brief inspection of physical security measures, typically avoiding large group conference room settings.

While DHS continues in its aim to inspect Tier 1 and 2 facilities every 12 months and Tier 3 and 4 facilities every 12-18 months, follow-up compliance inspections may be delayed as DHS catches up on postponed compliance inspections. The modified inspection format highlights the importance of having CFATS documentation compiled and ready to send to an inspector. ALL4 recommends that CFATS facilities maintain compliance binders containing CFATS-related procedures, recordkeeping templates, and sample records.

Throughout COVID, DHS continues to visit facilities in need of assistance, and ALL4 recommends that facilities maintain communication with their DHS contacts.

If you have questions regarding CFATS or any of the 2020 developments, please contact Lizzie Smith at lsmith@all4inc.com or at (770)-999-0269.

The Five Ws and How of Delaware’s Proposed Revisions to the Limit of VOC Content in Solvent Cleaning Machines

In May 2019, the Delaware Department of Natural Resources and Environmental Control (DNREC) proposed making numerous revisions to 7 DE Admin. Code 1124 Section 33.0 “Solvent Cleaning and Drying.” These revisions will update control requirements that will reduce the maximum acceptable volatile organic compound (VOC) content for solvents used in cold degreasers. This regulation is under development, but once implemented, has the potential to affect about 1,000 locations in Delaware. Read on to learn more about what these regulatory modifications entail and whether or not your business will be affected.

Who will be affected by the proposed revisions to 7 DE Admin. Code 1124 Section 33.0?

Anyone who owns and operates a solvent cleaning machine in Delaware that contains any amount of VOC material will be subject to Section 33.0. Previously, there was an applicability threshold of one liter of solvent, such that many facilities were not previously subject to the regulation. Now, some of those facilities not previously subject to the regulation will need to comply with Section 33.0. Anyone in Delaware who sells or imports solvents to be used in a solvent cleaning machine that contains any amount of VOC material will be subject to the revised Section 33.0, and will not be permitted to sell or offer for sale any solvent for use in a cold cleaning machine that contains more than 25 grams of VOC per liter. Most revisions to this section will affect cold cleaning machines, also known as cold degreasers. Cold cleaning machines include, but are not limited to, batch cold cleaners and conveyorized in-line cold cleaners. A cold cleaning machine will be defined as “a solvent cleaning machine that contains or uses a non-boiling liquid solvent into which parts are placed to remove soils from the surfaces of the parts or to dry the parts.” In Delaware, users of cold cleaning machines include vehicle sales and servicing locations, machine shops, and manufacturers of electronic, pharmaceutical, and aerospace equipment, just to name a few.

What revisions will be made to 7 DE Admin. Code 1124 Section 33.0?

The most notable proposed revisions to Section 33.0 will be the addition of VOC content restrictions for different types of cleaning machines. The following subsections will be added regarding VOC content:

- 3.7 “VOC requirements for cold cleaning machines”

- 4.5 “VOC requirements for batch vapor cleaning machines”

- 5.4 “VOC requirements for in-line cleaning machines”

- 6.9 “VOC requirements for cleaning machines not having a solvent/air interface”

- 7.5 “VOC requirements for alternative standard”

- 11 “Test Methods”

Each of these sections either specifies a new VOC content restriction or that no VOC restriction will be implemented, depending on the type of cleaning machine.

Where applicable, the VOC content for cleaning solvents will be limited to 25 grams of VOC per liter. There will be exceptions to this limit, which will be specified within the subsections listed above. This limit will set a restriction on VOC content that was not explicitly specified in the previous version of the regulation. Section 33.11 specifically outlines the methodology that is to be used to determine VOC content of materials subject to Section 33.0, as well as the operating parameters of the cleaning machine.

Additionally, there will be two new subsections added under Section 33.1 “Applicability.” These subsections will set new criteria for the types of VOCs in solvent cleaning machines that will be subject to Section 33.0. Proposed Section 33.1.5, for example, states that VOCs will not be separated into categories such as low-vapor pressure (LVP) chemical compounds or mixtures. LVP-VOCs (usually 100% VOC) will not be allowed in cold cleaning machines under the proposed revisions.

There are also several proposed modifications to the definitions in Section 33.2 “Definitions.” Cold cleaning machines and remote reservoir cold cleaning machines will be more specifically defined, and new definitions for idling mode, in-line cold cleaning machines, lip exhaust, and solvents will be added.

Section 33.3 “Standards for batch cold cleaning machines” will see the addition of three new subsections: 33.3.3.9, 33.3.3.10, and 33.3.3.11. These subsections will provide additional requirements for the control and maintenance of batch cold cleaning machines.

There will be other subsections added pertaining to monitoring, recordkeeping, and reporting requirements, such as 33.8.9, 33.9.6, and 33.10.3. Notably, Section 33.10.3 now requires that the owner/operator of a solvent cleaning machine must obtain a signed document specifying the VOC content of the solvent as determined by the test methods outlined in the aforementioned Section 33.11. This new requirement will require you to reach out to your solvent supplier.

Please reference the Draft of Regulation Revisions for a detailed overview of all proposed revisions to Section 33.0.

When will I have to comply with the proposed revisions?

Any new, modified, or reconstructed sources affected by this section must comply with the provisions upon start-up once the revisions become effective. Existing sources will have at least one year to comply once the revisions become effective. Per Section 33.1.3., your facility may have to submit a request to DNREC to amend your existing Title V Operating Permit or 7 DE Admin. Code 1102 permit. ALL4 can help you determine the actions your facility may have to take.

Currently, the regulation is under development. Public workshops were held on January 28 and January 30, 2020 in New Castle, DE and Dover, DE, respectively. The next step for the development of the regulation is a public hearing, which has yet to be scheduled but is anticipated to take place sometime in the 4th quarter of 2020.

Where will the proposed revisions have jurisdiction?

Because the revisions are being proposed in 7 DE Admin. Code 1124 Section 33.0, the affected entities will be located in Delaware, but other federal or local regulations may also apply. The revisions also apply to out-of-state suppliers selling cleaning solvents for use in Delaware.

Why are these proposed revisions taking place?

As presented in the January 28 and 30 public workshops, solvent use in cleaning machines produces VOC emissions, and VOCs contribute to smog. The most recent amendment of Section 33.0 happened on November 1, 2001. The hope is that the proposed revisions will reduce VOC emissions by one ton per day as well as decrease the formation of ground-level ozone in Delaware. The draft of the regulation revisions is based on the Ozone Transport Commission (OTC) Model Rule for Solvent Degreasing 2012. The OTC is an organization created under the Clean Air Act that develops solutions for ozone transport in the Northeast and Mid-Atlantic regions. Other states, such as New York, have already taken action to implement aspects of the OTC Model Rule.

There will also be potential economic benefits to these revisions. Lower emissions can result in lower annual emissions fees. As presented during the January 28 and 30 public workshops, lower VOC solvents can have lower costs associated with disposal, and low-VOC parts cleaners can cost up to $282 less per year than higher-VOC parts cleaners.

How can I prepare for these regulatory changes?

There are several ways to prepare for compliance with these revisions as mentioned during the January 28 and 30 public workshops:

- Explore a water-based cleaning solution that contains no VOC.

- Test your equipment in order to find the solution or particular solvent that is appropriate for your unique process.

- Reach out to your solvent supplier or other solvent users to get their opinions.

- Research the South Coast Air Quality Management District (SCAQMD) list of certified clean air solvents to see what solutions are available for your particular process.

- Stay engaged in the regulation development process by regularly checking the DNREC website for updates on key events.

ALL4 can also help you determine if you will be subject to these new requirements. Contact our team at info@all4inc.com should you have any questions or require additional information regarding the development of this regulation.

What you need to know about NY Rule 222

The State of New York (NY) has been updating its regulations pertaining to distributed generation (DG) sources in recent years in response to the state trying to meet the National Ambient Air Quality Standards (NAAQS). In 2016, the State passed the Distributed Generation Source rule (the rule) for all DG sources in NY known as Rule 222. For reference, a DG source is one that is classified as an economic dispatch source as defined under the rule as “A distributed generation source intended to provide electricity for general use to a building, structure, or collection of structures in place of electricity supplied by the distribution utilities. Demand response and price-responsive generation sources are considered economic dispatch sources. Economic dispatch sources do not include emergency generators or distributed generation sources that provide electricity to power equipment or structures not served by distribution utilities.” That rule placed nitrogen oxides (NOx) and particulate matter (PM) limitations on DG sources 200 horsepower (hp) and greater in the New York City (NYC) metro area and on sources 400 hp and greater in the rest of the state. While NOx emission limits varied by source type, as highlighted below, only PM emissions from DG sources firing diesel fuel were regulated with a PM emissions limit of 0.30 grams per brake horsepower-hour or an air pollution control device requirement to remove 85% or more of the PM from the exhaust stream.

The 2016 rule set forth a 2.3 grams per brake horsepower-hour NOx limit for economic dispatch reciprocating engines firing distillate oil and a 1.5 grams per brake horsepower-hour limit for economic dispatch reciprocating engines firing natural gas. In addition, those DG sources were to be registered or permitted as necessary and perform stack air emissions tests to demonstrate compliance by May 1, 2017. There was also a limitation that prevented maintenance and testing during the hours of 1pm to 8pm during the ozone season of May 1 through September 30. DG sources were expected to comply with the limits by May 1, 2017.

The rule was challenged in the Supreme Court of the County of Albany by seeking a preliminary injunction on March 1, 2017. As a part of those proceedings, the parties agreed to stay the implementation and enforcement of the rule pending the Court’s decision. As a result, the State promulgated a new Distributed Generation rule to replace the older rule that addresses only DG sources that meet the following criteria:

- Located in the NYC metro area (emissions limits for the rest of the state are no longer included).

- Located at a facility where the potential to emit for NOx is less than the major source threshold of 25 tons per year (tpy).

- Rated 200 hp or greater.

- Enrolled in demand response programs or price-responsive generation sources.

These sources must obtain a registration/permit if required and notify the New York Department of Environmental Protection (NYDEP) of the intent to operate as a DG source by March 15, 2021 or 30 days prior to operating as an economic dispatch source, whichever is later. The new rule removes the PM requirement set forth in the 2016 rule and focuses on regulating NOx emissions. Effective May 1, 2021, owners/operators of DG sources must meet revised NOx limits, which are lower than the 2016 rule limits for engines older than model year 2000.

Effective May 1, 2021, owners or operators of economic dispatch sources subject to this Part must comply with the following requirements:

(1) combustion turbines firing natural gas: must be of model year 2000 or newer or must have a NOx emission rate less than or equal to 2.96 pounds per megawatt-hour as certified in writing by a professional engineer;

(2) combustion turbines firing oil: must be of model year 2000 or newer or must have a NOx emission rate less than or equal to 2.96 pounds per megawatt-hour as certified in writing by a professional engineer;

(3) compression-ignition engines: must be of model year 2000 or newer or must have a NOx emission rate less than or equal to 2.96 pounds per megawatt-hour as certified in writing by a professional engineer;

(4) lean-burn engines: must be of model year 2000 or newer or must have a NOx emission rate less than or equal to 2.96 pounds per megawatt-hour as certified in writing by a professional engineer; or

(5) rich-burn engines: must be equipped with three-way catalyst emission controls.

In addition, the new rule sets forth even more stringent standards for compression-ignition engines firing distillate oil and spark ignition engines firing natural gas beginning May 1, 2025 with lower NOx limitations and the removal of the model year method of compliance:

(1) combustion turbines firing natural gas: 25 parts per million on a dry volume basis corrected to 15 percent oxygen;

(2) combustion turbines firing oil: 42 parts per million on a dry volume basis corrected to 15 percent oxygen;

(3) spark ignition engines firing natural gas: 1.0 grams per brake horsepower-hour;

(4) compression-ignition engines firing distillate oil (solely or in combination with other fuels) with nameplate ratings less than 750 horsepower: 0.30 grams per brake horsepower-hour; or

(5) compression-ignition engines firing distillate oil (solely or in combination with other fuels) with nameplate ratings greater than or equal to 750 horsepower: 0.50 grams per brake horsepower-hour.

Under the new rule, emissions testing is required to demonstrate compliance with the emissions limits that take effect on May 1, 2025. Engines participating in DR programs on or after May 1, 2025, must submit test reports demonstrating compliance with the standards prior to operating.

With this recent change, many DG sources will need to add air pollution control equipment in order to meet the more stringent NOx emission limitations for spark ignition and compression ignition engines firing distillate oil or natural gas. In some cases, it may be necessary to install new, cleaner engines to comply, as pollution control devices installed to comply with the 2016 rule may not be able to meet the new rule limits. In addition, there are registration and permitting requirements as well as recordkeeping requirements for these sources. To find out more about this rule or get assistance in determining how your facility is affected by the rule, please contact ALL4 at info@all4inc.com or call 610-933-5246.

Marine Loading Readily Available Permit (RAP)

The Air Permits Division of the Texas Commission on Environmental Quality (TCEQ) released a new Readily Available Permit (RAP) for Marine Loading operations on June 4, 2020. A RAP is a type of New Source Review (NSR) permit created by the TCEQ for specific types of operations. RAPs help streamline permit applications for specific operations to create an efficient permitting process. RAP applications are generally less expensive than case-by-case NSR applications and take less time to receive a permit; however, they often contain special conditions that might not otherwise apply to the facility.

About the Marine Loading RAP

The Marine Loading RAP can authorize emissions from storage tanks, loading, control devices, combustion units, fugitives, and Maintenance, Startup, and Shutdown (MSS) activities as an amendment to an existing permit or for an initial permit. The following sources can be covered by the Marine Loading RAP:

- Up to five storage tanks

- Loading operations

- Drum/tote

- Rail

- Non-inerted marine vessel

- Inerted marine vessel

- Truck

- One elevated flare

- One Vapor Combustion Unit (VCU)

- One vapor oxidizer

- One Carbon Adsorption System (CAS)

- Up to two emergency diesel engines

- Up to two heaters/boilers

- Fugitive emissions

- MSS activities

- Temporary emissions control units:

- One temporary flare

- One temporary VCU

- One temporary Thermal Oxidizer (TO)

To apply for the Marine Loading RAP, the following documents must be included in the application:

- Core Data Form (if needed)

- TCEQ’s “RAP: Marine Loading Workbook”

- Required documentation listed in section III of the instructions tab in the RAP: Marine Loading workbook including but not limited to:

- Core Data Form (if needed)

- Process Flow Diagram (PFD)

- Plot Plan and Area Map

- RAP: Marine Loading Application Workbook

The restrictions for the Marine Loading RAP include, but are not limited to:

- The application only includes emissions sources located in TCEQ Regions 10, 12 ,14, or 15

- The application must include project modified or affected sources

- No increases to actual or potential emissions rates for sources authorized outside the RAP are authorized

- The project’s emissions must not exceed Prevention of Significant Deterioration (PSD) or Nonattainment major source thresholds

- The application cannot include crude carriers with greater than or equal to 2.0 million bbl carrying capacity

For a complete list please visit section II of the instruction tab in the RAP: Marine Loading workbook.

Should I Apply for a Marine Loading RAP?

Depending on specific situations, it can be advantageous to apply for the Marine Loading RAP instead of going through the “normal” NSR case-by-case permitting process. The Marine Loading RAP is a great tool that can be utilized to streamline the permitting process for marine loading facilities. However, there are a few questions to consider as part of your decision.

- Is there a Permit By Rule (PBR) that can cover the emissions?

- If units/emissions can be covered under a PBR, it is recommended to go down that route to further decrease cost and permitting time.

- Are there any special conditions that would otherwise not apply to the facility that I am unwilling to accept?

- The special conditions are located in the tab titled “CND” in the RAP: Marine Loading workbook. For this specific RAP, the special conditions do not seem to ring any alarms, but you should read through these to confirm your specific facility can comply with no issues.

For more information or if you have any questions regarding this blog, please reach out to our team at info@all4inc.com or 281-937-7553.

Meet Meghan Skemp

Meghan Skemp // Project Manager // Houston Office

What three words would your coworkers use to describe you?

Outgoing, diligent, and driven.

What inspired you to become an environmental consultant?

During my Engineering Technical Communications course at Vanderbilt University, my professor, Dr. Julie Sharp introduced me and my classmates to the consulting world and how a people person can in fact be fulfilled in an engineer role. I was so inspired by her class that after graduation I’d routinely go back as a guest speaker to Dr. Sharp’s classes to provide an overview of environmental consulting to her classes. I offered insight into the types of roles available to engineering students that were not only technical but also forward facing on the people side.

Which of ALL4’s CORE values most resonates with you Ownership/Accountability/Authenticity/Culture and why?

Definitely ‘authenticity’! Too much needless energy gets wasted if you cannot be yourself each day, both personally and professionally.

Best career advice you ever received that you’d pass along to others?

To my younger self I would say “Attention to details matters!” Always make time to incorporate a QA step into proofing your work. To my older self: “Sometimes you just have to let stuff go!” – this has allowed me to remove obstacles in the way in order to focus on what really matters.

Favorite thing about working at ALL4?

Definitely the people.

What skills have you developed over the years that has served well in your career?

Being organized and time management. One currently under development is getting better at rolling with the punches and adapting to our everchanging world.

Any unexpected upsides during the pandemic?

A few things come to mind…the amount of quality time spent with my family (even when my kids pop up in video calls from time to time), being more intentional in sitting down for family meals, and making more home cooked/healthy meals. That being said, frozen pizza night has not been eliminated from the line up!

What are some binge-worthy shows currently on your radar?

Yellowstone and The Sopranos (again) for me and my husband, and Wild Kratts or any movie on Disney+ for Family Movie Night with the kiddos.

To learn more about Meghan, please visit her profile. You can connect with her on LinkedIn, or reach her at mskemp@all4inc.com // 281.937.7553 x307

New York State Proposed Particulate Matter Emission Limits – Could they Affect your Facility?

In October 2019, the New York State Department of Environmental Conservation (NYSDEC) proposed to revise the particulate matter (PM) emissions limits in Title 6, Part 227-1 of the New York Codes, Rules and Regulations (6 NYCRR 227-1) for stationary combustion installations. If promulgated as proposed, the revisions could trigger the installation of advanced emissions control equipment for fuel burning equipment such as biomass-fired boilers (biomass boilers). 6 NYCRR 227-1 was last changed in 1971 and the proposed revisions are likely to be finalized near the end of September 2020. The revisions are intended to help maintain the National Ambient Air Quality Standards (NAAQS) for PM and to meet regional haze requirements that will be incorporated into New York’s State Implementation Plan (SIP).

KEY CHANGES TO THE RULE

1. Revised PM Emissions Limit. The PM limits in the current rule vary by the heat input of the stationary combustion installation. For example, the PM limit for a biomass boiler with a rated heat input of 30 million British Thermal Units of heat input per hour (MMBtu/hr) is 0.42 pounds of PM per MMBtu of heat input (lb/MMBtu) and the PM limit for a biomass boiler rated at 10 MMBtu/hr is 0.60 lb/MMBtu of heat input. The proposed rule revises these and other PM emissions limits downward to 0.10 lb/MMBtu of heat input for stationary combustion installations with a maximum heat input capacity equal to or greater than:

a. 1 MMBtu/hr firing any amount of solid fuel (such as biomass); or

b. 50 MMBtu/hr firing oil or oil in combination with other liquid or gaseous fuels.

The emissions limit does not apply if a more stringent Federal emissions limit applies. This is regardless of whether the stationary combustion installation is located at a Major Source or Area Source of Hazardous Air Pollutant (HAP) emissions. Consider a new biomass boiler having a heat input equal to or greater than 10 MMBtu/hr and less than 30 MMBtu/hr, to be located at an Area Source of HAP emissions, and Subject to 40 CFR Part 63, Subpart JJJJJJ (National Emission Standards for Hazardous Air Pollutants for Industrial, Commercial, and Institutional Boilers Area Sources). The new boiler would be required to meet a filterable PM limit of 0.07 lb/MMBtu and would therefore have to meet the lower and more stringent, Federal limit.

2. Aggregation of Combustion Sources. The proposed rule requires facilities to aggregate the heat input of stationary combustion installations that share the same stack unless there is an air permit requirement prohibiting simultaneous operation of the stationary combustion installations. For example, the PM limit of 0.10 lb/MMBtu would apply if a facility was currently operating or planning to install and operate two identical biomass boilers rated at 0.5 MMBtu/hour each that operated simultaneously and shared the same stack.

3. Performance Testing. The proposed rule requires facilities to perform an initial compliance test to measure filterable PM via U.S. EPA Test Method 5 within six months of commencing operation of a new affected stationary combustion installation and within two years of the promulgation date of the rule change for an existing affected stationary combustion installation.

4. Monitor Visible Emissions. The proposed rule requires facilities to demonstrate compliance with opacity standards using a Continuous Opacity Monitoring System (COMS), U.S. EPA Test Method 9 visible emissions observations, or “testing with any other credible evidence.”

5. Fuel Sulfur Requirements. There are some affected stationary combustion installations that have fuel sulfur requirements under the rule. Depending on the heat input capacity, stationary combustion installations firing oil or oil in combination (with other liquid or gaseous fuels) must keep vendor certified fuel receipts with the sulfur content complying with 6 NYCRR Subpart 225-1.

WHY IS THIS IMPORTANT?

While the proposed revisions will presumably help reduce PM emissions released into the atmosphere, they could trigger additional compliance costs for existing and proposed facilities. For example, existing biomass boilers equipped with cyclone technology for PM control, may have to install more effective PM control equipment such as an Electrostatic Precipitator (ESP) to meet the proposed emissions limit of 0.10 lb/MMBtu. According to the NYSDEC regulatory impact summary, adding an ESP to a 10 MMBtu/hr biomass boiler could initially cost $60,000 to $175,000 and have operating costs of $1,000 to $3,000 per year. In addition, facilities will incur the cost of performance testing which could range from $5,000 to $10,000 for a Method 5 test for one stationary combustion installation. However, the proposed rule does not include provisions for evaluating the economic feasibility of pollution control equipment.

If you have any questions about Part 227-1 changes, please reach out to John Hinckley at jhinckley@all4inc.com or by phone at (610) 422-1178.

What the Final Policy and Technical Amendments to 40 CFR Part 60, Subparts OOOO and OOOOa Mean for the Oil and Gas Industry

On August 13, 2020, the U.S. Environmental Protection Agency (U.S. EPA) issued final policy and technical amendments to 40 CFR Part 60, Subparts OOOO (Standards of Performance for Crude Oil and Natural Gas Production, Transmission and Distribution for Which Construction, Modification or Reconstruction Commenced After August 23, 2011, and on or Before September 18, 2015) and OOOOa (Standards of Performance for Crude Oil and Natural Gas Facilities for which Construction, Modification, or Reconstruction Commenced after September 18, 2015). ALL4 had previously discussed the proposed amendments to Subpart OOOOa in length in a separate article here: U.S. EPA Proposed Amendments to 40 CFR Part 60, Subpart OOOOa. For this article, we focus on the finalized policy and technical amendments that are intended to provide clarity and simplify the compliance requirements for the affected oil and gas (O&G) industry. The final rule, generally welcomed by the industry[1], reflects both technical and legal amendments. The remainder of this article discusses specific rule revisions.

Removal of the Transmission and Storage Segment

In the final policy amendment, U.S. EPA determined that it had erred in earlier versions of the rule and that it was not appropriate to include the transmission and storage segment as one of the source categories in the 2012 and 2016 NSPS rules. As a reminder, Subpart OOOOa regulated sources in the following industry segments:

- Extraction and production

- Natural gas processing

- Natural gas transmission and storage

- Natural gas distribution

As a result of the final amendments, all the rule requirements [e.g., methane and volatile organic compound (VOC) standards] have been rescinded from sources that fall under the transmission and storage segment in the O&G industry. Typical sources found in the transmission and storage segment may include, but are not limited to, compressors, storage vessels, fugitive emissions components, and pneumatic controllers. As of the effective date of the amended rules, which will go into effect when the final amendments are published in the Federal Register, compliance requirements [e.g., leak detection and repair (LDAR) surveys] at transmission stations will no longer apply. However, some states have proposed or promulgated state specific O&G regulations that retain such requirements.

Removal of Methane Specific Requirements

The final policy amendment rescinds the methane emissions requirements but retains requirements for VOC for sources found in the production and processing segments. Although methane limits were removed in the final rule, U.S. EPA asserts that methane emissions will continue to be reduced in the production and processing segments because required controls that reduce VOC emissions also result in the reduction of methane emissions.

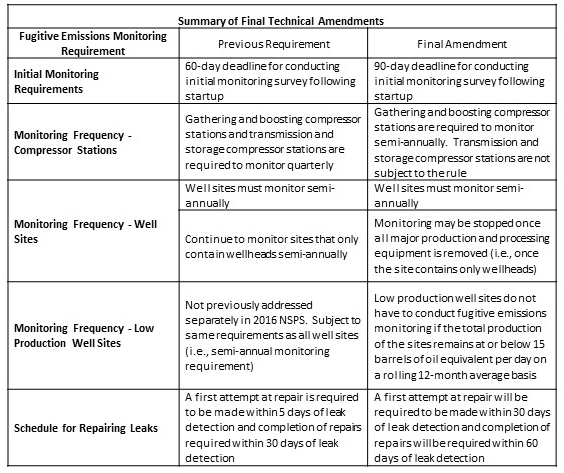

Fugitive Emissions Monitoring Revisions

The final rule also allows owners and operators to determine the best means for monitoring fugitive emissions components and relaxes the LDAR monitoring plan requirements (i.e., a site map with an outlined observation path is no longer required). Additionally, the final version of Subpart OOOOa relaxes the fugitive emissions monitoring aspects as summarized in the table below:

The final amendments also clarified that natural gas processing plants must comply with equipment leaks standards no later than 180 days after initial startup of a new, modified, or reconstructed process unit and established that equipment that operates less than 300 hours per year is exempt from VOC monitoring requirements.

[1] Several major oil companies including ExxonMobil, Shell, Equinor, and Total are on record as not being entirely on board with the revisions citing a need to regulate methane directly, maintenance of a federal regulatory ‘floor’ that provides a consistent, flexible, predictable, and comprehensive policy framework, and the possibility of the revisions undermining actions that have already taken to address climate change risk.

State Programs and Alternative Means of Emissions Limitations and Use of Emerging Technology

The final technical amendments incorporate certain existing State programs (i.e., fugitive emissions monitoring, leak repair, and recordkeeping requirements) as an alternative to meeting Federal fugitive emissions monitoring requirements for individual well sites and/or compressor stations. Owners and operators of well sites and/or compressor stations in California, Colorado, Ohio, Pennsylvania, Texas, and Utah (with exceptions) can comply with equivalent State specific programs to comply with Subpart OOOOa.

U.S. EPA also streamlined application requirements for using alternative means of emissions limitations (AMEL) and the use of emerging technology. The final rule allows any person to apply for an AMEL (i.e., AMEL applicants can work with manufacturers, vendors, or trade associations) to incorporate the use of emerging technologies.

Pneumatic Pump Revisions

The final rule expands existing Subpart OOOOa exemptions to cover pneumatic pumps at any well site. The original exemption only covered “non-greenfield” or existing well sites. A professional engineer (P.E.) or an in-house engineer may certify that a well site is exempt from control requirements if it is determined that it is technically infeasible to route emissions from a pneumatic pump to a control device. The final rule also allows owners and/or operators to demonstrate that closed vent systems associated with pneumatic pumps are operating with no detectable emissions by using the following practices:

- An annual inspection using U.S. EPA Method 21

- A monthly audio/visual/olfactory (AVO) inspection or;

- Optical gas imaging (OGI) monitoring at the frequencies specified in Subpart OOOOa for fugitive emissions monitoring

Revisions to Certification Requirements

As discussed above, Subpart OOOOa now allows both P.E. and in-house engineers to make certifications pertaining to the technical infeasibility of routing methane and VOC emissions from pneumatic pumps to existing controls or processes. It also allows both positions to certify that the design and capacity of a closed vent system is sufficient enough to route emissions to a control device from affected facilities.

Storage Tank Revisions

U.S. EPA clarified how to calculate potential VOC emissions for storage tanks to determine if Subpart OOOOa rules apply to potentially affected facilities. The final rule also establishes criteria for calculating emissions from individual storage tanks that are part of a controlled tank battery. If potential VOC emissions from an individual tank are greater than six tons per year (tpy), the tank is subject to Subpart OOOOa. The six tpy limit also applies to tanks in a battery configuration (i.e., the combined emissions from the tank battery may not exceed six tpy). If VOC emissions from the tank battery configuration exceed six tpy then all the tanks in the battery are subject to Subpart OOOOa.

Pre-publication versions of the final rule can be found here: Actions and Notices about Oil and Natural Gas Air Pollution Standards. If you have questions about how this finalized rule could affect your operations, or what your next steps should be, please reach out to our team at info@all4inc.com.