What’s Your One Thing?

We recently held some small group feedback discussions at ALL4. These types of discussions are routinely held with the goal to provide our leaders an opportunity to hear what’s working well within the organization, and what’s not. Employees are encouraged to be open, honest, and authentic. Core to our culture is having the humility to know we don’t always get everything right, knowing there is always room for improvement (even on things that are working well), and allowing employees to have a voice along with a forum within the organization to be in contribution.

Since one of my responsibilities is leading ALL4’s “Best-in-Class” program, I was particularly keen on garnering feedback as it pertained to ALL4’s “perks” and “recess activities” offered to employees. ALL4 “perks” include things like complimentary snacks and drinks, catered lunches, on-site chair massages, and manicures, and “recess activities” are events hosted over lunch or after work like mini golf, cornhole, escape room, or a happy hour. The overwhelming sentiment amongst employees was while all of these “perks” and “recess activities” are appreciated, there was clearly one thing that was consistently at the top of employees’ lists as most valued: “The people I work with.” Having colleagues who are supportive and respectful, and “who you actually like”, is not as common in the workplace as one would think.

You may have seen recently that ALL4 was the proud recipient of Inc. Magazine’s Best Workplaces 2018 designation. This is a big deal since less than 20% of the 1,800+ firms that competed were recognized. Within that recent employee satisfaction survey, support for the one thing sentiment was highlighted in responses to two of the questions that 100% of ALL4 employees agreed upon: “the people I work with treat each other with respect” and “co-workers will go the extra mile to achieve great results.” This has been a good reminder to me that the most basic courtesies at work, like being nice and respectful, go a long way. Even more importantly, that ALL4’s core value of “investing in others” is not just who we want to be, but who we are.

Bottom line – the simple things mean a whole lot more to employees than trying to create the next bigger, better, brighter “perk” or “recess event.” Thank you ALL4 employees for this great reminder!

U.S. EPA Proposes Affordable Clean Energy (ACE) Rule

This article is available as a podcast episode on ALL4’s Air Quality Insider

On August 21, 2018, the United States Environmental Protection Agency (U.S. EPA) proposed a pre-publication version of the Affordable Clean Energy (ACE) rule to serve as a replacement to the Clean Power Plan (CPP). The proposed ACE rule is technically directed to individual states; however, it is important for the power industry to be familiar with its proposed terms, as its provisions will inform what individual states include in their future state plans.

As was the case with the historic CPP, U.S. EPA defines in the proposed ACE rule what would be a nationally applicable Best System of Emissions Reduction (BSER) and further provides the following to states:

- Emissions guidelines which clarify the roles of U.S. EPA and the states under Clean Air Act (CAA) §111(d), where states have the authority and responsibility to establish and apply existing source standards of performance in their state plans that are consistent with what U.S. EPA defines as BSER to their electric generating units (EGUs). Under the proposed ACE rule, the states have broad discretion in establishing and applying emissions standards that are consistent with the BSER.

- A new preliminary major New Source Review (NSR) applicability test for determining whether a change to an EGU could constitute a modification for the purposes of major NSR applicability.

- A list of candidate technologies that states can use when developing their state plans.

The ACE rule provisions are currently proposed at the following locations within the Code of Federal Regulations (CFR):

- 40 CFR Part 51, Subpart I (Requirements for Preparation, Adoption, and Submittal of Implementation Plans – Review of New Sources and Modifications)

- 40 CFR Part 52, Subpart A (Approval and Promulgation of Implementation Plans – General Provisions)

- 40 CFR Part 60, Subpart Ba (Standards of Performance for New Stationary Sources – Adoption and Submittal of State Plans for Designated Facilities)

- 40 CFR Part 60, Subpart UUUUa (Emission Guidelines for Greenhouse Gas Emissions and Compliance Times for Electric Utility Generating Units)

Insights and Implications

At this point you are likely wondering if your EGU could be impacted by the proposed ACE rule and how. The EGUs that U.S. EPA is proposing be addressed in a future state plan are any fossil fuel-fired electric utility steam generation units that are not integrated gasification combined cycle (IGCC) units in operation or had commenced construction as of the publication date of the rule that meet the following criteria:

- The unit must serve a generator capable of selling greater than 25 MW to a utility power distribution system, and

- The unit must have a base load rating greater than 250 MMBtu/hour (260 GJ/hour) heat input (either alone or in combination with any other fuel).

Takeaways:

- The proposed ACE rule does not impose an overall GHG cap. The focus on BSER shifts the approach to a plant-specific emissions reduction strategy ultimately providing more autonomy to the states.

- The proposal includes a proposed amendment to the Federal NSR rules that would allow an “hourly” emissions increase test specifically for EGUs. While technically not an exemption from NSR, facilities could avoid triggering major NSR based on the results of the hourly increase test. Historical interpretation and precedent is that air pollution control projects are not automatically eligible for exemption under NSR regulations and must be evaluated considering emissions increases related to the project.

- Timing of rule implementation is uncertain. It is dependent upon the outcome of the public comment period and technical considerations that are raised. To allow time to address comments, it is likely that the proposal will require at least 6-12 months to be finalized.

U.S. EPA will take comments on the proposed rule for 60 days after its publication in the Federal Register and will hold at least one public hearing. States will have three years from the date of the final rule to prepare and submit state plans that establish a standard of performance. U.S. EPA will then have 12 months to evaluate each state plan. Please check back regularly for further posts about the proposed ACE rule. If you have any questions in the meantime, please feel to reach out to me at 610.933.5246 x131 or mmchale@all4inc.com.

New Mexico GCP-1 and GCP-4 Permittees: Are You Eligible for GCP-O&G?

On April 27, 2018, the New Mexico Environmental Department (NMED) issued a new General Construction Permit for Oil and Gas Facilities (GCP-O&G). General Permits cover sources that are similar in terms of operations, processes, and emissions and subject them to a fixed set of conditions. While general permits require public notice postings at the facility site and in newspapers, they do not require public review and have faster agency turnaround (up to 30 days from receipt of an application). The GCP-O&G replaces two existing permits: General Construction Permit for Level One Oil and Gas Installations (GCP-1) and General Construction Permit for Combustion Sources and Related Equipment (GCP-4). NMED is no longer accepting applications for revisions to GCP-1 or GCP-4 permits. Within nine months of the GCP-O&G issue date (i.e., by January 27, 2019), all current GCP-1 and GCP-4 permit holders must inform NMED of their intent to either transition to GCP-O&G, if eligible, or obtain a regular Part 72 permit. A regular Part 72 permit requires the preparation of an application pursuant to 20.2.72.203, full public notice, and possibly ambient air quality dispersion modeling. Issuance of a regular permit also takes longer than a General Permit, with a turnaround of up to 120 days. The fees and public notice requirements associated with registering under GCP-O&G are waived for those transitioning from GCP-1 and GCP-4. Once informed of a facility’s intent to transfer, NMED will issue the facility an application deadline for the elected permitting path.

The GCP-O&G permit is generally less restrictive than GCP-1 and GCP-4. However, it also reflects several new restrictions. Regardless of whether a facility is transitioning from an existing permit or newly applying, this article will help to determine if your facility is eligible for the GCP-O&G.

You are not eligible for the GCP-O&G if:

- Your facility is located in Bernalillo County, tribal lands, non-attainment areas, or the City of Sunland Park.

- Your facility includes a petroleum refinery, chemical manufacturing plant, flare pits, bulk gasoline terminal, or any source listed in Table 1 of 20.2.74.501 NMAC (Prevention of Significant Deterioration Source Categories).

Because it is a replacement of GCP-1 and GCP-4, GCP-O&G includes equipment covered under the two previous permits. It also includes the following additional equipment:

- Generators (driven by engines and turbines)

- Vapor recovery towers (VRT)

- Ultra-low pressure separators (ULPS)

- Blowcase vessels

- Pneumatics

- Compressors

GCP-O&G removes the “four-engine-and-turbine limit” of the two previous permits, as long as all engines and turbines comply with minimum stack parameters. Unlike GCP-1 and GCP-4, which imposed hard restrictions on stack height, GCP-O&G allows for varying minimum stack heights. The minimum heights are calculated based on temperature, velocity, diameter, and total facility NOX emissions.

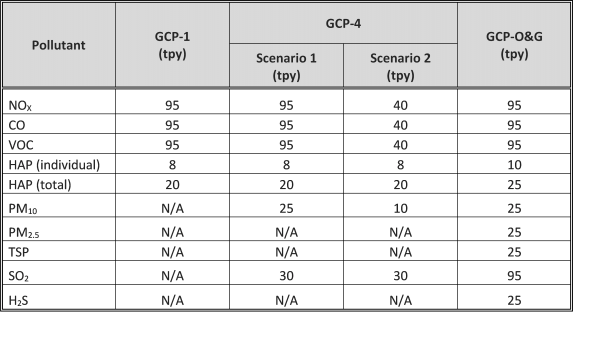

The following table summarizes the differences in facility-wide maximum eligible emissions rates between GCP-1, GCP-4, and GCP-O&G:

Note that the maximum eligible emissions rates allowed by GCP-O&G only determine whether your facility is qualified to apply for GCP-O&G and may not reflect a facility’s emissions limits under the permit. Note, also, that there are source-specific emissions, monitoring, recordkeeping, and reporting requirements that apply, as well as other general requirements related to operating hours and fuel restrictions. This blog post is intended only to be a general overview of the eligibility changes introduced by GCP-O&G. Please refer to the complete permit document for the full breakdown of requirements.

Still unsure if your facility is eligible to operate under GCP-O&G? Wondering what you can do before January 27, 2019 to become eligible? Have questions about the transition process? ALL4 would love to discuss it with you! Contact me at 610.933.5246, extension 173, or at jmartin@all4inc.com.

U.S. EPA’s Recent Round of ADI Updates and Key Takeaways

This article is available as a podcast episode on ALL4’s Air Quality Insider

The United States Environmental Protection Agency (U.S. EPA) intermittently publishes Federal Register notices announcing updates made to the Applicability Determination Index (ADI). The ADI is a database containing notices that determine applicability and compliance with the New Source Performance Standards (NSPS), National Emissions Standards for Hazardous Air Pollutants (NESHAP), and chlorofluorocarbons (CFC). We discussed ADI’s last year in our 4 The Record Article: “U.S. EPA’s Recent Interpretations on Refinery Rule Alternative Monitoring Plans: Helping Pave a Path to Facilitate Your Facility’s Compliance“. The most recent summary from U.S. EPA contained 54 new determinations and was released on May 16, 2018. While a large variety of topics are covered in the ADI, it is often wise to do a quick scan of the determinations to gather an idea of what types of requests are being made and where U.S. EPA’s decisions fall on these matters. I noticed many of the submissions regarded the approval of alternative monitoring petitions (AMP), often centered on the feasibility of continuous monitoring systems (CMS), replacing calibration gasses, and wet versus dry basis concentration monitoring.

Alternate Monitoring Petitions for Atypical Operation Periods

Keeping with a theme seen in the 2017 ADI update, several of the ADI Determinations were requests for U.S. EPA approval of an AMP for monitoring airborne chemical concentrations during infrequent and short-term operations. Examples of these would be degassing, cleaning, and maintenance activities.

- Numerous refiners1 subject to Subpart 40 CFR Part 60, Subpart J (Standards of Performance for Petroleum Refineries) and 40 CFR Part 60, Subpart Ja (Standards of Performance for Petroleum Refineries for Which Construction, Reconstruction, or Modification Commenced After October 14, 2011) were successful in receiving AMP approval to not install the hydrogen sulfide (H2S) and sulfur dioxide (SO2) continuous emissions monitoring system (CEMS) for fuel gas combustion devices for temporary and portable thermal oxidizer(s) or flare(s). U.S. EPA recognized the impractical nature of installing CEMS on thermal oxidizers used for intermittent operations such as tank degassing and other operations that use a temporary and portable thermal oxidizer for the purposes of volatile organic compound (VOC) destruction. U.S. EPA denoted that because the thermal oxidizers are temporary and portable it was economically infeasible and technically impractical to install CEMS for H2S or SO2 monitoring.

In each instance, U.S. EPA approved substituted monitoring measures (e.g., colorimetric stain tubes for determination #1700023) that can be completed before or during the operation of the short-term equipment. One important thing to note is that the approved AMP expires on the effective date of any changes U.S. EPA makes to the pertinent Federal code.

Calibration Gas Safety

U.S. EPA fielded several requests for the replacement of calibration gasses with those of lower concentrations. Multiple refiners2 subject to Subpart Ja and 40 CFR Part 60, Subpart A (General Provisions), received approval for alternative Quality Assurance/ Quality Control (QA/QC) requirements to eliminate the daily use of potentially dangerous high concentration calibration gases on a routine basis because of safety concerns. These requests were in regard to daily calibration checks and cylinder gas audits (CGAs), and the U.S. EPA approved AMPs with modified high-level concentrations for those two tests. As was the case in 2017, most of the AMPs were conditionally approved with occasional testing of high concentration calibration gas being required, often on a three-year basis. Most of our avid readers will recognize this is yet another continued trend in U.S. EPA determinations from previous summaries.

Wet basis vs. Dry basis Continuous Monitoring

The final theme I noticed was the inclusion of determination submissions surrounding the substitution of wet basis continuous emission monitoring system (CEMS) data for dry basis values required by Federal codes. In several instances, this methodology was approved. Requests to monitor minimum percent oxygen gas (% O2) limits using wet basis CEMS during startup and shutdown were unconditionally approved3. The reason for these AMPs was the potential disruption of analyzer that dry basis measurement presents. Both requests were justified by expressing concerns with catalyst fines plugging the analyzer, resulting in greater downtime. U.S. EPA allowed wet basis concentration to be substituted when minimum % O2 was in question, as wet basis oxygen concentration will always be lower. As such, if wet basis % O2 passes, dry basis would pass.

In more complex situations, it was requested that wet basis measurements of gas concentrations be submitted for dry basis, using moisture factors and U.S. EPA approved equation. An interesting case study of this can be seen comparing ADI #’s 1700019 and 1700034. In both circumstances, the applicant was requesting an alternative wet basis monitoring method. Both applicants requested the ability to make the conversion from wet to dry-basis using a static moisture factor. U.S. EPA noted that Performance Specification 2 of Appendix B to Part 60 allows data to be monitored on a dry basis or be corrected to a dry basis using continuously monitored moisture data. For this reason, ADI #1700019 was denied. However, ADI #1700034 was approved under very specific conditions laid out by U.S. EPA. The facility was given roughly half of a year to use the requested approach while a dry-basis CEMS was being installed to monitor O2 and SO2 concentrations. This is important to know for any clients looking to use an alternative monitoring method on a temporary basis until the proper systems can be installed.

A review of U.S. EPA’s yearly ADI update is an effective method for staying informed of recent regulatory determinations that affect your industry. This review of the determinations can provide information to use when requesting an applicability determination from U.S. EPA, providing insights that may lead to a higher likelihood of success. The requested approvals may also provide potential solutions that your facility hasn’t considered for demonstrating compliance. You can always reach out to ALL4 to discuss recent determinations and interpretations. ALL4 regularly assists clients in tracking regulatory changes including U.S. EPA determinations and interpretations. Our goal is to keep the regulated community informed and to maintain our own knowledge base so that we can assist our clients with optimum compliance strategies. If you have any questions, feel free to reach out to me at 610.933.5246 x172 or email at mgray@all4inc.com.

1ADI Control Numbers 1700021, 1700025, and 1700035

2ADI Control Numbers 1700020 and 1700027

3ADI Control Numbers M170014 and Z17003