Further Delay of Implementation of Certain NSPS Subpart OOOOa Requirements

On June 5, 2017, the U.S. Environmental Protection Agency (U.S. EPA) granted reconsideration and stayed the effectiveness of certain fugitive emissions, pneumatic pump, and Professional Engineer (P.E.) certification requirements of 40 CFR Part, 60 Subpart-OOOOa Standards of Performance for Crude Oil and Natural Gas Facilities (Subpart OOOOa) until August 31, 2017. Less than two weeks later, U.S. EPA proposed to further extend these stays. In two separate Federal Register (FR) notices published on June 16, 2017, U.S. EPA is proposing the following:

- A stay of two years beyond August 31, 2017 for the requirements mentioned above. The intent of the two-year stay is to provide U.S. EPA with sufficient time to propose, accept comment, and issue permanent changes to Subpart OOOOa

- An additional 3-month stay that would be effective immediately upon publication to the FR because it would not be considered a major rule change. Since the two-year stay is expected to be considered a major rule under the Congressional Review Act, it cannot become effective immediately upon publication to the FR. To avoid a potential gap between the current 2-month stay that was issued on June 5, 2017 and the finalization of the proposed 2-year stay, U.S. EPA is proposing this additional 3-month stay.

We believe more changes are in store for Subpart OOOOa beyond those addressed in the current stays. ALL4 will continue to track these changes and will provide updates our blog and newsletter, accordingly. In the meantime, if you have questions regarding your current obligations under Subpart OOOOa, contact Roy Rakiewicz at 610.933.5246 x127, or rrakiewicz@all4inc.com.

Boiler MACT Update and Preparing for your July Report

This article is available as a podcast episode on ALL4’s Air Quality Insider

Things have been fairly quiet with respect to Boiler MACT lately…or so it may seem. With the next semiannual report due by July 31, here’s an update on what you need to know.

December 2016 Remand

The last significant action around Boiler MACT was that the United States Court of Appeals for the District of Columbia Circuit (Court) granted U.S. EPA’s petition to remand the numeric emissions limits for key subcategories for further evaluation. That action was seen as a win from U.S. EPA, industry, and environmental group perspectives because a full vacatur as was originally proposed by the Court in July 2016 would have caused undue confusion and could have minimized emissions reductions already being achieved.

Although no formal updates from U.S. EPA have been provided regarding their review of the remanded standards, we know that they have been crunching numbers to calculate proposed revised emissions limits for certain subcategories and will likely have some news to share soon.

Regulatory Reform

In April 2017, U.S. EPA’s Regulatory Reform Task Force sought public input for potential repeals, replacements, or modifications of existing regulations as directed by President Trump’s Executive Order (EO) 13777. U.S. EPA’s Office of Air and Radiation (OAR) held a public meeting on April 24, and comments were accepted through May 15, 2017. We attended the public hearing and reviewed the comments that were submitted, and found that, in general industry and environmental groups had reciprocating comments pertaining to various regulations. Boiler MACT received its fair share of comments, and not surprisingly from industry requesting that U.S. EPA conclude the “saga” after practically 20 years of rulemaking.

One Year Compliance Extension Deadline Approaching

For those facilities that received a one-year extension to the compliance date, from January 31, 2016 to January 31, 2017, the deadline for conducting the initial compliance demonstration is quickly approaching. Pursuant to §63.7510(e), the initial compliance demonstration (i.e., performance test, fuel sampling, etc.) must be completed within 180 days of the compliance date, or July 30, 2017. Test results must then be submitted via U.S. EPA’s Compliance and Emissions Data Reporting Interface (CEDRI) and Electronic Reporting Tool (ERT) within 60 days of the test. The Notification of Compliance Status (NOCS) must also be submitted within 60 days of completing all compliance demonstrations. CEDRI was recently updated to optionally accept NOCS submittals electronically rather than hardcopy.

July 2017 Report

For those facilities that did not receive a one-year extension, the first semiannual compliance report was due by January 31, 2017, and the next semiannual compliance report is due by July 31, 2017. We supported several facilities with the first report, and learned some things along the way. Unlike the NOCS, this report must be submitted via CEDRI, which we sometimes found to be inconsistent with the specific Boiler MACT rule requirements. U.S. EPA has already made some updates to CEDRI to address these inconsistencies, but here are some areas to watch out for:

- CEDRI previously prompted you to submit continuous monitoring system (CMS) data for all parameters, not just continuous emissions monitoring system (CEMS). Pursuant to §63.7550(c)(5)(xvi), only CEMS data and particulate matter (PM) continuous parametric monitoring system (CPMS) data is required to be submitted. U.S. EPA appears to have updated CEDRI to address this item.

- Pursuant to §63.7575, a 30-day rolling average for CO CEMS is defined as the arithmetic mean of the previous 720 hours of valid CO CEMS data; however, CEDRI only accepts CO CEMS data on a 30-day rolling average basis (i.e., one value per day).

- CEDRI does not prompt you to submit startup and shutdown data unless you have CMS data to submit. Pursuant to §63.7550(c)(2) and (3), startup and shutdown data must be submitted regardless of whether you utilize CMS to demonstrate compliance.

Those are just some examples of things to watch out for – if you have questions about your semiannual report, your performance test, your NOCS, or anything else, just call.

Looking for some more details about any of these updates? Check out the following articles:

- D.C. Circuit Court Issues Remand and Vacatur of Certain Boiler MACT and CISWI Provisions

- Boiler MACT Vacatur and Remand: The Details Unfold

- Major Source Boiler MACT Report Due January 31, 2017

- Boiler MACT Remand and Planning for January 31, 2017

- U.S. EPA Task Force Seeks Public Input on Existing Regulations

- Public and Industry Comment on Regulatory Reform

New to Air Quality or All4 Inc.? Well so am I.

Never in a million years would I have thought there was so much that went into Air Quality. I guess the average person takes for granted all that’s regulated and expected into keeping our air clean. What I’m learning is that reaching out to that expert can be like your own insurance policy that everything is going to be within the rules and regulations that apply to your operations guidelines (a little CYA if you know what I mean). Have you ever thought you could do something based on a video you searched and watched online? Then 2 hours later you end up hiring an expert that specializes in that specific field? Yeah, me too. What did I learn from that? Besides the realization I’m definitely not a Plumber? I also learned that I can’t be an expert in everything and that it’s okay. Plus, I learned the hard way that I will never get those two hours back of my life again.

Here’s the deal, why not get it done right that first time before you end up paying more for an experiment, or roll of the dice? Not only that, why not allow ALL4 to do the heavy lifting for you? This way you can focus on other things. What things? How about the items that are on your ever growing to do list! You know to do list I’m talking about, the one you start thinking about late at night when you’re lying in bed and can’t fall asleep. I don’t know about you, but my time is valuable and it’s the only thing I never seem to have enough of.

I recently joined the ALL4 team and I have to say I’ve been very impressed with the company as a whole, from start to finish. My recruiting and on boarding process was professional and well-conceived. This coming from someone who has worked with some amazing organizations like MCI WorldCom, AT&T and Cox Media Group. Not only was I recruited and hired by some great organizations, I‘ve recruited and hired for those organizations as well. ALL4 really pulls out the red carpet and at the same time is very cautious about making the right choices for their team. Why is that important to you? ALL4 is making a conscious effort to go above and beyond in all areas of their business, starting with the recruitment and hiring of their employees. Why do we do this? A deliberate effort to provide our clients with first class service and create strong relationships all starts with hiring great people. You have to be an “ALL4 fit” to provide the quality and service they expect and I’m honored I made the cut.

What do I plan to bring to ALL4? Experience, 20 years of Sales Experience. I’ve worked in different industries B to B, B to C and everything in between. I specialize in a Consultative approach and have been very successful in my career by building long standing and trusting relationships with my clients. I communicate what’s in the best interest of their company and business. I initiate the “hard to have” conversations when I need to. I have impeccable follow through, if I have a deadline with you I will fulfill that deadline and if there is any kind of delay I will communicate with you. My job is to make the clients and the companies I work with successful and I will work my tail off to do just that. I take personal ownership in serving your company to the best of my ability and have a tremendous amount of pride in building my personal reputation.

You may have an existing Consulting Company that’s been good to you, you may be happy. What I can tell you is that you never know how “good”, good can be. I want the opportunity to show you great and be great for you! I chose ALL4 and I think you should take that leap too!

Refinery MACT I – Do You Really Know What Your DAHS is Doing?

This article is available as a podcast episode on ALL4’s Air Quality Insider

By now, I’m sure you have familiarized yourself with 40 CFR Part 63, Subpart CC – National Emission Standards for Hazardous Air Pollutants from Petroleum Refineries (Refinery MACT I) and you have (hopefully) developed a compliance strategy for the new requirements that apply to your facility, including updated monitoring provisions. In general, increased monitoring also means increased recordkeeping and reporting. Have you included updating and implementation of your monitoring plan as part of your compliance strategy?

I recommend that everyone affected by the Refinery MACT take another read through the monitoring plan documentation provisions. Refinery MACT I includes a unique set of continuous parametric monitoring systems (CPMS) requirements for inclusion in your facility’s monitoring plan. Specifically, 40 CFR §63.671(b) requires that a facility document “What data acquisition system algorithms are used to reduce the measured data into the reportable form of the standard and to calculate the applicable averages”. This provision means that you must truly understand what your data acquisition and handling system (DAHS) is doing and how it is doing it. The time has passed when your answer for how you demonstrate compliance could simply be “My DAHS does it”.

Unfortunately, Refinery MACT I does not explicitly list which details regarding your data reduction methodologies are required for a complete compliance solution. Such is life. There is hope – the process for developing a CPMS data management schema is systemic and certainly reproducible. As a starting point, your facility will need to determine what parameters to consider for developing a defensible CPMS data management schema. Other items to address while developing your strategy include the identification of what information needs to be monitored, the interpretation and decisions on how the monitoring needs to be completed (considering industry standards and guidance), the development of specifications documenting the various what’s and the how’s, and finally the implementation of the your solution.

Diving into each of these compliance algorithms and documenting the process will reduce your compliance risk and provide confidence for on-going compliance demonstration. Conversely, not understanding and documenting the basis of a compliance demonstration puts your facility at risk of violating an emissions standard. It’s time to buckle up and really dig in. Give me a call at 610-933-5246 extension 130, or email me at mbarber@all4inc.com or contact Eric Swisher at 610-933-5246, extension 117, or eswisher@all4inc.com and we can help you.

TCEQ Air Quality 101 Blog Series – NSR Permitting

In late March, I had the opportunity to participate in an event called the Texas Independence Relay (TIR), which is a 2-day, 10-person running event from Gonzales through Houston, covering 200 miles from start to finish. The relay commemorates the independence of the State of Texas and the race appropriately ends at the San Jacinto Monument, which is dedicated to those who fought at the Battle of San Jacinto (for those not from Texas, you might need to brush up on your history). As our team entered the final stretch of our race, we ran through Pasadena and Deer Park with the Ship Channel facilities in eyesight and the Texas sun overhead. During this time, I couldn’t help but don my air quality consulting cap—to shade myself from the sun, of course—and let my mind wander through the complexities of the Texas Commission on Environmental Quality (TCEQ) New Source Review (NSR) Permitting that facilities, such as those I was passing, are potentially subject to.

TCEQ permitting, just like other state permitting programs, includes many nuances and unique requirements. When I first began to work on TCEQ air permitting projects, I stumbled upon TCEQ’s very helpful online air permitting training course. While the training course provides a broad overview of air permitting topics, I found that it would be beneficial for me and others, who want a quick snapshot of TCEQ air permitting, to have a cheat sheet that summarizes air permitting options in Texas, hence this blog. Be on the lookout for similar blogs that are part of ALL4’s Houston Office series focused on providing information related to TCEQ-specific air quality rules and regulations.

TCEQ Permitting Basics

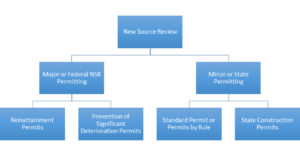

Let’s start off with the basics. With authority from the Texas Clean Air Act (TCAA), the TCEQ manages the air quality in the state of Texas by regulating the release of air contaminants and administers the air quality permitting program. Air permitting in Texas can be broken down into two main categories as presented in the following flow chart, Figure 1. The main categories are major (also referred to as Federal) NSR and minor NSR (also referred to as state) permitting. Each category can then be further divided based on different permitting programs. For this discussion we are focusing on the right side of the chart: Minor or State Permitting. Understanding this flowchart is key when planning a project in Texas.

Figure 1: Federal and State NSR Permitting Flow Chart

Defining the Project and What Permit You Need

The first step of any potential project is to evaluate the project-related actual or potential emissions from new or modified equipment. How the project impacts other facility operations and emissions units must also be considered. In most cases, the initial project construction can only commence if the permittee has an air quality permit in hand, hence the importance of an air permit application being correct and complete the first time. Therefore, budgeting enough time to get an air permit when considering a capital project is critical. Once the potential or actual emissions have been quantified, the appropriate permitting applicability, or exemption can then be determined.

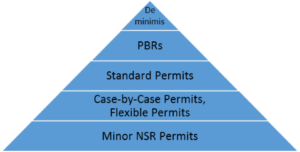

TCEQ authorizes Major NSR Permits (i.e., case-by-case for major sources), Minor NSR Permits (i.e., case-by-case for minor sources), Flexible Permits, Standard Permits, and permit by rules (PBRs). For sources and facilities that satisfy the de minimis rule requirements, those sources and facilities do not require an additional authorization permit prior to construction. Figure 2, depicts a breakdown of minor NSR permitting and exemption options in Texas. As the pyramid blocks increase in size, so too does the complexity of each permitting option.

Figure 2: TCEQ Air Permits Division Permitting Options Breakdown

De Minimis

A new or existing source may satisfy the requirements for a de minimis facility under 30 TAC §116.119. De minimis activities include small increases to background concentrations of air pollutants that would not cause a discernable impact on public health. Specifically, if a facility meets the de minimis criteria as described in 30 TAC §§116.119(a)(1)-(4), and if a facility maintains appropriate records that demonstrate the de minimis rule requirements are being satisfied, no other state authorization is required.

PBR

For those facilities or activities that have been deemed insignificant by the TCEQ, these facilities may be “permitted by rule”. Specifically, PBRs are standard permits for a population of source types that do not make a significant contribution of air contaminants to the atmosphere. Facilities must meet the exact requirements of a PBR for a PBR to become authorized. There are over 100 individual PBRs codified in 30 TAC §106. Facilities claiming PBRs must meet a series of general and recordkeeping requirements in 30 TAC §106.4 and 30 TAC §106.8, respectively. The facilities must also meet the specific requirements listed for each individual PBR citation/category. PBRs are not required to be renewed and merely require the facility to demonstrate continuous compliance with each PBR through recordkeeping and work practice standard requirements. Changes to the facility or source can be completed as long as the conditions of the PBR are still met. Costs vary for PBRs, but are no more than $450. The TCEQ target review time for PBRs is about 45 days. If your facility is considering a PBR, ALL4 recommends scheduling a meeting with TCEQ to confirm concurrence with the PBR category. Establishing a direct line of communication with TCEQ regarding your project is always a good practice regardless of permitting category your project falls into. Additionally, it should be noted that several Texas permitting programs offer expedited options as well as electronic submittal options.

Standard Permits

Similar to PBRs, standards permits specify a set of pre-determined requirements. Standard permits are intended for well-characterized classes of facilities and are typically used for sources with higher emissions than those authorized by a PBR. Standard permits are codified in 30 TAC §116, Subchapter F and offer an efficient mechanism for qualifying facilities to acquire authorization in lieu of permitting through a case-by-case air quality permit. A review of a standard permit application ranges from 45 to 60 days, requires a $900 application fee, and does not require public notice.

Minor NSR Permits

Sources that do not trigger major source permitting, and don’t fit into the aforementioned categories, may be subject to minor NSR permitting. Minor NSR permitting in TCEQ involves permitting on a case-by-case basis and can be broken out into two different permit types:

Case-by-Case Permits

Case-by-case permits are codified in 30 TAC §116 and are intended for more complex facilities and sources. This NSR permit process requires applicants to negotiate the best available control technology (BACT) and emissions limits. The permittee must demonstrate compliance with off-property health impacts due to the project emissions. An air quality impacts analysis may be required to demonstrate that a proposed facility will comply with the intent of the TCAA and the applicable federal and state rules and regulations. TCEQ’s Air Quality Modeling Guidelines (found here) provides more information regarding how to conduct off-property health impacts. While atmospheric dispersion modeling may ultimately be required, sources should not conduct modeling without first having a conversation with the corresponding TCEQ air permits division staff. Case-by-case review for a new construction can take 285 days or more. The case-by-case permit application fee depends on the project capital cost and proposed permits require public notice. Once issued, case-by-case permits consist of special conditions and the maximum allowable emission rate table (MAERT). A MAERT includes allowable emissions rates on an hourly and annual basis that have been established by a permit for a facility. A MAERT typically includes the potential to emit (PTE) for units at the facility.

Readily Available Permits or RAP provide another case-by-case permitting option. Refer to my historic blog, or the TCEQ presentation on RAPs at their Advanced Air Permitting Seminar for more information on how RAPs can be used as an efficient way to streamline an NSR permit application.

Flexible Permit

As an alternative to a case-by-case permit, a facility may obtain a flexible permit, which allows for physical operational changes as provided under 30 TAC §116, Subchapter G.· Flexible permits are valid state permits that require BACT and were designed to create an emissions cap by pollutant for facilities. This type of permit grants a facility more flexibility, as the facility manages compliance with a facility-wide cap, instead of managing individual emissions limits. A facility may structure the emissions cap to better serve the production needs of the facility.

Do the TCEQ air quality rules and TCEQ permitting program have you confused? Are you looking for your air quality permit application to be completed correctly the first time? Are you too busy tending to the daily operations of your facility? Well, ALL4 has you covered. ALL4 delivers permitting applications on time and on budget, and acts as a liaison between clients and TCEQ on important projects. Please reach out to me at fdougherty@all4inc.com, 281.937.7553 x302 if you have any TCEQ permitting questions or want to talk about air permitting support for your project.

U.S. EPA Grants Reconsideration of Additional NSPS Subpart OOOOa Provisions

As reported in our blog, U.S. Environmental Protection Agency (U.S. EPA) announced in an April 18, 2017 letter to oil and gas industry groups that it was reconsidering certain fugitive emissions monitoring requirements of the 40 CFR Part 60 Subpart OOOOa Standards of Performance for Crude Oil and Natural Gas Facilities (Subpart OOOOa). Today, the U.S. EPA published a notice of reconsideration and partial stay of additional provisions of Subpart OOOOa to the Federal Register (FR). U.S. EPA indicated that it had identified objections to two aspects of Subpart OOOOa that also meet the Clean Air Act §307(d)(7)(B) criteria for reconsideration. These objections relate to the requirements for Professional Engineer (P.E.) certification for:

- Closed vent systems used to comply with Subpart OOOOa emissions standards; and

- Technical infeasibility determinations for routing pneumatic pumps to control devices or processes.

In the F.R. notice, U.S. EPA acknowledges that these P.E. certification requirements were included in the final Subpart OOOOa rule without having been proposed for notice and comment. Therefore, U.S. EPA is reconsidering these provisions and intends to prepare a notice of proposed rulemaking that will provide opportunity to comment on these provisions as well as those included in its April 18. 2017 letter. U.S. EPA further indicated that it “intends to look broadly at the entire 2016 Rule”, which seems to indicate that reconsideration of further provisions of Subpart OOOOa may occur.

In connection with the grant of reconsideration discussed above, the F.R. notice also stays the effectiveness of the following Subpart OOOOa provisions until August 31, 2017:

- Fugitive emissions requirements;

- Standards for pneumatic pumps at well sites; and

- P.E. certification requirements.

If you would like to discuss all the recent changes and regulatory activity related to Subpart OOOOa, contact Roy Rakiewicz at 610.933.5246, extension 127, or rrakiewicz@all4inc.com.

Public and Industry Comment on Regulatory Reform

This article is available as a podcast episode on ALL4’s Air Quality Insider

This past April, Lindsey wrote about U.S. EPA’s Regulatory Reform Task Force seeking public input for potential repeals, replacements, or modifications of existing regulations as directed by President Trump’s Executive Order (EO) 13777. Written comments were due by May 15, 2017 and various public meetings were also held prior to the deadline.

ALL4 participated in the April 24 Office of Air and Radiation (OAR) public meeting and we have also been examining comments submitted to U.S. EPA. The majority of the comments pertaining to air quality regulations focus on a subset of regulations and programs that industry groups and companies feel are overly burdensome and complex, which include:

- National Ambient Air Quality Standards (NAAQS) – Several industry groups and individual companies indicated that the stringency of the NAAQS and the short frequency at which these are reviewed and updated are impacting companies’ ability to obtain the permits needed to make facility changes required to react to market conditions and remain competitive.

- New Source Review (NSR) – The stringency and complexity of current NSR regulations were raised as obstacles to companies’ ability to expand and make modifications to their facilities. Several entities requested that U.S. EPA streamline the NSR regulations and re-write these regulations in a way that provides more certainty for companies considering modifying or expanding their production capabilities.

- Clean Power Plan (CPP) – Opposition to the CPP was also recently voiced by industry groups. The CPP regulation has been opposed since its inception with companies and some states arguing that it is overly burdensome and that U.S. EPA overstepped its legal authority to regulate greenhouse gas (GHG) emissions from power plants in issuing the rule.

- GHG Reporting Rule – The GHG Reporting Rule was also brought up in industry comments as another regulation that is overly complex and costly, in addition to being duplicative of other Federal and state programs that already require reporting of GHG emissions.

- 40 CFR Part 60 Subpart OOOOa Standards of Performance for Crude Oil and Natural Gas Facilities (Subpart OOOOa) – This rule has been opposed by the oil and gas industry since it was originally proposed, in part due to the fact that it added GHG (i.e., methane) as a regulated pollutant in addition to criteria pollutants already regulated under earlier regulations. Opposition to this regulation remained strong in recent comments provided by industry. This regulation is also currently being reviewed under President Trump’s March 28, 2017 Executive Order Promoting Energy Independence and Economic Growth discussed in our March 31 blog post. Certain aspects of the rule have recently been stayed by U.S. EPA (see our April 27 blog post).

It should be noted that for every comment in support of repealing or streamlining regulations, U.S. EPA received a number of comments from private individuals and environmental groups opposing any weakening of regulations. This opposition from the public and environmental organizations signals the challenges ahead for any attempts by U.S. EPA to roll back existing regulations.

NSR Déjà vu?

If the current discussion regarding regulatory reform sounds familiar, you probably recall the discussion regarding NSR reform which began during the first term of the Clinton Administration. Many of the same concerns that are being expressed by the regulated community today mirror the same or very similar concerns that were identified in the years preceding the NSR reforms of 2002. The U.S. EPA initially published three “White Papers” in the mid-1990s, two of which addressed implementation issues associated with the Part 70 permit program and one which addressed flexible permitting, including plantwide applicability limitations (PAL). During this period the U.S. EPA also embarked on several flexible permitting initiatives including the Project XL and P4 programs and published a report titled “Evaluation of Implementation Experiences with Innovative Air Permits” which chronicled associated flexible permit successes.

Several of the flexibility concepts were reflected in the NSR reform rule of 2002. The NSR reforms of 2002 included a number of beneficial changes to the regulations including a revised definition of baseline actual emissions (BAE), the “actual-to-projected-actual” NSR applicability test, a definition of projected actual emissions (PAE), the use of “excludable” emissions in an NSR applicability analysis, clean unit (CU) provisions, pollution control project (PCP) provisions, and PALs. The reforms although successful, have been watered down by court and agency policy decisions since 2002. The CU and PCP provisions were vacated and removed from the NSR rules in June of 2007. Regulatory agencies have effectively narrowed the scope of several effective reform provisions through policy. Several additional reforms intended to address chronic NSR uncertainties (e.g., routine maintenance, repair and replacement, and project netting) were proposed as rule revisions subsequent to the 2002 NSR reforms but were never promulgated. The vacated portions of the rule and the proposals that were never promulgated would have gone a long way towards addressing industry concerns associated with NSR.

We expect that regulatory uncertainty will be a recurring theme in the foreseeable future. ALL4 will continue to track this ever-changing regulatory environment and to share what we find with our clients and the community at large. If you would like to have a conversation about how your current operations or future plans could potentially be impacted by regulatory reform or the lack thereof, contact Roy Rakiewicz at 610.933.5246 x127, rrakiewicz@all4inc.com.