The Ethylene MACT – An Air Quality Compliance Marathon

”

Over the years, ALL4 has chronicled the slow and not always steady regulatory development process in multiple blogs, articles, and presentations. For me, as the Air Toxics Knowledge Area Leader for ALL4’s RegTech Operations Group, I am responsible for tracking air quality regulatory and technical information, and then disseminating it throughout the company. In this role, I spend the majority of my time on the National Emission Standards for Hazardous Air Pollutants (NESHAPs; 40 CFR Part 63), and lately, with the Risk and Technology Review (RTR) program. For a refresher on the RTR program, our August 2014 article is a good place to start.

When economic drivers coincide with regulatory drivers such as the RTR program, we see growth opportunities, and ethylene production was a prime example in 2015. With respect to economic drivers, the ethylene production growth trend is tied to cheap and abundant natural gas. Though domestic oil and gas development has slowed considerably in 2016 due to lower prices, growth is expected to resume as supply and demand dynamics reach equilibrium in the coming years. Growth in the oil, gas, and petrochemical market is expected to continue along the U.S. Gulf Coast and in the Northeast and mid-Atlantic U.S., which contain the Marcellus and Utica shale formations. Industry publications consulted for this article, such as Petrochemical Update1 and various Daily Alerts published by the American Fuel & Petrochemical Manufacturers (AFPM) compare and contrast the advantages of ethylene production in these portions of the country based on infrastructure, environmental regulations, and workforce availability. The Northeast/mid-Atlantic U.S. regions are mature markets for petrochemical production. However, their aging infrastructure lags behind the Gulf Coast such that the cost to build an ethylene plant in the Northeast/mid-Atlantic region is expected to be $1 to $2 billion greater than a comparable plant on the Gulf Coast. Insufficient road and rail access are the primary factors driving this cost difference in the Northeast/mid-Atlantic U.S. For reference, Petrochemical Update estimates that the construction of a 1.0 million tons per year ethane cracker (which is the nucleus of an ethylene plant) at a brownfield site in the Northeast/mid-Atlantic U.S. would cost approximately $1.61 billion, with another $1 billion likely required for site development at a greenfield location.

This influx of growth is coinciding with increasingly complex air quality regulations, including, but not limited to: the recently lowered ozone National Ambient Air Quality Standard (NAAQS); RACT 2 in Pennsylvania; and, the ongoing development of an updated Ethylene MACT standard (40 CFR Part 63, Subpart YY). With the scale of economic investment required for an ethylene plant, the air quality regulatory permitting requirements for such a facility often are the critical path for a project. New Source Review (NSR) permitting, which will require control technology analyses; the implementation of stringent emissions limits; purchasing emissions offsets for projects located in nonattainment areas; and modeling; will be part of most, if not all, ethylene projects. For an appreciation of the value that ALL4 will bring to a project, consider the fact that air permitting services typically are much less than 1% of a project’s capital budget. However, without the air quality permit in hand, construction of the plant cannot start. For even more perspective, think about this: ALL4 understands that in some industry sectors, bank funding for large capital projects will not be approved until the air quality permit has been issued!

In an article last year, we discussed the status of an Information Collection Request (ICR) for the Ethylene MACT. The ICR process for the Ethylene MACT continues (slowly but steadily) and the next component of the process (Component 2) is underway. The remainder of this article will focus on what is next for the Ethylene MACT ICR, and how ALL4’s experience with the ICR process (and beyond) can make the process more bearable.

Ethylene MACT ICR

In 2015, the U.S. Environmental Protection Agency (U.S. EPA) completed Component 1 of the Ethylene MACT ICR, which focused on source category characterization with respect to the emissions inventory, as well as data collection of site-specific information on existing ethylene production units. In 2016, U.S. EPA will launch Component 2 of the ICR, with a focus on emissions testing. Component 2 is under development as of the date of this article, and a draft has been issued to industry and non-government organizations (NGOs) for review and comment. The current plan for Component 2 is to complete emissions testing by November 30, 2016. The focus of the testing program will be ethane cracking furnaces, including the decoking stacks. What is interesting about this testing focus is that while ethane cracking furnaces and associated decoking operations are included as part of the Ethylene MACT-affected source category [40 CFR §63.1103(e)(1)(i)], the emissions of hazardous air pollutants (HAPs) from ethane cracking furnaces, including emissions during decoking operations, are not subject to the control requirements specified in 40 CFR §63.1103(e)(3). According to §63.1103(e)(3), organic HAP emissions must be controlled by meeting the applicable requirements specified in Table 7 to Subpart YY. Under Subpart YY, organic HAP means the following compounds listed in Table 1 to 40 CFR Part 63, Subpart XX:

- Benzene

- 1,3-Butadiene

- Cumene

- Ethyl benzene

- Hexane

- Naphthalene

- Styrene

- Toluene

- o-Xylene

- m-Xylene

- p-Xylene

Based on these recent actions, all signs appear to be pointing to the development of new emissions standards for ethane cracking furnaces. This does not seem overly complicated until you actually consider the operations of an ethane cracking furnace. Ethane cracking furnaces typically cycle in multiple operating modes:

- Ethane cracking: The normal operating mode of the unit during which ethylene is being produced by cracking ethane.

- Cold startup and shutdown: This mode covers both the operation of the unit when it is initially started up following a turnaround and the period following feed being taken out of the unit until it is off-line.

- Decoking: During the ethane cracking mode, coke is formed within the radiant coils. Coke build-up eventually leads to high tube wall temperatures requiring decoking of the furnace. Every 30 to 60 days a furnace will go through decoking cycle, which will last for approximately 24 to 48 hours. The coke buildup is removed by injecting steam into the radiant coils while increasing the concentration of air to achieve controlled combustion of the coke in the furnace tubes.

- Hot steam standby: Once a furnace has been decoked, it is placed into hot steam standby until it is needed for cracking [i.e. one (1) of the other furnaces requires decoking].

- Feed in/Feed out: As part of the process of bringing a furnace down for purposes of decoking or maintenance, the furnace’s firing rate is reduced to a point where the feed to the furnace can be stopped. Similarly, when a furnace is being brought back online from hot steam standby, there is a period during which the firing rate is increased prior to when feed is placed into the furnace. These periods are referred to as feed in and feed out.

A review of recent air quality permit applications for ethylene production facilities indicates that best available control technology (BACT) emissions limitations for criteria pollutants have been established for the various operating modes of ethane cracking furnaces. Contrast this to HAP emissions, which to date are typically based on U.S. EPA AP-42 emissions factors for natural gas combustion. The lack of HAP emissions data for ethane cracking furnaces will be addressed by Component 2 of the ICR. The emissions data could then be used to set organic HAP emissions standards for one (1) or more of the operating modes of ethane cracking furnaces in the forthcoming Subpart YY.

ICR Experience

ALL4 has been involved with the testing components of multiple ICR efforts for MACT standards (and otherwise) in various industry sectors. While we do not conduct the testing personally (though many on our staff have performed stack testing throughout their careers), we often lead the development and execution of testing on a programmatic basis (identifying the range of operating conditions to be tested; identifying the critical process data to monitor and record; preparing test plans and protocol for submittal and approval by agencies; providing on-site testing program oversight; and reviewing, interpreting, and preparing test program results for submittal). We also have prepared and submitted comments on the ICR process on behalf of clients and/or industry trade organizations, which is where we find ourselves right now with respect to Component 2 of the Ethylene MACT ICR process.

So where do we go from here? If you are a facility affected by the Ethylene MACT ICR, reach out to us to discuss what is being requested from you, and how to make sense of it. There are significant data management obligations through this process, and while stack testing companies will obtain that data for you, ALL4 is prepared to evaluate and understand the implications of the data that will be reported to U.S. EPA, your state agency, and the general public. The emissions and related data that are being collected now could impact future projects at your (or your company’s) operations, and it is essential that you understand what is occurring now in other regulations such as the Petroleum Refinery MACT that could be setting a precedent for ethylene production plants. With our experience in these sectors, we can provide the proper perspective from an air quality regulatory compliance vantage point that will make this marathon feel like a 5K race.

“

When is the right time to hear something for the first time?

As an entrepreneurial company that is committed to Growth, CHANGE is what you sign up for when you join ALL4. Our ability to rapidly identify and implement change, based on both internal and external market forces, has supported our growth and enabled us to be ranked in the Inc. 5000 Fastest Growing Companies for eight consecutive years. This commitment to growth, and ability to change, means that new ideas, processes, systems, and decisions are constantly being made or created.

One of the distinctions associated with change is “When is the right time to hear something for the first time?” When we started ALL4, we often heard things for the first time while the entire company was sitting around the lunch room table or during the weekly leadership team meetings. Now I find myself learning about some ALL4 happenings when they are well beyond the initial formulation stage and sometimes long after they have been implemented! [Full disclosure… my initial reaction to some of these scenarios was “How the %^&* was this going on without me even knowing about it?!?”] If I was feeling this way, how was everyone else feeling when I am introducing our ALL4 2020 Business Plan or identifying the next market sectors that we intend to penetrate or even where our next office location will be as we outgrow the ALL4 Barn? (Note to the ALL4 team in Kimberton – I hear you… we will have some additional information soon – I promise! 🙂

I highlight this because I think everyone experiences similar reactions to hearing something for the first time. Personally, I am working hard to choose how I react in these moments. I find myself completely inspired (and reaching for a tissue…) by the reaction of people that actually HEAR for the first time. Check out this link (https://www.youtube.com/watch?v=LsOo3jzkhYA) for one of my favorite!!

Hearing something for the first time could evoke negative reactions such as anger, doubt, fear, confusion, or upset. When is the right time? I’m not sure there is one answer here as I would say that a big part of timing is dependent on the role of the person hearing the news for the first time. As the person delivering the message, consider the audience – help them understand “the why?” behind the message, and certainly consider the key question of “Am I trying to enroll this person in the decision-making process or inform them of a decision?” Sometimes, in hindsight, you may find that there were person(s) impacted in such a way that they SHOULD have heard the message earlier – at ALL4, I chalk that up to some of the communication challenges that are associated with rapid growth (and multiple offices) as the communication that once occurred around the Keurig Machine can be difficult to replicate. If you determine that these person(s) should have been involved in the decision-making process, then consider “Do I owe them an apology and/or explanation?”

What I have learned about myself is that when a group of people are aligned and committed to the success of the company and to the success of each other and I hear something for the first time from one of them – I pause and recall the reaction of Sarah Churman from the video… and then I choose to recognize the promise, joy, anticipation, and opportunity for future associated with each message!

U.S. District Court Rules on Risk and Technology Review for Pulp Mills

Every eight (8) years, U.S. EPA is required to conduct a Risk and Technology Review (RTR) for maximum achievable control technology (MACT) standards. Based on the results of the RTR, U.S. EPA must either promulgate revised emissions standards or publish a finding indicating that a revision is not necessary. In addition, U.S. EPA is required to prepare a Residual Risk Report to Congress on the methods to be used to assess the risk remaining (i.e., the residual risk) after control technology standards applicable to emissions sources of hazardous air pollutants (HAPs) have been promulgated and applied.

In a March 15, 2016 ruling by U.S. District Court, Northern District of California (Sierra Club and California Communities Against Toxics v. U.S. EPA) the court has established a timeline for U.S. EPA to comply with the missed RTR deadline for 40 CFR Part 63, Subpart MM- National Emission Standards for Hazardous Air Pollutants for Chemical Recovery Combustion Sources at Kraft, Soda, Sulfite, and Stand-Alone Semichemical Pulp Mills. Neither the plaintiff nor the defendant dispute that U.S. EPA has failed to meet its regulatory obligation to conduct the RTRs for these rules within the required eight (8) year period. The disputed issue is the timeline in which U.S. EPA must now complete the RTRs. The court has ruled generally in favor or the plaintiff and has required that U.S. EPA must complete the RTR for these standards, including revision of the standard or issuance of a final determination that a revision is not necessary, by October 1, 2017.

If your facility is subject to Subpart MM what should you expect? If U.S. EPA determines that rule changes are warranted, you should expect to see the development of a proposed rule, followed by publication and eventual development of the final rule package. The other possibility is that U.S. EPA will publish findings indicating that rule changes are not warranted. Because of the tight timeline established by the court, those facilities subject to Subpart MM should keep their collective ears to the ground on this issue. Watch for updates from ALL4.

Baby Steps…to Final RACT 2 Publication

“Baby steps onto the elevator…baby steps into the elevator…I’m in the elevator”

We are almost there. The elevator door is open, we just need to baby step inside…the long awaited RACT 2 Rule has passed the final significant hurdle as it moves toward official promulgation. The Pennsylvania House Environmental Committee approved the regulation on March 9, 2016. The Pennsylvania Senate followed suit and gave their approval the same day. The very next day on March 10, 2016, the Independent Regulatory Review Commission (IRRC) approved the regulation by a unanimous vote. The State Attorney General’s Office now needs to perform a review of the regulations for acceptability. This review rarely results in more than minor language revisions. As you have heard, the final RACT 2 Rule will not be officially promulgated, adopted, and/or effective until it is published in the Pennsylvania Bulletin. Publication should occur by the end of April 2016.

First time you’ve heard of this? Want to know more about what these regulations could mean to major sources of NOX and VOC in the Commonwealth? Go here and read all about it in ALL4’s previous RACT 2 blogs or reach out to Ron Harding at rharding@all4inc.com or (610) 933-5246 ext. 119 or me at jslade@all4inc.com or (717) 822-0009.

The Components of a RACT 2 Proposal

The proposed 25 Pa. Code §§129.96 – 129.100, Additional RACT Requirements for Major Sources of NOX and VOCs, also known as the RACT 2 Rule, is expected to be promulgated in Spring 2016. If you are a follower of our blogs, you already know that facilities will only have six (6) months from the date that the final form of the RACT 2 Rule is finalized in the Pennsylvania Bulletin to submit Reasonably Available Control Technology (RACT) proposals to the Pennsylvania Department of Environmental Protection (PADEP) for the control of nitrogen oxide (NOX) and volatile organic compound (VOC) emissions. This means that submittal of RACT 2 proposals could be required by October 2016. You may be thinking, who might submit a RACT 2 proposal and what does a RACT 2 proposal look like?

To determine whether submittal of a RACT 2 proposal would make sense for your facility, you need to first understand what constitutes RACT for each of your affected sources. Facilities may find that they have sources that:

- can comply with the presumptive RACT provisions of the rule;

- cannot comply with the presumptive RACT limits of the rule and will be complying with the rule’s NOX averaging provisions;

- either cannot comply with the presumptive RACT provisions of the rule or for which presumptive RACT provisions do not exist, who will be complying through submission of an alternative RACT 2 proposal and associated case-by-case control cost analysis; or

- are lucky enough to be exempt.

Those sources that cannot comply with the presumptive RACT provisions of the rule can elect to submit a case-by-case proposal and those sources for which presumptive RACT provisions do not exist must submit a case-by-case proposal. For more information on determining what constitutes RACT for your affected sources, please refer to our previous blog, “RACT 2 – I have less than a year to comply!? What should I be doing now?“.

So what is involved with developing a case-by-case RACT 2 proposal once you realize you will be submitting one?

A RACT 2 proposal is developed in the form of either an Operating Permit Modification Application or a Plan Approval Application (PAA), depending on whether you are proposing to install a control device. Pursuant to 25 Pa. Code §129.99(d), a case-by-case RACT 2 proposal must be developed in accordance with existing 25 Pa. Code §129.92(a)(1) – (5), (7) – (10), 25 Pa. Code §129.92(b), and 25 Pa. Code §129.99(d)(1) – (6) no later than six (6) months after the effective date of the rule. That is, the following must be included in the RACT proposal:

- A list of each air contamination source included in the RACT proposal.

- The size or capacity of each affected source and the types of fuel combusted, or the types and quantities of materials processed or produced in each source.

- A physical description of each source and its operating characteristics.

- Estimates of the potential and actual NOX and VOC emissions from each affected source, and associated supporting documentation.

- The actual proposed alternative NOX RACT requirement or NOX RACT emissions limitation, and/or the actual proposed VOC requirement or VOC RACT emissions limitation (as applicable).

- A RACT analysis which meets the requirements of §129.92(b), including technical and economic support documentation for each affected source (discussed further below).

- A schedule for completing implementation of the RACT requirement or RACT emissions limitation by January 1, 2017, including interim dates for issuance of purchase orders; start and completion of process, technology and control technology changes; and completion of compliance testing.

- The intended testing, monitoring, recordkeeping, and reporting procedures proposed to demonstrate compliance with the proposed RACT requirement(s) and/or limitation(s).

- Additional information requested by PADEP that is necessary for the evaluation of the RACT proposal.

As presented above, a component to the RACT proposal is a “RACT analysis.” Pursuant to 25 Pa. Code §129.92(b), the “RACT analysis” consists of a five (5)-step, top-down, control technology feasibility analysis. The five (5)-step process consists of (1) identifying all available control technologies for the source, (2) eliminating options that are technologically infeasible, (3) rank the remaining options in order of greatest control efficiency, (4) performing a cost analysis on the remaining options to determine if the control technology is economically feasible on a dollars per ton basis, and (5) selecting RACT for the source.

As detailed within, “RACT 2 Methods of Compliance“, facilities with affected sources that cannot comply with one (1) or more 25 Pa. Code §129.97 presumptive NOX RACT limits also have the option to combine multiple affected sources into a “facility-wide” or “system-wide” NOX Emissions Averaging Plan (Plan) pursuant to 25 Pa. Code §129.98, and demonstrate compliance with presumptive NOX emission limits “in aggregate” on a 30-day rolling total mass basis. Such Plans must be submitted to the PADEP as part of a RACT proposal.

If you find that you do not need to develop any case-by-case RACT 2 proposals (i.e., all of the NOX and/or VOC emitting sources at your facility are either exempt from the RACT 2 Rule, or able to comply with presumptive RACT 2 requirements or emissions limitations), you are still required to roll the applicable RACT 2 provisions into your current operating permit, pursuant to 25 Pa. Code §127.463. But as specified in §127.463 you will have at least 18 months, possibly much more, for making that change.

Because facilities will be required to demonstrate compliance with the published RACT 2 rule requirements by January 1, 2017, affected facilities should be actively working to develop their RACT 2 proposals now, as applicable. For more information regarding RACT 2, check out our RACT 2 Toolbox – a one-stop-shop for all things RACT 2. If you have any questions about developing a RACT 2 proposal, please reach out to me at (610) 933-5246, extension 155, or at cchinofsky@all4inc.com.

Tightening the Reins on GHG Emissions

-

-

-

-

-

- Landfills

- Coal mines

- Agriculture and

- Oil and Gas

-

-

-

-

Landfills

On August 14, 2015, the United States Environmental Protection Agency (U.S. EPA) issued two (2) proposed regulations intended to further reduce CH4 emissions from municipal solid waste (MSW) landfills. These proposals included a draft Emission Guideline (EG) and a supplemental draft New Source Performance Standards (NSPS) rule. If finalized as proposed, the EG would apply to existing landfills and the NSPS rule would apply to landfills constructed or modified after July 17, 2014. Comments on both proposals were accepted through October 2015, and both are expected to be finalized in the first quarter of 2016. If finalized as proposed, the threshold that triggers the installation of a landfill gas collection and control system (GCCS) for control of CH4 would be lowered from 50 to 34 megagrams per year (Mg/yr) for all landfills except existing, closed sites. It would, among other changes, also eliminate the startup, shutdown, and malfunction provisions that currently apply for MSW landfills.

Coal mines

On January 15, 2016, the Obama administration unveiled a three (3) year moratorium on new coal leases on federal lands. This moratorium does not halt mining and production currently underway, but gives time to the Department of Interior (DOI) to review the leasing program. According to the DOI Secretary, Sally Jewell, “We haven’t undertaken a comprehensive review of the program in more than 30 years, and we have an obligation to current and future generations to ensure the federal coal program delivers a fair return to American taxpayers and takes into account its impacts on climate change.” According to a recent study by The Center for American Progress “Coal from federal lands in Wyoming and Montana, including the Powder River Basin, contributed more than 13 percent of all GHG emissions from fossil fuels in the United States and more than 10 percent of all U.S. GHG emissions.”

Agriculture

In August 2014, the U.S. Department of Agriculture, U.S. EPA, and U.S. Department of Energy developed the Biogas Opportunities Roadmap to outline the voluntary actions to reduce CH4 emissions through biogas systems. The Roadmap supports the U.S. dairy industry’s voluntary 2008 goal to reduce its greenhouse gas emissions by 25 percent by 2020. According to the Roadmap Fact Sheet, more than 11,000 additional biogas systems could be deployed in the United States. If fully realized, these biogas systems could produce enough energy to power more than 3 million American homes and reduce methane emissions equivalent to 4 to 54 million metric tons of greenhouse gas emissions in 2030, the annual emissions of between 800,000 and 11 million passenger vehicles.

Oil and Gas

On August 18, 2015, the U.S. EPA proposed two (2) new regulations to reduce CH4 and volatile organic compounds (VOC) emissions from the oil and natural gas sector. These regulations include:

- Proposed Standards of Performance for New Stationary Sources (NSPS) that regulates CH4 as a pollutant for the oil and gas sector entitled “Oil and Natural Gas Sector: Emission Standards for New and Modified Sources;” and

- A proposed Federal Implementation Plan (FIP) for sources located in Indian Country entitled “Review of New Sources and Modifications in Indian Country: Federal Implementation Plan for Managing Air Emissions from True Minor Sources Engaged in Oil and Natural Gas Production in Indian Country.”

Concurrent with the proposed rules, U.S. EPA introduced a proposal to clarify the term “adjacent” for New Source Review (NSR) purposes, entitled “Source Determination for Certain Emission Units in the Oil and Natural Gas Sector. The “aggregation” proposal is intended to provide clarity regarding how oil and gas operations should be defined to evaluate major source status.

The U.S. EPA also released a draft Control Techniques Guidelines (CTG) entitled, “Release of Draft Control Techniques for the Oil and Natural Gas Industry” to reduce VOC emissions from existing oil and gas facilities that are located in ozone nonattainment areas. Comments on the draft proposal were accepted through December 4, 2015.

While the Obama Administration tightens the reins on reducing GHG emissions through regulatory actions, U.S. EPA is also enhancing (i.e., expanding) the GHG emissions reporting process.

Previously, ALL4 discussed the Final 2015 revisions to the GHG Reporting Rule for the Oil and Gas Sector where U.S. EPA finalized reporting requirements for onshore petroleum and natural gas gathering and boosting activities, onshore natural gas transmissions pipelines, completion and workovers of oil wells with hydraulic fracturing, well identification numbers, and finalized confidentiality determination for new data elements.

Since then, U.S. EPA has proposed amendments to specific provisions within the following 30 subparts of the GHG Reporting Rule:

| Subpart A (General Provisions) | Subpart C (Stationary Combustion) |

| Subpart E (Adipic Acid Production) | Subpart F (Aluminum Production) |

| Subpart G (Ammonia Manufacturing) | Subpart I (Electronics Production) |

| Subpart N (Glass Production) | Subpart O (HFC-22 Production and HFC-23 Destruction) |

| Subpart P (Hydrogen Production) | Subpart Q (Iron and Steel Production) |

| Subpart S (Lime Manufacturing) | Subpart U (Miscellaneous Uses of Carbonate) |

| Subpart V (Nitric Acid Production) | Subpart X (Petrochemical Production) |

| Subpart Y (Petroleum Refineries) | Subpart Z (Phosphoric Acid Production) |

| Subpart AA (Pulp and Paper Manufacturing) | Subpart CC (Soda Ash Manufacturing) |

| Subpart DD (Electrical Transmission and Distribution Equipment Use) | Subpart FF (Underground Coal Mines) |

| Subpart HH (Municipal Solid Waste Landfills) | Subpart II (Industrial Wastewater Treatment) |

| Subpart LL (Suppliers of Coal-based Liquid Fuels) | Subpart MM (Suppliers of Petroleum Products) |

| Subpart NN (Suppliers of Natural Gas and Natural Gas Liquids) | Subpart OO (Suppliers of Industrial Greenhouse Gases) |

| Subpart PP (Suppliers of Carbon Dioxide) | Subpart RR (Geologic Sequestration of Carbon Dioxide) |

| Subpart TT (Industrial Waste Landfills) | Subpart UU (Injection of Carbon Dioxide) |

According to the U.S. EPA Fact Sheet, the proposed amendments would include the following types of changes and would be implemented over reporting years 2016, 2017, and 2018:

- Revisions to streamline implementation and reduce burden. These changes would reduce or simplify requirements in a manner that would ease the burden on reporters and the U.S. EPA. These changes include revising requirements to focus U.S. EPA and reporter resources on relevant data, removing reporting requirements for specific facilities that report little or no emissions or removing reported data that are no longer necessary.

- Amendments to improve quality of data. These amendments are needed to ensure that accurate data are being collected under the rule and would expand monitoring or reporting requirements that are necessary to improve verification and improve the accuracy of data used to inform the Inventory of U.S. Greenhouse Gas Emissions and Sinks (U.S. GHG Inventory). For example, the proposed action would require underground coal mines reporting under subpart FF to use one (1) of two (2) existing methods, with some modification, to measure emissions from ventilation while eliminating the option to use a third, less accurate method. These proposed revisions are intended to improve the quality of the data collected.

- Minor amendments to better reflect industry processes and emissions. These revisions include amendments to calculation, monitoring, or measurement methods that would address prior petitioner or commenter concerns including those that add flexibility for facilities. For example, in response to stakeholder feedback, the proposed action would amend the conditions required to use different oxidation factors that are used for estimating emissions under municipal solid waste landfills (subpart HH).

- Minor clarifications and corrections to improve understanding of the rule. These revisions include corrections to errors in terms and definitions in certain equations; clarifications that provide additional information for reporters to better or more fully understand compliance obligations; and other editorial or harmonizing changes that would improve the public’s understanding of the rule.

U.S. EPA has extended the comment period on these proposed amendments from February 29, 2016, to March 30, 2016.

Although U.S. EPA is proposing revisions to 30 of these subparts, I have highlighted the significant proposed amendments for Subpart A (General Provisions) as well as five (5) example subparts that may be of interest to our readers as indicated in bold in the table.

Subpart A – General Provisions

U.S. EPA is proposing the following amendments to 40 CFR Part 98 Subpart A:

- Provide an option for reporters to discontinue reporting if annual emissions are less than 25,000 mtCO2e for five (5) reporting years or less than 15,000 mtCO2e for three (3) reporting years, or if process operations are permanently shut down for both direct emitters and suppliers.

- Identify provisions to discontinue reporting if any individual process or operation ceases operation.

- Clarify if the operations of a facility or supplier are changed such that a process or operation no longer meets the ‘‘Definition of Source Category’’ as specified in an applicable subpart, then the owner or operator is exempt from reporting under any such subpart for the reporting years following the year in which the change occurs, provided that the owner or operator submits a notification to the Administrator that announces the cessation of reporting for the process or operation no later than March 31 of the year following such changes.

- Limit resubmittal of reports to five (5) years prior to the current reporting year.

- Include the option to report fluorinated GHGs and fluorinated heat transfer fluids (HTF) individually.

- Revise 40 CFR §98 (c)(4) and (5) to include two (2) additional identifiers of fluorinated GHGs and fluorinated HTFs.

- Update the certificate of representation (COR) to require a list of all the 40 CFR 98 subparts under which a facility or supplier intends to report.

- Add provision (40 CFR §98.2(i)(6)) to include a requirement that a facility must inform the U.S. EPA whenever the facility (or supplier) stops reporting under one (1) e-GGRT identification number because the emissions (or quantity supplied) are being reported under another e-GGRT identification number.

- Revise 40 CFR §98.3(h)(4) to simplify the process for requesting an extension for the reporter to respond to U.S. EPA’s questions on a submitted report or submit a revised report to correct a reporting error identified by U.S. EPA during report verification.

- Amend the definition of ‘‘gas collection system’’ to clarify that active venting systems that convey landfill gas to the surface of the landfill by mechanical convection, but the landfill gas is never recovered or thermally destroyed prior to release to the atmosphere, are not considered a landfill gas collection system.

- Amend the definition for ‘‘ventilation hole or shaft’’ in 40 CFR §98.6 to clarify that the term ‘‘vent hole or shaft’’ for mine ventilation systems includes mine portals, adits, and other mine entrances and exits used to move air from the ventilation system out of the mine.

Subpart C – Stationary Combustion

U.S. EPA is proposing the following amendments to 40 CFR Part 98 Subpart C:

- Require reporting of the moisture content used to correct the default high heating value (HHV) for wood and wood residuals.

- Require reporting of the heat input capacity for all units greater than 10 million British thermal units per hr (MMBtu/hr) for emissions reported using the aggregation of units (GP) and common pipe (CP) configurations.

- Clarify the reporting requirements when the results of HHV sampling are received less frequently than monthly for certain sources.

- Streamline of the conversion factors used to convert short tons to metric tons.

- Revise Tables C–1 and C–2 to more clearly define emissions factors for certain petroleum products.

Subpart Y – Petroleum Refineries

U.S. EPA is proposing the following amendments to 40 CFR Part 98 Subpart Y:

- Clarify that pilot gas, which is considered the gas used to maintain a pilot flame at the flare tip, may be excluded from the quantity of flare gas used to perform GHG emissions calculations.

- Add a requirement that facilities provide a yes/no indication as to whether a flare has a flare gas recovery system.

- Provide a new methodology that will more accurately determine emissions from delayed coking units (DCU).

- Clarify the appropriate equations to be used for reporters with an asphalt blowing unit with a control device other than a vapor scrubber, thermal oxidizer, or flare.

Subpart AA – Pulp and Paper Manufacturing

U.S. EPA is proposing the following amendments to 40 CFR Part 98 Subpart AA:

- Clarify that Tier 4 continuous emission monitoring systems (CEMS) are not to be used for reporting emissions under Subpart AA.

- Amend the requirements to allow the use of the daily mass of spent liquor solids fired in megagrams (Mg) or tons per day as an alternative to using the maximum rate for the combustion unit or that the fuel meter can measure.

- Amend Table AA-2 to clarify requirements for Kraft lime kilns and fluidized bed calciners at Kraft mills.

Subpart II – Industrial Wastewater Treatment

U.S. EPA is proposing the following amendments to 40 CFR Part 98 Subpart II:

- Require facilities that perform ethanol production to indicate if their facility uses a wet milling process or a dry milling process.

- Add the definition of “weekly average” to clarify how to calculate weekly averages for chemical oxygen and 5-day biochemical oxygen demand (BOD) concentration, CH4 concentration, biogas temperature, biogas moisture content, and biogas pressure.

Subpart TT – Industrial Waste Landfills

U.S. EPA is proposing the following amendments to 40 CFR Part 98 Subpart TT:

- Provide new default degradable organic carbon (DOC) for waste disposed values for the following industrial waste streams:

- Boiler ash – 0.06

- Kraft recovery wastes – 0.025

- Pulp and paper wastewater sludge – 0.12

- Other pulp and paper wastes – 0.20

- Add a note to clarify that kraft recovery waste also includes green liquor, slaker grits, and lime mud.

Please contact us at info@all4inc.com with any questions.

Proposed Alignment of the Oil and Gas Sector GHG Reporting Rule (Subpart W) With NSPS OOOOa

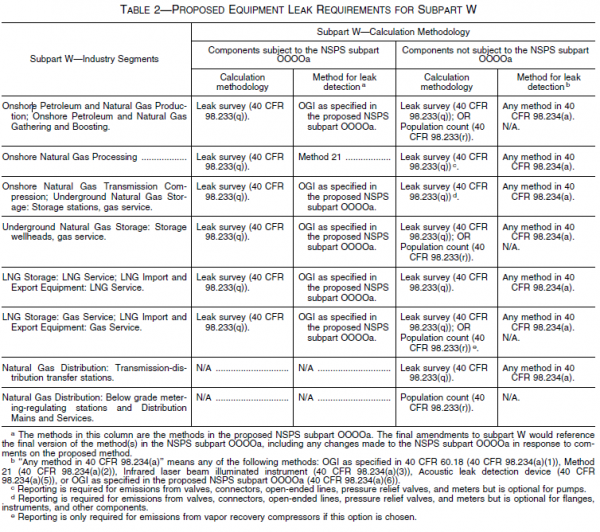

On January 29, 2016, U.S. EPA proposed revisions to 40 CFR Part 98 Subpart W – Mandatory Greenhouse Gas (GHG) Reporting for Petroleum and Natural Gas Systems (Subpart W). These proposed revisions come not long after several other new reporting requirements were finalized on October 22, 2015 for Subpart W (addressed in the blog, “Final 2015 Revisions to the GHG Reporting Rule for the Oil and Gas Sector” from December 2015). The recently proposed revisions will add new monitoring methods for leak detection, emission factors for leaking equipment (referred to as “leaker emission factors” within the proposed revisions), reporting requirements, and confidentiality determinations.

The purpose of the recently proposed equipment leak requirements from oil and gas equipment in Subpart W is to align leak detection methods with the recently proposed 40 CFR Part 60 Subpart OOOOa – Standards of Performance for Crude Oil and Natural Gas Production, Transmission and Distribution (Subpart OOOOa). As such, if Subpart OOOOa (when final) is amended in the future to incorporate new technologies or monitoring methods, Subpart W requirements will be automatically updated by reference. The proposed leak detection provisions would only be required for sources reporting under Subpart W that are also subject to Subpart OOOOa. Facilities with a Subpart OOOOa affected source would calculate and report their GHG emissions by using the data derived from the Subpart OOOOa fugitive emissions requirements, the Subpart W equipment leak survey calculations, and leaker emission factors. For sources reporting under Subpart W that are not subject to Subpart OOOOa, the proposed leak detection methods could be voluntarily used.

The table below, reproduced from Page 7 of the Federal Register “Table 2 – Proposed Equipment Leak Requirements for Subpart W,” provides a summary of the proposed amendments:

The U.S. EPA expects that the proposed Subpart W amendments would be published at the same time or soon after the final Subpart OOOOa rule is published to ensure alignment. The U.S. EPA anticipates finalization before the end of 2016. The new methods and emission factors would need to be used starting on the effective date of the finalized amendments.

The U.S. EPA has determined that the new data reporting elements in the proposed Subpart W amendments are not entitled to confidential protection and that the final confidentiality determinations previously made are unaffected and continue to apply. The comment period on this action has been extended from the original February 29, 2016 deadline, and comments must be received on or before March 15, 2016.

If you have any specific questions, feel free to reach out to JP Kleinle at jkleinle@all4inc.com or me at mstroup@all4inc.com.

Refinery Sector Rule Update: Compliance Dates for Flares and What You Should Be Doing Now

Back in December, the final Refinery Sector Rule (RSR) was published in the Federal Register, which outlined several new requirements for refinery flares. If you own or operate a refinery that has a flare, or plan to install a flare in the future, then you’ll want to know the new requirements and compliance dates, and get into action. All4’s article, “U.S EPA Proposes Substantial Refinery Flare Operating and Monitoring Requirements” from May 2014, by Roy detailed the originally proposed changes and my blog post, “Finalized Refinery Rule – Flare Edition” from November 2015 discussed the changes in the flare requirements from the proposed rule to the final rule.

When do I need to be in compliance?

On or before January 30, 2019. Just under three (3) years from now, your flare is expected to be in compliance with the flare requirements in §63.670 and §63.671, from 40 CFR Part 63 Subpart CC (National Emission Standards for Hazardous Air Pollutants from Petroleum Refineries). Existing flares used as a control device must be in compliance by January 30, 2019. If your flare is used, or is to be used as a control device and is constructed on or after January 30, 2019, the flare is subject to §63.670 upon startup.

For flares subject to 40 CFR Part 63 Subpart UUU (National Emission Standards for Hazardous Air Pollutants for Petroleum Refineries: Catalytic Cracking Units, Catalytic Reforming Units, and Sulfur Recovery Units), the owner and operators are required to meet the requirements of §63.670 on or before (you guessed it) January 30, 2019, regardless of the construction date of the flare. Prior to January 30, 2019, the flare must meet the control device requirements specified in §63.11(b) or the requirements of §63.670.

SO WHAT do I need to Do?

Flares that are subject to the requirements in §63.670 are also subject to the flare monitoring requirements in §63.671, which include developing a monitoring plan, operating a continuous parametric monitoring system (CPMS), and submitting periodic reports. These are brand new requirements for flares, and they may be confusing. Although three (3) years may sound like a long time, these projects will include many different parts of the refinery – from environmental and operators to engineers and instrumentation. The importance of a planned timeline is crucial to meet the January 30, 2019, compliance date and ensure that budgeting is in place and the projects can be planned in conjunction with facility operations.

To put the effort necessary to comply with the final flare requirements of Subparts CC and UUU in perspective, here is an idea of the tasks required under §63.670 and §63.671 to be completed leading up to the January 30, 2019, deadline:

- Develop or update flare management plans, including flare minimization assessment

- Develop root cause analysis (RCA) and corrective action analysis procedures

- Evaluate pursuing Alternative Means of Emission Limitation (AMEL) and AMEL Test Plan

- Evaluate the need for, develop, and submit Alternative Monitoring Procedure (AMP), as necessary

- Design and implement the flare CPMS:

- Purchase measurement devices, instrument(s), and install, test, and troubleshoot

- Implement data acquisition handling system (DAHS)

- Develop monitoring plans and quality assurance/quality control (QA/QC) plans

- Conduct visible emissions training

By January 30, 2019:

- Comply with flare monitoring requirements and operating limits including recordkeeping and reporting requirements

- Operate flare CPMS

- Complete initial compliance demonstrations for visible emissions monitoring

- Submit flare management plans to Administrator

- Submit CPMS Plans (if requested by Administrator, otherwise keep onsite)

Give ALL4 a call and we’d be happy to discuss the nuances of the new rule, and how we can help make your lives easier when it comes to flares. Meghan Barber (mbarber@all4inc.com, 610-933-5246 x130), Kristin Gordon (kgordon@all4inc.com, 281-937-7553 x301) or myself, Amanda Essner (aessner@all4inc.com, 610-933-5246 x129) would be happy to help!