U.S. EPA Issues Final Flare Emission Factor Decision: NOx Emission Factor Unchanged

In September 2014, we alerted you to U.S. EPA’s proposal to significantly increase the emission factors for various pollutants, most notably nitrogen oxides (NOX), emitted from industrial flares. As you may recall…

- In May 2013, environmental groups filed a lawsuit against U.S. EPA for failure to perform compulsory duties pursuant to the Clean Air Act (CAA) to review, and, if necessary, revise the emission factors for volatile organic compounds (VOC) for flares, liquid storage tanks, and wastewater collection, treatment, and storage systems.

- As a result of the litigation, in early 2014, U.S. EPA entered into a consent decree stipulating that they were going to review and, if necessary, propose new emission factors for VOC for the aforementioned sources.

- In August 2014, based largely on data collected during the 2011 Refinery Information Collection Request (ICR), the data referenced in the litigation, and other test data available to U.S. EPA, U.S. EPA decided to propose a new VOC emission factor for flares, as well as other emission factors for refinery operations and pollutants that were not specifically covered by the 2014 consent decree.

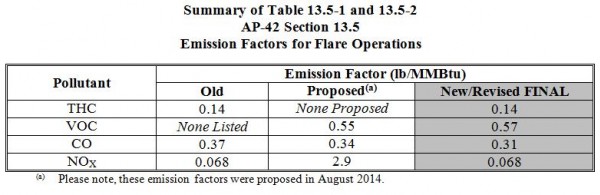

Since last August, U.S. EPA has received hundreds of comments from environmental groups and industry regarding the proposed emission factor revision. On April 20, 2015, U.S. EPA concluded that a revision to the NOX emission factor published in Section 13.5 of AP-42 (Compilation of Air Pollutant Emission Factors) was not necessary. As you can see in the table below, U.S. EPA has published a new emission factor for VOC, has reduced the published emission factor for carbon monoxide (CO), and has not changed the emission factors for total hydrocarbons (THC) or NOX.

Specifically regarding flares, U.S. EPA issued a statement saying, “Based on our review of NOX emissions data for flares and additional information received after proposal, we have determined that the data was not adequate to support revising the NOX emissions factor for flares. Based on comments received, U.S. EPA determined that the NOX data used for the proposal contained certain flaws that rendered the data quality suspect.” In addition to the revised NOX emission factor, affected facilities should also take note of the new VOC emission factor. According to AP-42, VOC emissions were previously assumed to be negligible. It is possible that increased VOC emissions could have impacts in emissions reporting and permitting decisions going forward.

In order to assist Petroleum Refineries in estimating emissions from various refinery operations, the U.S. EPA Office of Air Quality Planning and Standards (OAQPS) has published a revised “Emissions Estimation Protocol for Petroleum Refineries” (Refinery Protocol). U.S. EPA considers “the Refinery Protocol to provide site-specific emissions inventory guidance that will result in more accurate and complete emissions inventories.” Sections 1, 5, and 6 of the Refinery Protocol has been updated with these new emission factors.

U.S. EPA has also published new emission factors, or emissions estimation methodologies, for certain refinery operations and pollutants that were not covered by the original consent decree. These pollutants and refinery operations include: NOX, CO, and THC emissions from Sulfur Recovery Units, THC emissions from Catalytic Reforming Units, NOX emissions from Hydrogen Plants, and hydrogen cyanide (HCN) emissions from Fluid Catalytic Cracking Units. AP-42 Sections 5.1 and 8.13 have been updated to include these new factors. Please note that HCN emissions are potentially required to be reported under the jurisdiction both the Toxic Release Inventory (TRI) and the National Emissions Inventory (NEI) reporting programs. The revised emission factor for HCN could impact the TRI and/or NEI reporting obligations for facilities that use Fluid Catalytic Cracking Units.

More information, including U.S. EPA’s formal review of available documents and test reports used for developing these emission factors, can be found here.

Pennsylvania RACT 2 – Are We There Yet?

The Pennsylvania Department of Environmental Protection (PADEP) has announced several changes to the Final-Form Reasonably Available Control Technology regulations that affect major sources of nitrogen oxides (NOX) and volatile organic compounds (VOCs). This particular rule has been under development since 2012 and the Pennsylvania Air Quality Technical Advisory Committee (AQTAC) approved the final form rule on November 7, 2014 following a presentation by PADEP. ALL4 has been following the development of the RACT 2 rule since 2012 and has been providing periodic updates via our website. Several important changes have been made to the RACT 2 rule since AQTAC approval including generic revisions, source specific revisions, and interpretive revisions to the emissions averaging provisions. PADEP made these revisions after review of Federal RACT requirements and reconsideration of comments made both during and after the official comment period, citing their responsibility to adopt regulations that meet all of the Federal RACT requirements. While PADEP does not believe that it is necessary to re-propose the RACT 2 regulation or have AQTAC reconsider the Final Form rule for approval, they presented the changes to AQTAC during their meeting on April 16, 2015.

The source-specific RACT 2 changes impact Electric Utility Generating Units (EGUs) that are required to control NOX emissions for units with existing Selective Catalytic Reduction (SCR) controls. Previously the EGUs were required to meet a RACT emission limit of 0.15 pounds of NOX per million Btu of heat input when the SCR inlet temperature is at or above 600° F. PADEP lowered this RACT emission limit to 0.12 pounds NOX per million Btu of heat input. PADEP elected to lower this RACT 2 presumptive emission limit following reconsideration of the dataset used to establish the original limit, which included the removal of higher emitting affected EGUs from the average that were deemed not representative of typical SCR RACT performance levels.

The other changes were characterized by PADEP as “clarifications” of the RACT 2 regulations. The first clarification affected definitions and boiler/heater tune-up requirements, which were revised to be more consistent with Federal definitions and rules for those RACT affected source types. The second clarification was to the formula for determining the allowable emissions for facilities planning to use the 30-day rolling emission average limit option across multiple emission units. PADEP clarified that the 30-day allowable RACT limit must represent the lowest permitted emission rate for each affected source if such limits are lower than the presumptive RACT NOX emission limit specified in the RACT rule in Section 129.97. This revision effectively makes any NOX emission limit in an operating permit a de-facto RACT emission limit for purposes of a 30-day average for multiple sources if that NOX emission limit is lower than the presumptive RACT NOX emission limit. PADEP cited 25 Pa. Code Section 129.98(k) of the RACT 2 regulation as the source of this interpretation. 25 Pa. Code Section 129.98(k) states that NOX emission reductions required by state and federal regulations cannot be used to offset RACT NOX emission reductions.

No matter how one characterizes the changes to the method for determining the 30-day NOX RACT emissions limit, it will mean that more “case-by-case” RACT submittals will be prepared by affected sources and submitted to PADEP under RACT 2 for review, approval, and finally included in Pennsylvania’s State Implementation Plan (SIP) than would otherwise have been submitted before this clarification. Companies that were considering use of the RACT multi-source emission averaging provisions will need to carefully reconsider their margin of compliance before committing to this compliance option. Of special note are industrial natural gas-fired boilers that must meet the 0.10 pounds of NOX per million BTU of heat input under RACT 2. Such units would have been prime candidates for the NOX averaging provisions across multiple boilers. The RACT 2 natural gas industrial boiler presumptive emission limit is very tight considering that the New Source Performance Standard for these types of gas-fired boilers (e.g., which apply to “new” affected sources) is also 0.10 pound of NOX per million BTU of heat input. Many of the natural gas-fired boilers (or combustion units per the RACT rule vernacular) that are affected by RACT 2 were also impacted by Pennsylvania’s “first round” of NOX RACT in the 1990s and elected to install new, low-NOx burners to meet RACT at that time to comply. Additional controls would be required for many of these units to meet the new lower presumptive NOX RACT 2 emission rate.

This appears to be the final version of RACT 2 that will be presented to the Environmental Quality Board (EQB) in July or August this year for adoption. Now is the time to begin testing your RACT applicable emission sources and strategizing regarding how your facility will meet these new NOX and VOC regulations. Unless approved otherwise, compliance will be required within one (1) year of adoption. If you have any questions, give me a call at (717) 822-0009 or email me at jslade@all4inc.com.

So Many MACT Compliance Plans, Which Ones Do I Need?

”

If you are subject to one (1) or more National Emission Standards for Hazardous Air Pollutants (NESHAP) [often referred to as Maximum Achievable Control Technology (MACT) standards], you undoubtedly have heard talk of the various compliance plans required for a given rule. If you have not heard about these required plans, this article may drastically change your “to do” list for tomorrow. Performance test plans, parametric monitoring plans, and operations and maintenance (O&M) plans are just a few examples of the required plans under various NESHAPs. Several NESHAPs that are currently effective, have looming compliance dates, or are in the proposed stage all have some sort of compliance plan requirement. To give you a sense of the variety of plans required under a given NESHAP, we’ve provided a snapshot of the compliance plan requirements specified in the following rules:

- 40 CFR Part 63, Subpart ZZZZ – NESHAP for Stationary Reciprocating Internal Combustion Engines, “RICE MACT”

- 40 CFR Part 63, Subpart DDDDD – NESHAP for Major Sources: Industrial, Commercial, and Institutional Boilers and Process Heaters, “Boiler MACT”

- 40 CFR Part 63, Subpart LLL – NESHAP from for the Portland Cement Manufacturing Industry, “PC MACT”

- 40 CFR Part 63, Subpart UUU – NESHAP for Petroleum Refineries (Catalytic Cracking, Catalytic Reforming and Sulfur Plant Units), “Refinery MACT II”

In addition to the plan requirements specified in a given NESHAP, the general provisions of Subpart A of 40 CFR Part 63 also contain compliance plan requirements that apply. You will need to review the specific NESHAP you are subject to in order to determine its specific plan requirements.

The table below provides a matrix of the specific plan requirements in the rules noted above. These plans are “site-specific,” meaning you cannot rely on the details in the plan for a sister plant. However, for companies with several facilities across the U.S., these plans have commonalities that align well with developing modular plans that can be modified easily to accommodate specifics of a given facility.

So, what do these plans do, and what must be included? Let’s look at a more in-depth look at some of these plans.

”

”

Site-Specific Monitoring Plan

Generally speaking, if you demonstrate compliance through performance (stack) testing and demonstrate ongoing compliance with operating limits through monitoring, a site-specific monitoring plan is required for a continuous emissions monitoring system (CEMS), continuous opacity monitoring system (COMS), and/or continuous parameter monitoring system (CPMS) – collectively referred to as a continuous monitoring system (CMS). A site-specific monitoring plan is also required if you petition the U.S. EPA for alternative monitoring parameters under 40 CFR §63.8(f).

The contents of a site-specific monitoring plan are contained within a given subpart, as well as Subpart A. A site-specific monitoring plan typically includes the following:

- Initial and subsequent calibration of the CMS.

- Determination and adjustment of the calibration drift of the CMS.

- Preventive maintenance of the CMS, including spare parts inventory.

- Accuracy audit procedures, including sampling and analysis methods.

- Procedures for performance evaluations (performance evaluation test plan) and pass/fail tolerances.

- Program of corrective action for a malfunctioning CMS.

- Basis for selection of the CMS measurement location relative to each affected source such that the measurement is representative of control of the exhaust emissions.

- Equipment and specifications of the CMS (sample interface, the pollutant concentration or parametric signal analyzer, and the data collection and reduction systems).

- Procedures with data reduction requirements [in accordance with 40 CFR §63.8(g)(2), or as otherwise specified in the specific NESHAP].

- Procedures for the ongoing O&M, data quality assurance, and ongoing recordkeeping and reporting.

In most NESHAP, a site‐specific monitoring plan is not required if you have existing plans prepared under Appendix B to 40 CFR Part 60 that apply to CEMS and COMS and meet the monitoring, installation, operation, and maintenance requirements of the specific NESHAP.

As with the performance test plan, submit your site-specific monitoring plan upon request, at least 60 days before your initial performance evaluation of your CMS. Note that this submittal timeframe is from Subpart A, and some NESHAPs have different submittal schedules, so please check your applicable NESHAP for details.

Site-Specific Fuel Monitoring Plan

With few exceptions, for facilities with units subject to Boiler MACT, a site-specific fuel monitoring plan must be developed and implemented before conducting a required performance test, or if you will be using fuel analysis in lieu of performance testing to demonstrate compliance. The purpose of this plan is to identify the pollutant input loading to the boiler during the performance test, which will then become an operating limit (or an emission limit if using fuel analysis as the compliance option) until the next performance test is conducted. This plan does not have to be submitted unless the facility intends to use an analytical method other than those required by Table 6 of 40 CFR Part 63, Subpart DDDDD. You must, however, keep of copy of the plan as a record. The site-specific fuel monitoring plan must:

- Identify the fuels that are to be combusted.

- Determine who will be conducting the fuel analysis (the facility or the fuel supplier).

- Provide a detailed description of the sample locations and procedures for collecting and preparing the samples.

- Present the analytical methods, along with minimum detection levels, to be used.

- Present the calculations and supporting documentation.

”

Quality Assurance (QA)/Performance Test Plan

The requirement for a performance test plan is found at 40 CFR §63.7(c). Similar to a performance test protocol, this plan provides a summary of the overall test program, and must include a test program summary, the test schedule, data quality objectives (i.e., pretest expectations of precision, accuracy, and completeness of data), and both an internal and external QA program. The following should be considered when developing a performance test plan:

- Program contacts and responsibilities.

- Site-specific plan elements.

- Test program schedule.

- Testing conditions.

- Test method performance audit (PA).

- Unit/process operation and parameter monitoring.

- Control device operation and monitoring.

- Stack sampling location.

- Velocity and volumetric flow rate.

- Fixed gas composition.

- Moisture content.

- Pollutant-specific reference methods.

- Emission test data reduction.

Typically, the test plan is submitted to the U.S. Environmental Protection Agency (U.S. EPA) and/or your local permitting authority only upon request. If it is requested, it must be submitted at least 60 calendar days before the performance test is scheduled to take place, that is, simultaneously with the notification of intention to conduct a performance test required by 40 CFR §63.7(b), or on a mutually agreed upon date.

Emissions Averaging Plan

Boiler MACT is an example of a NESHAP that allows emissions averaging as a compliance option. The emissions averaging provisions are very prescriptive, but may be a viable option for certain facilities. A component of the emissions averaging compliance approach under Boiler MACT is the requirement to develop and implement an emissions averaging plan. If you choose to demonstrate compliance by using emissions averaging, you must submit the plan only upon request (no later than 180 days before the date that the facility intends to demonstrate compliance using the emissions averaging option); otherwise you must maintain a copy of the plan as a record. The plan must include the following:

- Identification of all existing boilers and process heaters that will be part of the averaging group.

- Date on which emissions averaging is to commence.

- Process parameters that will be monitored for each averaging group.

- The control technology or pollution prevention measure for each boiler or process heater in the averaging group.

- The test plan for measurement of emissions.

Energy Efficiency Implementation Plan

Energy efficiency credits are another option for existing boilers according to 40 CFR §63.7533 of the Boiler MACT. A facility may meet certain criteria to take credit for implementing energy conservation measures identified in the energy assessment. However, part of this option is the requirement for an implementation plan. The plan must identify all the boilers where the efficiency credits will be applied, include a description of the energy conservation measures implemented along with the energy savings from each energy conservation measure, and contain an explanation of the criteria utilized for determining the energy savings. If you choose to use efficiency credits from energy conservation measures to demonstrate compliance, you must keep a copy of the implementation plan and copies of all data and calculations used to establish credits. If requested, a facility must submit the implementation plan for efficiency credits for review and approval no later than 180 days before the date on which the facility intends to demonstrate compliance using the efficiency credit approach.

Startup and Shutdown Plan

As part of the proposed Boiler MACT reconsiderations, U.S. EPA will require a written startup and shutdown plan (SSP). If this requirement remains in the final version of the rule, the plan must be developed and written according to the requirements in Table 3 of the Boiler MACT rule. The focus of the SSP will be the facility’s definition of what constitutes startup and shutdown for its affected boilers, and how the facility will demonstrate compliance with the startup and shutdown work practice standards. As proposed, the SSP must be maintained onsite and available upon request for inspection.

Operation and Maintenance Plan

Certain NESHAP require a site-specific O&M plan to be developed and implemented. For example, the PC MACT specifies in 40 CFR §63.1343(c) and 40 CFR §63.1347 that the site-specific O&M plan include:

- Fugitive dust emissions control measures for open clinker storage piles.

- Location of current and future clinker storage piles.

- Basis for selection of site-specific fugitive dust emissions control measures.

- Procedure for proper O&M of the affected sources and air pollution control devices.

- Procedure for addressing periods of startup and shutdown, corrective actions, and annual inspections of the components of the combustion system.

Failure to comply with any provision of the PC MACT O&M plan developed is a violation of the standard. Under PC MACT, the O&M plan must be submitted for review and approval as part of the application for a Part 70 permit.

The RICE MACT requires a similar type of O&M plan if a RICE manufacturer does not have specific emissions-related written instructions.

Visible Emission & Opacity Monitoring Plan

Under the PC MACT, an affected facility is required to comply with opacity standards for non-kiln/clinker cooler equipment such as the raw material, clinker, or finished product storage bins, conveying system transfer points, bagging systems, bulk loading or unloading systems, raw and finish mills, and raw material dryers. Compliance with the opacity standards can be demonstrated by a COMS or by U.S. EPA Reference Method 22 (RM22) and U.S. EPA RM9. RM22 describes the procedures for identifying visible emissions and RM9 quantifies the percent opacity for comparison with the emission standard. RM9 is only required if visible emissions are observed when performing a RM22. A Visible Emission & Opacity Monitoring Plan is required for facilities utilizing the RM22/RM9 approach to comply with opacity standards for non-kiln/clinker cooler equipment. The Visible Emission & Opacity Monitoring Plan must include the procedures for completing the RM22/RM9 consistent with 40 CFR §63.1350(f)(1)(i)-(vii).

”

Corrective Action Plan

The proposed corrective action plan for the Refinery MACT stems from the Petroleum Refinery sector risk and technology review (RTR) completed in 2014. The comment period on the proposed rule ended on October 28, 2014, and the petroleum refinery sector is anxiously awaiting the final rule. The proposed rule contains benzene fenceline monitoring requirements, using two (2)-week time-integrated passive diffusive sampling. The results of the passive sampling would need to be compared to a regulatory benzene concentration action level. U.S. EPA modeled fenceline benzene emissions from the 2011 refinery information collection request (ICR) to determine an appropriate benzene concentration action level – the concentration that, if exceeded, a refinery would need to take corrective action. Based on U.S EPA’s air dispersion modeling study, the maximum post-MACT control benzene concentration modeled at the fenceline was determined to be 9 micrograms per cubic meter (µg/m3) of benzene. This concentration reflects refinery fugitive emission sources only and excludes a background concentration. A facility would exceed the concentration action level when the highest of the rolling annual average fenceline concentrations corrected for background is greater than 9 µg/m3.

If a facility determines that the benzene fenceline monitoring data action level has been exceeded for any 12-month rolling average, it must initiate a root cause analysis and determine an appropriate corrective action. If the action level is exceeded again for the next sampling episode, the facility must develop a corrective action plan. The plan must describe all of the corrective actions completed to date and additional measures that the facility proposes to employ to reduce fenceline concentrations below the action level. The corrective action plan must also include a schedule for completion of the proposed measures to be taken to reduce fenceline concentrations. This plan, as proposed, must be submitted to U.S. EPA within 60 days after determining that the action level was exceeded.

Some of the compliance plans that have been discussed are required now or in the near future. The plans generally need to be in place at least 60 days prior to the initial performance test in the event that U.S. EPA requests to review your plan (i.e., U.S. EPA will request you to submit the plan for review upon its receipt of the intent to test notification, which is required 60 days prior to the test date). The work towards compliance with these rules isn’t done with just passing the initial performance test. It begins with the development of well-crafted plans that are a balance between your facility’s operations and compliance obligations. You need to make sure that you meet the specified compliance plan requirements while also making sure that your facility can live with the commitments set forth in plan. This article doesn’t cover every scenario, but we can help you determine which compliance plans are required and how potential compliance options may be of use. Contact us today to let us help you navigate the compliance plan labyrinth. In particular, don’t hesitate to reach out to the individuals below depending on what rule(s) your facility is subject to:

- RICE MACT: Ron Harding

- PC MACT: Eric Swisher

- Boiler MACT: Mark Wenclawiak

- Refinery MACT: Nick Leone

“

How Will You Be Determining Your Clinker Production Rate In Order to Demonstrate Compliance With the PC MACT?

This blog post focuses on the clinker production monitoring requirements for PC MACT and presents questions that you should consider when developing your compliance strategy.

Before I outline the specific clinker production monitoring requirements, let’s take a moment to revisit why affected facilities need to determine their clinker production rate. A few PC MACT emission limits, such as particulate matter (PM) and mercury (Hg), are in units of pounds of pollutant per mass of clinker produced [i.e., lb/ton clinker or lb/million (MM) tons clinker]. Also, let’s not forget to include the emission limits that don’t appear in “Table 1” of the rule. Specifically, if your operations combine the clinker cooler exhaust or coal mill exhaust with the kiln exhaust, you may meet an alternative PM emissions limit that includes a 1.65 ton feed per ton clinker conversion factor. Therefore, monitoring clinker production is required to demonstrate compliance with these specific emission limitations.

You are probably thinking that we already have an established process for determining clinker production rate, which we have been using for years, and I’m not reinventing the wheel. So what’s the big deal? If you know me, you know I would tell you that “the devil is in the details.” Before I give you 99 reasons why you should be revisiting how you will be determining your clinker production rate for the PC MACT, let’s get clear on what the PC MACT clinker production monitoring requirements are, which are located at 40 CFR §63.1350(d) and also summarized below.

You must determine hourly (notice the emphasis on hourly) clinker production by one of two methods. Both methods require you to install, calibrate, maintain, and operate a permanent weigh scale system to measure and record weight rates in tons-mass per hour, which must be maintained within ±5 percent accuracy. The two options for a measuring system to determine clinker production are:

- The direct measurement of the amount of clinker produced, or

- The directed measurement of the amount of feed to the kiln and an applied kiln-specific feed to clinker ratio.

As noted above, measuring the amount of feed to the kiln requires an extra step to calculate your hourly clinker production rate. This extra step utilizes a kiln-specific feed to clinker ratio that is based upon reconciled clinker production and recorded feed rates.

That’s enough of the background; now it is time to get all tangled up with the details. I have identified below, in no particular order, a list of notes/comments/questions that hopefully spark your interest and get you into action now rather than later.

Feed to kiln method for determining clinker thoughts…

- Feed means the prepared and mixed materials, which include but are not limited to materials such as limestone, clay, shale, sand, iron ore, mill scale, cement kiln dust (CKD) and fly ash, which are fed to the kiln. Is your weigh scale system located in a position to record the weights of all feed materials? Do you insufflate CKD into the hot end of the kiln? Will your weigh system include this insufflated CKD? Does your weigh system need to include insufflated CKD?

- The PC MACT requires your calculated hourly clinker production to be based upon reconciled clinker production determined for accounting purposes. Do your clinker production records used for PC MACT compliance need to match your accounting records? Has this always been true—will it cause issues in the future? Furthermore, the PC MACT requires your clinker production ratio to be updated monthly. When have you historically updated this ratio—has it been monthly? Are your procedures for completing clinker production reconciliation documented?

- If your clinker production ratio changes at clinker reconciliation, you must use the new ratio going forward, but you do not have to retroactively change clinker production rates previously estimated. Will you retroactively change clinker production rates? That seems like more work? What if you have an emission limit exceedance and reconciliation will cause the exceedance to go away? Will you perform retroactive reconciliation on an as-needed basis? Do you remember Eric’s blog What should you be asking your DAHS vendor with respect to the PC MACT? How will your hourly clinker production rate be communicated and recorded within your DAHS? Will it be transmitted to the DAHS as an hourly value or will the system calculate the hourly values? Will a person need to manually input the data—when is the best time to do this? Can your DAHS accommodate retroactive clinker production reconciliation and reprocess the hourly emissions? What are the logistics for completing these processes?

- Remember that alternative PM emissions limit? It included a 1.65 ton feed per ton clinker conversion factor. Does this seemingly fixed factor get updated monthly? Does it fit into your reconciliation for accounting purposes?

Additional clinker production rate measurement thoughts…

- PC MACT requires you to determine, record, and maintain a record of the ongoing accuracy of the system of measuring hourly clinker production (or feed mass flow) each quarter of source operation. That doesn’t sound practicable. How do you plan to do this? Do you have the resources to do it in-house or will you need to contract a third party? Will you need to stop production to complete this requirement? If so, how long will it take? Are you going to include the procedure for the measurement system accuracy in your continuous monitoring system (CMS) Site-Specific Monitoring Plan?

- PC MACT requires you to measure clinker production directly, record the daily clinker production rates. Did you notice that the PC MACT requires you to determine hourly clinker production rates but, requires you to record daily clinker production rates? If you measure the kiln feed rates and calculate clinker production, you must record the hourly kiln feed and clinker production rates.

- PM emissions testing require you to determine a source specific 30-day rolling average operating limit using a lb/ton-clinker per milliamp value. This will set your operating limit at the PM CPMS output value. Mercury emissions testing requires you to calculate the emission rate using 30 days of clinker production during the same time period as the mercury emissions were measured. Again, how will retroactive reconciliation of clinker production affect your compliance with these testing requirements? How will your DAHS handle this?

You are probably thinking this is another PC MACT blog with lots of questions but not a lot of answers. That was intentional. The thought around developing a compliance solution comes now. If you have questions concerning this blog or any of the previous PC MACT series blog posts, give me a call at (610) 933-5246, extension 120 or send me an email at jkleinle@all4inc.com. I’d love to hear from you.

Happening Now: Air Quality Study by Aircraft Over Oil and Gas Production Areas

Beginning the week of March 22, 2015, an aircraft carrying a suite of meteorological and ambient monitoring instruments began a field campaign aimed at studying the air over oil and gas production areas. The study, named the Shale Oil and Natural Gas Nexus (SONGNEX), is led by the National Oceanographic and Atmospheric Administration (NOAA) and the Cooperative Institute for Research in Environmental Sciences (CIRES). It focuses on evaluating the impacts of emissions from oil and gas production sites on climate, air quality, and public health.

NOAA’s WP-3D Orion research aircraft is taking air samples over a variety of different tight oil and gas basins, focusing on the western United States. Flights are occurring over the following basins: Bakken, North Dakota; Upper Green River Valley, Wyoming; Uintah basin, Utah; Denver-Julesburg basin, Colorado; Haynesville shale, Texas; and Eagle Ford, Texas. SONGNEX will consider flights over the Marcellus, Pennsylvania region if time permits.

The study aims at collecting data to quantify emissions over the different oil and gas sites, as well as study the chemical transformation of these emissions in the atmosphere. The first main area of study, climate, will focus on understanding the effects of oil and gas production from the radiative forcing agents of methane and black aerosol carbon. Methane, a greenhouse gas and a main component of natural gas, is released into the atmosphere from equipment leaks, and the amount of emissions vary depending on different stages of production. The SONGNEX fly-over study will measure the methane emissions from the different basins using the same methodology to gain a better understanding of these amounts. Black carbon aerosols are emitted from natural gas flaring, and have recently been found to be an important anthropogenic emission in terms of climate forcing.

The second main area of study, air quality, will analyze the formation of ozone and fine particulate matter from emissions of methane, non-methane hydrocarbons, and nitrogen oxides over oil and gas production areas. Previous studies have shown enhancements of methane, non-methane hydrocarbons, and nitrogen oxides emissions over oil and gas basins, as well as elevated levels of ozone. Modeling of oil and gas production areas has also shown increasing ozone concentrations over shale regions. The data collected during SONGNEX will be used to quantify the precursor emissions and to analyze the springtime chemical transformation of the pollutants into ozone and fine particulate matter.

The last main area of study is air toxics. Oil and gas production may potentially release multiple air toxic compounds into the atmosphere. SONGNEX will quantify concentrations of hydrogen sulfide and benzene, toluene, ethyl benzene, and xylenes (BTEX compounds) over oil and gas production sites. The study will evaluate the mixing ratio and fraction of emissions at different stages of oil and gas production.

The SONGNEX fly-overs are happening now through May 2015, and are sure to collect some novel data relating to emissions over oil and gas production basins in the western United States. The analyses of the data will likely contribute to future regulations by the U.S. EPA regarding oil and gas production. It will be interesting to see how the climate conclusions affect greenhouse gas regulations and how the air quality study could influence ambient monitoring for criteria pollutants around oil and gas operations. The focus on ambient concentrations of oil and gas production emissions is similar to the proposed benzene fenceline monitoring requirements of 40 CFR Part 60, Subpart CC and UUU. The air toxics evaluation could provide a hint to future U.S. EPA regulation of emissions associated with oil and gas production.

Have you seen NOAA’s research aircraft flying over your facility? Leave a comment below to let us know! ALL4 will be keeping an eye on the studies that emerge from the SONGNEX campaign and how they shape future regulatory action.

Site Specific Monitoring Required by the PC MACT: Answering Your Questions

Compliance with the PC MACT requires multiple plans to be developed. These plans include the Operation and Maintenance (O&M) Plan, Site-Specific Performance Test Plan, Emissions Monitoring Plan, Site-Specific Monitoring Plan, and particulate matter continuous emission monitoring system (PM CEMS) Correlation Test Plan (if applicable). One could argue the importance of each plan; however, for the purpose of this blog post the focus is on the Site-Specific Monitoring Plan.

What Is The Site-Specific Monitoring Plan?

The Site-Specific Monitoring Plan is required for the continuous monitoring system (CMS) that will be operated as part of your PC MACT compliance strategy. The Site-Specific Monitoring Plan defines the procedures that a facility will follow as part of the initial performance evaluation, as well as the procedures for the ongoing operation and maintenance of the CMS.

Imagine that your facility is installing monitoring systems for compliance with the PC MACT for which your facility has limited operational experience such as mercury (Hg), hydrogen chloride (HCl), total hydrocarbon (THC), or Particulate Matter (PM). If this sounds a lot like you, then your CMS Site-Specific Monitoring Plan should be developed and address the following elements:

- Documentation of the representativeness of CMS installation location.

- Performance and equipment specifications.

- Data collection and reduction systems.

- Procedures to complete the initial performance evaluation (and to what pass/fail tolerances).

- A system for ongoing operation, maintenance, data quality assurance, and ongoing recordkeeping and reporting of the CMS data.

- Supporting calculations.

To further emphasize the importance of the Site-Specific Monitoring Plan, I would ask you to consider whether or not you plan on having your stack testing firm perform a relative accuracy test audit (RATA) on your THC analyzer. Hint take a look at Section 6.1 in Performance Specification 8A of 40 CFR Part 60, Appendix F.

CMS Installation By A Third Party?

Are you assuming that a third party will be completing the CMS performance evaluation as part of their scope? Now is the time to confirm how the CMS are going to be certified after installation and by whom. Some third parties may only complete the tasks that are necessary to ensure that the CMS data being collected are representative of operations and are not completing the CMS performance evaluation required by the PC MACT. If a third party will be contracted to complete the CMS performance evaluation, a well-designed CMS Site-Specific Monitoring Plan will ensure that the CMS will meet the requirements of the PC MACT and the underlying Performance Specifications or Procedures in 40 CFR 60 Appendix B & F respectively (as applicable).

Who’s Responsible For The Ongoing CMS Requirements?

After installation and certification of the CMS, who will be responsible for the ongoing operation, maintenance, and quality assurance of the data collected by the CMS? Assuming that your plant instrument technicians will be responsible for these items, the CMS Site-Specific Monitoring Plan is required to outline the procedures (and tolerances) for the ongoing quality assurance of the CMS. Your CMS Site-Specific Monitoring Plan should be a usable document, referencing information supplied by the equipment vendor (including manufacturer’s recommendations), and meeting the regulatory requirements of the PC MACT to ensure that the procedure are followed to quality-assure the CMS data. Don’t forget that although a thorough CMS Site-Specific Monitoring Plan is needed to ensure that your instrument technicians are in a position to quality assure the collection of your ongoing CMS data, training your staff on the implementation of the CMS Site-Specific Monitoring Plan is also needed for your monitoring plan to be successful.

When Should You Develop Your CMS Site-Specific Monitoring Plan?

Now! From a regulatory perspective, a CMS Performance Evaluation Test Plan must be in place at least 60 days prior to the CMS performance evaluation (i.e., no later than January 07, 2016 based on the latest possible performance test date of March 07, 2016) and available for submittal to your state agency or the U.S. EPA. The performance evaluation of the CMS must be completed as part of the performance test, which is required to be completed no later March 07, 2016 (i.e., 180 days after the compliance date). The CMS Performance Evaluation Test Plan is part of the Site-Specific Monitoring Plan which must be submitted (upon request), at least 30 days before the initial performance evaluation of the CMS.

Have Additional Facilities Subject To PC MACT?

The CMS Site-Specific Monitoring Plan is an area that is perfect to take advantage of the economies of scale. By working together you can develop a thorough, cost effective CMS Site-Specific Monitoring Plan that provides consistency amongst facilities, meets the regulatory of the PC MACT, and provides a platform for more efficient training.

How Can ALL4 Help?

The development of a CMS Site-Specific Monitoring Plan is both a science and an art. The science is in interpreting the regulatory requirements and understanding the technical aspects of the CMS. The art is in the development of a plan that can be used by multiple audiences with different needs including environmental and instrumentation personnel. At ALL4 we treat the CMS Site-Specific Monitoring Plan as a resource that needs to be used as part of your PC MACT compliance solution. Unlike what your prior experiences with others may have been, no more are plans developed solely to meet a regulatory requirement and remain on the shelf collecting dust as various quality assurance activities are missed. We strive to create a CMS Site-Specific Monitoring Plan that provides the necessary information structured in a manner that easily used. If you have any more questions on our approach to developing a robust CMS Site-Specific Monitoring Plan, give me a call or shoot me an email.

Give me a call (610.933.5246 x117) or shoot me an email (eswisher@all4inc.com) and we’ll get started!

As promised, ALL4 will continue a series of upcoming blog posts that will continue to dive further into the PC MACT in preparation of the September 09, 2015 compliance date.