Recent Court Case Sets 1-Hour SO2 NAAQS and Air Quality Modeling Precedent

What is the current status of the 1-hour SO2 NAAQS implementation process for areas without SO2 monitors?

Currently, U.S. EPA is reviewing comments submitted (the comment period ended on July 22, 2013) on the draft “SO2 NAAQS Modeling Technical Assistance Document” and the “Source-Oriented SO2 Monitoring Technical Assistance Document.”

U.S. EPA currently intends to issue final versions of the documents by the end of 2013. U.S. EPA then intends to identify those sources and areas that will deploy new monitors or that will be subject to air quality modeling in 2015 with monitoring and modeling protocols submitted in 2016. Finally, monitors will be deployed and air quality modeling initiated in January 2017.

Cement Manufacturing – Balancing Growth with Air Quality Requirements

In most areas of the U.S., it appears that the recession is a bad memory and the signs of recovery are all around us. As described by the Portland Cement Association (PCA) on its website[1], “following the strongest cement consumption gains in seven (7) years in 2012, cement consumption growth will continue in 2013 with a 6.2% increase.” PCA continues to explain that “the accelerated consumption predicted during the second half of 2013 should carry into the following year, with an increase of 9.2% for 2014.” PCA also upwardly revised its long-range projections for 2015-2017, with annual growth during that period expected to be as high as 11.1%. PCA predicts cement consumption levels will reach 120 million metric tons by 2017.

With this good news for U.S. cement plants, as well as similar projects across key construction sectors, the cement industry will need to balance this growth with challenging air quality requirements. A given cement manufacturing process can simultaneously be subject to multiple air quality regulations with varying requirements and compliance deadlines. Specifically, these requirements include the National Emission Standards for Hazardous Air Pollutants (NESHAPs) for the Portland Cement Manufacturing Industry (40 CFR Part 63, Subpart LLL; “PC MACT”); the Commercial and Industrial Solid waste Incinerator (CISWI) Rule (40 CFR Parts 60, Subparts CCCC or DDDD), the NESHAP for Major Sources: Industrial, Commercial, and Institutional Boilers and Process Heaters (40 CFR Part 63, Subpart DDDDD, “Boiler MACT”), and New Source Performance Standards (NSPS) for Portland Cement Plants (40 CFR Part 60, Subpart F). Since both CISWI and Boiler MACT have been given an enormous amount of attention in 2013, in this article we will explore PC MACT in some more detail and then discuss the relationship between these separate but inexorably connected rules.

Brief History of PC MACT[2]

Similar to Boiler MACT, PC MACT has existed for several years, beginning with the promulgation of standards in 1999. Following iterations of comments, reconsiderations, and amendments, revised standards were promulgated on February 12, 2013. PC MACT applies to both major and area sources of HAPs. One (1) of the primary drivers of the revised PC MACT was the impact of the U.S. Environmental Protection Agency’s (U.S. EPA’s) nonhazardous secondary materials (NHSM) rule, which resulted in the reclassification of 23 cement kilns as CISWI units. This required U.S. EPA to recalculate the floors that establish the PC MACT emission standards. With the recalculation of the floor came revisions to the standards for particulate matter (PM); the standards for mercury, total hydrocarbons (THC), and hydrogen chloride (HCl) remained the same as the 2010 version of PC MACT. PC MACT also includes an emission standard for dioxins and furans (D/F). In addition, startup and shutdown emission limits were replaced with work practice standards, and the monitoring requirements for the PM and THC pollutants were modified. Lastly, and potentially most importantly, the compliance date to meet the PC MACT emission standards was extended to September 9, 2015 for existing sources. A more near-term compliance date of February 12, 2014 was established for existing open clinker storage piles.

Affected Sources Under PC MACT

The affected sources in PC MACT consist of kilns, clinker coolers, raw material dryers, and open clinker storage piles. Emission standards and work practice standards are provided for new (post-May 6, 2009) sources and existing sources in normal, as well as startup and shutdown operating modes, that are located at major and area sources of HAPs. Emissions from open clinker piles must be effectively controlled through the use of an enclosure, installing and operating a water spray or chemical dust suppressant, or use of a wind barrier or tarpaulin.

Summary of Performance Testing and Monitoring Requirements

The compliance basis for the PM standards for kilns has been revised to a manual three-run stack test conducted annually. The opacity limits and the requirement for opacity monitoring of kilns and clinker coolers at major sources has been removed from PC MACT (effective September 2015), since facilities will now be required to use a PM continuous parametric monitoring system (PM CMPS) to demonstrate continuous compliance with PM emission limits. For raw material, clinker, or finished product storage bins; conveying system transfer points; bagging system; bulk loading or unloading system; raw and finish mills; and raw material dryers, a 10% opacity limit remains, with the option to use a continuous opacity monitoring system (COMS) or U.S. EPA Method 22. A continuous emissions monitoring system (CEMS) must be used to demonstrate compliance with THC emission standards. Kilns also have operating limits related to the temperature of the gas at the inlet to the kiln PM control device or to the sorbent injection rates, where employed. The operating limits are used as the continuous compliance demonstration methodology for D/F emissions. For mercury, THC, and HCl, initial performance tests using U.S. EPA reference methods are required, followed by the use of CEMS (or a sorbent trap monitoring system for mercury) as the on-going continuous compliance demonstration method. Monitoring of clinker production must be performed on an hourly basis.

Based on these requirements, the cement industry will be burdened with significant performance testing, CEMS installation, and operation and maintenance requirements for compliance purposes, particularly compared to other industries.

Is Your Kiln Subject to PC MACT or CISWI?

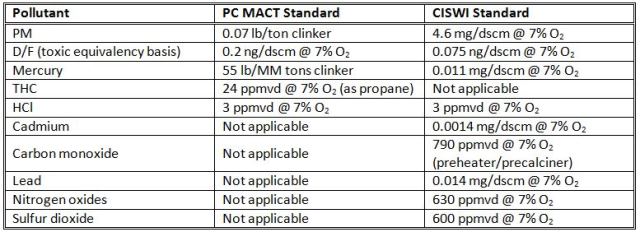

Because of the high temperatures required for the Portland cement manufacturing process, cement plants are continually searching for alternative fuels to supplement traditional fossil fuels. According to PCA, the average energy input required to make one (1) ton of cement is 4.7 million British thermal units (MMBtu), which is the equivalent of about 418 pounds of coal.[3] Today, many plants meet between 20 to 70% of their energy requirements with alternative fuels through consumer wastes or byproducts from other industries. Traditional Fuels like coal, coke, natural gas, and fuel oils contain carbon and release tremendous quantities of heat when they are burned. However, these “primary” fuels are not the only fuels that contain carbon. Tires, which typically have a higher heat input than coal, are also a great source of hydrocarbons (carbon and hydrogen). Using tires for combustion in a cement kiln produces 25% more energy than coal and it can also result in lower emissions. Many materials with high carbon content are used as fuels, such as paper, packaging, plastics, wood/saw dust, and solvents. Burning alternative fuels in cement kilns can be viewed as beneficial from a cost and sustainable operating perspective (e.g., reducing the amount of waste otherwise sent to a landfill). However, doing so can introduce the possibility of a kiln being classified as a solid waste incinerator (more appropriately, a waste-burning kiln), and therefore, subject to the CISWI regulations. Given the process temperature requirements and the cost of fossil fuels, the flexibility to use solid wastes in a kiln might be an opportunity worth considering (or continuing, for those units that already use such fuels). Therefore, one place to begin your evaluation of PC MACT versus CISWI would be to compare the applicable emission standards. The table below summarizes the pollutants include in PC MACT and CISWI, based on the assumption of an existing kiln located at a major source and under normal operating mode (for the purposes of PC MACT) as defined under each regulation.

ng/dscm @ 7% O2 = nanograms per dry standard cubic meter corrected to 7% oxygen

ppmvd = parts per million by volume, dry basis

mg/dscm @ 7% O2 = milligrams per dry standard cubic meter corrected to 7% oxygen

Because of the various units of measure of the emission standards and the range of operating conditions for cement kilns, an “apples to apples” comparison of the emission standards between PC MACT and CISWI is beyond the scope of this document. However, a qualitative discussion on the implications of complying with the emission standards in the PC MACT and CISWI is presented below.

According to PCA,[4] the CISWI standards present the cement industry with two (2) options: 1) continue to burn alternative fuels that are solid wastes and invest in air pollution control devices to comply with CISWI emission standards, or 2) discontinue using alternative fuels that are solid wastes to avoid CISWI and remain subject to PC MACT. The more beneficial option for a given cement plant will be based in part on a comparison of the incremental costs to install the necessary control devices and monitoring equipment to comply with CISWI over PC MACT, as well as the potential fuel cost savings resulting from the continued burning of solid wastes in lieu of fossil fuels.

PCA evaluated the emission control technologies[5] that are applicable to achieve compliance with the CISWI and PC MACT standards:

- Baghouses and electrostatic precipitators (ESPs) for particulate control for CISWI and PC MACT. Baghouses and ESPs also will control lead and cadmium emissions for CISWI purposes.

- Activated carbon injection (ACI), wet scrubbers, or a combination of both for mercury control for CISWI and PC MACT.

- ACI, a regenerative thermal oxidizer (RTO), or a wet scrubber combined with an RTO system for the control of THC for PC MACT.

- Wet scrubber systems to control HCl emissions for CISWI and PC MACT.

- Wet scrubber systems, lime injection and hydration systems, and calcinatory slip stream systems to control SO2 for CISWI. It is noted that the inherent process design of a kiln provides an alkaline internal environment that absorbs potential SO2 emissions; therefore, add-on pollution control devices to control SO2 from kilns for CISWI are likely to be polishing devices, if required at all.

- Selective non-catalytic reduction (SNCR) systems to control NOX emissions for CISWI.

- Burner enhancements and good combustion practices to control CO for CISWI.

- Achieving cooler exhaust temperatures to the kiln’s control devices to control D/F emissions for CISWI and PC MACT.

Based on PCA’s estimates for a 1.2 million ton dry kiln with a pre-calciner and pre-heater, the total industry investments to comply with PC MACT are estimated at $3.4 billion and are estimated at $2.0 billion for CISWI.[6] These data are limited to kilns. PC MACT also includes requirements for other processes at a cement plant, which introduces the complexity of a given plant with a CISWI-regulated kiln also obliged to comply with PC MACT for other regulated processes.

From College to Being a Consultant – Not That Different

Yes! I did it, I graduated college! As I soaked in the excitement of graduation accompanied by the memories of the past four years, I suddenly thought to myself: “Wait, so now what am I supposed to do? Are cell phone bills, early wake ups, morning commutes, and conference calls the only things on this earth that I have to look forward to?” Don’t worry soon-to-be-graduates; there is a happy ending to this story. The good news is that I’ve been working at ALL4 for almost three months and I have yet to dread an early morning wake up, or sitting in on a client conference call. Although I can’t deny my nostalgia for those lovely fall days walking around the quad, or throwing the Frisbee after class, I’ve begun to notice that life working at ALL4 has a striking resemblance to the pace of college life and, to be honest, I like it. So, how can this be possible? How can working full time after graduation be similar to college? Well, let me show you how a career at ALL4 as a consultant can compare to my college days.

I do work for people who expect the very best, with complete accuracy. At ALL4, I call them clients. In college, I called them professors. Clients are much like college professors, as both demand that projects and presentations be performed in a professional manner. In both cases I must demonstrate my mastery and expertise in a specific area of study.

As a consultant, I am on a team. In college I had my lab group. Now those lab partners have transformed into my project team. Collaboration and efficiency are still required to meet deadlines and working together is essential.

Consultants form relationships. Before working at ALL4, I defined my relationships as friendships. Now, relationships define my work. Strong relationships create repeat business contracts and a good reputation.

I still have the opportunity write essays…even as an engineer! I get to delve into my creative side and enhance my writing ability through both technical and blog writing. ALL4 teaches its consultants to be well rounded in very much the same way college educates the whole person so he/she can develop a variety of skills.

I could go on and on about highlighting all the similarities between a college lifestyle and life at ALL4, but I’m going to end with two that I regard as the most important. At ALL4 learning is essential. Our product is our knowledge. We are always learning new processes, new regulations, and new methods of efficiency. With learning at the forefront, ALL4 consultants must also juggle a multitude of different projects. Just as a student has a full plate of assorted work from various classes, the workload at ALL4 varies constantly.

As you sit there pondering life beyond those college dorms and academic halls, and think of the future unknowns, just know working as a consultant is more similar to college than you might have once thought. You’ll be prepared for the real world, as long as you are always ready to learn; for more learning is surely on the way. The real world after college isn’t as bad as some people say, especially when you are at a place like ALL4.

Alternative GHG Reporting Approaches May Be On The Horizon

Those of you within the community of facilities reporting under 40 CFR Part 98 (Mandatory Reporting of Greenhouse Gases Rule) may recall a twist to the most recent reporting season in which you were required to resurrect historic data from years 2010 and 2011 and report it to U.S. EPA as part of your 2013 reporting effort. This was required if you reported under any of the following subparts:

- C (Stationary Fuel Combustion)

- D (Electricity Generation)

- DD (SF6 from Electric Equipment Use)

- FF (Underground Coal Mines)

- HH (Municipal Landfills)

- II (Industrial Wastewater Treatment)

- SS (Electric T&D Equipment Manufacturing)

- TT (Industrial Waste Landfills)

This unique request by U.S. EPA stemmed from U.S. EPA’s August 2011 deferral of certain inputs to equations until either March 31, 2013 or March 31, 2015. The deadline varied per input to equation, and took effect in order to afford U.S. EPA the time it needed to fully evaluate the potential impact of releasing Confidential Business Information (CBI) to the public.

When U.S. EPA completed their evaluation of the first set of equation inputs and determined that they did not constitute CBI, facilities reporting under the subparts above were asked to report certain inputs to equations that were associated with 2010 and 2011 during 2013. It wasn’t tricky to fulfill their request since it had been a recordkeeping requirement all along to maintain these inputs, but it wasn’t pleasant either. Just because U.S. EPA isn’t concerned about the impact of releasing these inputs to the public doesn’t mean things are this comfortable at the facility-level.

On September 11, 2013, in an effort to soothe reporters’ concerns over those inputs still constituting CBI, U.S. EPA proposed alternative methods for reporters to comply with 40 CFR Part 98 which would still allow U.S. EPA to validate the information submitted. The approach essentially involves a reporter entering the requested data elements into an electronic tool that will both calculate emissions and provide verification of them. As proposed, the tool doesn’t retain the data that the reporter enters but it would nonetheless allow U.S. EPA the ability to review a verification summary confirming whether the facility’s reported emissions data varies from the emissions expected by the tool.

Before you get too excited about your future privacy, note that the alternative method is only proposed to affect those elements that U.S. EPA ultimately decides are CBI. If they determine they have no CBI concerns about a given reporting element, then that element would still need to be publicly reported to e-GGRT following the close of its applicable deferral period. The proposed alternative method affects 26 specific data reporting elements within the following 24 subparts of 40 CFR Part 98:

- C (General Stationary Fuel Combustion except Specified Stationary Fuel Combustion Sources Connected to Certain Electric Generators that are Connected and Able to Deliver Power to the Local or Regional Electric Power Grid)

- E (Adipic Acid Production)

- F (Aluminum Production)

- G (Ammonia Manufacturing)

- H (Cement Production)

- K (Ferroalloy Production)

- L (Fluorinated Gas Production)

- N (Glass Production)

- O (HCFC–22 Production and HFC–23 Destruction)

- P (Hydrogen Production)

- Q (Iron and Steel Production)

- R (Lead Production)

- S (Lime Manufacturing)

- U (Miscellaneous Uses of Carbonate)

- X (Petrochemical Production)

- V (Nitric Acid Production)

- Y (Petroleum Refineries)

- Z (Phosphoric Acid Production)

- AA (Pulp and Paper Manufacturing)

- BB (Silicon Carbide Production)

- CC (Soda Ash Manufacturing)

- EE (Titanium Dioxide Production)

- GG (Zinc Production)

- TT (Industrial Waste Landfills)

If you are part of the petroleum and natural gas industry, you were probably quick to note that Subpart W was not listed above. As proposed, Subpart W reporters would not be allowed to use the alternative methods and instead would have to report all required data publicly after March 31, 2015. U.S. EPA’s rationale for this exclusion relates to their belief that the information submitted is either already protected due to the level of geographical aggregation that the information is reported at or because the submitted data, if released, would not create a competitive disadvantage in the marketplace.

Comments on the proposed rule will be accepted by U.S. EPA through November 12, 2013. A public hearing will be conducted if requested by September 18, 2013.

The Difficulties With Attaining Compliance With Environmental Regulations – An Ode to the Environmental Compliance Manager

If you are an environmental compliance manager today with college age children you are probably encouraging them to become dentists or orthodontists, and not to follow in your footsteps as an environmental compliance manager. Arguably one of the toughest positions today is being responsible for managing environmental compliance at an industrial facility. The primary element to managing the constantly expanding litany of environmental regulatory requirements is to be sure you have identified all of them. Only then you can set about the task of planning.

I am primarily addressing the difficulties of dealing with environmental compliance with today’s air quality rules and regulations, because that is what I have done for the past 40 plus years. However, most environmental compliance managers do not have the luxury of only working on a single medium (e.g., air, or water, or waste). They wear multiple hats and may even have direct health and safety responsibilities to boot.

First if your facility burns coal in any way shape or form, you are either scrambling to figure out what your control strategies need to be to comply with new air quality regulations, or you are looking for alternative employment. If you are an environmental compliance manager at a coal-fired utility, the hot topic of discussion used to be worrying about whether it would be the Clear Air Interstate Rule (CAIR) or the Cross State Air Pollution Rule (CSAPR) or yet a third variant of the CAIR/CSAPR acronym that might shutdown your units. Not anymore, now it’s how are you possibly going to comply with the Mercury Air Toxics Standards (MATS) rule. Even oil-fired utilities get in on the significant challenges of the MATS rule. On top of all of that, U.S. EPA has revised and strengthened the National Ambient Air Quality Standards (NAAQS) for both nitrogen dioxide (NO2) and sulfur dioxide (SO2) which will, in all likelihood, prohibit major modifications at utility units. Combine all of this with major vacillations in fuels pricing with unconventional natural gas development, electric rate-deregulation in some areas of the country, and unprecedented numbers of facilities shutting down; we have major uncertainty for an entire industry that has been a pillar for the U.S. economy.

For environmental compliance managers at industrial sites, small and large, there are two new rules that are getting your attention which were promulgated under the Maximum Achievable Control Technology (MACT) standards for emitters of hazardous air pollutants (HAPs). Section 112(c) of the Clean Air Act (CAA) requires the U.S. EPA to publish a list of industry group (major source and area source) categories and subcategories that employ, manufacture, or emit HAPs. The 1990 CAA Amendments added provisions that require the U.S. EPA to promulgate technology-based emission standards and allow for the possible supplementation of health based standards. Prior to the1990 CAA Amendments, the regulatory standards for the HAP sources were health based standards. Fine you say, but my company is not a major emitter of HAPs so I don’t have much to be concerned with. Well, no matter how small your combustion source is, it does produce some level of HAP emissions. Enter the U.S. EPA Boiler MACT and the Reciprocating Internal Combustion Engine (RICE) MACT rules that have applicable requirements that even apply to non-major HAP (area source) facilities. Even if the specific emission standards are not difficult for compliance for your particular emission units, these rules come with a plethora of notifications, work practices, recordkeeping, and reporting requirements that are poised to possibly trigger deviations and even exceedances and violations. Failure to follow work practices, testing, monitoring, recording the necessary information within certain timeframes, and filing the proper notices and reports on time are the leading cause of non-compliance violations, not violations for exceeding emission standards.

Unless you don’t have any engines outside of mobile sources and your boilers are very small and only burn natural gas, you now have something to worry about. And not tomorrow, as today is too late in many instances. The first worry is with determining which provisions apply to which of my boilers and engines. There are decision tree charts and computer programs that have been written just to help you decide what applies to your facility because the rules are so complicated. Companies are only now realizing that they have engines they never knew about that may need runtime meters installed. In a similar vein, companies are scrambling to develop written maintenance protocols or are searching for manufacturers recommendations that may or may not exist to support maintenance related documentation requirements. Even if you know that the required maintenance has been performed, if you cannot prove when it was performed and that the work meets the rule or maintenance plan for the source, guess what – your facility is now in non-compliance.

The RICE rules and Area Source Boiler MACT rules know no bound for facility size or emission level. Your MACT requirements are specific to the engine and boiler types at your facility, not the size of your facility. The Boiler MACT rules even apply to school districts, universities, hospitals, small businesses, and many companies that currently do not even have air quality operating permits. Just figuring out if your RICE’s compliance date is June 17, 2007; May 3, 2013; or October 19, 2013 can be very complicated depending upon your facility’s major source status and the engine specifications. I know for a fact that there is a very large population of facilities that have no idea that they are already non-compliant with certain MACT requirements and will soon be in violation with other provisions. Just take a walk around your facility and ask your maintenance staff to show you all of the engines that they use for welding, pumping fluids, and emergency electric generation.

Don’t forget the portable units. I do not know of any environmental compliance manager that has not found previously unknown engines for which they had no record. And if you think just because those engines are portable that they qualify as non-road engines not subject to the RICE MACT, think again. If you cannot prove that the use(s) of your nonroad engines requires that they must be portable and that you have used them in different locations within the last 12 months, they are no longer classified as nonroad engines under the RICE rule. If they are no longer nonroad engines, they should be reflected in your operating permit, as applicable, as a stationary engine and as such are now subject to “new” requirements such as the RICE rules. If you don’t think that the U.S. EPA is enforcing this interpretation, just look at the U.S. EPA Applicability Determination Index (http://cfpub.epa.gov/adi/) of decisions. And if you ask the U.S. EPA if you can rely upon one of their “favorable” decisions for your company, you will be told that you cannot. The only way to really be certain that the engines at your facility that your company had originally purchased as nonroad engines, are still in fact qualified as nonroad engines, is to get your very own Applicability Determination from the U.S. EPA.

While there are many complicated Standards of Performance for New Stationary Sources (NSPS) and MACT rules for certain source categories, I know of no other rules like the RICE and Boiler MACT rules that are as complicated for such a large population of companies as these (except maybe Subpart OOOO, the NSPS for oil and gas operations). Environmental compliance managers like, and need to have, all of their source compliance requirements nailed down and their emission sources on defined compliance plans. The totality of all compliance requirements for the RICE and Boiler MACT rules almost guarantees your facility’s compliance will not be 100%.

Is the bad news over yet? Just when you were about to relax in your lounge chair and take off your hats, news that the designations for nonattainment areas for the most recently issued NAAQS, especially for SO2 and NO2, are happening right now. Is your facility location possibly already designated or about to be designated as nonattainment with a NAAQS? Not only are the new SO2 and NO2 NAAQS one hour emission standards very tight standards for which the ambient background is a large percentage of the NAAQS, but the U.S. EPA originally planned to implement them, even for existing facilities, using conservative air quality computer modeling. Previously this type of conservative air quality assessment was only used for proposed new emission sources or major modifications under Major Source Prevention of Deterioration (PSD) permitting rules.

Initially, the U.S. EPA said that they fully intended to use complex and conservative computer modeling of source emissions to determine the attainment status of all areas in the U.S. Then they back-tracked, as that was turning out to be too complicated for the state agencies (who actually must implement these new NAAQS standards) or maybe they have just deferred the modeling approach for the moment. And if your area is designated by actual measured ambient air quality monitoring as nonattainment, even though the monitor of record might not be near your plant, you can be sure that computer modeling will be involved in deciding what emission reductions you need to make to bring the area back into attainment. Combine this with added assurances that the area will remain in attainment for at least the next 10 years while considering future emissions from all sorts of sources such as automobiles. Environmental compliance managers need to be ahead of the curve on how the state and the U.S. EPA are deciding if your facility location will be designated as attainment or nonattainment with each of the NAAQS. Don’t forget ozone and particulate matter less than 2.5 micron in size (PM2.5). These pollutants are already troublesome for some companies to permit new sources and will likely be even more troublesome as the newer, lower NAAQS for these pollutants are implemented.

All of these new rules result in more air quality permitting to install either new complying emission units or installing control equipment on existing emission units. And even if you are required to install controls (ANY physical change or change in the method of operation), you still need to get air quality permits and possibly go through complicated New Source Review (NSR) permitting and offset the “calculated” emission increases as a result of being required to install controls. This doesn’t quite seem fair. Also with the economy being very challenging for industry, many plants are initiating changes to become more efficient, to adapt more quickly to changing product demand and price-points, and even installing their own electric generation capability to counter the uncertainty of regulations and the more frequent loss of electric supply for various economic and weather related reasons. All this adds up to more air quality permitting, more complicated air quality permitting, and lots more regulatory requirements.

The last few years have had unprecedented activity in new air quality rules and regulations; more than in any similar time period going back to the origin of the Clean Air Act. For environmental compliance managers there are also multiple new water and waste regulations to worry about. It is indeed a very complicated task to coordinate operational changes needed at your facility with the new regulatory changes, which makes planning not something you should do, but something you absolutely must do. My hat is off to environmental compliance managers everywhere who are doing a very important and complicated, but often unappreciated job.

A Bill to Track – Energy Efficiency Legislation

The Senate Bill 1392 offers ALL4 clients a couple of opportunities to benefit in the investment for energy efficiency. In addition, the Bill includes provisions to increase the rate at which government developed technologies and practices are shared and utilized to increase the energy efficiency and efficiency of the manufacturing process. Specifically, the Bill proposes to coordinate Department of Energy (DOE) technology improvements with the needs of industry and manufacturing. By coordinating the emerging technologies being developed, greenhouse gas (GHG) emissions will be reduced and small and medium manufacturing sectors will benefit. The Bill also includes a proposal to provide economic incentives for advanced motor and drive systems. The Bill would authorize a rebated fund of $5,000,000 in 2014 and again in 2015 for industry to install more efficient motors and drive systems. Similarly, upgrading transformers would also qualify for a separate rebate, with this program also being funded for $5,000,000 per year 2014 and 2015. Finally, the Bill would authorize additional spending for the Energy Independence and Security Act of 2007 to the amounts of $200,000,000 for 2013/2014; $150,000,000 for 2015; and $100,000,000 for fiscal years 2016 through 2018.

Senate Bill 1392 seems to be a reasonable approach for improving manufacturing efficiency with the end result of reducing the amount of pollutants generated and the amount of GHG emitted. Companies should remain aware of the Bill’s status and if it becomes law, be prepared to take advantage of the rebate program or emerging technologies developed by the DOE.

U.S. EPA Requires Electronic Non-Trade-Secret Toxic Release Inventory Reporting

The final rule, which was codified at 40 CFR §372.85(c), is effective January 14, 2014 and will affect all non-trade-secret TRI reports. Facilities that submit trade secret TRI information will continue to submit their trade secret reporting forms and substantiation forms in hard copy. U.S. EPA strongly suggests that facilities submitting TRIs containing trade secret information use a computer or typewriter to prepare their hard-copy submissions of TRI information.

The TRI-MEweb software pre-populates forms based on the prior year’s reporting data and performs data validation on the information that has been submitted for the current reporting year, allowing for facilities to better identify potential errors in the data. In order to prepare, transmit, certify and submit a TRI using TRI-MEweb, one or more representatives from each facility must establish an account with U.S. EPA’s Central Data Exchange (CDX). Representatives must identify themselves as either a form Preparer or Certifying Official, both of which can enter and validate information on the TRI-MEweb software. Only a Certifying Official may approve, certify, and submit the final TRI forms to U.S. EPA, which must be accompanied with an Electronic Signature Agreement (ESA). As established with RY 2012, Certifying Officials may use a third-party identity verification vendor to establish an ESA by providing personal identifying information to authenticate his/her identity. An ESA can also be established through the submittal of a paper ESA form two (2) weeks prior to the submittal of the TRI.

An updated version of the TRI-MEweb software will be released in January 2014, and will allow for a facility to electronically revise or withdraw TRI reports for prior reporting years, back to RY 1991. Previous TRI reports did not have to be submitted using TRI-MEweb in order to be revised or withdrawn via TRI-MEweb. The TRI-MEweb software will be populated with historically reported TRI data for RY 2005 through the current reporting year. The TRI-MEweb software will display blank forms for any revisions that need to be made for RYs 1991 through 2004. Any revisions and withdrawals made to previous TRI reporting forms will need to be submitted to the state, tribe, or territory that received the initial TRI report.

Instructions, tutorials, and additional information on how to use the TRI-MEweb software is located on U.S. EPA’s TRI website.