Major Source Boiler MACT Compliance with Oxygen Trim Systems

The National Emission Standards for Hazardous Air Pollutants (NESHAP) for Major Sources: Industrial, Commercial, and Institutional Boilers and Process Heaters promulgated at 40 CFR Part 63, Subpart DDDDD, commonly referred to as the Major Source Boiler MACT (MSBM) standards, provide multiple continuous compliance options that require monitoring. Among these options is the use of a continuous oxygen (O2) trim system for continuous compliance with the carbon monoxide (CO) emission standard. This article will discuss the following questions about O2 trim systems:

- What are O2 trim systems?

- Does my boiler have an O2 trim system?

- Can I put an O2 trim system on my existing boiler?

- How are O2 trim systems use for continuous compliance with MSBM?

- Are there any advantages/disadvantages to O2 trim systems?

What are O2 trim systems?

The MSBM defines an O2 trim system at 40 CFR §63.7575 as:

“Oxygen trim system means a system of monitors that is used to maintain excess air at the desired level in a combustion device. A typical system consists of a flue gas oxygen and/or CO monitor that automatically provides a feedback signal to the combustion air controller.”

In other words, an O2 trim system is designed to continuously measure and maintain an optimum air-to-fuel ratio in the boiler combustion zone. The amount of O2 present in the exhaust gas of a boiler indicates how much excess air was present in the gas mixture. An O2 trim system measures the amount of O2 in the exhaust gas stream and provides feedback to automatically position the air damper to the proper position to maintain a set point of excess air. For the most part, boilers that operate with minimal excess air are more efficient.

Does my boiler have an O2 trim system?

Since O2 trim systems make boilers operate more efficiently, thereby using less fuel, you may be surprised to learn that your boiler already has an O2 trim system. Plant engineers and/or operators will know if your boiler uses an O2 trim system. When asking around, be sure to inquire about several specific items of the O2 trim system, such as:

- Can the automatic nature of the O2 trim system be disabled?

- If the O2 trim system can be disabled, do boiler operators operate the boiler in “manual” mode?

- Can the boiler be operated with the O2 trim system in “automatic” mode at all times?

- How is the O2 trim system used during startup, shutdown, fuel switching, etc.?

- How is the O2 trim system maintained and quality-assured?

- What parameters of the O2 trim system are recorded in a data historian?

Remember that if an O2 trim system is used as a compliance option for the MSBM, it is now an environmental instrument used to demonstrate continuous compliance. As a result, the O2 trim system must be operated at all times, potentially requiring revisions the boiler’s standard operating procedures. The O2 trim system must also be installed, calibrated, maintained, and operated in accordance with the manufacturer’s recommendations. The data measured from the O2 trim system must be quality-assured to assess its accuracy even if the manufacturer’s recommendations are limited. The data measured from the O2 trim system must also be recorded for compliance purposes.

Can I put an O2 trim system on my existing boiler?

O2 trim systems most likely can be installed your existing boilers. However, there may not be a cost effective impact on boiler efficiency. O2 trim systems are primarily designed to increase the efficiency of boilers. If your boiler is already designed to operate at lower excess air levels, any improved efficiency that is gained from an O2 trim system may not be cost effective in comparison to the O2 trim system design, installation, and operating costs. However, now that an O2 trim system can be part of a compliance option for the MSBM, its cost effectiveness may increase.

How are O2 trim systems use for continuous compliance with MSBM?

An O2 trim system is a continuous compliance option for certain MSBM subcategory boilers that are subject to a CO emission standard. O2 trim systems can also extend the boiler tune-up requirements for other MSBM subcategory boilers. For continuous compliance with MSBM, a minimum O2 trim system set point is established from the lowest hourly average O2 concentration measured during the most recent CO performance test. Continuous compliance is demonstrated by properly maintaining and quality-assuring the O2 trim system and the allowing the O2 trim system to automatically control the amount of excess air to the established set point.

Are there any advantages/disadvantages to O2 trim systems?

There are advantages to using an O2 trim system as a compliance option for the MSBM. The O2 trim system may already exist, making the installation cost minimal. It is also a “set-point” compliance demonstration, meaning that the O2 trim system is set to a concentration that was established during performance testing and compliance is determined by the O2 trim system adjusting the excess air to that set-point. The O2 measurements from the O2 trim system are not used for direct compliance.

An O2 trim system may also have compliance advantages during startup and shutdown. The MSBM has defined the periods “when startup ends” and “when shutdown begins.” At this point, certain subcategory boilers will be subject to the numerical emission standards for CO rather than the work practice standards. Many boilers may struggle with meeting a numerical CO emission standard by measuring CO emissions directly by a continuous emission monitoring system (CEMS). An O2 trim system, on the other hand, does not provide a direct measurement against the emission standard and could provide an alternative means for compliance during these periods.

The disadvantages of O2 trim systems include the costs associated with installation (if applicable) and the cost associated with maintaining the O2 trim system as an “environmental instrument.” However these costs may be small in comparison to the other MSBM compliance options for CO. Other disadvantages may include the impact on boiler operations, in that there may be operational limitations when using the O2 trim systems during startup, shutdown, fuel switching, etc.

Determining your MSBM compliance strategy can be the best and worst part of the implementation process. Evaluating the available compliance options for cost, operational impacts, and long-term facility plans can be exciting, but it can also be overwhelming. Educate yourself on the MSBM, the multiple types of control and monitoring technologies/ approaches, and compare to what others are doing. The decisions made today can greatly impact your facility’s future success.

What CO compliance options are you considering for your facility? Contact Eric Swisher at 610.933.5246 x117 or eswisher@all4inc.com to discuss the impacts that an O2 trim system may have for your boiler.

Revised GP-5 Is Final, So Now What?

The Pennsylvania Department of Environmental Protection (PADEP) published the final General Plan Approval and/or General Operating Permit for Natural Gas Compression and/or Processing Facilities (GP-5) on February 2, 2013. The final GP-5 and an associated fact sheet are available on PADEP’s website. For those familiar with the previous versions of GP-5 (i.e., General Permit for Natural Gas, Coal Bed Methane or Gob Gas Production or Recovery Facilities) dating back to 1997, the “new” GP-5 represents a significant change in applicability, scope, and requirements. In essence, GP-5 has been overhauled as summarized below.

GP-5 Applicability and Scope

The applicability of GP-5 has changed dramatically with its revision, in that natural gas “production” is no longer covered under GP-5. Major sources are also prohibited from using GP-5, and records of actual emissions from GP-5 facilities must be maintained on a rolling 12-month basis to demonstrate that the facility is not a major source. Concurrent with the finalization of GP-5, PADEP proposed a “conditional” exemption for “Category No. 38” pertaining to oil and gas exploration, development, and production facilities. This conditional exemption is anticipated to be finalized in the next few months. GP-5 now applies to a very broad list of sources and is organized into the following 10 sections, each pertaining to specific operations under the broad natural gas compression and/or processing facility umbrella:

- Section A – General Conditions identifies the regulatory basis/authorization of GP-5, specifies general requirements such as definitions, applicability, scope, testing, prohibitions, fees, recordkeeping, notification, and identification of potentially applicable federal standards (e.g., NSPS and NESHAP).

- Section B – Natural Gas Fired Spark Ignition Engines identifies emission standards for existing and new engines, including best available technology (BAT) based standards for new engines that are, in most cases, more stringent than potentially applicable NSPS and/or NESHAP standards, and specifies the obligation to comply with 40 CFR Part 60, Subpart JJJJ, and 40 CFR Part 63, Subpart ZZZZ. Section B also specifies requirements associated with engine startup and shutdown, performance testing, work practice standards, and monitoring, recordkeeping, and reporting requirements.

- Section C – Natural Gas Fired Simple Cycle Combustion Turbines identifies emissions standards for new turbines, including BAT based standards for pollutants not regulated under potentially applicable NSPS. Section C also specifies requirements associated with turbine startup and shutdown, performance testing, work practice standards, and monitoring, recordkeeping, and reporting requirements.

- Section D – Centrifugal Compressors specifies the obligation to comply with applicable requirements specified in 40 CFR Part 60, Subpart OOOO for centrifugal compressors.

- Section E – Storage Vessels/Tanks specifies the obligation to comply with applicable requirements specified in 40 CFR Part 60, Subparts Kb and OOOO, 40 CFR Part 63, Subpart HH, 25 Pa. Code §§ 127.1 and 127.12(a)(5), 25 Pa. Code § 129.56, and 25 Pa. Code § 129.57.

- Section F – Glycol Dehydrators specifies the obligation to comply with 40 CFR Part 63, Subpart HH, as applicable, as well as requirements for existing glycol dehydrators and for new glycol dehydrators that are not subject to 40 CFR Part 63, Subpart HH.

- Section G – Onshore Natural Gas Processing Plants specifies the obligation for fractionation units to comply with applicable requirements of 40 CFR Part 60, Subpart KKK

- Section H – Equipment Leaks requires that natural gas compression and/or processing facilities conduct leak detection and repair (LDAR) activities including monthly audible, visual, and olfactory (AFO) inspections, as well as quarterly leak detection surveys using forward looking infrared (FLIR) cameras or other devices as approved by PADEP.

- Section I – Pneumatic Controllers specifies the requirement to comply with applicable requirements in 40 CFR Part 60, Subpart OOOO.

- Section J – Sweetening Units specifies the obligation to comply with applicable requirements in 40 CFR Part 60, Subparts KKK and OOOO.

Other GP-5 Requirements

As mentioned above, major sources are prohibited from using GP-5, so major facilities that elect to use GP-5 will become synthetic minor sources by default. A facility is a major source in most of Pennsylvania for Title V permitting purposes if its potential to emit (PTE) exceeds any of the following thresholds in units of tons per year (tpy):

- Nitrogen oxides (NOX), carbon monoxide (CO), sulfur oxides (SOX), particulate matter with an aerodynamic diameter less than 10 microns (PM10) and 2.5 microns (PM2.5) – 100 tpy

- Volatile organic compounds (VOC) – 50 tpy

- Any individual hazardous air pollutant (HAP) – 10 tpy

- Total HAPs – 25 tpy

- Greenhouse gases (GHG), expressed as carbon dioxide equivalent (CO2e) – 100,000 tpy

As a synthetic minor source, a system to calculate emissions from each operation at the facility and to tabulate emissions of each pollutant on both a monthly and on a rolling 12-month basis will need to be established. The requirement to calculate and tabulate emissions to demonstrate the synthetic minor status of the facility on an on-going basis is specified in Section A of GP-5.

While the need to calculate and tabulate emissions from individual operations under GP-5 may not seem burdensome, it should be noted that applicants using GP-5 must also include a completed Attachment A – Questionnaire and Checklist for Single Source Determination accompanied by a map/layout of adjacent facilities (e.g., well(s), compressor stations, processing plants, etc.) which are under common control. Such a determination could quickly and unexpectedly increase the size of a facility via the dreaded practice of “source aggregation.”

Finally, it should be noted that the use of the new GP-5 for a modification at an existing natural gas compression and/or processing facility could subject other “non-modified” emissions units at the facility to GP-5 requirements that are specified for such emissions units, including the Section H LDAR requirements. This interpretation at least in part explains PADEP’s inclusion of requirements for “existing” reciprocating internal combustion engines and glycol dehydrators in the final GP-5

Other Permitting Options

In Pennsylvania (and in most states), limited air permitting options are available for new and modified sources and include the use of permitting exemptions (as applicable), general permits, or construction permit applications (i.e., Plan Approval Applications). If a source is not explicitly exempt from the requirement to obtain a Plan Approval, an applicant can request that PADEP evaluate whether a new source or modification is exempt from permitting requirements via the Request for Determination of Changes of Minor Significance and Exemption from Plan Approval/Operating Permit Under Pa Code § 127.14 or § 127.449 process (a.k.a. the RFD process). If a new source or modification is not exempt from permitting, the permitting options default to a general permit (if applicable) or to a construction permit application (i.e., Plan Approval Application).

The advantages of a general permit include timing (i.e., 30 day turn around) and no public comment period. The disadvantages include permit conditions that are “set” with no ability to customize the permit based on site and/or equipment specific conditions. The advantages and disadvantages of a Plan Approval Application path are directly opposite from a general permit. The advantage is the ability to craft a permit application that reflects the nuances of site and/or equipment conditions that more closely reflect the variability of actual operations. The disadvantage is that the preparation, technical review, and public review process for the construction permitting takes additional time and can easily exceed six months.

So Now What?

In many cases for the oil and gas industry, the timing and certainty advantages associated with the use of a general permit (including GP-5) will at first glance seem to far outweigh the time penalty that is typically associated with preparing and submitting a Plan Approval Application. Our advice to facilities that are facing decisions regarding air permitting options would be to proceed with caution. Make sure that the compliance obligations (e.g., notification, air pollution control, testing, monitoring, recordkeeping, and reporting) associated with any underlying applicable requirement (e.g., NSPS and NESHAP) are fully understood and are considered during the design phase of the new source or modification. Such requirements are incorporated by reference and a GP-5 permit will not specifically identify the individual NSPS and NESHAP compliance obligations that may be applicable to a facility. It is also important to understand how existing, un-modified emissions units may be impacted by the requirements specified for such units in GP-5 before a decision is made regarding the use of GP-5. Finally, the possible future expansion of a site may make the Plan Approval process a much more flexible permitting option than a general permit.

ALL4 can help you determine the most optimal permitting strategy for your project. Please contact John Slade (610.933.5246 x136; jslade@all4inc.com) or Roy Rakiewicz (610.933.5246 x127; rrakiewicz@all4inc.com) to discuss your air permitting needs.

New Phone Extensions at the Kimberton Office!

ALL4 recently updated the phone system at the Kimberton Office. As of March 25, 2013, all extensions will now consist of three (3) digits. A “1” has been added to the front of all previous extensions at the Kimberton Office to accommodate the change. Please refer to each ALL4 employee’s individual profile page here for the new extension or just add a “1” to the front of the old extension.

ALL4’s Is That Your Final Answer?

Last Month’s Answer and Winner:

It was an interesting month for answers to February’s “Is That Your Final Answer” question. As you may recall, the question involved how much money I had in my pocket if I had one of each coin or paper bill with a president’s likeness on it and a currency date of 2011 or later. The range of answers suggested that I had anywhere from $105,086.66 in my pocket, which sadly is not the case, to $90.66, which is closer, but still not correct. The correct answer is $87.91 and includes the penny, nickel, quarter, fifty cent piece, nine presidential coins (where the release date is indentified on the side of the coins), and the one, two, five, twenty, and fifty dollar bills. Since frequent correspondent Scott Kirkpatrick of NewPage was the closest at $90.66 he is being credited as the winner. So congratulations to Scott.

Question:

The recent publication of the Maximum Achievable Control Technology (MACT) standards for Industrial/Commercial/Institutional Boilers and Process Heaters has received significant attention by the regulated community (ALL4 has provided presentations at recent Boiler MACT conferences and will be hosting our own webinar series beginning in May). Prior to being issued as final, the Boiler MACT standards underwent significant litigation that was conducted via the U.S. Court of Appeals, also referred to as the U.S. Circuit Court. Assuming that there will be more litigation along the way, our March “Is That Your Final Answer” question asks how many Circuit Courts are available to hear potential Boiler MACT suits and what is the most likely district to the hear a potential suit. Good luck with this month’s question.

Answer:

Please e-mail your answer to final.answer@all4inc.com. Include in the e-mail your name, answer, and address (to receive your prize).

ALL4’s Final Answer is a monthly feature of our Blog Digest. It is designed to test your knowledge across the environmental field, quiz you on the building blocks of air quality rules, stump you on ALL4 general trivia, and challenge you with brain teasers that have perplexed us. The first correct answer e-mailed to us will qualify the respondent for free ALL4 gear and will enter the winner in our end-of-the year “Final Answer Championship.” The subsequent month’s Final Answer will identify the winner and the correct answer from the previous month’s question. You must be an active subscriber of ALL4’s Blog Digest to win a monthly prize and be eligible for the championship prize. ALL4 employees and family members are not eligible to compete. Hope you enjoy this feature and good luck!

Join Us: ALL4’s PSD and Non-Attainment NSR Training (AQ201)

Once an ALL4 staff member has completed AQ101, we require that they attend an advanced AQ201 program that delves into further detail on some of the more complex air quality rules and permitting requirements. One of our important AQ201 training classes focuses specifically on the major New Source Review (NSR) air permitting regulations and the applicability requirements for these rules. The major NSR rules include the Prevention of Significant Deterioration (PSD) regulations that apply to major sources and major modifications in areas that are attaining the National Ambient Air Quality Standards (NAAQS), and the Non-attainment New Source Review (NNSR) regulations that apply in areas designated as not attaining the NAAQS.

The major NSR regulations are considered by many environmental professionals to be the most complex rules facing the regulated community. Having the ability to determine when projects trigger major NSR, to assess the rule requirements, to develop permit strategy options, and to conduct the various aspects of the major NSR permitting processes are core skills for air quality professionals. Our AQ201 – Major NSR training course is a 1-day program that focusses on the PSD and NNSR rules and the rule applicability determination process. AQ201 is an intense and interactive program that includes working through real-world examples of complicated facility changes that are designed to bring out the subtle and often complicated issues that typically arise when clients are planning new projects and assessing major NSR applicability.

Clients often ask us if ALL4 can provide training related to air permitting. As we planned our internal 2013 technical staff training, we decided to open up some of our training to our clients to give them the opportunity to participate and experience the same level of training we provide to our staff. The first such offering is this year’s AQ201 – Major NSR training. Join us Monday, April 15th in Exton, PA, near ALL4’s corporate headquarters in the Philadelphia suburbs. As a thank you to our clients, any current clients* can have up to three (3) representatives attend the training free of charge. Additional attendees, including individuals that are not current clients, can also attend the training for a fee of $1,000. Details for the training session including the syllabus can be found here. Space is limited and will be on a first come, first serve basis: Register Today! If you would like additional information please e-mail me at jegan@all4inc.com, or call me directly at 610-933-5246, x14 (Please note that starting March 25, 2013, John’s extension will change to 114).

*Current clients are those who are currently working with ALL4 and/or subscribe to EnviroReview or those that worked with us in 2012.

Please note that AQ201 is not an introductory air quality training course. Should you be interested in an Intro to Air Quality training, please reach out to us and we’ll be glad to share information about our other training courses and options.

Tic-Toc: T-Minus 45 Days and Counting – Is Your RICE Impacted by the Upcoming Compliance Deadlines?

Have you ever slept in past your alarm and gotten to work later than you should have? No one likes to start off the day with that unwanted stress. Let’s pretend that your first day of work is the closest compliance deadline for the Reciprocating Internal Combustion Engine (RICE) Maximum Achievable Control Technology (MACT) Rule, which is on May 3, 2013. Consider this blog as your alarm clock that will “wake you up” early enough so that you “get to work on time” (i.e., have enough time to determine how your RICE is affected by the RICE MACT and to get ready for the compliance deadlines). If you ignore it or “hit the snooze” (i.e., read it and put it off to the side), the deadlines will sneak up on you and you will not “wake-up” until it is too late.

If you are still reading, you are off to a good start. The vast majority of RICE operated at industrial and non-industrial facilities alike are emergency RICE (i.e., emergency generators, emergency water pumps, emergency RICE used to turn kilns, etc.) With the RICE MACT Rule deadlines looming, the million-dollar question is Does the RICE MACT Rule (i.e., 40 CFR, Part 63, Subpart ZZZZ) apply to the emergency RICE at your facility? Let’s go turn the lights on and pour a bowl of cereal while becoming acquainted with how an emergency RICE might be affected by the RICE MACT.

If we want to answer this question logically, we should start by looking at the definition of a stationary combustion engine, as defined by the RICE MACT Rule, since the RICE MACT Rule only impacts stationary RICE:

Stationary RICE means any Reciprocating Internal Combustion Engine which uses reciprocating motion to convert heat energy into mechanical work and which is not mobile. A Stationary RICE differs from a mobile RICE in that a stationary RICE is not a non-road engine as defined at 40 CFR §1068.3, and is not used to propel a motor vehicle or a vehicle used solely for competition.

RICE can be either Compression Ignition (CI), or Spark Ignition (SI). An example of a CI RICE would be one that fires diesel fuel, whereas an example of an SI RICE would be one that fires natural gas.

Now that your cereal bowl is empty, it is time to take a shower and get dressed for work, but first, we need to be careful that the water is not too hot. It is critical to take precaution with how the rule defines “emergency.” You might consider your RICE to be an “emergency” RICE, but it could qualify as a “non-emergency” RICE in accordance with the wording provided in the rule.

Emergency stationary RICE means any stationary internal combustion engine whose operation is limited to emergency situations and required testing and maintenance.

An emergency stationary RICE will typically be used to generate electricity for a facility to power important operating equipment during the loss of primary power at the facility that is beyond the control of the owner/operator of the facility or during times of maintenance. Emergency RICE may also be operated periodically in order to verify their operational status. The rule also states:

Any operation other than emergency operation, maintenance and testing, and operation in non-emergency situations for 50 hours per year, as described in paragraphs §63.6640(f)(1)(i) through (iii), is prohibited. If you do not operate the engine according to the requirements in paragraphs (f)(1)(i) through (iii) of this section, the engine will not be considered an emergency engine under this subpart and will need to meet all requirements for non-emergency engines.

Sections §63.6640(f)(1)(i) through (iii) include some specific requirements that are described below:

(i) “There is no time limit on the use of emergency stationary RICE in emergency situations.” This is as simple as it sounds. As long as you are running the emergency RICE in emergency situations, you can operate it for an unlimited amount of hours.

(ii) “You may operate your emergency stationary RICE for the purpose of maintenance checks and readiness testing, provided that the tests are recommended by Federal, State or local government, the manufacturer, the vendor, or the insurance company associated with the engine.” There is, however, a 100 hour/year limit on the amount of time that readiness testing and maintenance checks are performed.

(iii) “You may operate your emergency stationary RICE up to 50 hours per year in non-emergency situations.” However, there are some restrictions to this statement, such as:

- The 50 hours of non-emergency operations count towards the 100 hours per year provided for maintenance and testing as described in paragraph (ii).

- The 50 hours per year for non-emergency situations cannot be used for peak shaving or to generate income for a facility to supply power to an electric grid or otherwise supply power as part of a financial arrangement with another entity; except that owners and operators may operate the emergency engine for a maximum of 15 hours per year as part of a demand response program if the regional transmission organization or equivalent balancing authority and transmission operator has determined there are emergency conditions that could lead to a potential electrical blackout, such as unusually low frequency, equipment overload, capacity or energy deficiency, or unacceptable voltage level.

- The engine may not be operated for more than 30 minutes prior to the time when the emergency condition is expected to occur, and the engine operation must be terminated immediately after the facility is notified that the emergency condition is no longer imminent.

- The 15 hours per year of demand response operation count as part of the 50 hours of operation per year provided for non-emergency situations.

As you are brushing your teeth, it is important to note that in addition to the RICE MACT rule, your emergency RICE might also be subject to one (1) of the two (2) RICE NSPS rules (40 CFR Part 60, Subparts IIII and JJJJ), depending on the type of RICE operated at your facility:

- Engines less than 500 Hp:

- A new or reconstructed stationary RICE located at an area source.

- A new or reconstructed 2 stroke lean burn (SLB) stationary RICE located at a major source of HAP emissions.

- A new or reconstructed 4SLB stationary RICE with a site rating of less than 250 brake HP located at a major source of HAP emissions.

- A new or reconstructed spark ignition 4 stroke rich burn (4SRB) stationary RICE located at a major source of HAP emissions.

- A new or reconstructed stationary RICE located at a major source of HAP emissions which combusts landfill or digester gas equivalent to 10 percent or more of the gross heat input on an annual basis.

- A new or reconstructed emergency stationary RICE located at a major source of HAP emissions.

- A new or reconstructed limited use stationary RICE located at a major source of HAP emissions.

- A new or reconstructed compression ignition (CI) stationary RICE located at a major source of HAP emissions.

- Engines greater than 500 Hp:

- A new or reconstructed stationary RICE located at an area source.

One thing to note, if this is the first you’ve heard regarding the RICE regulations, is that an emergency RICE cannot be subject to BOTH Subpart IIII and Subpart JJJJ because each of these subparts is engine ignition type-specific. For instance, 40 CFR Part 60, Subpart IIII applies to CI RICE, while 40 CFR Part 60, Subpart JJJJ applies to SI RICE.

Federal Compliance Deadlines

So this is what it all boils down to: now that you know the type of RICE operated at your facility, it is time to look at the compliance deadlines. According to the rule for CI stationary RICE:

If you have an existing non-emergency CI stationary RICE with a site rating of more than 500 brake HP located at a major source of HAP emissions, an existing stationary CI RICE with a site rating of less than or equal to 500 brake HP located at a major source of HAP emissions, or an existing stationary CI RICE located at an area source of HAP emissions, you must comply with the applicable emission limitations and operating limitations no later than May 3, 2013.

The SI stationary RICE compliance date is not as soon, but will still occur in 2013. According to the rule for SI stationary RICE:

If you have an existing stationary SI RICE with a site rating of less than or equal to 500 brake HP located at a major source of HAP emissions, or an existing stationary SI RICE located at an area source of HAP emissions, you must comply with the applicable emission limitations and operating limitations no later than October 19, 2013.

That’s it. You have been made aware of the deadlines. You have your shoes on, briefcase in one hand, a fresh cup of coffee in the other, and your keys in your front pocket; you are now ready to go to work. If you would like further assistance in determining whether or not your RICE is subject to the RICE MACT rule or either of the NSPS RICE rules, ALL4 can be the GPS that will show you how to get to work in the most efficient way possible. Ron Harding is our resident expert on the RICE regulations, and the leader of the ALL4 RICE Initiative Team. You can contact him at (610) 933-5246 (ext. 19) with any RICE related questions.

Don’t get caught sleeping-in; these deadlines will be here before you know it. And there’s nothing worse than getting woken up by a loud engine and realizing that you slept in and you have no chance at getting to work on time.

Sprinkle Some ALL4 On It!

As we approach ALL4’s 11th anniversary, I occasionally get asked what I do at ALL4 – especially now that we are 35 people and have multiple offices. Some folks may say that I “don’t do much” anymore… but I would compare my role here at ALL4 to that of Old Bay seasoning. First, for full disclosure, I am a huge seafood fan and Old Bay is a staple in my house, in my office, and is the driving force behind our annual CrabFest. I put Old Bay on just about anything!

Old Bay started as a seasoning for seafood… mainly crabs and shrimp. And, just like Old Bay, my role at ALL4 started out as mainly providing air quality support. But as ALL4 has grown over the past 11 years, so have my roles and my responsibilities. Just like how Old Bay seasoning now markets itself as being “great on seafood and great on everything else”, my main role of providing air quality support has grown to encompass a little bit of “everything else” here at ALL4.

This analogy of Old Bay also applies to how ALL4 supports our clients. Some clients use ALL4 for complex air permitting projects (great on seafood), while others sprinkle us around on all of their air media needs – or even other environmental projects (great on everything else). No matter the type of project, or the role that we serve for our clients, our core values or “spices” of ownership and authenticity do not change! We continue to focus on what’s made us successful: building strong relationships, expanding our technical knowledge, and attracting and retaining amazing people. So the next time that you are looking for an environmental consultant, sprinkle some ALL4 on it!

P.S., check out my latest find for Old Bay – Old Bay wings. They are awesome!

PM2.5 Modeling Guidance Released by U.S. EPA

On March 4, 2013 the U.S. EPA Office of Air Quality Planning and Standards (OAQPS) released “Draft Guidance for PM2.5 Permit Modeling” memorandum. The memorandum provides additional clarification on addressing both primary and secondary formed fine particulate (PM2.5) in National Ambient Air Quality Standards (NAAQS) and Prevention of Significant Deterioration (PSD) Increment air quality modeling demonstrations. The OAQPS Air Quality Modeling Group also conducted a webinar on March 13, 2013 providing an overview of the draft memorandum. The slides from this presentation can be found here.

On January 4, 2012, the U.S. EPA granted a petition previously submitted by the Sierra Club on July 29, 2010, to initiate rulemaking which designates air quality models for ozone and PM2.5 for use by all major sources applying for a PSD permit. The U.S. EPA committed to engage in rulemaking to evaluate updates to Appendix W of 40 CFR Part 51 “Guideline on Air Quality Models” which would incorporate new analytical techniques or models for ozone and secondary PM2.5. The release of this guidance document meets U.S. EPA’s commitment to the Sierra Club petition. U.S. EPA will accept comments on the memorandum until April 17, 2013. Additional comments will be taken into consideration during the Air and Waste Management Association’s (AWMA) Specialty Modeling Conference scheduled for March 19-21, 2013 and during the 2013 Regional, State, and Local (RSL) Modelers’ Workshop currently scheduled for April 22-25, 2013. On April 23rd, the RSL Workshop will be open to industrial representatives and consultants. OAQPS then intends to finalize the guidance memorandum by July 31, 2013.

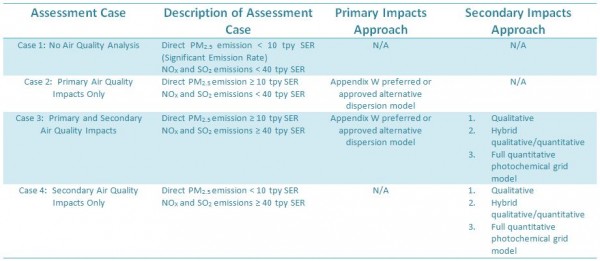

The draft guidance memorandum outlines four (4) separate procedures for addressing primary and secondary formed PM2.5 based on the following assessment cases:

Assessing primary formed PM2.5 will not differ any from how historical air quality modeling demonstrations have been completed for other pollutants. U.S. EPA’s approved air dispersion model AERMOD will still be used to assess primary PM2.5 impacts for comparison to the 24-hour and annual NAAQS and PSD Increments. To address secondary formed PM2.5 from nitrogen oxides (NOX) and sulfur dioxides (SO2), the draft memorandum outlines three (3) separate procedures for Cases 3 and 4 including:

- A qualitative assessment,

- A hybrid of qualitative and quantitative assessments utilizing existing technical work,

- A full quantitative photochemical grid modeling exercise.

U.S. EPA indicates that in most situations a qualitative assessment of the impacts from secondary PM2.5 formation will suffice for demonstrating that secondary PM2.5 impacts associated with a source’s precursor emissions will not cause or contribute to a violation of the 24-hour or annual PM2.5 NAAQS. Each qualitative demonstration will be unique; however, the memorandum outlines the following factors that should be thoroughly justified.

- A detailed conceptual description of the background air pollution concentrations,

- A narrative explaining how any identified significant precursor emissions and subsequent secondary PM2.5 formation could contribute to the existing PM2.5 concentrations in the region,

- A conceptual description of the meteorological conditions in the area that occur during high periods of 24-hour PM2.5 concentrations and how meteorological factors could enhance or limit the formation of secondary PM2.5 from any significant precursor emissions.

The second approach to demonstrating compliance with PM2.5 precursors is the hybrid qualitative/quantitative approach. In addition to the steps involved in a qualitative assessment outlined above, a quantitative analysis would involve reviewing past or current State Implementation Plan (SIP) attainment demonstration modeling, published modeling studies, or peer-reviewed literature with estimates of model responsiveness to precursor emissions. Another potential quantitative assessment outlined in the memorandum, for use in the hybrid approach, would involve converting emissions of precursors into equivalent amounts of direct PM2.5 emissions. Pollutant offset ratios and dispersion modeling would be used to assess the impacts of the combination of direct PM2.5 emissions and equivalent direct PM2.5 emissions.

The last and most involved method to demonstrate compliance with PM2.5 precursors would be the use of a photochemical grid model to do a full quantitative assessment. U.S. EPA indicated that the need for a full quantitative assessment with a photochemical grid model would only happen in rare cases. However, if a full quantitative assessment was required, the memorandum states that an alternative model as outlined in Section 3.2.2 of 40 CFR 51.112 and 40 CFR Part 51 Appendix W should be used. The memorandum recommended the use of a Lagrangian or Eulerian photochemical grid model for the full quantitative assessment but did not identify a specific model.

Even though the guidance is still draft and out for review it seems as though States are moving forward with requiring an assessment of PM2.5 precursors for facilities that trip Significant Emission Rates (SER) for NOX or SO2. Facilities should keep in mind that there is the possibility of a substantial amount of effort involved assessing PM2.5 precursors. Especially, as the first facilities go through the process. This guidance memorandum along with the recent court decision on the PM2.5 Significant Impact Level (SIL) is making it more important for facilities to look for emission reductions or controls to try and remain below PM2.5 and precursor (i.e., NOX and SO2) SER. In addition, this is one of the first times OAQPS has provided a public review process for a guidance memorandum. Therefore, make sure your voice is heard before April 17th so that your comments can be taken into consideration.

Continuing the Momentum on Air Toxics Rules – Utility MACT

In the midst of a tug of war between environmental groups, state agencies, and industry, the U.S. Environmental Protection Agency (U.S. EPA) remains bullish on the issuance of its proposed revisions to the Utility Maximum Achievable Control Technology (MACT) standards. The Utility MACT, also known as the Mercury and Air Toxics Standards (MATS), includes emission limits for mercury, particulate matter (PM), acid gases, and certain individual metals, and affects only coal‐ and oil‐fired power plants that will be built in the future.

The proposed revisions include a relaxation of the mercury limit for bituminous and sub-bituminous coal (“non-low rank virgin coal”) from 0.0002 pounds per gigawatt-hour output (lb/GWh) to 0.003 lb/GWh, in response to industry concerns. Non-low rank virgin coal is defined as having a heat value above 8,300 British thermal units (Btu) per pound (note that this heat value would exclude lignite coal from the definition of non-low rank virgin coal). The proposed revisions also include raising the filterable PM limits for most coal plants from 0.007 pounds per megawatt-hour output (lb/MWh) to 0.09 lb/MWh, and acid gas limits for most coal plants from 0.0004 lb/MWh to 0.01 lb/MWh.

Not surprisingly, environmental groups oppose the proposed revisions that relax the emission limits, contending that the limits will not be as stringent as those in current practice. State agencies are aligned with environmental groups, declaring U.S. EPA does not always set limits “on the basis of the unit that demonstrates the lowest calculated emission rate.”

To date, industry concerns with the MATS have been largely related to the technical challenges related to demonstrating compliance with limits that are as low as the levels of quantitation for instruments that are currently available to measure emissions (e.g., CEMS). However, industry has indicated that U.S. EPA has properly included available data in its evaluation and is generally supportive of the proposed revisions. It is interesting to note that despite the general public agreement with the proposed revisions, utilities are suing over the MATS in federal appeals court (though the case is currently suspended pending the final outcome of the reconsideration process).

To keep up with the status of the MATS, you can visit U.S. EPA’s website at http://www.epa.gov/airquality/powerplanttoxics/actions.html. ALL4 also will follow-up with a summary blog regarding the rule when it is issued.

A Resolution in the Case of ‘Upset’ Emissions

U.S. EPA has ended an almost two-year long battle with environmental groups regarding provisions in State Implementation Plans (SIPs) related to emissions during Startup, Shutdown and Malfunction (SSM) events. U.S. EPA had approved SIPs that permitted these so-called ‘upset’ emissions without penalty. Please click here to see a map of the states that will be affected if this proposed rule becomes final. The dispute with environmental groups, including the Sierra Club and WildEarth Guardians, dates back to June 2011, when these groups first petitioned U.S. EPA to change the rule. Environmentalists claimed SIPs that exempted emissions during SSM events allowed for elevated levels of pollution during events that should be controlled, essentially giving a free pass to facilities to exceed emission limits. U.S. EPA was pressured by the groups to issue a ‘SIP Correction,’ which would force states to immediately address this issue by extracting these provisions from their SIPs. When it became clear that U.S. EPA was going to delay their response to this petition, environmental groups took swift action and sued in order to force a deadline.

On February 12, 2013, U.S. EPA issued a ‘SIP Call,’ in which states found to be in violation will have 18 months to rewrite and submit a revised SIP in hopes of U.S. EPA approval. In the proposed rule, U.S. EPA no longer allows facilities to emit excess pollution during periods of planned startup and shutdown, but DOES permit facilities to continue to allow excess emissions during unplanned malfunction events. In the case of a malfunction event that causes excess emissions, the facility must submit an ‘affirmative defense’ to U.S. EPA in order to shield themselves from penalties. This approach is consistent with recent actions related to SSM events as specified in the General Provisions in Part 63, Subpart A of the National Emission Standards for Hazardous Air Pollutants (NESHAP). Regarding the proposed rule, U.S. EPA states that they “realized that [current] provisions allow opportunities for sources to repeatedly emit pollutants during such periods in quantities that could cause unacceptable air pollution in nearby communities with no legal pathway for air agencies, the EPA, or the courts to require the sources to make reasonable efforts to reduce these emissions.” By issuing the ‘SIP Call,’ U.S. EPA has stated that it is “articulating a policy that reflects this principle.” An attorney for the Sierra Club said that the group was pleased with the actions that U.S. EPA took to end SSM exemptions, but that U.S. EPA could, and should, have done more to protect human health and the environment from dangerously high levels of pollution. U.S. EPA will accept public comment on the proposal for 30 days from the date it is published in the Federal Register.